Abstract

This study examines the influences of the cement to clayey-silt (c/cs) ratio on the strength, compressibility, and usability in embankments. Laboratory experiments were conducted to determine the influence of the c/cs ratio on the shear strength, stress–strain behavior, and volumetric compressibility, which in turn determine whether cemented soil can be advantageous in controlling the failure of canal embankments. Canal embankment breaches occur for a variety of reasons, the most common being the loss of embankment strength. Our results indicate that the strength parameters, namely cohesion (c) and friction angle (Φ), increased by up to 30% when the c/cs ratio was 0.15/0.85. When the c/cs ratio was 0.1/0.9, there was more compressibility than when the ratio was 0.05/0.95. For vertical strains, a c/cs ratio of 0.1/0.9 showed 13% more strains than that of natural soil. The cs/c ratio is what leads to the strain hardening along the axial strains. The preliminary results suggest that using cemented soils with proper compaction, canal embankments can be strengthened to avoid failures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Canals are used to supply water for drinking and irrigation purposes. The embankments of these canals are mainly composed of homogenous clayey silt. Failure of embankments may cause loss of property, human life, and agricultural crops. The most common breach failures are due to erosion [1], seepage, overtopping, and piping [2]. Several canal embankment breaches and their failure mechanisms, particularly in Pakistan, have been reported by [3].

To avoid the risk of failure of such canal embankments, it is necessary to identify possible strengthening techniques to stabilize existing embankments and suggest solutions for the construction of new embankments in the future. One possible solution is to stabilize the soils of canal embankments (i.e., clayey silt) with cement. Cement has been widely used as a stabilizing agent in various types of soils [4, 5]. The addition of cement to soil improves its engineering properties. Cemented soils have been used to provide stability to highways, slope protection, ditch linings, and foundations. Generally, cemented soils provide high compressive and shear strengths. Moreover, the addition of cement to soil improves its bearing capacity, which allows it to resist erosion and mechanical damage [6].

Previously, several studies have been conducted on cemented soils; for example, [7] studied cemented soils from the perspective of the ratio of porosity to cement. Yang et al. [8] reported that an acid–base solution caused the cemented soil to increase the unconfined compression rate slowly compared to that of normal cemented soils. Some researchers have also improved soils with cement and waste fiber [9]. The behavior of cemented soils under isotropic and k0 conditions was studied by [10], and they found that the effects of bonding are only significant for stresses below an apparent pre-consolidation stress. The strength and stiffness increased with increasing density and cement content; however, the effect of cement content on these parameters decreased as the density increased. Additionally, [11] have presented a comprehensive review of cemented soils.

Several studies have also been conducted to better understand embankment failures [12,13,14,15], and a number of full-scale physical model studies and case studies have been conducted and summarized [16,17,18,19]. However, the literature does not mention how the use of cement in soils can be advantageous in controlling the failure of canal embankments.

The main objective of this study is to investigate the strength properties and behavior of soils from canal embankments when mixed with cement, as well as to collect the basic necessary baseline data required for a numerical analysis of the strengthening of existing canals. Hence, the focus of this study is on the mechanical properties of cemented soils to be used in embankments, focusing on the influence of cement on the strength parameters, stress–strain behavior, and behavior of cemented soils in terms of compressibility.

Direct shear and triaxial tests were performed to study the stress–strain behavior and strength parameters of cemented soils. Oedometer tests were conducted to study the consolidation characteristics of cemented soils, including compressibility parameters. The results have been compared with those of natural soils as well as soils with various cement percentages and moisture contents to draw better conclusions.

2 Materials and Methods

2.1 Materials

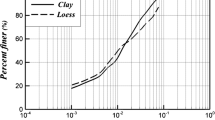

Natural soil and ordinary Portland cement (OPC) were used in this study. The natural soil was collected from the toe of the embankment of a canal. Based on sieve analysis (Fig. 1) it was determined that the soil was clayey silt having a specific gravity of 2.68–2.70 and bulk density of 1.7–1.8 g/cm3. The specific gravity and dry densities are shown in Table 1. The optimum moisture content of the clayey silt was 14.5%, and the maximum dry density was 1.83 g/cm3 (Fig. 2). The liquid limit, plastic limit, and plasticity index of the soil sample were determined. The liquid limit (Fig. 3) and plastic limit were found to be 32% and 26%, respectively.

