Abstract

Overburden of industrial waste is a geoenvironmental concern, and its utilization in revamping the properties of expansive clays is an adoptable sustainable solution. Processed left outs from sugarcane based industries generates bagasse ash (BA) in voluminous amounts, the same can be used to detain the volume change attributes of the expansive soil which is presented in this paper. The bagasse ash was added to the expansive soil in increasing percentages by weight ranging from 0 to 20%. The parameters that are vital for the stabilisation criterion were assessed even with the presence of lime. Because it is necessary to lessen the effects of the expansive soil’s repeating wetting–drying phenomena, wetting–drying cycles tests were also conducted on the expansive soil blended with bagasse ash, both by itself and in combination with lime. The reactivity between additives and the expansive soil was examined through powdered X-ray diffraction, field emission scanning electron microscopy (FE-SEM) and energy dispersive spectroscopy (EDS) along with Fourier transform infrared (FTIR) analyses. Based on the analysis of the experimental results, it was found that the bagasse ash helped in particle adhesion and pozzolanic reaction initiated in the presence of lime helped in attaining dense micro structure which was evident from FESEM images. This proved that ternary blends (expansive soil, bagasse ash and lime), are more effective when compared to binary blends of BA and expansive soil. The addition of 5% of lime and 15% of bagasse ash was found to be a more effective sustainable solution in combating the volume change attributes of the black cotton soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Black cotton soils (BC) also called as expansive soils are prominent in many parts of world constantly present challenges to geotechnical engineers. The issue with the expansive soil is that they volume changes ascribed, to the presence of clay mineral presence that evinces shrink-swell characteristics depending upon the proportion of moisture content. This property makes the clay unsuitable as a subsoil and foundations surrounded by such soils are in peril [1]. Structures built on such soils undergoes settlement due to the problematic nature of the soil. Shrinking and swelling behaviour of the clay is due to the presence of montmorillonite mineral [2]. The annual loss incurred due to expansive soils is greater than the damage ensued by natural calamities [3].

Diverse ground improvement techniques are in practice that include special foundation techniques, physical and chemical methods of stabilising expansive clays by blending with lime, cement, calcium and sodium chlorides, lignin and other cementing agents [4,5,6,7]. In recent years, various industrial wastes are being effectively used for ameliorating the volume change attributes of the expansive soils. The pozzolanic reactivity of the soil with these industrial left outs helps in mitigating the waste reaching the fill with economic benefits.

Fly ash which is considered as a by-product of coal-based power generation, has generated plethora than its utilization [8, 9]. This brought the necessity in the utilization of fly ash as a substitute to raw materials in the construction of embankments, roads and manufacturing of blended cement [10, 11]. Extensive research works were also carried out on usage of fly ash in various civil engineering projects. Thermal power plants also generate bottom ash, which has been used in the treatment of fine grained soil. Studies revealed that the bottom ash also can be replaced by up to 30% in fine grained soils for both strength and replacement aspects Geopolymerization techniques were also adopted for minimizing the volume change attributes and strengthening of expansive soils. To form cementitious geopolymers, natural pozzolans and alkalis of potassium hydroxide (KOH) or calcium hydroxide [Ca(OH)2] along with pozzolans are used in the geopolymerization technique [12].

Silica fume, a by-product produced from the silicon industries, is also used in ameliorating the problems of expansive soils. When expansive soil is subjected to cycles of swelling and shrinkage, the addition of 20–30% silica fume lessens the progressive deformation [13]. During the first swell-shrink cycle, the greatest reduction was noticed. In addition, it was shown that adding 15% silica fume significantly altered the properties of expansive soil [14].

The paper production industries produce lignosulfonate, a waste by-product. The stabilisation of expansive soils has been successfully attempted utilising this waste [15, 16]. Several researchers observed that using industrial wastes or industrial by-products along with lime was found to be more effective rather than using them alone [17]. It is also observed that, the properties of expansive soils when blended with volcanic ash alone is proved to be less effective in comparison with the mixture of lime and volcanic ash with black cotton soil [18]. The geotechnical parameters of expansive soils blended with lime mixture and silica fume were also studied [19]. Silica fume very slightly altered the expansive soil behaviour, while binary combinations of silica fume and lime were found to be extremely successful at altering expansive soil’s behaviour [13]. It is also observed that binary addition of lime and lignosulfonate on the stabilization of expansive soils exhibited better performance rather than using lignosulfonate alone with expansive soils [20].

