Abstract

The corrosion of mild steel in HCl medium containing different concentrations of sulfonated polysulfone polymer (SPS) has been evaluated by electrochemical, chemical and theoretical studies. SPS shows around 84% inhibition efficiency at 3000 ppm concentration. Inhibition efficiency increases with increase in temperature from 30 to 60 °C. The adsorption of SPS on mild steel was found to be Langmuir’s adsorption isotherm. The calculated thermodynamic functions were employed to give further insight into the mechanism of inhibition action of SPS. Quantum chemical calculations were supported the results. Dipole moment of SPS was found to be 4.6 D, ΔE (energy difference) was 5.02, and these values suggest the good interaction between inhibitor and mild steel surface. Scanning electron microscopy images confirm the adsorbed inhibitor film on the metal surface. FTIR results validate the interaction of SPS with mild steel surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Corrosion is the degradation of metals and alloys by interaction with their surroundings. Corrosion failures need for expensive replacements may occur, even though there was small destruction by corrosion. In industries, acid pickling, acid cleaning, acid de-scaling and oil well acidizing are very common and hydrochloric acid is used to employ it [1,2,3]. In this processes, steel undergoes corrosion by interacting with an acidic solution [4, 5]. To control the corrosion, among the various methods, the use of inhibitor is efficient and flexible. A corrosion inhibitor is an organic or inorganic compound, and it controls the corrosion by adsorbing on the metal surface [6,7,8,9,10,11,12].

Nowadays the use of polymers as corrosion inhibitors concerned considerable attention due to low cost, stable and non-toxic nature. Polymers find applications as efficient corrosion inhibitors for steel [13, 14]. The high surface energy of polymers has a more tendency to make complex with metals [15]. Only few polymers exhibit interaction with metal; this is attributed to high charge density on their polymer ion leading to complex with metal ion [16]. Polyaniline has been used as an effective corrosion inhibitor for mild steel in HCl [17].

The influence of poly (styrenesulfonic acid)-doped polyaniline polymer on the inhibition of corrosion of mild steel in HCl was investigated [18]. Badran et al. [19] reveals the effect of different polymers on the efficiency of waterborne methylamine adduct as corrosion inhibitor for surface coatings. Varsha et al. [20] developed the poly (aniline-co-o-toluidine) as inhibitor. Several reports have been shown that the polymer is a possible protective material, especially for mild steel [21,22,23].

Polymers are used as corrosion inhibitors because of their functional groups. They form complexes with metal ions, and these complexes occupy a large surface area, thereby blanketing the surface and protecting the metal from corrosive agents present in the solution. The inhibitive power of these polymers is related structurally to the cyclic rings, heteroatoms (oxygen and nitrogen), that are the major active centers of adsorption.

The present work is aimed at investigating the corrosion inhibition characteristics of sulphonated polysulfone polymer (SPS) on corrosion of mild steel in 1 M HCl solution. SPS is a big molecule and nowhere has tried as corrosion inhibitor for any metals. This polymer contains sulfur and oxygen atoms, and these are mainly donating the electron to make a chemical bond with metals. These are mainly responsible to choose this polymer as corrosion inhibitor for these studies. Weight loss, potentiodynamic polarization and EIS techniques were performed to evaluate the results. Adsorption isotherm and thermodynamic parameters were studied to establish the mechanism of corrosion inhibition. Quantum study was also conducted to verify the experimental results with theoretical results.

2 Experiments

2.1 Materials

Mild steel specimens of dimension 4 cm × 2.5 cm × 0.05 cm were used for weight loss method. Specimens with an exposed area of 1 cm2 (rest was covered with araldite resin) with 3.0 cm long stem were used for electrochemical methods. The specimens were abraded by using different grade emery papers, washed thoroughly with distilled water, degreased with acetone and dried at room temperature. The corrosive medium was HCl and was prepared by double distilled water.

2.2 Test Solution

SPS was synthesised and characterized by adopting the standard and reported procedure [24]. The structure of the polymer is shown in Fig. 1.

The stock solution was prepared in DMSO (dimethyl sulfoxide) and then diluted to required concentration in the HCl medium (0–5000 ppm). However, the same concentration of DMSO was added to the blank solution to cancel its effect.