The prepared samples were tested for scanning electron microscopy (SEM) and mineralogy composition. The Fig. 1 shows the SEM results for the soils with no cement, 5% cement and 10% Cement, respectively. The images shown in Fig. 4 are of the samples which were broken in half piece. It could be seen that sample with no cement has more finer particles as compared to sample with 5 and 10% cement. It could be seen that tiny particles as visible in soils with no cement, tend to diminish due to addition of cement and probably become larger particle due to bonding effect of cement, which in turn, results in soils having more voids.

Energy dispersive X-ray spectrometer (EDS) analysis example for 10% cement soil is shown in Fig. 5 and in Fig. 6 shows combined results for no cement soil, 5% cemented soil, and 10% cemented soils.

It was observed that addition of cement increased the silicon content in the samples. Initially soils with no cement showed silicon as 9% whereas 5% and 10% cemented soils showed, 11.5% and 17.7% of silicon content. Moreover, it was observed with addition of 10% cement.

2.2 Methods

The samples for the tests were prepared by mixing the cement with soil and water. For the oedometer tests, the cement content was taken as 5% and 10% based on the dry weight of the soil. The samples were prepared at an optimum moisture content of 14.5%. After mixing the soil, cement, and water, the samples were left for 1, 3, and 24 h to harden prior to testing. It was observed that the bulk density of the prepared cemented soil decreased after adding the cement.

To determine the consolidation behavior of the cemented soils, oedometer tests were performed on the prepared samples. The oedometer tests were conducted in accordance with [20]. Each sample was allowed to obtain sufficient bonds between the soil particles and cement for a particular time interval, i.e., 1, 3, and 24 h, before the tests were commenced. The specimens were prepared in three layers until the mold attained the required height, i.e., 20 mm.

The sample preparation method described by [21] was adopted in this study. The base and top of the mold were enclosed on a porous stone. All the tests were performed on samples prepared under fully saturated conditions. A series of loads were applied to the specimens in incremental steps of 5, 10, 20, 40, 80, 160, 320, and 640 kPa. After the application of each load, the specimens were allowed to consolidate until no significant change in height was observed, or for a maximum period of 24 h. For the direct shear tests and triaxial tests, the cement percentage was maintained at 0%, 5%, 10%, and 15% based on the dry weight of soil, and the moisture content was maintained between 15 and 20% for all the samples. After mixing the soil, cement, and water, the samples were left to dry for 0, 7, and 15 days. This ensures that the cement bonds properly with the soil. Direct shear tests were conducted on the remolded samples according to [22]. Direct shear tests were performed and have been used to determine the drained strength behavior of the collected and remolded samples. For the triaxial test, the cement percentages were maintained at 0%, 5%, and 10%.

3 Results

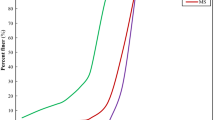

3.1 Stress–Strain Behavior in Oedometer

The strains experienced by the samples subjected to varying vertical stresses are shown in Fig. 7. It was observed that the addition of cement to the soil, irrespective of its percentage, resulted in higher vertical strains. It was observed that the samples that were given a longer setting time (24 h) prior to testing showed more strains. At a vertical effective stress of 640 kPa, the vertical strain for natural soil (i.e., clayey silt) and soil with 10% cement was 14% and 27%, respectively. The vertical strain values corresponding to various stresses are listed in Table 2.

3.2 Void Ratio

The void ratios are plotted as e − log σ'v (Fig. 8). It was observed that the samples with 10% cement and a 24-h setting period prior to testing showed higher initial void ratios of 1.31. The hardening time prior to the testing of the samples also caused the void ratios to increase.

The specimen containing no cement had low void ratio as 0.38. The detailed void ratios and sample behavior in response to vertical stresses are shown in Fig. 5.

The strains observed in the oedometer tests are plotted as normalized void ratio (%) vs. the logarithm of normal stress, i.e., log σ′v (kPa). The rate of reduction of void ratios was also slightly higher (at 22%) for samples that were given more time to set as compared to samples that were given less hardening time prior to testing (Fig. 8).

The tests performed using the oedometer were also subjected to loading and unloading. The values were normalized, as shown in Fig. 9. The stress–strain and swelling behaviors of all types of soils tested were similar to each other, with differences in numerical values.

In response to the unloading behavior, it was observed that the cement had no effect on the swelling behavior. This is because during the application of vertical stresses, the soil skeleton undergoes deformations, the bond developed by the cement weakens, and the cemented soil behaves like natural soil (i.e., clayey silt). It can be interpreted that with the application of stresses on cemented soils, the added cement has no effect on strength.