Bagasse ash, a waste generated from the sugar cane based industries. Extensive farming of sugarcane crop worldwide and substantial amount of its cultivation in India, almost 10 million tonnes of bagasse ash generated is left unutilized [21, 22]. Bagasse ash are fibrous in nature, also contain calcium and magnesium ions. The pozzolanic activity initiated by such minerals helps in combating the volume change attributes of the expansive nature of clay. Advantages being low cost and eco-friendly material effectively utilised in stabilising the subgrade. [23, 24]. Several studies have been performed to control the swell-shrink cycles of expansive soil due to its pozzolanic properties [25,26,27,28]. However, the studies reveal that the volume change attributes are not completely ceased or reduced to an acceptable level for any percentage of addition of bagasse ash. Moreover the internal mechanism with micro-structural analysis in the utilization of bagasse ash was not revealed.

Based on the previous research it is observed that, there is a need to explore the possibility of sustainable solution in utilization of bagasse ash to completely cease or minimize the idiosyncrasy of an expansive soils to an acceptable level. Hence to attain a sustainable solution, bagasse ash in conjunction with lime was explored in the present study, as the lime could trigger the pozzolanic activity and control the volume change attributes of the black cotton soil to an acceptable level. The impact of lime on the properties of black cotton soils blended with different proportions of bagasse ash were explored in this present investigation. Thus, this paper aims to provide a sustainable solution for utilization of bagasse with lime in combating the volume change attributes of the black cotton soil.

Materials and Methods

Expansive Soil

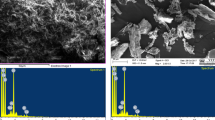

The black cotton soil (BC) was gleaned from the natural clay deposits of Amalapuram sedimentary basin, Andhra Pradesh, India at 16°38′25″ N 82°06′14″ E. The geology of parent rock for the soil obtained is of paleo-tidal lithological origin. The disturbed black cotton soil was collected by open excavation, from a depth of 0.5 m from the ground level of this basin. This soil was placed in plastic bags and transported to the laboratory. Smectite group clay minerals are abundant in these deposits that constitute montmorillonite, kaolinite, feldspar and illite. The mineralogical composition obtained from EDS is represented in Fig. 1(a) and (b). The liquid limit (WL) and plastic limit (WP) of the black cotton soil was found to be 86% and 41% respectively. The shrinkage limit of the black cotton soil was found to be 13%. The gravel content, sand content and silt and clay content in the black cotton soil were found to be 0.9%, 25.1% and 74% respectively. Soil group is identified to be clay of high plasticity (CH) according to the Unified Soil Classification System. The free swell index (FSI) of the soil is 130%. The degree of expansiveness of the soil is categorised as very high based on the value of FSI [29].

Additives

Processed Bagasse ash (BA) for the study was acquired from sugar mill research institute, Vellore, Tamil Nadu, India. The bagasse ash was calcinated for the further usage. The fibrous portion of burnt ash was filtered out through 425-micron sieve to eliminate the organic traces of sugarcane from ash and to attain uniformity. Good proportions of aluminium, amorphous silica, calcium and iron oxides suggests the binding and pozzolanic properties of material procured.

Hydrated lime procured from commercial store, was used in the present study for modifying the soil behaviour. The amount of lime needed for stabilization depends on several factors [30]. Type of lime, type of soil, moisture content, pH level of the soil and curing time are the factors to be considered while adding lime for stabilization. Initial blends of 1%, 3%, 5% and 10% is tested for consistency limits and swell index properties, imply that 5% lime is suitable for imparting pozzolanic reactivity between clay and bagasse ash. This bolstered the expansive clays in reducing swelling in moisture presence and shrinkage upon desiccation.

