Abstract

Reinforced concrete structures, which generally resist high temperatures well and usually do not suffer destruction, therefore require an assessment of the concrete’s condition after a fire. This review explores various techniques for assessing Fire Exposed Concrete (FEC) and provides comprehensive insights into their application by examining the principles, advantages, drawbacks, and feasibility of these methods. This comprehensive analysis aims to enhance assessment effectiveness and improve outcomes in restoring the integrity and safety of fire-damaged concrete structures. Overall, this review contributes to the literature by systematically outlining assessment techniques and providing valuable insights for researchers, engineers, and practitioners in selecting suitable methods and aiding informed decision-making on repair strategies. Samples extracted utilizing core procedures may be subjected to laboratory studies, especially non-linear approaches. The bibliometric analysis concludes significant linkages and trends in study areas including fire resistance and Non-Destructive Testing (NDT) of FEC are presented by analyzing keyword networks during the last 20 years. With more than 40 citations to back up their findings, highlighted the importance of and relationships between important subjects in this discipline. Techniques such as crack density measurement, indirect UPV, impact echo, Ground-Penetrating Radar (GPR), petrography, Differential Thermal Analysis (DTA) and Thermogravimetric Analysis (TGA) may be performed to determine the damage depth of concrete subjected to fire; however, caution is advised as each approach has its limitations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Concrete is inherently fire-resistant and non-combustible, with low thermal diffusivity. Catastrophic collapse of concrete structures during fires is rare although, isolated cases have been documented (Buchanan and Abu 2016). The temperature and duration of exposure to fire influence the extent of thermal damage to the reinforced concrete structures. Typically, damages are most severe at the surface and diminish with depth but exposure to fire leads to physical and chemical alterations in concrete, further reducing its mechanical properties. The appraisal process for fire-exposed concrete structures commences with collecting relevant information, including the structure’s blueprint, building materials, usage, cause of fire, and duration of exposure. Subsequently, visual observations and various non-destructive and semi-destructive tests are conducted.

In scientometric assessments, academics use “science visualization” to evaluate bibliometric data for various purposes. Visualization software, such as VOS Viewer, is widely used and highly regarded in academic literature. This review paper employed various studies for bibliometric analysis. Figure 1 illustrates the correlation frequency of keyword networks, showing their connections and the density related to correlation frequency (Qin et al. 2022). The size of each keyword node represents its frequency, while its position indicates its co-occurrence in publications for the last two decades. This visualization effectively highlights the relationships and prominence of different keywords in the analyzed studies. The overall linkage between fire resistance under elevated temperatures, “NDT of FEC,” and “Testing of FEC” was analyzed using more than 40 citations from the last two decades via Dimension.ai. As shown in Fig. 2, distinct groups were detected, highlighting key research areas and trends in non-destructive testing methodologies for fire-damaged concrete.

Ensuring fire safety in building design is crucial for occupant protection. Fire-induced damage significantly deteriorates reinforced concrete (RC) structures, despite concrete’s noncombustible nature. Wróblewska and Kowalski (2020) highlight the limitations of traditional assessment methods and propose alternative techniques to evaluate non-uniform damage depth. Andrushia et al. (2021) present a method using Discrete Ripplet Transform (DRT) for detecting thermal cracks in fire-exposed concrete, demonstrating superior performance over other techniques. Akca and Özyurt (2020) examine the post-fire behavior of concrete beams, showing that high temperatures degrade morphology and mechanical properties, while post-fire re-curing aids recovery. Biradar et al. (2024) explore fire-related damages in RC structures, offering future safety enhancement suggestions. Kog (2021) reviews 21 case studies, providing a comprehensive guide for assessing fire-damaged structures and discussing various repair materials. Qin et al. (2022) summarize firefighting deficiencies and recovery measures, identifying common causes of fire damage. This review aims to consolidate these insights to advance fire safety and resilience in RC structures. The fire resistance of concrete was initially investigated by Lea (1922), who noted a decrease in concrete strength with rising temperatures. The residual strength of compromised concrete depends on various factors including maximum temperature reached, duration of the fire, mix design, type of aggregate, and applied load during heating and technique used as shown in Table 1.

Wróblewska and Kowalski (2020) identified a significant limitation in the conventional method of estimating the compressive strength of cores. This traditional approach often assumes uniform material properties throughout the core, disregarding potential variations and anomalies within the specimen. Consequently, it fails to account for heterogeneity, which can lead to inaccurate strength assessments. The method also typically overlooks the influence of microcracks and other imperfections that might be present. These oversights can result in an overestimation or underestimation of the actual compressive strength, thus compromising the reliability and accuracy of the results derived from such conventional testing methods.

Since the dawn of human civilization, individuals have utilized non-destructive evaluation techniques, initially relying on their senses such as touch, hearing, and vision to detect damage or abnormalities. Modern Non-destructive testing (NDT) methods aim to provide objective assessments of the extent of damage. The evolution of techniques used for non-destructive assessment of materials and structures is closely linked to advancements in medical disciplines, where examinations of human beings are conducted (Grosse 2013). NDTs have broad applications including quality control during construction, ensuring material compliance with standards, monitoring concrete strength development post-casting, detecting voids and defects within structures, and assessing residual strength following accidental damage. NDTs can be classified based on their relationship with concrete properties as non-linear and linear methods. They can also be categorized according to the nature of the test as non-destructive, semi-destructive, and destructive techniques. Another classification criterion is based on the location of tests, distinguishing between onsite and laboratory tests. Additionally, classification may be based on individual or combined tests. In this paper, NDTs are classified into preliminary technique, surface hardness technique, stress wave technique, and miscellaneous technique as illustrated in Fig. 2.

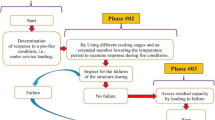

The Concrete Society has outlined a stepwise procedure for comprehensive assessment of concrete structures (Dilek 2009). Figure 3 depicts the flowchart illustrating the evaluation and restoration of concrete structures. The appraisal procedure involves selecting appropriate tests, and determining the location and number of test points to assess the residual condition.

2 Preliminary Survey: Visual and Audio Technique

A thorough assessment is required following a fire accident, typically before debris removal and once the building becomes accessible (Annerel and Taerwe 2011). Visual and audible techniques aid in identifying areas for a more comprehensive evaluation. The visual method assists in condition assessment, while the audible technique helps detect voids and delamination.