3.3 Compressibility, Swelling, and Compression Index

The compressibility can be defined as the coefficient of volumetric compressibility (mv), which is defined as the change in volume per unit volume per unit incremental effective stress [23]. The compression index (Cc) can be defined as the slope of the linear portion of the consolidation line in the plot e − log σ'v (Fig. 5), and it is a dimensionless quantity. The coefficients of volumetric compressibility and compressibility index can be written as Eqs. 1 and 2, respectively [23].

where e represents the void ratio, \({\sigma }^{{\prime}}\) represents the effective stresses, and subscripts 0 and 1 represent the two points on the normal consolidation line. The calculated values of mv and Cc are presented in Table 3. The values of mv and Cc were calculated for the stress range of \({\sigma }_{1 }^{{\prime}}\)= 320 kPa and \({\sigma }_{1 }^{{\prime}}\)= 640 kPa. It was further described by [23] that for a particular soil, the value of mv is not constant but depends on the stress range over which it is calculated.

The compression index (Cs) was determined for the soils stabilized with 5% and 10% cement, and their comparison was made with soils with no added cement, and it was determined from the unloading curve of e − log σ′v. The swelling index was calculated using Eq. 3.

where Cs is the swelling index, e0 and e1 are the void ratios of the desired range, and σ0 and σ0 are the vertical stress points of the desired range. It was observed that soils without cement showed a swelling index, Cs, of 0.008, whereas soils stabilized with 10% and 5% cement showed a swelling index of 0.005 and 0.003, respectively.

It was observed that mv depended on the cement content and hardening period. The specimen with a higher cement content and a longer hardening period exhibited a higher value of mv and the specimen with zero cement exhibited a lower value of mv. This implies that with the addition of cement to the soil, more voids developed, which increased the compressibility of the cemented soil. The values of mv for the natural clayey silt and the soil with 10% cement content and a 24-h setting time are, 0.058 m2/MN and 0.128 m2/MN, respectively. According to [24], the values of mv of natural clayey silt and soil with 10% cement content at 24 h setting time show low and medium compressibility, respectively. Similarly, the slope of the consolidation line in the plot e − log σ'v (Fig. 5) depends on the cement content in the specimen and the hardening period. According to [24] the values of Cc of natural clayey silt and the soil with 10% cement content at 24 h of setting time show medium compressibility and high compressibility, respectively.

Settlement analysis based on the coefficient of volumetric compressibility can be performed using the constrained modulus [25] presented in Eq. 4.

The settlement of any (ith) layer can be estimated using Eq. 5 [25].

where \({\sigma }_{z,i}\) is the vertical component of the incremental stress in the middle of ith layer, \({h}_{i}\) is the thickness of the ith layer, and \(E_{{\text{c}}}^{{\prime}}\) is the constrained modulus. The values of the constrained modulus are shown in Table 3. According to [24] the values of the constrained moduli of natural clayey silt and soil with 10% cement content at 24 h setting time show low and medium compressibility, respectively.

3.4 Stress–Strain Behavior in Direct Shear and Triaxial tests

Figures 10 and 11 show the typical behavior of tests performed at consolidation stresses of 100 kPa. It was observed that cemented soils showed higher shear stress than soils without cement. Furthermore, the addition of moisture caused more shear stress in cemented soils. It was observed that an addition of 10% cement increased the shear stress by 20%.

Figure 12a, b show the vertical height behavior during the shear tests. At lower stresses, the cemented soil exhibited dilatant behavior, and at higher stresses, contractant behavior was observed. It was observed that cemented soils with 5% and 10% cement contents showed more dilatancy compared to natural soil with no cement, as shown in Fig. 12a.

Whereas 15% cemented soils showed a similar reduction behavior to that of natural soil at lower stresses, i.e., 25 kPa. Figure 13a, b show the vertical height behavior plotted for various stresses and moistures. It was observed that additional moisture caused the vertical height to decrease slightly. The vertical height reduction at 15% moisture and 200 kPa stress was approximately 1.2%, whereas the vertical height was 1.4% for cemented soil with 20% moisture content.

It was observed that all the tests at lower normal stresses i.e., up to 50 kPa, exhibited dilatant behavior, whereas beyond these stresses, contractant behavior was observed.

