Abstract

The selection of MgFeSi alloy and inoculants used for ductile iron treatment has confounded members of the foundry industry for many years. Frequently foundries have used certain types of alloys “because they have always done it that way” or “because someone else was doing it.” The current study involves ductile iron produced with three grades of MgFeSi with varying levels and types of rare earths along with four different inoculants. The iron was cast into test samples of various thickness from 2×2×8 inches to 10×10×8 inches. Mechanical properties and microstructures were evaluated at multiple locations in each of the 36 samples for a total of 156 points of data. In this paper, we will summarize the findings for differing section sizes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The effects of section size on properties are not widely published and understood among casting designers and casting buyers. Ductile iron casting producers know that the mechanical properties and microstructure will degrade with increasing section thickness. The ISO 1083 standard identifies a decrease in mechanical properties with increasing section thickness. The table provided in Appendix 1 goes up to 200 mm (7.87 inches) detailing expected mechanical property drop off with each section change. In the construction of large heavy equipment utilized for wind energy, large die casting equipment and large machining equipment, castings of section thickness can exceed the 7.87-inch section. Castings with section thickness 24 inches and even greater are produced with little data on the overall properties of the casting. With many designers assuming the mechanical properties published in the ASTM standard to be the minimum for all castings, this can create operational issues with the casting. This study is an effort to maximize the mechanical properties of heavy section ductile iron. Many variations of MgFeSi alloys and inoculants are produced making it unfeasible to test them all in this study. Three MgFeSi alloys were chosen for this study along with four different inoculants.

The first step is to determine what carbon and silicon ranges should be targeted. Figure 1 defines the target carbon equivalent is between 3.9 and 4.55. Carbon is the element responsible for graphite and hence expansion during solidification. There is minimum carbon requirement to equalize contraction from austenite precipitation as expressed by the equation,

The C and Si compositions for various section thicknesses of different ductile irons. Shaded in yellow is the area for high silicon irons and blue area is the original Henderson diagram.1

Also, carbon is constrained to a maximum to avoid floatation and exploded graphite. A minimum level of silicon is necessary to minimize carbides and to achieve adequate yield strength. Silicon in excess can contribute to shrinkage. A diagram of these limitations has been used in the industry attributed to Harvey Henderson, as depicted in blue shaded area in Figure 1. The area is bound by silicon ranges of 2.0–2.8% and maximum CE = C+1/3Si < 4.55% and minimum CE = C+1/7Si > 3.9%.1 These equations are for determining acceptable ranges for heavy section ductile iron, not to be confused with the standard Carbon Equivalent equation of CE = C + 1/3Si.

Rare Earth Elements

Advancements in magnesium ferrosilicon and ferrosilicon alloys have improved the properties of heavy section ductile iron. In this paper, several combinations of materials were tested to determine the best combination to optimize the properties in heavy sections. The materials chosen were based on discussions with the suppliers and research into the effects of the elements contained in the materials. One thought path was the need to reduce the amount of rare earth added for heavy section castings. DIS Hot Topics Issue #5 2007 contains a graph of Percent Mg residual versus Percent TRE (figure 2).2 For heavy section ductile iron, the graph recommends for a residual Mg of 0.04 to 0.05, the percent TRE should be less than 0.005. In the AFS transactions 95-49 A. Javaid and C. R. Loper Jr. present a minimum RE calculation.3 The formula is: Wt% RE = 0.5037(Bi+Pb+Sb) + 0.0037.

A quick snapshot of the typical chemistry for this foundry had an average bismuth of 0.0029%, lead of 0.0026% and antimony of 0.00415%. The minimum wt.% RE level required is 0.00725 wt.% RE. One of the paper’s objectives will be to understand what effect varying excess rare earth has on the properties of the different section thickness ductile iron castings.

Experiment

D65-45-12 was chosen for test pieces because it is the most used iron grade in the market. Three different magnesium ferrosilicon alloys were selected along with four different ferrosilicon inoculants. 12 groups of test castings were produced with different combinations of each. Test castings were 2×2×8 inch, 4×4×8 inch, 6×6×8 inch, 8×8×8 inch, 10×10×8 inch in size and were poured in different molds for each combination. After reviewing the volume of test samples, it was decided to focus on the 2-, 6- and 10-inch sections. Due to the 10x10x8 inch behaving more like an 8-inch section thickness, Tests 8, 9 and 12 were repeated with 10×10×11 inch blocks with repeats of the 2 and 6 inch to verify consistent results. The focus of the retests was on mechanical properties. Modified keel blocks along with cast-on test bars were also produced for each test. The evaluation of the keel block, cast-on and sectioned test blocks will provide information to determine if one combination can be used on 1 inch to 10-inch sections (Tables 1, 2 and 3).