2.3 Methods

2.3.1 Weight Loss Measurements

Weight loss measurements were carried out by immersing the mild steel specimen in a 100 cm3 of corrosive media (1 M HCl) in the presence of different concentrations of the inhibitor. Specimens were weighed before immersing into the corrosive medium, and after 4 h of immersion, the specimen was washed with water, dried and weighed accurately (ASTM standards). The difference between the weight before and after the experiment was recorded. All these experiments were conducted twice, and average values were reported.

2.3.2 Electrochemical Measurements

The electrochemical measurements were performed twice by CHI 608D electrochemical workstation (CH Instruments, Austin, USA) at different temperatures. Mild steel, platinum and silver–silver chloride electrodes were used as working electrode, a counter electrode and reference electrode, respectively. One hour time was given to the electrodes to achieve the equilibrium potential. Polarization experiments were conducted from −0.2 V anodically to +0.2 V versus the OCP at a scan rate of 0.001 V s−1. Electrochemical experiments were conducted from 30 to 60 °C. These experiments were conducted at different temperatures, to know the performance of the inhibitor at different temperatures. Above 60 °C, mild steel dissolution is very high so it is conducted up to 60 °C.

The impedance measurements were conducted by using AC signal with 5 mV amplitude at OCP in the frequency range of 100 kHz–10 MHz. Polarization results and impedance results were consistent during the measurements.

2.3.3 Surface Morphology Studies

The surface morphology of the mild steel specimens in the presence (3000 ppm) and absence of SPS at 30 °C was investigated using scanning electron microscopy (JEOL JSM-6380LA). 3000 ppm shows maximum inhibition efficiency, and it covers almost all parts of the metal so it is choosing for studies.

2.3.4 Quantum Chemical Studies

Quantum chemical calculations for SPS inhibitor were carried out in the gas phase by using parametric method 3 (pm3). These calculations were performed by using Hyperchem 7.5 package program (Hypercube Inc., Florida, 2003).

3 Results and Discussion

3.1 Weight Loss Studies

The corrosion inhibition efficiency (% η w) values are reported in Table 1.

The % η w was calculated from the following relationship

where W° and W are a weight loss of mild steel in the absence and presence of inhibitor.

The result indicates that % η w was increased with inhibitor concentration up to 3000 ppm, and above this concentration, no changes in efficiency were observed.

3.2 Potentiodynamic Polarization Studies

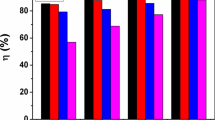

The polarization behavior of mild steel in 1 M HCl at different temperatures in the presence of different concentrations of SPS is shown in Fig. 2.

Table 2 gives the electrochemical parameters obtained by Tafel method.

The % η p was calculated from the following relation

where i corr and i corr° are corrosion current densities in the presence and absence of inhibitor, respectively.

Corrosion current values (i corr) were decreased with inhibitor concentration, and it decreases up to 3000 ppm. Corrosion current values were decreased from 302 to 138.9 µA cm−2 at 30 °C. In the same way, corrosion current decreased from 1007 to 159 µA cm−2 at 60 °C. In this study, 3000 ppm of the SPS was considered as an optimum concentration for achieving maximum inhibition. The variation of E corr values shows a steady trend with different temperatures and concentrations of the inhibitor. It is known that if the displacement of E corr is smaller than 85 mV, then it is considered mixed-type inhibitor [25]. In our studies, changes in E corr are around 15–35 mV, and in average displacement it is around 20 mV.

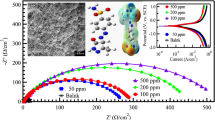

3.3 Electrochemical Impedance Spectroscopy (EIS) Studies

Figure 3 gives the EIS data of mild steel in 1 M HCl with different concentrations of SPS at a different temperature.

Table 3 gives data obtained by the impedance method. R p values were increased with inhibitor concentration, and it is also supported by the diameter of the semicircle in Fig. 3 [26, 27]. Equivalent circuit model was used to analyze the EIS data (Fig. 4). This circuit was established by using Zsimp software. R p is polarization resistance, and R s is solution resistance. C dl is double-layer capacitance. Inhibition efficiency (%η z) was calculated using following equation.

where R p and \(R_{\text{p}}^{\text{o}}\) are polarization resistance values in the presence and absence of inhibitor.