This implies that the interparticle strength of the soil structure is dominant up to a strength of 50 kPa. Upon application of higher normal stresses i.e., 100 and 200 kPa, the interparticle structure (possible bond created by cement) starts to break. This was evident through the contractant behavior at 100 and 200 kPa and higher stresses.

In addition to direct shear tests, triaxial tests were performed to investigate the stress–strain behavior of natural and cemented soils. The tests were performed under confining stresses of 50, 100, 150, and 200 kPa. Figure 11 shows the stress–strain behavior of natural soils, i.e., with no cement. It was observed that the soil exhibited strain-hardening behavior along the axial strain direction. No significant peak was observed. It was seen that as the confining stresses increased, the deviatoric stresses also increased with a similar increment ratio. The maximum deviatoric stresses were 140, 250, 360, and 480 kPa for tests at confining stresses of 50, 100, 150, and 200 kPa, respectively. The stress–strain behavior of the soil mixed with 5% cement is shown in Fig. 14. Soil mixed with 5% cement showed mostly strain hardening, followed by strain-softening behavior, leading to perfect plastic.

It was observed that the tests performed at lower stresses, i.e., 50 and 100 kPa, showed peak values before reaching an axial strain of 5%. However, the peak values of the tests at 150 kPa and 200 kPa were attained between 5 and 10% of the axial strain (Fig. 15).

Whereas, beyond 10% axial strain, the material exhibited perfect plastic behavior. The test at lower stresses, i.e., 50 and 100 kPa, showed peak values of 380 and 400 kPa, followed by residual values of 220 and 400 kPa, respectively, whereas the maximum deviatoric stresses at tests carried out at 150 and 200 kPa were approximately 600 and 620 kPa, respectively, which were approximately 22% higher than that of soil without cement. The stress–strain behavior of soils with 10% cement is shown in Fig. 16. The peak values before 5% axial strain at 50 and 100 kPa showed a similar pattern for the 5% cemented soils. However, the tests performed at 150 and 200 kPa showed strain-hardening behavior.

The maximum deviatoric stress at 200 kPa was found to be 665 kPa, which is approximately 38% higher than that of soils with no cement and approximately 9% higher than that of soils with 5% cement. It was observed that the addition of cement has a significant impact on the stress–strain behavior and increases the deviatoric stresses.

The modulus of elasticity from oedometer (Eoed) and triaxial tests (Eur) and (E50) were calculated and are shown in Table 4. The example of determination of (Eur) and (E50) for 10% cemented soils is shown in Fig. 17.

It was evident that from one dimensional test i.e., Eoed tends to decrease as cement is added. This shows that cemented soils may have more compression, this is mainly because the samples were prepared with no compacting energy. The similar behavior was observed by [26]. Whereas the elasticity (E50) values for soils with no cement in triaxial showed significantly lower values compared to cemented soils. The dilatancy angle was calculated form vertical height behavior during shearing process in direct shear tests (Fig. 12) and shown in Table 4. It was observed that dilatancy angle was increasing upon addition of cement. This is mainly because bonding between particles increases, and soil shows more dilatant behavior at lower stresses.

3.5 Effect of Time and Moisture on Shear Stress

Figure 18a, b shows the shear behavior versus displacement of cement soils plotted at different curing times. From the results, it can be seen that an increase in curing time slightly increased the shear stress by up to 4%. This implies that the addition of cement attains most of its strength within seven days. Moreover, the addition of moisture increased the shear stresses by up to 6%, as shown in Fig. 19a, b. The addition of moisture may have triggered even more cement bonding due to the hydration process.

3.6 Strength Parameters

The strength parameters were evaluated using the Mohr–Coulomb failure criterion, which is given by [23] and shown in Eq. 6.

where \(\tau\) is the shear stress, \(\sigma\) is the normal stress, \(\phi\) is the friction angle, and \(c\) is cohesion. Typical values of shear stress vs. normal stress are shown in Fig. 20a, b, and the strength parameters are listed in Table 5.

Table 5 shows that the strength parameters were evaluated in terms of \(c \mathrm{and} \phi .\) Regarding the strength parameters, the friction angle represents the interlocking between the particles. The greater the interlocking, the greater the friction angle. It was observed that the friction angle increased slightly from 5 to 15% with the addition of cement. The soil cemented with 15% cement exhibited the highest friction angle. This is because the addition of cement increases the bonding between soil particles and strengthens the resistance to the sliding and breaking of particles. In addition, the cohesion intercept increased up to 30% owing to the addition of cement. According to [27] cemented soils can have greater cohesion and can improve the strength properties of soils.