Methods

Sample Preparation

The soil was air dried for duration of 24 h at ambient temperature to attain the equilibrium. After the process of air drying, sample is oven dried, and lumps being tamped and pulverized. The soil is then sieved as per the test procedures to required particle sizes and required proportional samples in weight. Preliminary index property tests on soil like Atterberg limits and free swell were conducted in differed percentages of lime namely 1%, 2%, 3%, 5% and 10% by dry weight of the soil and 5% lime is proved to be optimum. Different percentages of BA content (5–20%) with increments of 5% by total dry weight of the soil was adopted. The lime content and bagasse ash were adopted based on the prior studies [6, 7, 26, 27].

Swell Potential and Swell Pressure Tests

Swell potential is calculated using the ratio of the final thickness increase to the initial thickness, when the soil is submerged and is expressed in percentage [31]. This test was performed on a soil specimen prepared with the required unit weight and the appropriate water content. A seating pressure of 0.7 kPa was then applied to the specimen. The specimen was flooded and allowed to heave after the seating pressure was applied. Up until there were no more changes in the swelling, the swellings were periodically monitored using a displacement transducer. The swell potential Sp is expressed as

where

ΔH—swelling/heave (mm) and

H—initial thickness of the specimen (mm).

Swelling pressure is defined as the pressure needed to recompress the fully heaved soil to its original voids ratio [31]. Swell potential and swelling pressure tests were performed in the one dimensional odometer test apparatus as per to ASTM standards [32]. The test was done in the consolidometer test apparatus. The specimen placed in the consolidometer at a desired unit weight was immersed and left to swell at a seating pressure, until primary heave was completed. The swell pressure was determined from voids ratio (e) versus pressure (P) curve (e-logP curve) in accordance to the initial thickness.

Swelling-Shrinkage Cycles Test

Better repeatability of the test is the biggest benefit of performing swelling-shrinkage cycles tests. [33, 34]. This research was carried out to see the benefit of adding lime on the behaviour of BA stabilised BC soil, subjected to the cycles of swelling and shrinking. Every specimen was totally submerged in water, causing them to heave. After the specimens had fully swelled, the water was drained off, and it was left to dry until the water content was nearly equal to the original moisture level. The specimens were dried in the consolidation cell after which the consolidation cell with the specimen was kept in the odometer test setup. Following that, water was used to flood the specimens, allowing them to swell. This consisted of a single cycle of the wetting and drying phenomena. Also, the samples have gone through five rounds of swelling and shrinking. According to earlier research, the outcomes following five cycles of swelling and shrinkage did not significantly differ [13, 33, 35]. Therefore, the wetting–drying tests in the current investigation were therefore stopped after 5 cycles of wetting–drying.

Unconfined Compression Test

Unconfined compression test was conducted to determine the undrained strength of the soil with and without additives. The test was conducted according to ASTM standards [36]. Specimen of size 76 mm in length and 38 mm in diameter were prepared at the maximum dry unit weight corresponding to the optimum moisture content as determined from the compaction test for a given additive content as shown in Table 1. All the specimens were tested, after the specimens were allowed to get cured for 7 days in the vacuum desiccators. In order to identify the reasons for difference in the properties of the BC soil due to the above additives, FE-SEM analyses were also performed on the specimens after conducting unconfined compression test.

Results and Discussion

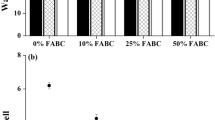

Consistency Limits

On every soil sample that was blended with additives, plastic limit and liquid limit tests were conducted in accordance with ASTM standards [37]. Figure 2 shows how the additive content affects the plasticity characteristics of the black cotton soil. It should be noted that the plasticity index decreases as the BA level rises. The plasticity index dropped with 20% BA from 45 to 27.5%. Similarly the plasticity index decreases as lime content increases, but it can be seen that plasticity index reduced significantly when the BC soil treated with lime and BA soil. When 10% of lime was added to the BC soil, the plasticity index dropped from 45 to 4%. As the lime content was raised from 0 to 5%, the plasticity index of BC soil decreased quickly, and only less variation once it reached 10%. To investigate the impact of lime on the BC soil-bagasse ash blends, 5% of lime was added. Other researches [7, 38] also adopted similar optimal proportion of lime. Figure 2 shows that by adding 5% lime to the BC soil blended with any percentage of BA, the plasticity index was further lowered. It was discovered that the BC soil’s plasticity index was 5% when combined with lime and 20% BA content. When 5% of lime was added to BC soil mixed with 20% of BA, the plasticity index decreased by 80%. The decrease in the plasticity index is a sign that the characteristics of the black cotton soils that are likely to cause volume change have decreased [20, 39]. The decreased double layer and agglomeration of soil particles cause a decrease in the surface area of the clay particles, which in turn causes a decrease in the plasticity of the black cotton soil [40].

