Abstract

In the present work, we investigate wetting behavior and chemical composition of anodized titanium nanotubular surfaces for orthopedic implant research. The wetting behavior of the nanotubes by alternating UV irradiation and dark storage is reported. This study suggests that hydrophobicity due to aging in air can be restored by annealing, and release of residual fluorine was observed as a function of annealing time, which is important considering side effects of fluorosis. Fabrication of nanotubes on thermal plasma-sprayed implants and super-hydrophilic behavior of these nanotubular surfaces needed for enhanced bioactivity are demonstrated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Surfaces capable of promoting osseointegration would be beneficial for orthopedic implants. Increasing the surface wettability of titanium nanotube surfaces by post-anodization annealing has been shown to enhance in vitro osteoblast proliferation [1]. The hydrophilic to hydrophobic transition of Ti-based nanotubular surfaces due to aging in air is well known [2]. Enhanced osteoblast adhesion and proliferation is influenced by surface morphology, topography and chemistry. In vivo experimental studies in the frontal skull of pigs demonstrated that nanotube surfaces gave enhanced bone formation and bone development with better osteoblast function compared to bare titanium surfaces [3]. The in vivo experimental studies in the femora with titania nanotubular surfaces in rats demonstrated increased bone formation, at 4- and 12-week time points [4]. Wettability is an important property for biological functions. As-anodized TiO2 nanotubes show super-hydrophilic behavior which becomes hydrophobic after aging in air. As the reaction of stabilization from Ti(OH)4 to TiO2 occurs, the hydroxyl groups disappear in air. In biomedical applications of titanium, alteration of wetting properties of the surface is important [5]. The hydrophobic transition can also be achieved by coating nanotubular surface with octadecylsilane and octadecylphosphonic acid molecules which can be reversed to hydrophilic by UV illumination [6]. One approach to enhance osseointegration, cell adhesion, proliferation and biocompatibility is to increase hydrophilicity by introducing Ti–OH groups on the nanostructured commercially pure titanium (Cp Ti) surface [7]. Biocompatibility is governed by factors including material of the implant, structure and chemistry of the implant surface and micro/nanostructured topography. TiO2 nanotube (TiNT) coatings, as nanophase materials on orthopedic implants, have been demonstrated to improve bonding with surrounding bone [8]. TiNTs create research interest due to better osseointegration as nanotubes provide numerous anchoring sites for cells.

During the past few years, researchers have investigated optical, chemical, electrical and wettability properties of organized TiNT surfaces on orthopedic implants, while there are few literature reports on controlled wettability and chemistry composition of the TiNT surfaces needed for orthopedic implant applications [9]. Therefore, the goal of present work was to quantify these promising characteristics of TiNT surfaces with controlled wettability and chemical composition.

In the first part of this study, the wetting condition of TiNT surfaces was analyzed to evaluate hydrophobicity induced due to surface aging during dark storage. This analysis can be useful for shelf life perspective for orthopedic implants with TiNT surfaces. For this analysis, two types of Cp TiNT surfaces anodized using two different electrolytes were used. Comparison of two Cp TiNT morphologies for ability to retain hydrophilicity was made. A previous study reported that UV irradiation of 1.0 μW/cm2 for 240 min can improve the surface wettability of annealed and unannealed Cp TiNT surfaces [10]. In order to study the effect of more intense UV irradiation for comparatively short duration on wettability, the unannealed alloy TiNT surfaces were UV irradiated. The aim was to determine the possibility of restoring hydrophilicity of aged amorphous alloy TiNT surfaces in less time.

Crystallinity and chemistry of TiNT surfaces could be other factors that affect bio-performance [11]. Wettability can be improved by changing the chemistry and crystallinity of the surfaces. Thermal annealing can make anodized surfaces super-hydrophilic partly because of formation of the anatase phase [10]. Therefore, the later part of this paper focuses on post-anodization thermal annealing of TiNT surfaces to identify whether the residual fluorine in the TiNT surfaces can be controlled in addition to restoring wettability. Lastly, a procedure for fabrication of nanotubes on thermal plasma-sprayed (TPS) surfaces was also investigated.

2 Materials and Methods

2.1 Substrate Preparation

Strips of commercially pure titanium (CpTi) AMS 4902 J grade 2 with 99.7 wt% purity (TIMET, USA) and Ti–6Al–4V alpha/beta titanium alloy of ASTM B 265-11 grade 5 (TIMET, USA) were mechanically polished using #150 grit fine crocus cloth and #800 grit ultra-fine sanding cloth. After cleaning in deionized (DI) water followed by acetone, the samples were dried in air at room temperature. The samples that were 12 mm × 12 mm × 0.5 mm thick were cut from strips. Thermal plasma-sprayed CpTi surfaces were cleaned as received with no further preparation.

2.2 Fabricating Nanotubes

The TiNTs were fabricated by electrochemical anodization of Cp Ti and alloy using a DC power source (Protek 3006B), with direct current (DC) output 0–60 V, 1.5 A. Two electrolyte recipes used to anodize the nanotubes with specific compositions, as listed in Table 1, are hereafter abbreviated as low-water, high-fluorine (LWHF) and high-water, low-fluorine (HWLF). To fabricate TiNTs, the surfaces were electrochemically anodized at room temperature with a graphite rod as the cathode and the titanium strip as the anode. The anodized samples were further categorized whether they were as-anodized or included 5 min of sonication in deionized water after anodization. The purpose of sonication for short time was to clean the top surface of nanotubular layer by removing the surface aggregation formed during anodization without affecting the nanotubes. This was confirmed with scanning electron microscopy.