R p values increased and capacitance values decreased with inhibitor concentration. Decreased capacitance values confirm the adsorption of the inhibitor on metal surface. Which is due to reduce in the local dielectric constant with increase in the thickness of the electrical double layer. The effect of concentration of inhibitor and temperature on the inhibition efficiency was followed the same trend like polarization method. The obtained η z are in good agreement with η p and η w.

3.4 Effect of Inhibitor Concentration

Inhibition efficiency at various temperatures is given in Tables 2 and 3. In the studied temperature, range inhibition efficiency of the inhibitor molecules increases up to 3000 ppm, and above this concentration, the inhibition efficiency is almost same or less. It suggests that 3000 ppm of the inhibitor concentration is the optimum level for achieving good inhibition. SPS covers entire metal surface at 3000 ppm and gives maximum efficiency. Above 3000 ppm concentration, inhibitor may come out from the metal surface and exposes of the metal surface to the corrosive environment. So, corrosion rate increases above 3000 ppm inhibitor concentration.

3.5 Effect of Temperature

Tables 2 and 3 give the variation of inhibition efficiency with temperature in the range 30–60 °C. Inhibition efficiencies of SPS were increased with the temperature up to 60 °C. Physisorption and chemisorption are the possible methods of adsorption of the inhibitor on the metal surface. In this case, the inhibitor is adsorbed on the metal surface by chemisorption alone or a combination of both physisorption and chemisorption method. SPS may form a strong bond with the metal surface. This phenomenon holds good up to 60 °C, and above this temperature, adsorbed molecules may be desorbed and the metal surface is exposed to the acid environment, so corrosion is increased. SPS gains threshold energy efficiently for making a strong chemical bond to a metal surface with a rise in temperature up to 60 °C. Above 60 °C, the time gap between adsorption and desorption of inhibitor molecules on the metal surface is too small. Hence, the metal surface remains exposed to the acid environment for a longer period. Therefore, inhibition efficiency falls at elevated temperature.

Polymers are bigger molecules than organic molecules, and they cover most of the metal compared to other organic inhibitors. In this case, SPS is adhered to the metal firmly by both chemisorption and physisorption method. At 50 and 60 °C, chemisorption is dominated and shows higher inhibition efficiency. SPS blocks active sites of the metal by forming a passive layer, and it acts as a barrier between metal and acid. It indicates that SPS is an excellent corrosion inhibitor at a higher temperature.

3.6 Quantum Chemical Studies

Quantum chemical method is a theoretical method to elucidate the structure and mechanism of corrosion inhibition of the inhibitor. This method is extra evidence to the experimental results. The optimized molecular structure of monomer unit of sulfonated polysulfone polymer (SPS) is given in Fig. 5. The evaluated quantum chemical data are provided in Table 4. Adsorption of the inhibitor on metal surface takes place by donating the electrons by the inhibitor molecule to the metal surface. Higher the E HOMO, and lower the E LUMO values related to the higher tendency of donation and acceptance of electrons from the inhibitor to the metal surface. The compound with lower ΔE values gives higher inhibition efficiencies because the excitation energy gap is more polarizable and is associated with chemical reactivity. SPS ΔE value is 5.02 eV, and it justifies the results. Corrosion inhibition efficiency increases with decrease in ΔE values [28, 29]. In this present study, the calculated ΔE value is 5.02 eV and this value is small and indicates as a good corrosion inhibitor. Dipole moment (μ) plays a significant role in deciding the inhibition efficiency of the adsorbed inhibitor molecule on mild steel surfaces. The evaluated dipole moment (μ) of SPS is 4.606 debye. It shows that SPS is an excellent corrosion inhibitor for mild steel in 1 M HCl medium. Quantum studies give the further evidence and confirm the experimental results.

3.7 Surface Morphology Study

SEM images were taken for the mild steel specimen in 1 M HCl with and without SPS inhibitor.