Shrinkage limit is an another important property particularly for the expansive soil which measures the volume change attributes and desiccation cracks of the soil upon drying [20]. The test was done as per ASTM standards [41]. The shrinkage limit was found to increase marginally with an increase in the BA content as shown in Fig. 3. Even at 20% of bagasse ash content the volumetric shrinkage was found to be 20%. The changes in the shrinkage limit observed upon addition of bagasse ash is similar to the results obtained in earlier research [26, 27]. It can be noted that the shrinkage limit increased along with the lime content accordingly. Even with less content of lime, the shrinkage limit was high. Blending of lime and the BC soil reduces the plasticity characteristics, which became more friable in nature and requires more water content for the change in the volume of the soil. Hence adding lime to the BC soil blended with BA, helped to reduce the shrinkage properties of the soil. By adding 5% of lime, the volumetric shrinkage of the BC soil mixed with 20% of BA was found to be 36% (Fig. 3). This indicates that the soil will undergo less shrinkage upon drying in addition of 5% of lime to the black cotton soil stabilized with BA.

Free Swell Index Test

Free swell index test helps to measure the degree of expansiveness of the soil. Hence, the free swell index tests were intended to estimate the influence of bagasse ash and lime on the degree of expansiveness of the BC soil. Figure 4 shows the variation of free swell index (FSI) by adding different proportions of BA to the BC soil. Figure 4 also depicts the influence of 5% lime on the BC soil blended with same proportion of BA content. It can be noticed that the FSI of the BC soil reduces from 130 to 70%, when BA content increases to 20%. When 5% of lime is added to BC-BA mixtures, the free swell index is found to decrease further. FSI is determined to be 31.5% for 5% lime and 20% BA content. Black cotton soil’s degree of expansiveness decreased from very high to high when 20% BA was added, but it dropped from very high to moderate swelling, when 5% lime was added to the BC soil mixed with 20% BA. There is a very solid indicator that adding lime along with bagasse ash causes a significant shift in the black cotton soil's behaviour.

Influence of Lime on the Swelling Properties of Black Cotton Soil

Figures 5 and 6 show the effects of lime on the swelling potential and swelling pressure of BC soil blended with various BA concentrations. With a rise in BA concentration, the swelling potential (Sp) and swelling pressure (Ps) gradually decrease. The decrease in maximum density and the rise in optimal moisture content are the major causes of the decrease in swelling potential and swelling pressure. Table 1 provides a summary of the moisture content and maximum dry unit weight values for the BC soil combined with various BA proportions. Lower maximum dry density and lower optimal moisture content result in lower swell potential (Sp) and swelling pressure (Ps) [13, 34]. On the other hand, though there is an marginal increase in maximum dry density, by adding 5% of lime to BC soil combined with any percentage of BA content, further lowered these values of swelling pressure and swelling potential due the pozzolanic reactions. These values of swelling potential and swelling pressure decrease, as the BA content rises. The swell potential of BC soil decreased with the addition of 20% BA content, falling from a starting value of 16.62–5.94% for the natural soil. Likewise in regard to 20% of BA in the BC soil the swell pressure changes from 198 to 78.5 kPa. A Similar trend is also observed in the past works [25]. The interaction between the ions present in the BC soil, lime, and BA, is another factor contributing to the decline in the swell potential and swelling pressure of the BC soil. Both the soil and bagasse ash in BC contain silica and alumina ions in large quantities. Calcium silicate hydrates (CSH) and calcium aluminium hydrates (CAH) are the products of these ions’ interactions with the calcium ions in lime. Due to the presence of magnesium ions in bagasse ash, further novel compounds of magnesium silicate hydrate (MSH) are produced. The hydrates stabilise the soil, which in turn lessens the BC soil's propensity to swell. The scanning electron microscopic pictures presented later ensure the production of these hydrates (Sect. “Micro-Structural Studies”).