2.1 Visual Examination

A Visual examination is the foremost step in the appraisal procedure of FEC. It is one of the most acceptable and robust NDT methods. The Visual inspection collects info regarding attributes of FEC such as spalling, cracking, surface crazing, exposed reinforcement, excessively deflected members, and collapse. From the visual examination, practical info can be retrieved concerning the fire’s growth and its intensity and probable mineralogical changes in the concrete. Figure 4 illustrates the mineralogical changes in concrete with prolonged thermal exposure, including ettringite dissociation, loss of bond water, gypsum decomposition, compound oxidation, quartz transition, portlandite dihydroxylation, and carbon dioxide release, as deterioration progresses (Ingham 2009).

The visual inspection identifies areas of peculiar impairment and any inherent failure that needs to be isolated from the general damage. To locate the spread of fire and predict the highest temperature attained, the concrete as well as field combustible residue is examined by visual method The visible examination is rapid involves the least cost, and provides a qualitative assessment of FEC. Aseem et al. (2019) and Ha et al. (2016) have carried out case studies and classified the damage accordingly. The visible examination report helps to map out potential damage zones at structural members and reveal approximate elevated temperatures. Figure 5 gives details of all related information collected from the visible survey and their class of damage thus defining the scale of damage. Color changes of FEC with temperature give a clue about the maximum temperature reached during a fire accident.

2.2 Colorimetry

Heating concrete results in the drying of the cement matrix and a change in surface color. Initially, this change is attributed to the evaporation of free water, capillary water, and the release of physically bound water. The alteration in color begins with the removal of free water through evaporation from the cement paste, followed by the elimination of chemically bonded water (Castellote et al. 2004). To quantify FEC in terms of color, color image analysis can be employed (Stone 2019), offering a valuable alternative to visual methods. Color measurement provides insights into thermal history, including temperature distribution and maximum temperature exposure of FEC (Felicetti 2004). Color analysis can also assess damage occurring along the depth of FEC.

Understanding color measurement concepts can be complex and challenging (Berns 1995). The human eye perceives colors within a wavelength range of 380–770 nanometers. Despite the illuminant’s negative effect, digital cameras can effectively capture concrete chromatic changes. Digital images enable distinct analysis of mortar matrix and aggregates, facilitating evaluation of the residual capacity of concrete structures. On-site application of digital cameras allows investigation of color differences on FEC surfaces and concrete powder obtained from drilling holes. The color observed from an opaque surface is the combined effect of the Spectral Power Distribution (SPD) of incident light and the reflectance factor of the surface. In the case of grey color, each wavelength experiences equal absorption, resulting in a uniform reflection across the SPD curve (Annerel and Taerwe 2011; Felicetti 2004; Stone 2019). Colors are recorded and encoded into color spaces (Stone 2019). Color space serves as a tool for identifying and quantifying color, ideally characterized by perceptual linearity, intuitiveness, and device independence (Annerel and Taerwe 2011). Common examples of color spaces include RGB (Red, Green, Blue), HSI (Hue, Saturation, Intensity), CIE (International Commission on Illumination) XYZ, and CIE. The RGB color space is represented as a subset of the three primary colors (Wei et al. 2019). Table 2 provides a comparative overview of the advantages and limitations of different color spaces for effective selection.

2.3 Crack Measurement Technique

Cracks may form in concrete following a fire accident due to the thermal gradient between the surface and inner layers, as well as vapor pressure buildup within the concrete (Annerel and Taerwe 2013). Typically, FEC specimens are examined under light filtration at a specific magnification, with images captured using a camera or other image acquisition devices. These images are then manually analyzed to measure crack length relative to the observed surface area. Crack density measurement is strongly correlated with the maximum exposure temperature of FEC (Georgali and Tsakiridis 2005). This technique can estimate the depth of concrete damaged by fire exposure, aiding in repair work. Moreover, crack density measurement applies to concrete produced with various grades of cement and aggregate. Short et al. (2002) concluded from their study that there is a significant correlation between crack density and compressive strength of concrete, while Xu et al. (2003) found a stronger correlation with tensile strength rather than compressive strength.

2.4 Audile Technique

The audile technique refers to a sound-based method for assessing concrete exposed to fire. For the preliminary survey of fire-damaged concrete structures, visible inspection methods along with hammer and chisel techniques are employed (Mukupa et al. 2017). This method helps identify grey areas and zones of delamination that require detailed investigation (Chew 1993). Human hearing perception can distinguish between ringing or dull/thud (low-frequency) sounds produced during the inspection of FEC. The comparative soundings may suffice to establish the level of deterioration in FEC. The problem with the hammer and chisel technique is that it can only be used for spatial measurement; it cannot quantify the extent of damage and is also subject to individual bias. A laboratory test conducted by Kulkarni et al. (2017), which involved measuring the impact sound level using a steel ball dropped from a certain height, can determine the deterioration in FEC. The sound level measurement was captured using a dosimeter in decibels (dB). A good correlation was found between the sound level and the deterioration level of FEC.

3 Mean Surface Hardness Techniques

3.1 Schmidt Rebound Hammer

The Rebound Hammer (RH) is a well-established technique for measuring the surface hardness of structures. When the RH is pressed against a hard concrete surface, a hammer mass is released by a spring system and subsequently rebounds to a distance known as the rebound number (Kowalski and Wróblewska 2018). The rebound hammer method is useful for categorizing concrete areas into three broad classes: complete loss, partial loss, and no loss of structural value. The surface temperature can be roughly estimated using RH, and damage can be compared accordingly (Panedpojaman and Tonnayopas 2018).

The rebound hammer is capable of examining the strength and stability of concrete members. However, an experimental study conducted by Aseem et al. (2019) found that RH tends to overestimate the compressive strength of fire-exposed concrete and is unable to evaluate conditions inside the structure. Several studies have reported that the concrete surface hardens after fire exposure, leading to an increased rebound number. RH measurements are influenced by various factors, including concrete moisture, carbonation depth, condition of the tested area, how the concrete surface was exposed and prepared before measurements, its ingredients, composition, and age (Soshiroda and Kimura 1998). Lower rebound numbers were found on wet concrete surfaces compared to dry surfaces. Thus, the evaluation of mechanical strength using the rebound method is not applicable for all degrees of fire exposure.

3.2 Penetration Technique

Voellmy first employed the penetration method in 1954 to measure concrete compressive strength (Kim et al. 1990). This method was later developed into the Windsor probe test in the United States for the same purpose. The Windsor probe equipment includes a driver (gun), alloy probe, cartridges, depth gauge, and additional accessories (Malhotra and Carino 2014). The method operates on the principle that a probe is fired by the driver, and the depth of penetration is measured using an electronic gauge. This penetration depth correlates with the compressive strength of the concrete, which is influenced by the hardness of the aggregate.