From the triaxial tests, it was observed that the soil exhibited a friction angle of 28° for all the soils, i.e., with and without the addition of cement. No significant effect of the cement was observed on the friction angle. However, it was observed that soils with no cement showed 10 kPa cohesion, whereas for the soils with 5% and 10% cement, the values of cohesion were 60 and 72 kPa, respectively, which showed 83% and 86% increases. The maximum deviatoric stress at a consolidation stress of 200 kPa was found to be 680 kPa, which is approximately 30% higher than that of soils with no cement and approximately 9% higher than that of soils with 5% cement. It was observed that the addition of cement affected the stress–strain behavior and increased the deviatoric stresses.

3.7 Discussion

In this study, the consolidation behavior of natural clayey silt and cemented soils was investigated. Referring to Fig. 4, where higher strains in cemented soils were observed, it can be clearly seen that cemented soils can deform more than natural soils. A possible reason for the higher strains could be the presence of fines (cement) added to the soil samples. More cement (fines content) resulted in more vertical strains, as shown in Fig. 9. Figure 21 shows the normalized vertical strains of the samples with 5% and 10% cement, where more deformations were observed in the samples with 10% cement.

Apart from the fine content, the effect of the voids cannot be neglected. The addition of the cement can cause the soil particles to change their shape during the hardening process of cement, which may lead to the expansion of the sample and an increase in its voids. Referring to Fig. 5, it is evident that the addition of cement causes the number of voids to increase. Therefore, the development of larger strains in cemented soils is partially due to the generation of more voids owing to the addition of cement. The increase in voids may depend on the amount of cement used, moisture content of the soil, and time allowed for hardening prior to testing.

It was observed that the initial hardening time had a significant effect on the strains. More time given to the sample for hardening prior to testing showed more vertical strains in this study. This shows that, with time, the cemented soils can continue the bonding process, resulting in more voids and more strains upon the application of vertical loads, as shown in Fig. 22. This confirms that higher deformations were observed owing to the addition of cement. In contrast, according to [25], the cementation effect may not be observed at higher stresses. The deformations presented herein were based on a vertical stress of 640 kPa.

The lower values for soils with no cement were probably due to the fact that soil was loosely packed, and progression of stresses showed strain-hardening behavior at higher strains, which caused the calculated elasticity values in triaxial as low. This phenomenon is described in the Fig. 23.

This phenomenon further also endorses the idea of utilization of cemented soils specially for embankments. For example, in real life using cemented soils can prevent the failure as it needs less deformations to reach to peak strength as compared to soils with no cement where structure may already fail due to higher deformations even before reaching peak stresses from soil. Specially for this reason Swedish Geotechnical Society [29] recommends determining the stresses not at peak but 0.15 radians. Because if structure already fails at 0.15 radians, then peak values have not much importance.

However, the addition of cement can significantly enhance the strength properties as well. According to [27], cemented soils can have greater cohesion and can improve the strength properties of soils. In the studies conducted by [30], it is clearly seen that the shear strength increases owing to the time effect. Figure 24 shows that the sample with 10% cement after 5 days of hardening time showed a shear stress approximately 20 kPa higher than compared of the 1-day time samples.

In response to the number of fines in the soils used for embankments, it can be said that fines can reduce seepage through embankments. However, the amount of fines can also give rise to pore pressure in embankments [28], which may lead to failure. Meanwhile, more voids in embankments can lead to more deformation and seepage. However, if proper compaction is achieved during the construction stage with cemented soils, it may result in stable embankments and reduce seepage. However, detailed numerical modeling of seepage and slope stability of canal embankments must be carried out to suggest techniques for strengthening existing and new canal embankments.

Strain-hardening behavior was observed in almost all the tests. It was observed that the addition of cement increased the shear strength of soils. It was observed that soil with 5% cement showed an almost similar strength to 10% and 15% cemented soils at an optimum moisture content of 15%. This is likely because of the amount of water required for the cement to react. Therefore, it was observed that adding 10% and 15% cement did not significantly affect the soil strength.

The reason that the 5% cement sample showed higher strength was probably because only 5% of the cement reacted when it came in contact with 15% moisture. The remaining cement in the soil acted as the soil in Fig. 25. Strain-hardening behavior was observed in most of the tests performed in this study. Tests performed at higher stresses can lead to strain-hardening behavior [4]. This can be due to the fact that the samples were loosely constructed following the sample preparation method given by [21].