Swelling-Shrinkage Cycles

Buildings, pavements, canal linings, waste containment liners, and cover systems are all adversely affected by the substantial progressive deformation of BC soils caused by the cyclic swelling-shrinkage phenomenon [13, 33]. By investigating wetting–drying cycles, the effect of swelling-shrinkage cycles on the swelling potential of the BC soil can be noticed. Figure 7 shows the outcomes of cycles of swelling and shrinking. According to the figure previously mentioned, it is clear that when the number of swelling-shrinkage cycles rises, the swell potential of the BC soil tends to decrease slightly. The marginal decrease is because of the repositioning and readjusting of the structural components of the micro-aggregates. It should be observed that even after three cycles of wetting and drying, the BC soil mixed with BA did not exhibit a noticeable decrease in swelling. After the first swell-shrink cycle, the BC soil’s swell potential is noticeably reduced by the addition of 5% lime and 20% BA. With stabilised BC soil containing 15–20% BA (for 5% of lime and 20% of BA is only given in Fig. 7), equilibrium is reached after the first swell-shrink cycles. The fact that BC soil and BA’s swell potential decreases after the first swell-shrink cycle ceases is a significant findings of the present research. The cause is that, following the initial wetting–drying cycle, the ion exchange process and pozzolanic reactions are complete. Hence, following the initial cycles of swelling and shrinking, the BC soil remains inactive to volume changes when susceptible to additional wetting and drying cycles. This demonstrates the efficacy of lime is effective in enhancing the pozzolanic activity of the expansive soil treated with BA.

Unconfined Compression Test

The Unconfined compression test was performed to determining the unconfined compressive strength (UCS) of the BC soil using additives. Each and every specimen was compacted at an (OMC) optimum moisture content determined from standard proctor compaction test. The soil specimen was cured for period of 7 days had significant influence on the increase in the unconfined compressive strength for clays of high plasticity. Hence the curing process was fixed for a period of 7 days. Figure 8 display the stress–strain behaviour of the BC soil merged with 5% of lime and for varying content of BA. It can be seen that the compressive strength of the BC soil improves with a raise in 15% of BA content. The stress–strain behaviour of BC soil, show an increase of stress with strain up to a certain stage and thereafter the stress remains almost the same with increasing strain. On addition of BA content, the stress is found to increase significantly at a relatively low strain. The unconfined compressive strengths found to improve with an improvement in the amount BA. The unconfined compressive strength was observed to be elevated for the BC soil mixed with 15% of BA and 5% of lime. Beyond 15% of BA, the UCS was found to decrease. This resulted in the increment of BA content beyond 15% which reduces the plasticity characteristic of the BC soil leading to brittle failure. Based on the unconfined compressive strength, the optimum percentage of lime and bagasse ash is found to be 5% and 15% respectively.

Micro-Structural Studies

X-Ray Powder Diffraction (XRD) Analysis

X-Ray powder Diffraction (XRD) analysis is used to identify peak alterations in intensities with respect to the diffraction angle this is observed through illustrations of X-ray diffraction. Bagasse ash utilised for all the 8 mixes is calcinated at temperature of 700° C for a time period of 180 min this activates the pozzoloans in bagasse ash [24]. Black cotton soil is primarily analysed to match with the other mixes to assess the rate of pozzolanic reaction happened. Studies on bagasse ash reported the significance of diffraction angle for BA ranging from 15° to 35° and such range indicate presence of amorphous substances [12].