The penetration test is quick and easy to perform and can be conducted even on uneven or rough surfaces (Bungey and Soutsos 2001). An improved correlation between the penetration depth and concrete strength has been observed compared to other methods (Short et al. 2001). For FEC, the penetration technique has proven valuable, particularly for assessing surface concrete, as demonstrated by experimental studies. When the penetration is near a reinforced bar, the results indicate increased concrete strength. However, the impact energy imparted by the probe to the concrete may cause serious damage or fractures (Tay and Tam 1996). This affects the non-uniform strength assessment of concrete as the penetration resistance is influenced by discrete surface degradation.

3.3 Pull-off Test

The pull-off test is conducted both with and without a cored concrete surface. In this test, a round-shaped metal disc is firmly glued to the concrete surface using adhesive. The disc is then pulled away from the concrete surface until the concrete breaks in tension as shown in Fig. 6(a) and (b). The tensile force per unit area provides the tensile stress of the concrete, which correlates with its compressive strength (Bungey and Soutsos 2001).

A key advantage of the pull-off method is that it is quick to perform and relatively insensitive to the constituent materials of the concrete. It is particularly suitable for estimating bond strength and assessing repair patches. Haddad et al. (2013) used this technique to investigate the relationship between bond stress and slip of embedded reinforcement. According to Wróblewska and Kowalski (2020), the pull-off test can be conducted at two specific locations: at the surface and at a specific depth, depending on the distance from the fire-exposed surface. Concrete surfaces should be prepared for disc adhesion by washing and scrubbing. However, using the pull-off method near the surface of fire-exposed concrete strength estimation can be misleading. Thus the method may not be applicable for severely fire-damaged concrete surfaces and can be challenging to implement.

3.4 CAPO Test

The Cut and Pullout (CAPO) test is carried out by drilling a hole at a measured point in concrete which is chosen carefully by taking into consideration reinforcement inside (Fig. 7). A compressed steel ring is inserted inside the hole which expands in the prepared hole. The force needed to pull the steel ring out of the concrete member is estimated and based on correlation, compressive strength is known (Bungey and Soutsos 2001; Khoury 1992; Tay and Tam 1996). A fairly good enough correlation is obtained by the CAPO test method. This method requires surface preparation and is thus time-consuming and difficult to use for FEC (Standards New Zealand 2006). Also, results are depending on the size and type of aggregate.

3.5 BRE Internal Fracture

In the Building Research Establishment (BRE) internal fracture technique a hole is drilled (6 mm diameter) and a metal anchor bolt with a spilled sleeve is placed in the hole. The sleeve is made to expand and then torque applied to fracture concrete is noted which correlates with compressive strength (Abolhasani et al. 2022). This method is easy and quick to perform. BRE internal fracture test can be applied to spalled surfaces (Tay and Tam 1996). The test results obtained by this technique are highly variable. A careful approach is needed while using the correlation for deteriorated concrete. The reason for such variability is due to differences while drilling holes aggregate in concrete may cause distorted load transfer mechanism and thus give misleading failure load.

3.6 Drilling Technique

The drilling technique involves cutting a hole using a drill bit, making it a semi-destructive method capable of assessing concrete at various depths. The drilling technique proved to be a fast method with the added advantage of scanning material properties along with depth. Felicetti (2006) used this method to assess the deterioration in FEC. The hammer drill machine in the experiment was loaded with a force of 100 N and had a self-weight of approximately 70 N. A hammer drill is equipped with sensors to measure power consumption, torque, and hole depth. In this experiment, drilling resistance, in terms of work per unit hole depth, drill time, and other metrics were compared against the damage level of concrete.

The drilling resistance was the most sensitive indicator of concrete soundness and this technique is useful for estimating damage thickness. The field application of the drilling technique is feasible and offers the additional benefit of detecting voids, and delaminated layers. However, the experimental analysis revealed a poor correlation between work done per unit depth and compressive strength and proved less sensitive. Felicetti 2013 also attempted the hammer drill pulse transmission method for damage estimation but it was found insensitive to thermal damage. Kulkarni et al. (2017) explored drilling with a constant thrust for the assessment of the mechanical properties of concrete. This technique yielded good results for assessing the degree of thermal damage, and it provided qualitative information. Table 3. presents the pros and cons of various surface hardness methods.

4 Stress Wave Techniques

Stress wave techniques in NDT for fire-exposed concrete encompass both linear and non-linear approaches to assess the material’s integrity and strength.

4.1 Linear Techniques

Linearity in NDT techniques refers to the proportional relationship between the input signal and the output response. In linear NDT methods, the response of the material or structure being tested is directly proportional to the applied stress or signal.

4.1.1 Ultrasonic Pulse Velocity Technique

Since 1955, researchers have used Ultrasonic Pulse Velocity (UPV) to inspect concrete quality (Elvery and Vale 1955). Ultrasonic equipment consists of a pulse generator and a pair of transducers (a transmitter and a receiver). Generally, a piezoelectric element is excited using an electrical signal, causing the element to vibrate at its resonant frequency and produce an ultrasonic pulse wave. The transmitter, in contact with the material, induces a compressive wave that travels through the material to the receiver. The travel time is recorded electronically, and the velocity is calculated using the time-distance relationship. UPV readings through concrete can be taken using three modes: direct (opposite surface), semi-direct (adjacent surface), and indirect (same surface). Pulse velocity is correlated with the compressive strength of concrete. Researchers have also used UPV techniques to determine the damage depth of FEC. Wu and Law have proposed a method for estimating damage depth (Jhang 2009). According to the ultrasonic method, stress waves through damaged concrete can travel in two paths, as shown in Fig. 8.

In the Fig. 8. (b) of travel time versus distance (L), a change in slope indicates that there is damage in the surface layer. The inverse of wave velocities in zones gives slopes of the lines and Eq. 1 gives the thickness of the damaged layer (Cheng Kang Wu and Law 1985). The study conducted by Dilek and Leming (2007), overestimates actual damage depth.

