Abstract

A series of the experimental testing program was carried out to determine the influence of cell geometry and multi-layer system on the behaviour of a square footing resting on geocell reinforced sand. Geocells made of three different PVC polymers of varying thickness and strength were used for testing purpose. Laboratory plate load tests were conducted to determine the pressure–settlement response of reinforced soil for different geometric parameters like diameter, height, depth of placement, and shape of the geocell. The effect of geocell material strength on load carrying capacity is also included in this paper. Performance comparison of single layer and multi-layer geocell reinforced sand with different spacing is also presented in this paper. The test results confirm that the reinforced sand layer shows an excellent improvement in bearing capacity in comparison with the unreinforced sand. The optimum geocell geometry to get maximum benefit in terms of bearing capacity were determined and presented in this paper. Optimum spacing for a two layer geocell system was also determined experimentally and presented in this paper.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bearing capacity of poor soils can be improved by various ground improvement techniques such as soil reinforcement and soil stabilisation methods. Reinforcement techniques can be efficiently applied to improve the properties of the soft soil. Geocell can be considered as one of the advanced methods of reinforcement technique in geotechnical applications. Geocell consists of a three-dimensional honeycomb-like structure interconnected at the joints. Literature suggested that placing cohesionless soil overlays reinforced with cellular confinement systems result in greater improvement in strength and lesser deformation for almost all types of soils.

Some studies were performed to observe the response of geocell reinforced soil by various investigators [2,3,4,5,6, 10, 14,15,16,17, 19, 20], and these studies confirmed that the geocell reinforced soil is an efficient technique for improving the load-carrying capacity of the soils. Experimental investigations were conducted by Dash et al. [3, 5] and Sireesh et al. [14] to study the effect of different parameters including the size, strength, and pattern of geocell on improving the bearing capacity of reinforced sand under a strip and a circular footing. Performance comparison of different forms of reinforcement was also reported by Dash et al. [5], Lal et al. [11], Latha et al. [12], Tafreshi et al. [18], and confirmed that geocell reinforcement is very effective in imparting the strength due to overall confinement provided against lateral movement. Experimental and numerical studies of geocell reinforced sand were also conducted by various researchers [7, 8, 13].

Test results of previous studies showed that improvement responses of reinforced soil are influenced by properties of test soil as well as the size and strength of geocell. Limited works were reported in the case of square footing resting on a geocell reinforced sand. Very few works were aimed to optimise the geocell geometry and effect of multilayer geocell system on improving the bearing capacity.

This paper reports the test results of numbers of laboratory plate load tests on geocell reinforced sand by using different geocell material of varying geometric properties and tensile strength. This paper also includes the influence of the multi-layer system of geocell on load carrying capacity of the soil by changing the spacing between the geocell layers.

Materials Used for Testing

River Sand

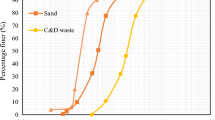

The experimental investigations were carried out using locally available river sand. The dry river sand has effective particle (D 10) as 0.25 mm and uniformity coefficient and coefficient of curvature as 4.6 and 0.57 respectively. The maximum and minimum unit weights of sand are 15.9 and 13.8 kN/m3 respectively. The undrained cohesion and peak friction angle of dry sand from triaxial compression testing are found to be 0 and 38° respectively. According to Unified soil classification system, the dry river sand was classified as poorly graded sand. Particle size distribution curve of river sand is shown in Fig. 1.

Geocell Material

Geocell fabricated from PVC polymer sheet was used for the experimental investigations. The geocell was formed by cutting the polymer sheet into required size, and this sheet was shaped into a cylindrical form by joining the ends with the help of glue. Three PVC polymer materials of varying thickness and tensile strength were used for the testing. The test results of engineering properties of Geocell materials are tabulated in Table 1. The load–strain behaviour of PVC polymer sheets was determined using the Universal testing machine that tests the mechanical properties of plastic and plastic composites in accordance with ASTM D-638 using standard dumbbell-shaped test specimens [1]. The load–strain behaviour of PVC polymer sheets is shown in Fig. 2. The strength of the seam was also tested, and the strength was found to be almost equal to the parent material. Photograph of the fabricated geocell and geocell filled with sand is shown in Fig. 3.