The BA addition did not widely alter the major diffraction peak of quartz but upon lime supplementation the presence of portlandite is diminished due to the reactivity between clay minerals indicating the consumption of lime. Mineralogical transformations occurred due to amendment of pozzolans is sensed with change in diffraction angle. Change in the diffraction angle 2θ values indicate the change in crystalline size (Dp) of the particle of each mix (Table 2). Increase in DP average values of lime blended mixtures except at 10% BA is noticed with the help of curve fitting software and presence of clay mineral at 28° is in line with study done by Ekrem Kalkan [13]. Figure 9 shows typical XRD patterns of the 5%BA mix at curing period of 7 days. Even though increase in crystalline size of particle, the diffraction angle and Full width half maximum of major SiO2 peak remains same for both L + 15%BA and clay samples, this suggests the optimum proportion of incorporation of admixtures. This statement is reinforced by the incremental trend of UCC values upon addition of lime resulted from agglomeration of particles with CAH and CSH bond formation proves the pozzolanic activity. Bond formation is assessed with the help of FT-IR analysis and new elements are traced by XRD peaks. The Virgin clay has minerals that include quartz, mica as basic elements and clay minerals like montmorillonite, kaolinite, attapilgite and illite. With incorporation of bagasse ash cristabalite, hematite, hydrated hayllosite are traced. Reactivity between Bagasse ash, lime and Soil is assured on formation of alumino silicates of magnesium, hydrogen and potassium imputed to 2θ = 8.490, 25.870 and 30.610.

Fourier Transform-Infrared Radiation (FT-IR)

Elements in the soil samples are tested for its concentration, functional groups and their covalent bond information based on absorbance and transmittance of the infrared rays emitted back from the soil compound. Minute variation in peaks is observed for all the samples of clay blended with bagasse ash and samples when lime is added. Inner –OH stretching bond of hydroxyl groups indicates the presence of water on to the surface of clay mineral witnessed in the range of 3342 and 3616 cm−1. Si–O stretching is observed within 991–1001 cm−1 for all the mixes whereas replacement of clay minerals by Mg and Fe is seen at 914 cm−1 wavelengths which indicates the isomorphous substitution between the compounds. Si–O bonds at 794 and 777 cm−1 wavelengths and Si–O–Si bonds at 682–692 cm−1 range shows the presence of quartz which is major peak in all the mixes in XRD analysis whereas 501–520 cm−1 range shows Al–OH and Si–O–Al functional groups additional OH group is present in all mixes that are blended with lime. Detailed discussion is attached in Table 3.

Field Emission-Scanning Electron Microscopy Analysis

Morphological changes affiliated to the bond formations and elemental changes of clay mineralogy for each mix is observed on thermo fisher quanta 250FEG to examine information of nano or micro structure of chromium coated samples. Uncalcinated BA is shown in Fig. 10(a) to depict the fibrous nature of bagasse ash on comparison with layered micro structure of calcinated BA in Fig. 10(b) and (c). Amorphous nature of clay is seen in 5BA (Fig. 10d) and less reactivity of BA with clay due to the less proportion of BA is visible in 10 BA (Fig. 10e). The sequential adhesion and reactivity between fibrous bagasse ash particle and lime treated clay is seen in Fig. 10(h, i and j). Different geometrical shapes of the clay and bagasse ash particles are left un-bonded in Fig. 10(f) for 20BA and which were bonded due to cementitious property of lime and pozzolans in Fig. 10(k) and (l) at L + 15BA and L + 20BA.

Conclusions

The conclusions arrived have been stated below on the basis of studies done and results obtained:

-

1.

The plasticity index of black cotton soil decreases nearly 38.5% when black cotton soil is treated with 20% bagasse ash but the decrease in plasticity is about 80% when 20% bagasse ash is used in conjunction with 5% lime. Similarly, free swell index is also found to decrease by 77% for the above combination of the admixtures. This shows the efficacy of lime in ameliorating the properties of black cotton soil stabilised with bagasse ash.

-

2.

When 5% lime is supplied along with 15–20% bagasse ash, a noticeable decrease in swell potential is observed after the first wetting–drying cycles; however, this is not the case when stabilising black cotton soil just with bagasse ash. This happens because the addition of lime which supplements the pozzolanic reactions and ion exchange process makes the BC soil inactive to the volume change attributes, when subjected further to wetting—drying process.

-

3.