The UPV test is non-destructive and easy to perform and its capability to assess the damaged concrete makes it the most preferred one to evaluate FEC (Hwang et al. 2018). UPV reading through direct mode is related to concrete elastic modulus and moisture content due to temperature rise, there is a loss of moisture content and a reduction in concrete elastic modulus. UPV techniques can also be performed on cored concrete from the structure (Kumavat and Chandak 2024). The direct mode of UPV helps to assess areas or identify voids or flows in concrete (C.K. Wu and Law 1985). UPV technique can be used to characterize cracks more accurately (Pahlavan et al. 2018). The study conducted by Lin et al. (2011), concludes a good correlation between pulse velocity with residual strength of concrete. Spalled or rough surfaces in concrete cause insufficient acoustic coupling, thus creating difficulties in taking UPV readings. Large voids and cracks lead to lower UPV readings. As the water-cement ratio in concrete increases, there is a decrease in UPV readings (Wróblewska and Kowalski, 2020). Hwang et al. (2018) carried out an experimental study and took UPV readings during the thermal exposure of concrete and reaching ambient temperature after cooling indicating that the higher the grade of concrete higher the losses in UPV reading. UPV reading during the thermal exposure is higher than the same concrete after cooling.

4.1.2 Impact Echo

An impact echo test, a short-duration stress pulse is generated by mechanical impact. On defective concrete member, the generated p-wave travels within the member to its boundary surface reflects the impact point, and repeats this cycle. A transducer placed adjacent to the impact captures the signal. The signal frequency is calculated by converting it from the time domain to the frequency domain using a fast Fourier transform. Epasto et al. (2010) used continuous wavelet transform for an overcomplete representation of the impact echo signal. The damage thickness can be calculated using the Eq. 2.

where VP is wave velocity, f represents frequency, and T is thickness. Wave velocity is measured by placing two transducers at a known distance on the surface and noting the propagation time. Elastic waves propagate easily through concrete due to its high acoustic impedance. Acoustic impedance, is determined by wave velocity, and density and depends on the thermal history of FEC (Candelaria and Kee 2023). FEC exhibits reduced acoustic impedance and altered wave propagation. The dominant frequency correlates with the mechanical properties of damaged concrete (Koabaz et al. 2012; Krzemień and Hager 2015). The impact echo test can estimate the damage thickness and locate voids, flaws, or cracks inside concrete. It is simple, cost-effective, and allows for the assessment of large areas quickly without requiring precautionary measures (Epasto et al. 2010). The test is effective with only a single surface of the member, and reinforcement does not affect the measurement (Wróblewska and Kowalski, 2020). However, it provides an average thickness value and cannot identify specific layers or the thickness of the damaged layer in FEC (Dilek and Leming 2007). While the correlation between resonance frequency and compressive strength holds well in theory, practical implementation of FEC structures has shown inconsistent results (Krzemień and Hager 2015).

4.2 Non-linear Techniques

Non-linear techniques are considered when the non-linearity parameters are obtained to have a non-linear correlation with the degree of damage in concrete, particularly with contact-type defects. These defects may be due to micro-cracks, opening, and pores formation in concrete structures due to shrinkage and expansion of cement-mortar matrix and coarse aggregate respectively. The non-linear techniques can be broadly divided into two categories: (i) Non-linear resonance techniques and (ii) Non-linear modulation techniques.

4.2.1 Non-Linear Resonance Technique

The non-linear resonance technique measures variation between frequency from input and output signal through a heterogeneous medium, which is proportional to the degree of damage (Jhang 2009; Krohn et al. 2004). Equation of stress σ (Eq. 3) and elastic modulus E (Eq. 4) as a function of strain and as follows,

Where β and δ are the second and third-order non-linearity, α is the hysteretic nonlinearity, = rate of strain, Δɛ [Δɛ= (Δɛ max - Δɛ min )/2) for a simple continuous sine excitation] is a change of strain amplitude across the preceding period, sign(ἐ) = + 1 whenever ἐ is greater than 1 and sign(ἐ) = -1 if ἐ less than 1. Equation 5, gives a relationship between input amplitude change and resonance frequency shift (Van Den Abeele et al.,2000a).

In the non-linear resonance technique, the linear resonance frequency (f0), resonance frequency (f) considering the amplitude-dependent effect, and αh, the hysteric non-linear parameter, are important. Hysteric non-linearity, the amplitude-dependent shift of resonance frequency, and non-linear attenuation can be estimated using this technique. Figure 9(a) and (b) illustrate the setup used to measure these non-linear parameters and excited the concrete sample by impacting it with a steel bead, while Boukari et al. (2013) used a transducer producing a sinusoidal wave to excite the sample at resonance vibration.

4.2.2 Non-Linear Modulation Technique (Wave Interaction Technique)

The principle behind this technique is that modulated high-frequency wave at contact-type defects is formed when a high-frequency wave passes through the opposite face of fire-damaged concrete and a low-frequency wave is produced with mechanical impact in traverse direction (Boukari et al. 2013). Figure 10 shows the arrangement for this test. Equation 5, the non-linearity parameter (D) is proportional to the spectral energy of a high-frequency wave (Eh), the spectral energy of a low-frequency wave (El), and the sideband component (Es) (Yim et al. 2012).

The non-linear resonance and modulation techniques are sensitive to the degree of thermal damage of concrete (Castellano et al. 2021). The non-linear parameter obtained by impact modulation gives a good correlation with the compressive strength of heated concrete. Evaluation of the tensile strength of FEC may be done through the non-linear resonance vibration technique (Park et al., 2016). Non-linearity parameters can also be used to estimate the exposed temperature of concrete and are not influenced by the mix proportion.

The investigation was conducted by (Park and Yim 2017) to compare the effectiveness of non-linearity parameters obtained by resonance and modulation techniques for the evaluation of FEC. The study concludes that the non-linear modulation technique is more effective than the non-linear resonance method for evaluating contact-type defects in FEC at high temperatures (Park et al., 2016). There is a lack of repeatability and reproducibility of results in both techniques. The application of a non-resonance test on a large structure would not be easy to perform (Boukari et al. 2013).

4.3 Acoustic Emission

Acoustic emission is the acoustic measurement technique, when thermal load act on the concrete member, the micro-seismic activity act inside. The micro-seismic activities involve disturbances like intergranular friction, micro cracking, and dislocation movement. To measure acoustic activity, one or even more transducer is kept on the surface of that member, a preamplifier is used to amplify the signal and data acquisition to capture data (Balayssac et al. 2012). A systematic layout for acoustic measurement is given in Fig. 11.

Ozawa et al. (2012), employed an acoustic emission technique to observe the spalling of high-strength concrete while heating. Acoustic activities increase with an increase in the temperature of concrete up to the spalling event. This method can estimate the fracture process during the heating of concrete and can be used to study microcracks, to detect defects in concrete and spalling characteristics (Balayssac et al. 2012). Son and Hosoda (2010) stated that the higher the maximum aggregate size in concrete mix higher the acoustic signal captured. Many studies suggest that α-β quartz transition occurs in concrete at a temperature between 500 and 600 °C, leading to serious micro-cracking in concrete. (Geng et al. 2016), studied acoustic signals during dynamic loading for fire-damaged concrete and observed that for higher temperatures, fewer acoustic signals were generated. Noise such as electric pulse, environmental sound, impact, and friction is a cause of concern when dealing with an acoustic signal. Although some measures are taken to remove noise complete elimination of noise seems difficult.