The magnesium treatment was carried out in an open tundish ladle utilizing the sandwich method. Iron tap temperature ranged from 2600 to 2620 F (1427 to 1438 C). Alloy addition details are listed in Appendix 3. For each test, a modified keel block was poured. Each test piece had a cast-on test bar to represent a customer cast-on test bar requirement (Figure 3).

Test blocks were sectioned to produce test bar and microstructure samples for a progression from the outer part of the casting to the center of the section. The 2x2x8 inch was milled to machine a test bar from just the very center. The 6x6x8 inch was sectioned into three test bars and a microstructure section. The 10x10x8 inch into 5 test bars and a microstructure section as shown in Figure 4.

Results and Discussion

Final Chemistries

Complete chemical analysis can be found in Appendix 2. The goal was to have consistent carbon, silicon, and magnesium values to reduce any influence of varying chemistry (Table 4).

The silicon values reported do not include the in-mold inoculant increase in the silicon which is calculated to increase the silicon by 0.2 % +/- 0.05%.

Evaluating the data in Figure 5, Sample 11 is one of the worst for mechanical properties. Sample 12 has the better combination of properties. Sample 8 has the best overall tensile and yield strength with acceptable elongation. Sample 9 is under the maximum excess rare earth, similar tensile and yield strength to sample 12 with the highest average elongation. Most of the samples (1 through 7 and 10) are all within normal sample variance for tensile and yield strength.

Mechanical Properties—Section Thickness Effect

One focus of this project is the effect of the MgFeSi and inoculant selection on mechanical properties of heavy sections. The iron selection for the application is based on mechanical properties from published standards. The ISO/European standards have section thickness effect information. The tensile strength requirement reduction from under an inch to greater than 8 inches decreases 7.5 to 16% depending on iron grade. The yield strength reduction is slightly smaller at 4 to 9%. The elongation reduction is the most dramatic with a decrease of 27 to 32% (Figure 6). As section thickness increases in ductile iron, it becomes increasingly more difficult to achieve high nodule count and good nodularity. The changes with increase in section thickness will be covered in the microstructure section of this article.

For a general review of the effects of magnesium ferrosilicon and the inoculant selection, the average value of all section thicknesses was used (Table 5).

Reviewing the data collected from this trial compared to a conversion of the ISO table for D65-45-12, the data follow the trend except the elongation. The elongation increases to a point, contrary to the ISO data. The elongation reduction in the 10-inch section does not follow the trend of the other section thickness tests. The mechanism for this change is not part of this investigation.

Foundries tend to gravitate toward only one MgFeSi alloy in use for all section thicknesses. This helps reduce the potential for a mistake in the treatment of the ductile iron. Figures 7, 8, 9 and 10 show the results of the test pieces from the keel block and the 2-inch test block. The best of the keel block were samples 1, 4, 5, 9 and 12. The best of the 2-inch test were 3, 5, 9 and 10. Sample 9 had very good average properties as well. Samples 6 and 7 keel blocks had very poor properties due to inclusions observed while turning the test bars. All of the Inoc#2 keel blocks had significant inclusions with Sample 6 being the worst.

In the evaluation of the thickest section of the trial, the 10-inch section, the best properties were from Sample 8, 9 and 12. Sample 8 has the best tensile and yield strength properties. Sample 9 and 12 have very similar properties. Sample 12 has the lowest variation in results especially the elongation results (Figures 11, 12, 13).

Based on the results of all samples from all sections, if we were to settle on one MgFeSi and inoculant combination, the sample 9 combination would be the best overall.

Microstructures

In castings weighing 50,000 pounds (22679.6 kg) with section thickness around 24 inches, the solidification times are exceedingly long allowing carbon migration. The result most often found is very few large nodules and at times exploded graphite. The long solidification times with heavy section ductile iron also allows for more segregation of manganese, chromium, vanadium, molybdenum, and phosphorus that will concentrate in the areas last to solidify.

While mechanical properties are the focus of this project, microstructures were also evaluated to get a better understanding of how the different magnesium ferrosilicon and inoculant combinations affect graphite formation and growth.

Evaluating the results from analyzing the microstructure, the data show the best nodularity was observed in Sample 8, 9 and 12, while the best nodule count was observed in Sample 4, 9 and 12.