Figure 6 shows some flake, and almost all part of the metal is corroded. These heterogeneous surfaces undergo corrosion easily. In the presence of the inhibitor, metal is completely covered by the inhibitor (SPS), and it strongly adheres to the metal surface. It gives uniform surface and covered the metal surface by avoiding the interaction between metal and corrosive environment so it gives more inhibition efficiency. Polymers are larger in size, so they cover the metal surface thoroughly and uniformly [30].

FTIR spectra of the pure SPS and scraped compound from the metal surface were recorded and are given in Fig. 7.

In the scraped compound, stretched frequency of the compound is completely merged. It indicates the strong interaction between metal and SPS so it gives more inhibition efficiency in the presence of SPS.

3.8 Adsorption Isotherm and Thermodynamic Parameters

Adsorption isotherm provides the basic information on the interaction between the inhibitor and metal surface. Polarization measurements values were used to evaluate the degrees of surface coverage (θ) in the presence of different concentrations of inhibitor. The data were applied to different isotherms including Langmuir, Temkin, Frumkin and Flory–Huggins isotherms. The Langmuir adsorption isotherm gave the best fit. The equation could represent the Langmuir adsorption isotherm:

where K is the adsorption/desorption equilibrium constant, C is the corrosion inhibitor concentration in the solution and θ is the surface coverage, which is calculated using equation

where % η p is the inhibition efficiency as calculated using Eq. 2.

The plot of C/θ versus C gives a straight line with intercept 1/K of Langmuir adsorption isotherm is shown in Fig. 8.

The thermodynamic parameter, standard free energy of adsorption (ΔG °ads ), is calculated from the thermodynamic equation

where K is the equilibrium constant for the adsorption/desorption process, 55.5 mol dm−3 is the molar concentration of water in the solution, T is temperature and R is the gas constant.

Standard enthalpy of adsorption (ΔH °ads ) and standard entropies of adsorption (ΔS °ads ) were obtained from the plot of (ΔG °ads ) versus T according to the basic thermodynamic equation

The thermodynamic data obtained from adsorption isotherm are tabulated in Table 5

The correlation coefficient (R 2) was used to choose the isotherm. The linear regression coefficients are also close to unity, and the slopes of straight lines are nearly unity, suggesting that the adsorption of SPS obeys Langmuir’s adsorption isotherm. SPS has strong adsorption on the metal surface and is proved by high K values. Negative ΔG °ads indicates that adsorption of the inhibitor on the metal surface is spontaneous and stable. The ΔG °ads values for SPS on the mild steel surface are −30.02 to −37.89 kJ mol−1, indicating the chemisorption with slight effect of physisorption. SPS polymer gained threshold energy at a higher temperature and adsorbed strongly on the metal surface by making coordinate covalent bond. Therefore, inhibition efficiency increases up to 60 °C, but, above this desorption, will play a dominant role, and adsorbed molecules may be desorbed from the metal surface. Therefore, inhibition efficiency is decreased.

A plot of ΔG ads° V/s T was used to calculate the heat of adsorption ΔH ads° and the standard adsorption entropy ΔS ads°. According to Eq. 7 shows the good dependence of ΔG ads° on temperature. The thermodynamic data are given in Table 5. Thermodynamic parameters can obtain mechanism of corrosion inhibition. The enthalpy of adsorption could be approximately regarded as the standard enthalpy of adsorption (ΔH ads°) under experimental conditions. The positive sign of ΔH ads° indicates that the adsorption of inhibitor molecule is an endothermic process. In general, an exothermic adsorption process signifies either physisorption or chemisorption, while the endothermic process is attributable unequivocally to chemisorption [31]. The ΔH ads° values obtained for the studied inhibitor on the mild steel surface in 1 M hydrochloric acid ranges is around 56.57 kJ mol−1, indicating chemical adsorption. The negative value of entropies (ΔS ads°) is −0.28 Jmol−1K−1 which implies that an ordering takes place when the inhibitor gets adsorbed on the metal surface.

4 Conclusions

SPS (sulfonated polysulfone) polymer acts as a good corrosion inhibitor for mild steel in acid medium. Corrosion inhibition efficiency of SPS increases with temperature and concentration. The adsorption mechanism of SPS on the mild steel surface obeys Langmuir’s adsorption isotherm. The strong interaction between SPS and the mild steel surface is proved by negative values of Gibbs free energy of adsorption (ΔG ads). Electrochemical results show that SPS is a mixed-type inhibitor. A quantum study proves the experimental results.