4.4 Combined Method: SonReb

SonReb is a combined technique that comprises both rebound index and pulse velocity. This technique has gained importance because it predicts damaged concrete strength with fair enough reliability. The idea of the combined method was the brainchild of Facaoaru in 1960. Based on the fact that both rebound number and pulse velocity are very much dependent on the moisture level in FEC, which is a significant factor in determining its strength (Uva et al. 2018). The experiments carried out by Akman and Güner (1984), show that reliable prediction by this SonReb model up to 300 °C is possible.

5 Miscellaneous Techniques

5.1 Ground Penetrating Radar Technique

GPR technique is a rapid assessment technique utilizing electromagnetic signals to image infrastructure, including fire-exposed concrete (FEC). GPR operates within a wave frequency range of 500 MHz to several GHz for concrete investigation (Büyüköztürk and Rhim 1997). As the GPR signal penetrates the material, it scatters and reflects due to differences in electric and magnetic properties, which are captured by the receiver for imaging purposes (Wai-Lok Lai et al. 2018). GPR has various applications, such as assessing geometrical heterogeneity, estimating damaged depth, and identifying common surface boundaries between different layers. Lo Monte et al. (2017) successfully employed GPR to monitor real-time moisture front migration in concrete during heating, outperforming methods like Neutron Radiography Imaging (NRI) and Nuclear Magnetic Resonance (NMR). However, the GPR method’s limitation lies in its ability to adequately distinguish properties for identifying layer interfaces, and its thickness estimation is not highly accurate due to reliance on a constant velocity assumption (Balayssac et al. 2012).

5.2 Petrographic Test

The petrographic test combines both visual examination and high-level microscopic inspection of prepared samples. A thin section sample is prepared by incorporating fluorescent dyes into the resin to facilitate the examination of micro-cracking, pores, and mineralogical changes. For microscopic observation, light is allowed to pass through samples placed on glass slides. This technique is capable of determining the maximum temperature exposure and estimating the damage depth of fire-exposed concrete (FEC). It can also help locate weak zones for detailed inspection and assist in deciding whether to repair or demolish the damaged structure (Ingham 2009). Performing a petrographic test requires care and expertise from skilled and experienced individuals.

5.3 Differential Thermal Analysis and Thermogravimetric Analysis

Differential Thermal Analysis (DTA) and Thermogravimetric Analysis (TGA) are laboratory methods used to examine the changes in the physico-chemical characteristics of FEC. In DTA and TGA analysis, the alteration in physico-chemical characteristics of FEC is studied by heating samples in the laboratory. Thermograms, which depict the percentage mass versus temperature, are analyzed to understand these changes. The level of calcite content in concrete indicates the maximum temperature exposure during a fire incident. This method enables the measurement of damage extent along the depth of the concrete. The data obtained from DTA/TGA can be utilized for repairing FEC structures (Handoo et al. 2002). Sample collection for performing this test should be conducted within 48 h.

5.4 Thermo-Luminescence (TL)

When crystals and minerals like sand, quartz, and feldspar are heated, they emit visible light due to ionizing radiation energy, influenced by material radiation and thermal exposure history (Daniels et al. 1953). The thermoluminescence (TL) technique quantifies the leftover TL energy from thermal exposure in a small sand sample, measured as visible light signals in the glow curve (Placido 1980). TL testing estimates FEC’s thermal history and requires only a small sample (Smith and Placido 1983). Lower temperature ranges up to 200 °C fail to eliminate significant signals even after prolonged heating, whereas an hour at 400 °C almost eliminates signals above blackbody radiation levels. Acid treatment of a known weight sample can eliminate limitations in quantifying TL signal loss during fire exposure. TL testing can also be performed on sand samples from brickwork mortar and coarse aggregate. TL testing is limited to temperatures up to 500 °C, with the TL signal reduction depending on both temperature exposure and duration of fire (Pei et al. 1997).

5.5 Coring Technique

The coring technique involves drilling and extracting a core sample for destructive testing, making it the most reliable method for assessing the strength of fire-exposed concrete (FEC) as it undergoes mechanical testing. This method is considered semi-destructive and is used to determine in-situ concrete strength. Coring can also assess the depth of fire damage and mechanical damage gradient. The strength of the core sample is influenced by factors such as moisture content, drilling direction, presence of reinforcement, length-to-diameter ratio, and concrete strength. However, coring has limitations—it is a time-consuming and not cost-effective technique. Additionally, the details obtained from coring are limited to small zones, making it unsuitable for overall assessment (Cioni et al. 2001).

6 Conclusions and the Way Forward

A preliminary assessment of fire-exposed concrete structures includes techniques, such as visual inspection and tools like hammers and chisels, to map potential damage zones. These methods, while quick, lack accuracy in estimating maximum temperature exposure. Techniques like colorimetry, crack density measurement, petrography, DTA-TGA, and thermoluminescence (TL) provide better insights into thermal exposure, though they vary in effectiveness. Mechanical properties of FEC show convincing correlations with parameters from the rebound hammer (RH), pull-off test, penetration test, ultrasonic pulse velocity (UPV), and non-linear modulation techniques. However, these methods may be limited in certain scenarios. Case studies support the use of RH, and UPV along with core methods for assessing mechanical properties in heated concrete. The analysis of keyword networks over the past two decades reveals significant relationships and trends in research areas such as fire resistance and non-destructive testing (NDT) of fire-exposed concrete. The findings of bibliometric analysis supported by over 40 citations, underscore the prominence and connections between key topics in this field. Surface hardness and various stress wave techniques, such as UPV and Impact Echo, may be used for in situ FEC assessments. However, caution while using these techniques is advised as each technique has its restrictions. For the effective selection of color space, a table has been prepared that presents its advantages and limitations. To choose an effective approach for evaluating FEC, the advantages and disadvantages of the mean surface hardness techniques were discussed.