Research by D. H. Withey and C. Loper, Jr.6 found that the only way to achieve nodule count between 60 and 70 nodules/sq. mm was with late inoculation while limiting the amount of cerium and/or rare earths. This study tested this with the Samples 3, 7, and 11. The data show that the cerium added did not lower the nodule count with Sample 3 and 7 having additional cerium. However, sample 11 had a very low nodule count and nodularity. The data for the nodule count and nodularity for sample 11 require a retest due to a low Mg on the original test. The mechanical properties were retested but the micro-samples were not retested prior to this analysis (Figure 14).

The key focus being improving properties of heavy section ductile iron through MgFeSi alloy and inoculant combination, the microstructure of the 10-inch section is of importance. This may help with understanding the major drop in the elongation properties. From Figure 15, the nodule count and nodularity are both lower as expected with some major degradation. Samples 3 and 9 have the highest nodule count. Samples 8 and 9 have the best nodularity in the 10-inch section. This again points to Sample 9 as the best combination for this foundry making heavy section ductile iron castings (Table 6).

The samples with the bismuth addition have higher nodule count and nodularity with the exception of sample 8. In the 2-inch section of sample 12, the nodule count was 214 for the average of the measurements from the center of the section.

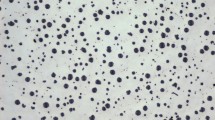

Figure 16 demonstrates that the 2-inch block contains 100 to 150 nodules/sq. mm. With increasing casting section, the nodule count decreases. In the 6-inch section for all trials, the nodule counts measured 70 to 120 nodules/sq. mm. The 10-inch section shows continued graphite particle count degradation to 40 to 80 nodules/sq. mm.

Nodularity follows a similar trend in the 2-inch section having a nodularity in the range of 86 to 90%. The 6-inch section falls to 74 to 86% and the 10-inch 66 to 80%.

Degraded graphite was also evident in Sample 2 of the test. Sample 2 was very close to the 1 value for degraded graphite. Sample 12 in figure 17 has a few exploded nodules in the 10 inch section. Figures 17, 18, 19, 20, 21 and 22 show the variation in the microstructure of some of the samples.

Sample 9 has shown the best mechanical properties for the keel block, 2 inch and thick 10 inch section. Sample 9 also has good nodule count and nodularity.

The Matrix

One of the known contributing factors to variation in mechanical properties is the amount of pearlite in the matrix. The more pearlite, the greater the tensile and yield strength and typically a reduction in the elongation. This trial would not be complete without reviewing the resulting etched microstructure of the samples. The table below lists the samples and the average pearlite content (Table 7).

Measurement with image analysis systems currently available leaves some opportunity for variation in the results. The threshold setting can change the values significantly. The values in Table 7 were all processed by one person to reduce some of the variability. The same person etched the samples to also reduce variability. The longer the etchant remains on the sample, the likelihood of having a higher pearlite number. Most of the values are above the normal target of less than 10% pearlite. The average of the 12 samples is 15%. The majority of the test samples are within a few percent of the average. The pearlite may have played a small role in the mechanical properties.

Conclusions

One of the project's main goals was to better understand how the properties can be influenced by different MgFeSi and inoculant over varying section thickness. The data show a steady decline from 1-inch size (separately cast modified keel block) through the 10-inch section. The interesting part often found in testing at this location is an increase in elongation. The ISO standard allows for a steady decrease in elongation. The data from the tests conducted show an increase in elongation up to the 6-inch section. The 10-inch section has decreased elongation compared to the 6-inch section. The increase in elongation is likely from the slower cooling as the section thickness increases resulting in a decrease in pearlite. The large nodules and likely corresponding large grains are likely to be influencing the reduction in elongation.

After evaluation of both mechanical and microstructural data sets, samples 8 and 9 provide the best results. Sample 8 is a balanced rare earth with 6.15% Mg combined with an inoculant containing 1.0% bismuth and no rare earths. Sample 9 is a balanced rare earth with 3.7% Mg combined with an inoculant containing 2.37% barium. The amount of rare earth was also different in the magnesium ferrosilicon. Sample 8 contains 0.60% rare earth and sample 9 contains 0.32% rare earth in the alloy used for the test. A theory is with sample 8, the cerium and bismuth may have combined to increase nucleation sites and/or modify existing nucleation sites to be more stable for graphite growth.3 This is also possible with sample 9 that contains barium. The initial hypothesis for this research was that the less rare earth the better for heavy section ductile iron. The main conclusion is that properties of ductile iron can be enhanced through the use of different MgFeSi and inoculant combinations. Another interesting take away is that several combinations tested, the majority of the samples yielded very little difference in tensile and yield strength. This demonstrates the need in many cases to test several different combinations to find the best results.