The increase in the unconfined compressive strength of the lime modified mixes is due to the cementitious bonding of elements between clay, lime and bagasse ash which is this is obvious from the formation of C–A–H and C–S–H bond from the FT-IR test, improved crystalline size noticed from XRD. Change in composition with each mix from EDS and morphological transformations witnessed through agglomerated clay matrix under FE-SEM implied the same. This proves ternary blends are more effective in stabilising aspects when compared to binary blend of BA and black cotton soil.

-

4.

Based on the strength and other aspects the threshold values of lime and bagasse ash were found to be 5% and 15% respectively. This proposed combination of optimum percentage of admixtures to the black cotton soil is proved to be beneficial in enhancing the engineering characteristics of the black cotton soil rather than utilization of bagasse ash alone in the stabilization of black cotton soil. Furthermore, this study also reduces the burden on sugarcane industries in disposal of bagasse ash and so it provides a sustainable and cost-effective solution for stabilization of black cotton soils.

Data Availability

The data generated/analysed during the study are available from the corresponding author on reasonable request.

References

Chijioke CI, Donald CN (2019) Emerging trends in expansive soil stabilisation: a review. J Rock Mech Geotech Eng 11:423–440

Foster MD (1954) The relation between composition and swelling in clays. Clays Clay Miner 3(1):205–270

Bhuler R, Cerato AB (2007) Stabilization of Oklahoma expansive soils using lime and class C fly ash. GeoDenver: new peaks in Geotechnics, GSP 162: problematic soils and rocks and in-situ characterization, Denver, CO. 18–21

Phanikumar BR, Malini CA, Karthika R (2012) Swell-consolidation characteristics of artificial sand clay mixes. J Geomech Geoeng 7(1):69–74

Cokca E (2001) Use of class C fly ash for the stabilization of an expansive soil. J Geotech Geoenviron Eng 127(7):568–573

Al-Rawas AA, Taha R, Nelson JD, Al-Shab TB, Al-Siyabi H (2005) A comparative evaluation of various additives used in the stabilization of expansive soils. Geotech Test J 25(2):199–209

Eujine GN, Chandrasekaran S, Sankar N (2017) The Engineering behavior of enzymatic lime stabilized soils. Instit Civil Eng 170(1):1–11

Sridharan A, Rao SA, Sivapullaiah PV (1986) Swelling pressure of clays. Geotech Test J 9(1):24–33

Kumar A, Walia BS, Bajaj A (2007) Influence of fly ash, lime and polyester fibers on compaction and strength properties of expansive soil. J Mater Civ Eng 19(3):242–248

Baykel G, Doven AG (2000) Utilization of fly ash by pelletization process: theory, application areas and research. Recour Conserv Recycl 30(1):59–77

Behera B, Mishra MK (2012) California bearing ratio and Brazilian Tensile strength of mine overburden-fly ash-lime mixtures for mine haul road construction. Geotech Geological Eng 30(2):449–459

Miao S, Shen Z, Wang X, Luo F, Huang X, Wei C (2017) Stabilization of highly expansive black cotton soils by means of geopolymerization. J Mater Civ Eng 29(10):04017170–9

Kalkan E (2011) Impact of wetting-drying cycles on swelling behavior of clayey soils modified by silica fume. Appl Clay Sci 52:345–352

Bharadwaj S, Trivedi MK (2016) Impact of micro silica fume on engineering properties of expansive soil. Int J Sci Technol Eng 2(12):435–440

Alazigha DP, Indraratna B, Vinod JS, Heitor A (2016) Mechanisms of stabilization of expansive soils with lignosulfonate admixtures. Transp Geotech 14:81–92

Baharam T, Reza N (2017) Stabilization of clayey soil using lignosulfonate. Transp Geotech 12:45–55

Murat T, Hasan S, Gorkem T (2017) The effect of silica fume and lime on geotechnical properties of a clay showing both swelling and dispersive features. Arab J Geosci 11:735

Yongzhen C, Wang S, Li J, Huang X, Li C, Jingke Wu (2018) Engineering and mineralogical properties of stabilized expansive soil composting lime and natural pozzolans. Constr Build Mater 187:1031–1038