Laboratory tests, especially non-linear methods, can be applied to core samples, but further research is needed to gather sufficient data for FEC evaluation due to varying residual properties of concrete based on its composition, age, concrete type, and thermal exposure. Assessing the depth of damage is crucial, as surface layers might differ significantly from inner layers. Techniques like crack density measurement, drilling, indirect UPV, impact echo, ground-penetrating radar (GPR), petrography, and DTA-TGA have been explored for this purpose, but their applicability is limited. In practice, FEC assessment relies on a combination of methods to comprehensively understand the degree of damage, as demonstrated in case studies. Combining multiple techniques ensures a more accurate and reliable assessment, aiding decision-making regarding the repair or demolition of fire-damaged structures.

Overall, evaluating FEC requires integrating various non-destructive techniques, semi-destructive techniques and NDT. Techniques like color space analysis, crack density measurement, and advanced methods like non-linear techniques provide valuable insights into fire damage. Proper calibration and selection of methods are essential for accurate predictions and effective remediation, ultimately enhancing the integrity and safety of fire-exposed concrete structures.

Data Availability

No datasets were generated or analysed during the current study.

Abbreviations

- FEC:

-

Fire Exposed Concrete

- NDT:

-

Non- Destructive Testing

- DRT:

-

Discrete Ripplet Transform

- UPV:

-

Ultrasonic Pulse Velocity

- GPR:

-

Ground-Penetrating Radar

- RH:

-

Rebound Hammer

- XRD:

-

X-ray diffraction

References

Abolhasani A, Shakouri M, Dehestani M, Samali B, Banihashemi S (2022) A comprehensive evaluation of fracture toughness, fracture energy, flexural strength and microstructure of calcium aluminate cement concrete exposed to high temperatures. Eng Fract Mech 261:108221. https://doi.org/10.1016/j.engfracmech.2021.108221

Akca AH, Özyurt N (2020) Post-fire mechanical behavior and recovery of structural reinforced concrete beams. Constr Build Mater 253:119188. https://doi.org/10.1016/j.conbuildmat.2020.119188

Akman MS, Güner A (1984) The applicability of sonreb method on damaged concrete. Matér Constr 17:195–200. https://doi.org/10.1007/BF02475244

Andrushia AD, Anand N, Arulraj P, G (2021) Evaluation of thermal cracks on fire exposed concrete structures using Ripplet transform. Math Comput Simul 180:93–113. https://doi.org/10.1016/j.matcom.2020.07.024

Annerel E, Taerwe L (2011) Methods to quantify the colour development of concrete exposed to fire. Constr Build Mater 25:3989–3997. https://doi.org/10.1016/j.conbuildmat.2011.04.033

Annerel E, Taerwe L (2013) NDT methods for the Assessment of concrete structures after fire exposure. In: Büyüköztürk O, Taşdemir MA, Güneş O, Akkaya Y (eds) Nondestructive testing of materials and structures. Springer Netherlands, Dordrecht, pp 773–778. https://doi.org/10.1007/978-94-007-0723-8_110

Aseem A, Latif Baloch W, Khushnood RA, Mushtaq A (2019) Structural health assessment of fire damaged building using non-destructive testing and micro-graphical forensic analysis: a case study. Case Stud Constr Mater 11:e00258. https://doi.org/10.1016/j.cscm.2019.e00258

Balayssac J-P, Andrade C, Monteiro JS, Scheel H (2012) Ruptures of prestressing cables. In: Breysse D (ed) Non-destructive Assessment of concrete structures: reliability and limits of single and combined techniques: state-of-the-art report of the RILEM Technical Committee 207-INR. Springer Netherlands, Dordrecht, pp 305–334. https://doi.org/10.1007/978-94-007-2736-6_7

Berns RS (1995) Practical color measurement: A primer for the beginner, a reminder for the expert, by Anni Berger-Schunn, John Wiley & Sons, New York, 1994. 175 pp. $54.95. Color Res. Appl. 20, 211–212. https://doi.org/10.1002/col.5080200312

Biradar G, Ramanna N, Madduru SRC (2024) An in-depth examination of fire-related damages in reinforced concrete structures-A review. J Build Pathol Rehabil 9:81. https://doi.org/10.1007/s41024-024-00438-y

Boukari Y, Rivard P, Bulteel D, Ballivy G, Abriak NE (2013) Comparative study of Nonlinear Resonance and Wave Interaction techniques for concrete damage Assessment. In: Büyüköztürk O, Taşdemir MA, Güneş O, Akkaya Y (eds) Nondestructive testing of materials and structures. Springer Netherlands, Dordrecht, pp 137–142. https://doi.org/10.1007/978-94-007-0723-8_19

Buchanan AH, Abu AK (2016) Structural Design for Fire Safety, 1st ed. Wiley. https://doi.org/10.1002/9781118700402

Bungey JH, Soutsos MN (2001) Reliability of partially-destructive tests to assess the strength of concrete on site. Constr Build Mater Near Surf Test of 15:81–92. https://doi.org/10.1016/S0950-0618(00)00057-X

Büyüköztürk O, Rhim HC (1997) Radar imaging of concrete specimens for non-destructive testing. Constr Build Mater Invest Mater 11:195–198. https://doi.org/10.1016/S0950-0618(97)00037-8

Candelaria MDE, Kee S-H (2023) Evaluation of thermal damages of concrete subjected to high temperatures using recurrent neural networks for ultrasonic pulse waves. Constr Build Mater 407:133416. https://doi.org/10.1016/j.conbuildmat.2023.133416

Castellano A, Fraddosio A, Piccioni MD, Kundu T (2021) Linear and Nonlinear Ultrasonic techniques for monitoring stress-Induced damages in concrete. J Nondestruct Eval Diagn Progn Eng Syst 4:041001. https://doi.org/10.1115/1.4050354

Castellote M, Alonso C, Andrade C, Turrillas X, Campo J (2004) Composition and microstructural changes of cement pastes upon heating, as studied by neutron diffraction. Cem Concr Res 34(H F W Taylor Commemorative Issue):1633–1644. https://doi.org/10.1016/S0008-8846(03)00229-1

Chew MYL (1993) The assessment of fire damaged concrete. Build Environ 28:97–102. https://doi.org/10.1016/0360-1323(93)90010-Z

Cioni P, Croce P, Salvatore W (2001) Assessing fire damage to r.c. elements. Fire Saf J 36:181–199. https://doi.org/10.1016/S0379-7112(00)00050-3

Daniels F, Boyd CA, Saunders DF (1953) Thermoluminescence as a Research Tool. Science 117:343–349. https://doi.org/10.1126/science.117.3040.343

Dilek U (2009) Condition assessment of concrete structures. Failure, distress and repair of concrete structures. Elsevier, pp 84–137. https://doi.org/10.1533/9781845697037.1.84