Experimental Setup

The model foundation used for the study was a square rigid steel plate of size 150 mm × 150 mm × 25 mm. The model plate load test was carried out in a square steel tank of dimension 750 mm × 750 mm × 750 mm. The dimension of the test tank was selected as five times the width of the test plate based on IS: 1888–1982 to reduce the scaling effects [9]. The sides of the test tank were braced with the help of mild steel angles in vertical and horizontal directions. The two end faces of the steel plate were polished to reduce the effect of friction.

The relative density of the test sand was fixed as 65% to create the medium dense condition. The relative density of 65% was achieved using the sand raining technique by changing the height of fall. Sand pouring was done with the help of a perforated plate from different heights, and the corresponding density from each trial was determined using a steel container of known volume from various positions in the tank. A calibration curve was plotted showing the variation of relative density achieved from a different height of fall. The height of fall necessary for achieving a relative density of 65% was determined with the help of calibration curve. Sand pouring was done from the necessary height with a layer thickness of 5 cm. Sand pouring was discontinued to keep the geocell layer in required depth and continued to the desired level after placing the geocell layer.

The model square footing was positioned on the top of the sand layer, and loading was done with the help of hand operated hydraulic jack of 250 kN capacity. Increment loading was applied, and each load increment was given for sufficient time to stabilise the footing settlement. Settlement of model footing was taken using two dial gauges (Dg1, Dg2) of sensitivity 0.01 mm placed diagonally on the footing. The surface heave was observed using two dial gauges (Dg3, Dg4) which were kept at a distance equal to the width of the model footing (B) from the two edges of the footing. Footing settlement and surface deformations were taken as the average reading obtained from both dial gauges. Photograph showing the testing arrangement is shown in Fig. 4.

The test setup for plate load test is shown in Fig. 5. A number of laboratory plate load tests were carried out to study the pressure–settlement behaviour of reinforced soil by changing the geocell opening size (d), the height of geocell (H), placement depth of geocell from the bottom of the footing (u) and tensile strength (T) of geocell material. The experiment was also performed to examine the effect of one layer and two layer geocell system by varying the spacing (h) between the layers. The size of the geocell opening (d) was fixed based on the diameter of the equivalent circular area of the opening [19].

The experimental testing program includes seven different types of plate load test and the parameters considered for these experiments are described in Table 2. Test series-1 was carried out on the unreinforced sand, and test series 2, 3 and 4 have been conducted on reinforced sand by changing the geometric parameters of the geocell layer. Test series-5 and 6 were performed on reinforced sand by varying the tensile strength and shape of the geocell layer. Test series-7 was carried out on reinforced sand with two layer geocell system by changing the spacing between the layers.

Results and Discussions

Experimental results obtained from seven series of plate load tests are discussed below. Improvement in bearing capacity due to geocell reinforced system is represented by bearing capacity improvement factor (I f ). Bearing capacity improvement factor is defined as the ratio of bearing capacity of geocell reinforced sand at a given footing settlement to the bearing capacity of unreinforced sand for the same settlement [3, 5]. The settlement of footing (s) is represented based on footing width (B) as s/B (%). The improvement factor obtained from different test series (2–7) are tabulated in Table 3.