Goodarzi A, Goodarzi SH, Akbari HR (2015) Assessing geomechanical and micro-structural performance of modified expansive clayey soil by silica fume as industrial waste. Trans Civ Eng 39(C2):333–350

Ijaz N, Dai F, Meng L, Rehman ZU, Zhang H (2020) Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: a sustainable waste solution. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.119985

Ganesan K, Rajagopal K, Thangavel K (2007) Evaluation of bagasse ash as supplementary cementitious material. J Cem Concr Compos 29:515–524

Prashant OM, Vyawahare MR (2013) Utilization of bagasse ash as a partial replacement of fine aggregate in concrete. Procedia Eng 51:25–29

Gupta VK, Ali I (2000) Utilization of bagasse fly ash (a sugar industry waste) for the removal of copper and zinc from wastewater. Sep Purif Technol 18(2):131–140. https://doi.org/10.1016/S1383-5866(99)00058-1

Yadav AL, Sairam V, Muruganandam L, Srinivasan K (2020) An overview of the influences of mechanical and chemical processing on sugarcane bagasse ash characterisation as a supplementary cementitious material. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.118854

Rajakumar C, Meenambal T (2015) Experimental study of bagasse ash utilisation for road application on expansive soil. Nat Environ Pollut Technol 14(4):903–908

Zaika Y, Soeharjono A (2016) Bagasse ash (BA) and additive materials treated expansive soil. Electron J Geotech Eng 21:7085–7094

Bahadori H, Hasheminezhad A, Taghizadeh F (2019) Experimental study on marl soil stabilization using natural pozzolans. ASCE J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002577

Pradeep PS, Mayakrishnan M (2023) Microstructural characterization of lime modified bagasse ash blended expansive clays using digital image analysis. Environ Earth Sci. https://doi.org/10.1007/s12665-023-10848-9

Chen FH (1988) Foundations on expansive soils, 2nd edn. Elsevier Scientific Publishing Co., Amsterdam

Eades JL, Grim RE (1966) A quick test to determine lime requirements for limes. Highway Research Record 139

Jennings JE (1963) Discussion on the heave of buildings and associated economic consequences with particular reference to orange free state gold fields. Civil Eng SA 5:122

ASTM D 4546 (2016) Standard test methods for one-dimensional swell or collapse of soils. ASTM International, West Conshohocken

Rao SM, Reddy BVV, Muttharam M (2001) The impact of cyclic wetting and drying on the swelling behavior of stabilized expansive soils. Eng Geol 60:223–233

Guney Y, Sari D, Cetin M, Tuncan M (2007) Impact of cyclic wetting-drying on swelling behavior of lime stabilized soils. Build Environ 42:681–688

Gangadhara S (1998) Cyclic swell-shrink behavior of laboratory compacted expansive soils. PhD Thesis, Indian Institute of Science, Bangalore, India

ASTM D 2166/D2166M-16 (2016) Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International, West Conshohocken, PA

ASTM D 4318-10 1996 (2016) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM International, West Conshohocken., PA

Muthukumar M, Shukla SK (2018) Influence of fibre on volume change attributes of expansive soils blended with lime. Ground Improvement 172(1):37–43

Saride S, Puppala A, Srujan RC (2013) Swell-shrink and strength behaviors of lime and cement stabilized expansive organic clays. Appl Clay Sci 85(1):39–45

Dash SK, Hussain M (2012) Lime stabilization of soils: Reappraisal. J Mater Civ Eng 24:707–714

ASTM D427 (04) (2016) Test method for determination of shrinkage factors of soils by the mercury method. ASTM International, West Conshohocken., PA

Author information

Authors and Affiliations

Contributions

The co-author SP, Research Scholar, contributed in carrying out the experimental investigation and digital image analysis. The corresponding author MM has reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pradeep, P.S., Mayakrishnan, M. Understanding the Engineering Behaviour of Expansive Soil Amended with Bagasse Ash and Lime Using Microstructural Analysis. Int. J. of Geosynth. and Ground Eng. 9, 26 (2023). https://doi.org/10.1007/s40891-023-00445-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-023-00445-y