References

Chauhan LR, Gunasekaran G (2007) Corrosion inhibition of mild steel by plant extract in dilute HCl medium. Corros Sci 49:1143–1161

Khaled KF (2008) Application of electrochemical frequency modulation for monitoring corrosion and corrosion inhibition of iron by some indole derivatives in molar hydrochloric acid. Mater Chem Phys 112:290–300

Abd El-Maksoud SA, Fouda AS (2005) Some pyridine derivatives as corrosion inhibitors for carbon steel in acidic medium. Mater Chem Phys 93:84–90

Abed Y, Azzar Z, Aounit A, Hammouti B, Kertit S, Mansri A (1999) An electrochemical study of the action of a poly(vinylpyridine) derivative as inhibitor for corrosion of iron in 1 M H2SO4. J Chem Phys 95:1347–1355

Prasanna BM, Praveen BM, Hebbar N, Venkatesha TV, Tandon HC (2014) Ketosulfone drug as a green corrosion inhibitor for mild steel in acidic medium. Ind Eng Chem Res 53:8436–8444

Prasanna BM, Praveen BM, Hebbar N, Venkatesha TV, Tandon HC (2016) Inhibition study of mild steel corrosion in 1 M hydrochloric acid solution by 2- Chloro 3- formyl quinoline. Int J Ind Chem 17:9–19

Yesudass S, Olasunkanmi LO, Bahadur I, Kabanda MM, Obot IB, Ebenso EE (2016) Experimental and theoretical studies on some selected ionic liquids with different cations/anions as corrosion inhibitors for mild steel in acidic medium. J Taiwan Inst Chem Eng 64:252–268

Sasikumar Y, Adekunle AS, Olasunkanmi LO, Bahadur I, Baskar R, Kabanda MM, Obot IB, Ebenso EE (2015) Experimental, quantum chemical and Monte Carlo simulation studies on the corrosion inhibition of some alkyl imidazolium ionic liquids containing tetrafluoroborate anion on mild steel in acidic medium. J Mol Liq 211:105–118

Ramaganthan B, Gopiraman M, Olansukanmi LO, Kabanda MM, Yesudass S, Bahadur I, Adekunle AS, Obot IB, Ebenso EE (2015) Synthesized photo-cross-linking chalcones as novel corrosion inhibitors for mild steel in acidic medium: experimental, quantum chemical and Monte Carlo simulation studies. RSC Adv 5:76675–76688

Mashuga ME, Olasunkanmi LO, Adekunle AS, Yesudass S, Kabanda MM, Ebenso EE (2015) Adsorption, thermodynamic and quantum chemical studies of 1-hexyl-3-methylimidazolium based ionic liquids as corrosion inhibitors for mild steel in HCl. Materials 8:3607–3632

Dibetsoe M, Olasunkanmi LO, Fayemi OE, Yesudass S, Ramaganthan B, Bahadur I, Adekunle AS, Kabanda MM, Ebenso EE (2015) Some phthalocyanine and naphthalocyanine derivatives as corrosion inhibitors for aluminium in acidic medium: experimental, quantum chemical calculations, QSAR studies and synergistic effect of iodide ions. Molecules 20:15701–15734

Singh A, Lin Y, Quraishi MA, Olasunkanmi LO, Fayemi OE, Sasikumar Y, Ramaganthan B, Bahadur I, Obot IB, Adekunle AS, Kabanda MM, Ebenso EE (2015) Porphyrins as corrosion inhibitors for N80 steel in 3.5% NaCl solution: electrochemical, quantum chemical QSAR and Monte Carlo simulations studies. Molecules 20:15122–15146

Olivares O, Likhanova NV, Gomez B, Navarrete J, Llanos-Serrano ME, Arce E, Hallen JM (2006) Electrochemical and XPS studies of decylamides of α-amino acids adsorption on carbon steel in acidic environment. Appl Surf Sci 252:2894–2909

Yi Yuetao, Liu Guangyang, Jin Zhiming, Feng Dawei (2013) The use of conducting polyaniline as corrosion inhibitor for mild steel in hydrochloric acid. Int J Electrochem 8:3540–3550