Effect of Placement Depth of Geocell Layer from Bottom of the Footing

The plate load tests were performed by changing the depth of placement of geocell layer (u) from the footing base (test series 2). The pressure–settlement behaviour representing the effect of geocell placement depth is shown in Fig. 6. From the pressure–settlement behaviour, it is evident that load carrying capacity decreases when depth increased from 0.06B to 1B. The load carrying capacity was improved slightly when placement depth increased from 0 to 0.06B. When footing was placed directly on the geocell layer (u/B = 0), early buckling of geocell wall may happen due to direct contact of geocell with the model footing [3]. The maximum benefit was obtained when the geocell mattress is placed at a depth 0.06B from the bottom of the footing. At a depth u = 0.06B, the presence of a small layer of sand cushion above the geocell layer that will avoid the direct contact between the geocell and footing. This thin layer of sand cushion will prevent buckling of geocell walls in an early stage, and this will result in maximum load carrying capacity compared to the footing placed directly on the geocell. A decrease in load carrying was observed with an increase in the depth of the sand cushion between the geocell and the footing due to lateral shifting of the soil mass during loading. When the geocell is kept at a greater depth from the bottom of the footing, there is a major reduction in improvement factor and surface heave become predominant as there is a significant shifting of sand in the lateral direction. It is very clear from the Fig. 7 showing the variation of improvement factor that improvement becomes marginal when the geocell layer is kept at a depth beyond 0.25B. Dash et al. [3] conducted a test on strip footing on geocell reinforced soil and the maximum pressure–settlement response was reported at u = 0.1B. From the Fig. 8 showing the variation of surface heave or settlement for different u/B values, it is evident that surface heave/settlement was substantially reduced for reinforced soil in comparison with the unreinforced soil. Minimum surface heave/settlement was observed at u = 0.06B.

Effect of Diameter of the Geocell

The plate load tests were carried out by changing the diameter of the geocell opening (d) as stated in test series 3. The pressure–settlement behaviour representing the influence of diameter of the geocell opening is shown in Fig. 9. The experimental results revealed that the load carrying capacity continuously increased with a decrease in the opening size of geocell. When the diameter of geocell reduces, there is an increase in the confinement offered by the cell and that will provide greater resistance to lateral movement of sand. When pocket size increases, confinement provided by the geocell reduces and that will lead to larger settlement and surface heave. The improvement factor different s/B % is shown in Fig. 10. The maximum improvement is noticed when the d/B ratio becomes 0.5. From the Fig. 11 showing the surface heave/settlement, it is very clear that for higher d/B ratio, surface heave becomes more significant compared with the lesser d/B ratio. Similar findings were reported by Dash et al. [3]. When d/B is >1.25, the improvement in load carrying capacity becomes marginal as there is a reduction in confinement offered per unit volume of the sand.

Effect of Height of Geocell Layer

The plate load tests were performed on the geocell reinforced sand for different H/B values to investigate the influence of height of geocell layer (test series 4) on bearing capacity. Figure 12 shows the pressure–settlement behaviour of reinforced sand for various H/B values. The increase in the height of geocell layer will offer better confinement against the lateral movement, and the more stiffened layer is obtained for load transfer which in turn leads to higher bearing capacity. The improvement factor for different s/B % is shown in Fig. 13 and effect of the height of geocell on surface deformation is shown in Fig. 14.

The significant improvement in bearing capacity was noticed when H/B increases from 0.5 to 1.5. However, the reduction in bearing capacity can be observed beyond H/B value of 1.5. The decrease in improvement in bearing capacity may be due to lateral buckling happened for the geocell layer due to applied pressure and leading to the higher settlement rates [3]. The reduction in bearing capacity may also be due to the decrease in the density of sand which in turn results in higher settlement. Dash et al. [3] conducted a test on strip footing reported that significant change in pressure–settlement response was not observed beyond H/B value of 2. Dash et al. [5] performed a test on circular footing reported that local buckling of geocell walls results in lesser improvement beyond H/B ratio of 2.1.

Effect of Strength of Geocell Layer

The influence of tensile strength of geocell material on bearing capacity was investigated by conducting the load test on geocell made of three different polymers of varying thickness (test series 5). The pressure–settlement response is shown in Fig. 15. Geocell made of PVC-type 3 showed higher bearing capacity compared to PVC-type 1 and type 2. The improvement in bearing capacity is mainly due to higher strength value exhibited by the PVC-type 3 polymer compared to other polymers. The bearing capacity improvement factor for different s/B % is shown in Fig. 16, and the effect on surface deformation is shown in Fig. 17. Geocell made of PVC-type 3 showed higher performance at higher settlements due to its better stiffness value. Improvement factor for the type-3 polymer was obtained as 4.12 for s/B of 20%. Experimental results proved that strength and stiffness of geocell material plays a vital role in imparting the strength.