Dilek U, Leming ML (2007) Comparison of Pulse Velocity and Impact-Echo Findings to Properties of Thin Disks from a Fire Damaged Slab. J. Perform. Constr. Facil. 21, 13–21. https://doi.org/10.1061/(ASCE)0887-3828(2007)21:1(13)

Elvery RH, Vale DW (1955) A portable ultrasonic concrete-testing apparatus. Mag Concr Res 7:161–164. https://doi.org/10.1680/macr.1955.7.21.161

Epasto G, Proverbio E, Venturi V (2010) Evaluation of fire-damaged concrete using impact-echo method. Mater Struct 43:235–245. https://doi.org/10.1617/s11527-009-9484-0

Felicetti R (2004) Digital Camera Colorimetry for the Assessment of Fire Damaged Concrete

Felicetti R (2006) The drilling resistance test for the assessment of fire damaged concrete. Cem Concr Compos Non-Destructive Test 28:321–329. https://doi.org/10.1016/j.cemconcomp.2006.02.009

Felicetti R (2013) Assessment of Fire damaged concrete via the Hammer-Drill pulse transmission technique. Nondestructive testing of materials and structures. Springer, Dordrecht, pp 205–212. https://doi.org/10.1007/978-94-007-0723-8_30

Geng J, Sun Q, Zhang W, Lü C (2016) Effect of high temperature on mechanical and acoustic emission properties of calcareous-aggregate concrete. Appl Therm Eng 106:1200–1208. https://doi.org/10.1016/j.applthermaleng.2016.06.107

Georgali B, Tsakiridis PE (2005) Microstructure of fire-damaged concrete. A case study. Cem Concr Compos 27:255–259. https://doi.org/10.1016/j.cemconcomp.2004.02.022

Grosse CU (2013) Evolution of NDT Methods for Structures and materials: some successes and failures. In: Güneş O, Akkaya Y (eds) Nondestructive testing of materials and structures, RILEM Bookseries. Springer Netherlands, Dordrecht, pp 3–18. https://doi.org/10.1007/978-94-007-0723-8_1

Haddad RH, Al-Rousan R, Almasry A (2013) Bond-slip behavior between carbon fiber reinforced polymer sheets and heat-damaged concrete. Compos Part B Eng 45:1049–1060. https://doi.org/10.1016/j.compositesb.2012.09.010

Handoo SK, Agarwal S, Agarwal SK (2002) Physicochemical, mineralogical, and morphological characteristics of concrete exposed to elevated temperatures. Cem Concr Res 32:1009–1018. https://doi.org/10.1016/S0008-8846(01)00736-0

Ha T, Ko J, Lee S, Kim S, Jung J, Kim D-J (2016) A case study on the Rehabilitation of a fire-damaged structure. Appl Sci 6:126. https://doi.org/10.3390/app6050126

Hwang E, Kim G, Choe G, Yoon M, Gucunski N, Nam J (2018) Evaluation of concrete degradation depending on heating conditions by ultrasonic pulse velocity. Constr Build Mater 171:511–520. https://doi.org/10.1016/j.conbuildmat.2018.03.178

Ingham JP (2009) Application of petrographic examination techniques to the assessment of fire-damaged concrete and masonry structures. Mater Charact 60:700–709. https://doi.org/10.1016/j.matchar.2008.11.003

Jhang K-Y (2009) Nonlinear ultrasonic techniques for nondestructive assessment of micro damage in material: a review. Int J Precis Eng Manuf 10:123–135. https://doi.org/10.1007/s12541-009-0019-y

Khoury GA (1992) Compressive strength of concrete at high temperatures: a reassessment. Mag Concr Res 44:291–309. https://doi.org/10.1680/macr.1992.44.161.291

Kim YH, Lee S, Kim HC (1990) Quantitative vibration mode analysis of mortar and concrete blocks containing flaws. NDT Int 23:67–74. https://doi.org/10.1016/0308-9126(90)91890-6

Koabaz M, Renault N, Pliya P, Gallias J-L (2012) Characterization by the impact-echo method of the high temperature-induced damage on concrete specimens. Int Rev Civ Eng 3:457–462

Kog YC (2021) Practical guide for the Assessment and Repair of Fire-damaged concrete building structures. Pract Period Struct Des Constr 26:04021010. https://doi.org/10.1061/(ASCE)SC.1943-5576.0000570

Kowalski R, Wróblewska J (2018) Application of a sclerometer to the Preliminary Assessment of Concrete Quality in structures after fire. Arch Civ Eng 64:171–186. https://doi.org/10.2478/ace-2018-0069

Krohn N, Pfleiderer K, Stoessel R, Solodov I, Busse G (2004) Nonlinear acoustic imaging: fundamentals, Methodology, and NDE-Applications. In: Arnold W, Hirsekorn S (eds) Acoustical Imaging, Acoustical Imaging. Springer Netherlands, Dordrecht, pp 91–98. https://doi.org/10.1007/978-1-4020-2402-3_12

Krzemień K, Hager I (2015) Post-fire assessment of mechanical properties of concrete with the use of the impact-echo method. Constr Build Mater 96:155–163. https://doi.org/10.1016/j.conbuildmat.2015.08.007

Kulkarni KS, Yaragal SC, Babu Narayan KS, Vardhan H (2017) Assessment of thermally deteriorated concrete by drilling resistance test and sound level. Russ J Nondestruct Test 53:805–815. https://doi.org/10.1134/S1061830917110031

Kumavat HR, Chandak NR (2024) Statistical analysis for evaluating concrete strength of existing structure using non-destructive and destructive test. Innov Infrastruct Solut 9:173. https://doi.org/10.1007/s41062-024-01490-w

Lai W-L, Dérobert W, Annan X, P (2018) A review of Ground Penetrating Radar application in civil engineering: a 30-year journey from locating and testing to imaging and diagnosis. NDT E Int 96:58–78. https://doi.org/10.1016/j.ndteint.2017.04.002

Lea FC (1922) The resistance to fire of concrete and reinforced concrete. J Soc Chem Ind 41. https://doi.org/10.1002/jctb.5000411814

Lin Y, Hsiao C, Yang H, Lin Y-F (2011) The effect of post-fire-curing on strength–velocity relationship for nondestructive assessment of fire-damaged concrete strength. Fire Saf J 46:178–185. https://doi.org/10.1016/j.firesaf.2011.01.006

Lo Monte F, Lombardi F, Felicetti R, Lualdi M (2017) Ground-Penetrating Radar monitoring of concrete at high temperature. Constr Build Mater 151:881–888. https://doi.org/10.1016/j.conbuildmat.2017.06.114