The strain-softening behavior after the maximum shear stress in the tests was conducted at normal stresses, i.e., s = 300 kPa. This phenomenon can be attributed to the internal particle strength due to high stresses, where particles tend to become densely compacted, leading to breakage and rearrangement of particles. In this study, it was observed that the addition of cement to soils caused the skeleton to deform more. The deformation observed was higher as much as 13% in soils with 10% cement compared to normal soils i.e., with no cement at consolidating stresses of 680 kPa. Apart from compression, the soil response, i.e., stress–strain behavior, was observed to be similar irrespective of whether cement was used. This confirms that higher deformations were observed owing to the use of cement. In contrast, according to [25], the cementation effect may not be observed at higher stresses. The deformations presented herein are based on log σ′v = 680 kPa.

Based on the vertical height behavior shown in Fig. 26, it is evident that soils exhibit dilatant behavior at lower stresses i.e., 25–50 kPa and contractant behavior at higher stresses i.e., 100–200 kPa. This implies that the interparticle strength lies between 50 and 100 kPa. Moreover, the addition of cement caused the soils to have more inter-particular strength; therefore, more dilatancy was observed at lower stresses compared with natural soils with no cement, as shown in Fig. 12a, b. Meanwhile, the higher compression in cemented soils compared to natural soils can be attributed to the fact that cemented soils possess more voids, which upon application of load results in higher deformations Fig. 13a, b. As far as stress–strain behavior in triaxial tests is concerned, it was observed that soils with no cement (natural soils) showed strain-hardening behavior with no visible peak curve. From this behavior, it is evident that the soil was in a loose state. This was expected, as the soil was not compacted prior to testing, to avoid the possible breakage of soil particles, which might have influenced the results. Moreover, it is also evident that during shearing of the sample, possible particle overlapping does not occur, and the particles are either compressed or broken. This implies that the cohesion properties of soil play a negligible role in the stress–strain behavior.

The addition of cement to soils, however, influenced the behavior of the soil along the axial strain. The addition of cement to soils showed a behavior similar to dense soil. However, the cemented soil was not dense, as observed from the hydraulic conductivity tests. Therefore, the other understandable reason is the strong bonding between particles, which causes the soil to behave as a dense soil. The addition of cement to soils caused the cemented soils to show peak deviatoric stress values, followed by a reduction in deviatoric stress along the axial strain. This reduction can be explained by the possible breakage of the bond created by the cement. This implies that as the shear stress progresses, the sample shows a reduction in the maximum stress that the bond can carry; once it reaches the point where it no longer can take further stresses, it starts to break, which in turn shows a reduction in deviatoric stress. Thus, the peak deviatoric stress is related to the bonding strength supported by the relevant confining stresses. This phenomenon was valid only for lower confining stresses, i.e., 50 and 100 kPa (Fig. 27).

However, at higher stresses, the soil sample is dominated by confining stresses rather than bonding owing to cement. Therefore, the applied shear stress is resisted by both the soil and confining stresses. From the results, it can be said that the bonding stress coupled with the confining stress due to cement lies somewhere between 100 and 150 kPa. In addition, bonding due to cement increases the deviatoric response. With regard to the strength parameters in the direct shear tests, it was observed that the addition of cement to the soil samples slightly increased the friction angle, as reported in Table 5. However, the cohesion intercept was zero.

According to [27], cemented soils can have greater cohesion and can improve the strength properties of soils. The authors believe that cohesion is usually a mathematical parameter intercepting at σ′v = 0. The fact that the cohesion intercept in this study was found to be zero demands more detailed investigation of similar samples under various stresses and various water contents, as in this study, an optimum water content of 9% was used. In triaxial tests, it was observed that no significant change in the friction angle was observed by the addition of cement, even considering the fact that the addition of cement caused more deviatoric stresses, as shown in Fig. 28.

The addition of cement increased the cohesion properties of the soil owing to particle bonding. Thus, the friction angle was the same as 28° from cemented and non-cemented soils. The higher cohesion values indicate strengthening of interparticle bonding, which can be related to the traditional cohesion properties, as shown in the figure above. The cohesion was found to be 10 kPa in the non-cemented soil and 72 kPa in the 10% cemented soil. Therefore, the difference of 62 kPa was due to the addition of 10% cement.