Effect of Shape of Geocell Layer

Three different shapes of geocell such as circular, square and annular shapes were fabricated in the present study using PVC-type 2 polymer (test series 6). The different forms of geocells are shown in Fig. 18. One annular cell was formed by joining the ends of two circular cells which have the same center with different radii, arranged one cell inside the other. The same quantity of material was used for making a square and circular form by keeping the same perimeter, whereas almost 40% extra material used for fabricating the annular form. Typical pressure–settlement response representing the influence of geocell shape is shown in Fig. 19. For the same quantity of material, square and circular forms showed almost comparable improvement in load carrying capacity. It is evident from the experimental results that annular form shows an improvement of 28.5% more compared with the circular and square form for s/B = 20% due to increased stiffness offered by the inner and outer cell against lateral movement. The annular shape geocells can be used in the cases where more bearing capacity is required from a single layer of geocell. From the Fig. 20 showing the effect on surface deformations, it is evident that settlement and surface heave were considerably lesser for annular geocells.

Effect of Layer and Spacing of Geocell

Series of plate load test were conducted by placing two layers of geocell by varying the spacing between the layers (test series 7). Top geocell layer was placed at a depth of 0.06B under the model footing and the second layer was positioned at a spacing of h = 0B, h = 0.1B and h = 0.3B from the bottom of the first geocell layer. Typical pressure–settlement response representing multi-layer effect at different spacing is shown in Fig. 21. From the pressure–settlement response, it is very clear that bearing capacity improvement of two layer system is only marginal when compared with the single layer system. The variation in improvement factor for two layer geocell system of varying spacing with different s/B % are shown in Fig. 22 and surface heave/deformation is shown in Fig. 23. For s/B = 20% improvement factor for two layer system is 3.13 whereas one layer system has an improvement factor of 2.82. Reinforcement should be provided within in the pressure bulb to attain the maximum benefit in terms of the load carrying capacity. As the testing was done with the model footing of relatively smaller size compared to the original foundation, the depth of pressure bulb is not that deep. Hence two layer geocell of sufficient height is placed beneath the footing; the second layer may cross the pressure bulb if the spacing between the layers is increased. In such cases, the improvement attained by a multilayer system will be marginal compared with the one layer system of sufficient height.

A minor improvement in load carrying capacity was noticed when two geocell layers are placed without any spacing. When the two geocell layers are placed without any spacing, it will act as a one layer system with a height two times the original height. This study has already noticed that there is a decrease in load carrying capacity when the height of geocell layer increases beyond 1.5B. The optimum spacing of two layers is obtained as 0.1B. If the size of the footing is relatively larger, a multi-layer system with sufficient spacing will be able to offer a higher load carrying capacity compared with one layer system.

Conclusions

This paper has examined the behaviour of geocell reinforced sand under a square footing by varying the geometric parameters and strength of geocell layer. This paper has also examined the effect of the multi-layer system with different spacing on bearing capacity improvement. The following conclusions are drawn from the present study

-

The pressure–settlement response of square footing resting on geocell reinforced sand showed improved performance in bearing capacity than unreinforced sand

-

A noticeable reduction in surface heave and footing settlement was observed in geocell reinforced sand.

-

The highest improvement in load carrying capacity was noticed when the geocell was placed at a depth of 0.06B from the footing base. A thin layer of sand between geocell and footing would avoid the direct contact and helps to distribute the loads evenly.

-

The improvement of the geocell reinforced system is considerable up to a height equal to 1.5B. A remarkable improvement was not noticed beyond this height.

-

The inverse relationship was observed between the load carrying capacity and the diameter of the geocell opening. When the diameter of the opening is reduced, the confinement offered for the sand increases which in turn improve the bearing capacity.

-

The experimental results showed that the strength and stiffness of geocell layer confining the soil has a crucial role in imparting the strength

-

For the same quantity of material, square and circular forms showed almost comparable improvement in load carrying capacity.