Malhotra VM, Carino NJ (2014) Handbook on nondestructive testing of concrete, 2nd edn. CRC, Boca Raton. https://doi.org/10.1201/9781420040050

Mukupa W, Hancock C, Roberts G, Al-Manasir K, De Ligt H, Chen Z (2017) Visual inspection of fire-damaged concrete based on terrestrial laser scanner data. Appl Geomat 9:143–158. https://doi.org/10.1007/s12518-017-0188-9

Ozawa M, Uchida S, Kamada T, Morimoto H (2012) Study of mechanisms of explosive spalling in high-strength concrete at high temperatures using acoustic emission. Constr Build Mater 37:621–628. https://doi.org/10.1016/j.conbuildmat.2012.06.070

Pahlavan L, Zhang F, Blacquière G, Yang Y, Hordijk D (2018) Interaction of ultrasonic waves with partially-closed cracks in concrete structures. Constr Build Mater 167:899–906. https://doi.org/10.1016/j.conbuildmat.2018.02.098

Panedpojaman P, Tonnayopas D (2018) Rebound hammer test to estimate compressive strength of heat exposed concrete. Constr Build Mater 172:387–395. https://doi.org/10.1016/j.conbuildmat.2018.03.179

Park GK, Yim HJ (2017) Evaluation of fire-damaged concrete: an experimental analysis based on destructive and nondestructive methods. Int J Concr Struct Mater 11:447–457. https://doi.org/10.1007/s40069-017-0211-x

Park S-J, Yim HJ (2016) Evaluation of residual mechanical properties of concrete after exposure to high temperatures using impact resonance method. Constr Build Mater 129:89–97. https://doi.org/10.1016/j.conbuildmat.2016.10.116

Pei J, Han Y, Sun X (1997) Determining burn degree of fire-damaged concrete constructions by thermoluminescence. Chin Sci Bull 42:1829–1833. https://doi.org/10.1007/BF02882655

Placido F (1980) Thermoluminescence test for fire-damaged concrete. Mag Concr Res 32:112–116. https://doi.org/10.1680/macr.1980.32.111.112

Qin D, Gao P, Aslam F, Sufian M, Alabduljabbar H (2022) A comprehensive review on fire damage assessment of reinforced concrete structures. Case Stud Constr Mater 16:e00843. https://doi.org/10.1016/j.cscm.2021.e00843

Short NR, Purkiss JA, Guise SE (2001) Assessment of fire damaged concrete using colour image analysis. Constr Build Mater 15:9–15. https://doi.org/10.1016/S0950-0618(00)00065-9

Short NR, Purkiss JA, Guise SE (2002) Assessment of fire-damaged concrete using crack density measurements. Struct Concr 3:137–143. https://doi.org/10.1680/stco.2002.3.3.137

Smith L, Placido F (1983) Thermoluminescence: a comparison with the residual strength of various concretes. Spec Publ 80:293–304. https://doi.org/10.14359/6596

Son HN, Hosoda A (2010) Detection of microcracking in concrete subjected to elevated temperature at very early age by Acoustic Emission. J Adv Concr Technol 8:201–211. https://doi.org/10.3151/jact.8.201

Soshiroda T, Kimura A (1998) Recommended Method for Earlier Inspection of Concrete Quality by Nondestructive Testing., in: Concrete Research and Technology. pp. 11–19. https://doi.org/10.3151/crt1990.9.1_11

Standards New Zealand (2006) NZS 3101-1: Concrete structures standard - The design of concrete structures. NZS 3101.1&2:2006 (Inc A1, A2 A3)

Stone M (2019) A Field Guide to Digital Color. A K Peters/CRC, New York. https://doi.org/10.1201/b12887

Tay DCK, Tam CT (1996) Situ investigation of the strength of deteriorated concrete. Constr Build Mater 10:17–26. https://doi.org/10.1016/0950-0618(95)00057-7

Uva G, Porco F, Fiore A (2018) The SonReb Method: Critical Review and Practical Aspects, in: di Prisco, M., Menegotto, M. (Eds.), Proceedings of Italian Concrete Days 2016. Springer International Publishing, Cham, pp. 161–171. https://doi.org/10.1007/978-3-319-78936-1_12

Van Den Abeele KE-A, Johnson PA, Sutin A (2000) Nonlinear Elastic Wave Spectroscopy (NEWS) techniques to discern material damage, part I: Nonlinear Wave Modulation Spectroscopy (NWMS). Res Nondestruct Eval 12:17–30. https://doi.org/10.1080/09349840009409646

Wei Y, Kong W-K, Wan C, Wang Y-Q (2019) The Colorimetry Method in assessing fire-damaged concrete. J Adv Concr Technol 17:282–294. https://doi.org/10.3151/jact.17.282

Wróblewska J, Kowalski R (2020) Assessing concrete strength in fire-damaged structures. Constr Build Mater 254:119122. https://doi.org/10.1016/j.conbuildmat.2020.119122

Wu CK, Law CK (1985) On the determination of laminar flame speeds from stretched flames. Symp Int Combust 20:1941–1949. https://doi.org/10.1016/S0082-0784(85)80693-7

Xu Y, Wong YL, Poon CS, Anson M (2003) Influence of PFA on cracking of concrete and cement paste after exposure to high temperatures. Cem Concr Res 33:2009–2016. https://doi.org/10.1016/S0008-8846(03)00216-3

Yim HJ, Kim JH, Park S-J, Kwak H-G (2012) Characterization of thermally damaged concrete using a nonlinear ultrasonic method. Cem Concr Res 42:1438–1446. https://doi.org/10.1016/j.cemconres.2012.08.006

Acknowledgements

The authors would like to express their gratitude to CSIR-CBRI, Roorkee for access to computational facilities, which were instrumental in the completion of this review paper.

Funding

No financial, professional, or personal interests have influenced the design, execution, analysis, or interpretation of this manuscript.

Author information

Authors and Affiliations

Contributions

AD: Conceived and designed the study, collected and analyzed data, and wrote the manuscript.ST: Assisted in data collection, conducted literature review, and contributed to manuscript preparation.KSK: Provided guidance on the review design and critically reviewed.SS: Provided guidance.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deep, A., Tomar, S., Kulkarni, K.S. et al. Comprehensive Review of Techniques for Assessing Fire-Exposed Concrete: Principles, Applications, and Integration Strategies. Iran J Sci Technol Trans Civ Eng (2024). https://doi.org/10.1007/s40996-024-01581-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40996-024-01581-9