Emregul KC, Atakol O (2003) Corrosion inhibition of mild steel with Schiff base compounds in 1 M HCl. Mater Chem Phys 82:188–193

Jeyaprabha C, Sathiyanarayanan S, Venkatachari G (2006) Effect of cerium ions on corrosion inhibition of PANI for iron in 0.5 M H2SO4. Appl Surf Sci 253:432–438

Uffana Riaz, Ashraf SM, Ahmad Sharif (2007) High performance corrosion protective DGEBA/polypyrrole composite coatings. Prog Org Coat 59:138–145

Tallman DE, Vang C, Wallace GG, Bierwagen GP (2002) Direct electrodeposition of polypyrrole on aluminium and aluminium alloy by electron transfer mediation. J Electrochem Soc 149:173–179

Badran M, Mohammed HA, Aglan HA (2002) Effect of different polymers on the efficiency of water-borne methyl amine adduct as corrosion inhibitor for surface coatings. J Appl Polym Sci 85:879–885

Srivastava Varsha, Singh MM (2010) Corrosion inhibition of mild steel in acidic medium by poly (aniline-co-o-toluidine) doped with p-toluene sulphonic acid. J Appl Electrochem 40:2135–2143

Kinlen PJ, Ding Y, Silverman DC (2002) Corrosion protection of mild steel using sulfonic and phosphonic acid-doped polyanilines. Corrosion 58:490–497

Da Silva JEP, De Torresi SIC, Torresi RM (2007) Polyaniline/poly(methylmethacrylate) blends for corrosion protection: the effect of passivating dopants on different metals. Prog Org Coat 58:33–39

Moraga GA, Silva GG, Matencio T, Paniago RM (2006) Poly(2,5-dimethoxy aniline)/fluoropolymer blend coatings to corrosion inhibition on stainless steel. Synth Met 156:1036–1042

Noshay A, Robeson LM (1976) Sulfonated polysulfone. J Appl Polym Sci 20:1885–1903

Ferreira ES, Giancomelli C, Giacomelli FC, Spinelli A (2004) Evaluation of the inhibitor effect of l-ascorbic acid on the corrosion of mild steel. Mater Chem Phys 83:129–134

Martinez S, Stern I (2002) Thermodynamic characterization of metal dissolution and inhibitor adsorption processes in the low carbon steel/mimosa tannin/sulfuric acid system. Appl Surf Sci 199:83–89

Singh AK, Quraishi MA (2010) The effect of some bis-thiadiazole derivatives on the corrosion of mild steel in hydrochloric acid. Corros Sci 52:1373–1385

Prabhu RA, Venkatesha TV, Shanbhag AV, Kulkarni GM, Kalkhambkar RG (2008) Inhibition effects of some Schiff’s bases on the corrosion of mild steel in hydrochloric acid solution. Corros Sci 50:3356–3362

Yadav M, Behra D, Kumar S, Sinha RR (2013) Studied corrosion inhibition performance of three benzmidazole derivatives for mild steel in HCl. Ind Eng Chem Res 52:6318–6328

Prasanna BM, Praveen BM, Hebbar Narayan, Venkatesha TV, Tandon HC, Abd Hamid SB (2017) Electrochemical study on inhibitory effect of Aspirin on mild steel in 1 M hydrochloric acid. J Assoc Arab Univ Basic Appl Sci 22:62–69

Umoren SA, Obot IB (2008) Polyvinylpyrrolidone and polyacrylamide as corrosion Inhibitors for mild steel in acidic medium. Surf Rev Lett 15:277–284

Acknowledgements

The authors are great full to the All India Council for Technical Education, New Delhi, Govt. of India [Project Sanction No. Ref. 8024/RIFD/MOD-292 2010-11 dated 31-03-2011], for providing instrumental facilities under MODROBS scheme. Authors are also grateful to Management and authorities of Srinivas group, Mangalore, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rithin Kumar, N.B., Praveen, B.M. & Crasta, V. Electroactive Sulfonated Polysulfone Polymer as Corrosion Inhibitor for Mild Steel in Acidic Medium. J Bio Tribo Corros 3, 46 (2017). https://doi.org/10.1007/s40735-017-0106-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-017-0106-z