References

A. Alagarsamy, S. Kumar, Demystifying shrinkage porosity in ductile iron castings. Inter Metalcast 14, 1136–1151 (2020). https://doi.org/10.1007/s40962-020-00440-3 (Figure 16)

Role of rare earth elements in production of ductile iron, Hot topics issue #5, 2007, Al Alagarsmy

A. Javaid, C.R. Loper Jr., Production of heavy-section ductile cast iron. Trans. Am. Foundrymen’s Soc. 103, 135–150 (1995)

Determine the relationship between solidification time and mechanical properties of heavy section ductile iron castings DIS project 23 by Arthur Spangler

T. Skalund, “A model for graphite formation in ductile iron,” PhD. Thesis, Metallurgisk Institutt Trondheim, 1992

D.H. Withey, C.R. Loper Jr., Effect of the use of chills in heavy-section ductile iron castings. AFS Transactions 77, 262–280 (1969)

L. Magnusson Aberg, “Trace elements and control limits in ductile iron,” Nov 13, 2014

P. Ferro, A. Fabrizi, R. Cervo, C. Carollo, Effect of inoculant containing rare earth metals and bismuth on microstructure and mechanical properties of heavy-section near-eutectic ductile iron castings. J. Mater. Process. Technol. 213(9), 1601–1608 (2013)

Acknowledgements

This paper would not be possible without the support from the authors’ respective companies. The MgFeSi and inoculant materials were supplied by Elkem and Carpenter Brothers Inc. The charge materials, production time and resources to cast the trial samples, as well as sample preparation and analysis, were supplied by the ownership/management at Betz Industries. This paper is an invited submission to IJMC selected from presentations at the 7th Keith Millis Symposium on Ductile Iron held October 18–20, 2023, at the Crown Plaza Atlanta Perimeter at Ravinia, Atlanta, GA. It is published in the IJMC by permission of the DIS (Ductile Iron Society).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 7th Keith Millis Symposium on Ductile Iron held October 18-20,2023, at the Crown Plaza Atlanta Perimeter at Ravinia, Atlanta, GA. It is published in the IJMC by permission of the DIS (Ductile Iron Society).

Appendices

Appendix 1: ISO Standard section thickness mechanical properties

See Table 8.

Appendix 2 Chemistry results

Sample | MgFeSi | Inoculant | CE | C | Si | Mn | P | S | Cu | Cr | Mo | Ni | Mg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 | 1 | 1 | 4.310 | 3.560 | 2.251 | 0.388 | 0.018 | 0.008 | 0.114 | 0.045 | 0.006 | 0.018 | 0.051 | |

2 | 1 | 2 | 4.355 | 3.580 | 2.326 | 0.413 | 0.024 | 0.008 | 0.100 | 0.036 | 0.003 | 0.014 | 0.044 | |

3 | 2 | 3 | 4.369 | 3.590 | 2.336 | 0.408 | 0.024 | 0.009 | 0.101 | 0.037 | 0.004 | 0.014 | 0.056 | |

4 | 1 | 4 | 4.344 | 3.590 | 2.263 | 0.406 | 0.015 | 0.009 | 0.110 | 0.056 | 0.006 | 0.019 | 0.041 | |

5 | 2 | 1 | 4.399 | 3.630 | 2.306 | 0.390 | 0.019 | 0.009 | 0.108 | 0.046 | 0.006 | 0.018 | 0.053 | |

6 | 2 | 2 | 4.302 | 3.550 | 2.255 | 0.413 | 0.021 | 0.007 | 0.105 | 0.044 | 0.004 | 0.016 | 0.049 | |

7 | 1 | 3 | 4.405 | 3.640 | 2.295 | 0.411 | 0.021 | 0.010 | 0.102 | 0.050 | 0.004 | 0.027 | 0.048 | |

8 | 2 | 4 | 4.393 | 3.620 | 2.320 | 0.405 | 0.014 | 0.011 | 0.099 | 0.065 | 0.006 | 0.028 | 0.039 | |

9 | 3 | 1 | 4.435 | 3.660 | 2.325 | 0.389 | 0.020 | 0.009 | 0.102 | 0.046 | 0.004 | 0.017 | 0.046 | |

10 | 3 | 2 | 4.350 | 3.590 | 2.279 | 0.399 | 0.017 | 0.009 | 0.099 | 0.054 | 0.004 | 0.035 | 0.041 | |

11 | 3 | 3 | 4.323 | 3.560 | 2.290 | 0.390 | 0.013 | 0.009 | 0.095 | 0.062 | 0.006 | 0.028 | 0.046 | |

12 | 3 | 4 | 4.387 | 3.620 | 2.300 | 0.383 | 0.015 | 0.004 | 0.098 | 0.041 | 0.003 | 0.016 | 0.059 | |