-

The annular form shows an improvement of 28.5% more compared with the circular and square form for s/B = 20% due to increased stiffness offered by the inner and outer cells against lateral movement.

-

The two layer system gives only marginal improvement (I f = 3.13) when compared with the single layer system (I f = 2.82).

-

The maximum load carrying capacity in a two-layer system was noticed when geocells were placed at a spacing of 0.1B.

-

If the size of the footing is relatively larger, a multi-layer system with sufficient spacing will offer better load carrying capacity compared with single geocell layer system.

References

ASTM D638-14 Standard test method for tensile properties of plastics. American Society For Testing and Materials, West Conshohocken, PA, USA

Bathrust RJ, Jarrett PM (1989) Large-scale model tests of geocomposite mattresses over peat subgrades. Transp Res Rec J 1188(1277):28–36

Dash SK, Krishnaswamy NR, Rajagopal K (2001) Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext Geomembr 19(4):235–256

Dash SK, Krishnaswamy NR, Rajagopal K (2001) Strip footing on geocell reinforced sand beds with additional planar reinforcement. Geotext Geomembr 19(8):529–538

Dash SK, Sireesh S, Sitharam TG (2003) Model studies on circular footing supported on geocell reinforced sand underlain by soft clay. Geotext Geomembr 21(4):197–219

Dash SK (2012) Effect of geocell type on load-carrying mechanisms of geocell-reinforced sand foundations. Int J Geomech 12(5):537–548

Hedge A, Sitharam TG (2013) Experimental and numerical studies on footings supported on geocell reinforced sand and clay beds. Int J Geotech Eng 7(4):347–354

Hedge A, Sitharam TG (2015) Experimental and analytical studies on soft clay beds reinforced with bamboo cells and geocells. Int J Geosynth Ground Eng 1(2):1–13

IS:1888 (1982) Method of load test on soils. Bureau of Indian Standards, New Delhi

Krishnaswamy N, Rajagopal K, Latha GM (2000) Model studies on geocell supported embankments constructed over a soft clay foundation. Geotech Test J 23(1):45–54

Lal D, Sankar N, Chandrakaran S (2017) Effect of reinforcement form on the behaviour of coir geotextile—reinforced sand beds. Soils Found 57(2):227–236

Latha GM, Somwanshi A (2009) Effect of reinforcement form on the bearing capacity of square footing on sand. Geotext Geomembr 27(6):409–422

Latha GM, Dash SK, Rajagopal K (2009) Numerical simulation of the behavior of geocell-reinforced sand in foundations. Int J Geomech 9(4):143–152

Sireesh S, Sitharam TG, Dash SK (2009) Bearing capacity of circular footing on geocell–sand mattress overlying clay bed with void. Geotext Geomembr 27(2),89–98

Sitharam TG, Sireesh S, Dash SK (2011) Model studies of a circular footing supported on geocell-reinforced clay. Can Geotech J 42(2) 693–703

Sitharam TG, Sireesh S (2005) Behavior of embedded footings supported on geogrid cell reinforced foundation beds. Geotech Test J 28(5):452–463

Sitharam TG, Sireesh S, Dash SK (2007) Performance of surface footing on geocell reinforced soft clay beds. Geotech Geol Eng 25(5):509–524

Tafreshi SNM, Dawson AR (2010) Comparison of bearing capacity of a strip footing on sand with geocell and planar forms of geotextile reinforcement. Geotext Geomembr 28(1):72–84

Tafreshi SNM, Dawson AR (2012) A comparison of static and cyclic loading responses of foundations on geocell-reinforced sand. Geotext Geomembr 32:55–68

Wesseloo J, Visser AT, Rust E (2009) The stress–strain behavior of multiple cell geocell packs. Geotext Geomembr 27:31–38

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sherin, K.S., Chandrakaran, S. & Sankar, N. Effect of Geocell Geometry and Multi-layer System on the Performance of Geocell Reinforced Sand Under a Square Footing. Int. J. of Geosynth. and Ground Eng. 3, 20 (2017). https://doi.org/10.1007/s40891-017-0097-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-017-0097-3