4 Conclusions

An experimental study was conducted to determine the effect of cement on natural clayey silt obtained from a canal embankment. Based on the results obtained from this study, the following conclusions were drawn:

-

With an increase in the cement content of the soil, the shear stress, vertical strain, and void ratio increased. 13% more vertical strains were observed in the specimen with 10% cement than in the natural soil. The increases in the vertical strain and void ratio were dependent on the cement content.

-

The coefficient of compressibility and compression index values suggested that the 10% cemented soil showed greater compressibility than natural soil.

-

The cemented soils exhibited dilatant behavior at lower stresses and contractant behavior at higher stresses.

-

The strength parameters, i.e., cohesion and friction angle, increased by up to 30% and 5%–15%, respectively, with the addition of 5% and 10% cement, respectively.

-

Although the void ratio increased with addition of cement, yet the gain in shear strength parameters could be very effective in controlling failure of canals embankments.

5 Future Studies

Future studies on the numerical modeling of seepage and slope stability are needed to suggest techniques to strengthen existing and future canal embankments.

Availability of Data and Materials

All data, models, and codes generated or used during the study appear in the submitted article.

References

Fell R, Wan CF, Cyganiewicz J, Foster M (2003) Time for development of internal erosion and piping in embankment dams. J Geotech Geoenviron Eng 129(4):307–314. https://doi.org/10.1061/(asce)1090-0241(2003)129:4(307)

Wu W, Kang Y (2011) A simplified breaching model for cohesive embankments. In: World environmental and water resources congress 2011: bearing knowledge for sustainability, pp 2207–2215. https://doi.org/10.1061/41173(414)230

Bhanbhro R, Al-Ansari N, Knutsson S (2014) Frequent breaches in irrigation canals in Sindh Pakistan. J Water Resour Prot 6(4):214–223. https://doi.org/10.4236/jwarp.2014.64027

Rinaldi VA, Capdevila JA (2006) Effect of cement and saturation on the stress-strain behavior of a silty clay. In: Unsaturated soils 2006, pp 1157–1168. https://doi.org/10.1061/40802(189)94

Azadegan O, Li J (2015) Effects of lime and cement treated platform on the behavior of circular footing founded on soft clay. Int J Geotech Eng 9(2):214–221. https://doi.org/10.1179/1939787914y.0000000041

Bathini DJ, Krishna VR (2022) Performance of soil nailing for slope stabilization—a review. In: IOP conference series: earth and environmental science, vol 982, no. 1. IOP Publishing, p 012047. https://doi.org/10.1088/1755-1315/982/1/012047

Rios S, Viana da Fonseca A, Baudet BA (2012) Effect of the porosity/cement ratio on the compression of cemented soil. J Geotech Geoenviron Eng 138(11):1422–1426. https://doi.org/10.1061/(asce)gt.1943-5606.0000698

Yang Y, Wang G, Xie S, Tu X, Huang X (2013) Effect of mechanical property of cemented soil under the different pH value. Appl Clay Sci 79:19–24. https://doi.org/10.1016/j.clay.2013.02.014

Tran KQ, Satomi T, Takahashi H (2018) Improvement of mechanical behavior of cemented soil reinforced with waste cornsilk fibers. Constr Build Mater 178:204–210. https://doi.org/10.1016/j.conbuildmat.2018.05.104

Huang JT, Airey DW (1998) Properties of artificially cemented carbonate sand. J Geotech Geoenviron Eng 124(6):492–499. https://doi.org/10.1061/(asce)1090-0241(1998)124:6(492)

Khajeh A, Jamshidi Chenari R, Payan M (2020) A simple review of cemented non-conventional materials: soil composites. Geotech Geol Eng 38(2):1019–1040. https://doi.org/10.1007/s10706-019-01090-x

Zhong Q, Wang L, Chen S, Chen Z, Shan Y, Zhang Q, Liu J (2021) Breaches of embankment and landslide dams-State of the art review. Earth Sci Rev 216:103597. https://doi.org/10.1016/j.earscirev.2021.103597

Hanson GJ, Cook KR, Hunt SL (2005) Physical modeling of overtopping erosion and breach formation of cohesive embankments. Trans ASAE 48(5):1783–1794. https://doi.org/10.13031/2013.20012

Talukdar P, Dey A (2019) Hydraulic failures of earthen dams and embankments. Innov Infrastruct Solut 4(1):1–20. https://doi.org/10.1007/s41062-019-0229-9