Median | 4.362 | 3.590 | 2.298 | 0.402 | 0.018 | 0.009 | 0.101 | 0.046 | 0.004 | 0.018 | 0.047 | |||

Std Dev | 0.0409 | 0.0348 | 0.0289 | 0.0111 | 0.0036 | 0.0017 | 0.0055 | 0.0092 | 0.0012 | 0.0068 | 0.0062 |

Al | Ti | Sn | Sb | Bi | Ce | V | Nb | Co | B | Zr | La |

|---|---|---|---|---|---|---|---|---|---|---|---|

0.024 | 0.008 | 0.012 | 0.006 | 0.0000 | 0.013 | 0.053 | 0.008 | 0.004 | 0.0000 | 0.000 | 0.0053 |

0.038 | 0.008 | 0.012 | 0.006 | 0.0009 | 0.014 | 0.045 | 0.007 | 0.004 | 0.0001 | 0.001 | 0.0048 |

0.021 | 0.006 | 0.012 | 0.007 | 0.0012 | 0.016 | 0.045 | 0.009 | 0.003 | 0.0001 | 0.001 | 0.0023 |

0.026 | 0.007 | 0.012 | 0.005 | 0.0012 | 0.014 | 0.045 | 0.007 | 0.004 | 0.0006 | 0.001 | 0.0053 |

0.021 | 0.008 | 0.012 | 0.006 | 0.0004 | 0.016 | 0.052 | 0.009 | 0.005 | 0.0001 | 0.001 | 0.0023 |

0.034 | 0.007 | 0.012 | 0.006 | 0.0008 | 0.016 | 0.046 | 0.006 | 0.004 | 0.0002 | 0.001 | 0.0025 |

0.019 | 0.006 | 0.012 | 0.005 | 0.0002 | 0.015 | 0.048 | 0.004 | 0.007 | 0.0005 | 0.000 | 0.0053 |

0.020 | 0.011 | 0.014 | 0.006 | 0.0006 | 0.015 | 0.045 | 0.010 | 0.003 | 0.0003 | 0.001 | 0.0016 |

0.020 | 0.005 | 0.012 | 0.005 | 0.0004 | 0.015 | 0.046 | 0.008 | 0.004 | 0.0002 | 0.001 | 0.0014 |

0.035 | 0.019 | 0.012 | 0.005 | 0.0001 | 0.016 | 0.059 | 0.006 | 0.013 | 0.0002 | 0.001 | 0.0013 |

0.026 | 0.010 | 0.014 | 0.006 | 0.0003 | 0.017 | 0.044 | 0.010 | 0.003 | 0.0002 | 0.001 | 0.0016 |

0.021 | 0.005 | 0.012 | 0.005 | 0.0017 | 0.018 | 0.046 | 0.007 | 0.004 | 0.0002 | 0.000 | 0.0027 |

0.022 | 0.008 | 0.012 | 0.006 | 0.001 | 0.015 | 0.046 | 0.008 | 0.004 | 0.000 | 0.001 | 0.002 |

0.0066 | 0.0039 | 0.0007 | 0.0004 | 0.0005 | 0.0014 | 0.0045 | 0.0016 | 0.0030 | 0.0002 | 0.0003 | 0.0016 |

Appendix 3: Alloy Additions

Sample | MgFeSi | Inoculant | Weight | Mg | Inoc | Mg Addition Rate (%) |

|---|---|---|---|---|---|---|

1 | 1 | 1 | 10000 | 135 | 50 | 1.35 |

2 | 1 | 2 | 10000 | 118 | 56 | 1.18 |

3 | 2 | 3 | 10000 | 129 | 50 | 1.29 |

4 | 1 | 4 | 10000 | 125 | 50 | 1.25 |

5 | 2 | 1 | 15000 | 195 | 75 | 1.30 |

6 | 2 | 2 | 24000 | 319 | 131 | 1.33 |

7 | 1 | 3 | 19000 | 296 | 59 | 1.56 |

8 | 2 | 4 | 25000 | 336 | 125 | 1.34 |

9 | 3 | 1 | 17000 | 219 | 79 | 1.29 |

10 | 3 | 2 | 11000 | 136 | 55 | 1.24 |

11 | 3 | 3 | 10000 | 136 | 50 | 1.36 |

12 | 3 | 4 | 17000 | 289 | 85 | 1.70 |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Beach, T., Clayton, J., Leblang, P. et al. The Effects of MgFeSi and Inoculant Selection on Microstructure and Mechanical Properties of Varying Section Size Ductile Iron Castings. Inter Metalcast 18, 2022–2035 (2024). https://doi.org/10.1007/s40962-024-01265-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-024-01265-0