Zhang J, Li Y, Xuan G, Wang X, Li J (2009) Overtopping breaching of cohesive homogeneous earth dam with different cohesive strength. Sci China Ser E Technol Sci 52(10):3024–3029. https://doi.org/10.1007/s11431-009-0275-1

Xu GZ, Gao YF, Xu C (2015) Permeability behavior of high-moisture content dredged slurries. Mar Georesour Geotechnol 33(4):348–355. https://doi.org/10.1080/1064119x.2014.890258

Ashraf M, Soliman AH, El-Ghorab E, El Zawahry A (2018) Assessment of embankment dams breaching using large scale physical modeling and statistical methods. Water Sci 32(2):362–379. https://doi.org/10.1016/j.wsj.2018.05.002

Bobet A, Hwang J, Johnston CT, Santagata M (2011) One-dimensional consolidation behavior of cement-treated organic soil. Can Geotech J 48(7):1100–1115. https://doi.org/10.1139/t11-020

Zheng H, Shi Z, Shen D, Peng M, Hanley KJ, Ma C, Zhang L (2021) Recent advances in stability and failure mechanisms of landslide dams. Front Earth Sci 9:659935. https://doi.org/10.3389/feart.2021.659935

ASTM Committee D-18 on Soil and Roc (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. ASTM Int. https://doi.org/10.1520/d2435-11

Bhanbhro R, Auchar Zardari M, Ahmed Memon B, Ali Soomro M, Edeskär T, Knutsson S (2021) Mechanical properties and particle breakage of uniform-sized tailings material. J Mater Civ Eng 33(3):04020481. https://doi.org/10.1061/(asce)mt.1943-5533.0003597

ASTM D (2011) Standard test method for direct shear test of soils under consolidated drained conditions. D3080/D3080M 3:9. https://doi.org/10.1520/d3080_d3080m

Knappett J, Craig RF (2019) Craig’s soil mechanics. CRC Press, Boca Raton. https://doi.org/10.1201/9781351052740

Carter M, Bentley SP (2016) Soil properties and their correlations. Wiley, Oxford. https://doi.org/10.1002/9781119130888

Marchetti S, Monaco P, Totani G, Marchetti D (2008) In situ tests by seismic dilatometer (SDMT). From Res Pract Geotech Eng. https://doi.org/10.1061/40962(325)7

Dahal BK, Zheng JJ (2018) Compression behavior of reconstituted clay: a study on black clay. J Nepal Geol Soc 55(1):55–60. https://doi.org/10.3126/jngs.v55i1.22789

Horpibulsuk S, Liu MD, Liyanapathirana DS, Suebsuk J (2010) Behaviour of cemented clay simulated via the theoretical framework of the Structured Cam Clay model. Comput Geotech 37(1–2):1–9. https://doi.org/10.1016/j.compgeo.2009.06.007

Lade PV, Trads N (2014) The role of cementation in the behaviour of cemented soils. Geotech Res 1(4):111–132. https://doi.org/10.1680/gr.14.00011

Spross J, Olsson L, Stille H (2018) The Swedish Geotechnical Society’s methodology for risk management: a tool for engineers in their everyday work. Georisk Assess Manag Risk Eng Syst Geohazards 12(3):183–189. https://doi.org/10.1080/17499518.2017.1416643

Bhanbhro R, Zardari MA, Qureshi AS (2019) Feasibility of using cemented-soils for canal embankments in Pakistan. In: Proc. XVII Eur. conf. soil mech. geotech. eng. https://doi.org/10.32075/17ECSMGE-2019-0954

Acknowledgements

These studies were conducted in the geotechnical laboratories of Quaid-e-Awam University of Engineering Sciences and Technology (QUEST), Nawabshah, Pakistan. We acknowledge QUEST for providing the necessary resources and support for this study. The financial support from the Higher Education Commission of Pakistan, through its National Research Program for Universities (NRPU) project, is highly acknowledged.

Funding

Higher Education Commission, Pakistan, through NRPU Number 9352.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there are no competing interests related to this article.

Consent for Publication

All the authors hereby do agree and provide consent to this paper be published.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zardari, S., Bhanbhro, R., Zardari, M.A. et al. Effect of Cement on Clayey Silt for Stabilization of Canal Embankments. Int J Civ Eng 21, 957–972 (2023). https://doi.org/10.1007/s40999-023-00804-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-023-00804-w