2.3 Surface Characterization

Characterization of the anodized surfaces was done using field emission scanning electron microscopy (FESEM, Hitachi S-4700). The wt% chemical compositional analysis of TiNT surfaces was done by energy-dispersive spectroscopy (EDS) with standardless quantitative analysis on the FESEM at 10 kV.

2.4 Thermal Treatment Protocol

The post-anodization thermal annealing was performed at 350 °C for 3 h in air using a programmable automatic heating chamber (Fisher Scientific Isotemp® Programmable Muffle Furnace). The heating rate chosen was 7.5 °C/min, and the slow cooling to room temperature was obtained inside the chamber.

2.5 Contact Angle Imaging and Measurements

An air displacement micropipette (Eppendorf Research Plus adjustable from 0.5 to 10 μL) was used to deposit 1-μL droplets. Phosphate-buffered saline (PBS) solution of pH 7.4 was used to simulate the body fluid interaction with alloy TiNT, and DI water of pH 7 alone was used for Cp TiNT. Images were acquired using a Kohler illumination system and microscope-integrated camera in ambient conditions. In this work, the advancing contact angle of the droplet at the air–liquid–solid interface each second for 30 s total was recorded. Images corresponding to 10 s after putting a droplet were considered as stable. The water contact angle (WCA) measurements were performed by the drop shape analysis method for angles more than 15° and by the tangent method for angles less than 15° of the spherical crown of the droplet.

2.6 Wetting Behavior as a Function of Time by Alternating UV Irradiation and Dark Storage

To analyze and compare hydrophobic conversion from as-anodized hydrophilic Cp TiNT surfaces due to aging, the two types of Cp TiNT surfaces were kept in dark storage for 2, 20, 40 and 60 days under ambient condition. Two types of Cp TiNT surfaces anodized using HWLF and LWHF electrolyte were used for this purpose to analyze the aging effect on two different morphologies. After each storage time interval, the contact angle was measured.

Only alloy TiNT surfaces were used to investigate photo-induced hydrophilicity. The alloy TiNT samples were exposed to UV irradiation before and after dark storage at different time intervals under ambient conditions. The UV light (λ = 365 nm, 450 µW/cm2 intensity) was used for 30 min to study the effect of high intensity UV irradiation for a short duration on wettability. The purpose was to determine whether hydrophobicity of alloy TiNT surface due to aging could be reversed to a more hydrophilic state. After each irradiation time interval, the contact angle was measured. After initial irradiation, the alloy TiNT samples were kept in dark for 2, 20, 40 and 60 days. After aging, the samples were again irradiated under UV light for 30 min to investigate the possibility of UV-induced wettability. Each contact angle measurement was repeated twice at different places on the sample surface.

2.7 Statistical Analysis

The EDS spectra were collected at three different locations on each surface for compositional characterization using standardless quantitative analysis on FESEM, and the data were reported as an average. For all contact angle measurements, the uncertainty of the measurements is ±3°. This is based on the ability to reproducibly determine a tangent line or elliptical shape at the solid–liquid–vapor contact while doing contact angle measurements.

3 Results

3.1 Surface Morphology: SEM Analysis

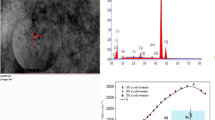

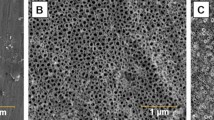

The morphology of the TiNT structures showed a strong dependence on electrochemical anodization potential and anodizing time. FESEM images in Fig. 1 show representative TiNT surfaces. The alloy and pure nanotubes produced in the LWHF electrolyte (40 min) were found to have a length of ~1.5 μm with a honeycomb like tightly bound vertically aligned structure and smooth walls. These tubes present an ordered and well-packed structure. In contrast, the pure nanotubes produced in the HWLF electrolyte (240 min) were found to have a shorter length of ~1.0 μm with cantilever like well-spaced individual-vertically aligned structures. These tubes showed ripples in their side walls, which introduce a small-scale surface component. Table 2 summarizes the characteristic mean values of tube dimensions.

3.2 Chemical Composition of As-anodized Structures

The chemistry of an implant surface is vital in biological events after implantation. Surfaces with a mechanical similarity to bone and controlled chemistry at the nanometer scale can promote spreading and attachment of osteoblasts on the implant surface [12]. Only a few studies have provided details on the residual chemistry of TiO2 nanotubular surfaces.

The three types of as-anodized TiNTs were characterized to compare the effect of the electrolyte and anodizing process (Table 3). The oxygen content in TiNTs represents the formation of the oxides during anodization. The nanotubes show 33 wt% of oxygen. The lower oxygen count can be justified by the presence of TiOH on the nanotube surface. During anodization, the diffusion-controlled growth of nanotubes leads to formation of hexafluorotitanate complex TiF6 2− by fluorine diffusion from electrolyte to titanium [5]. The presence of fluorine in the anodized surfaces is indicative of the diffused TiF6 2− during anodizing rather than free fluoride ions.

3.3 Wetting Condition Analysis

The wettability originates from the surface hydroxyls. These surface hydroxyls combine with water molecules forming hydrogen bonds, which further results in increased wettability. The mechanism of transition from hydrophobicity to hydrophilicity of the surface upon UV irradiation is explained by the excitation of oxide with reduction of Ti4+ by surface-trapped electrons [13]. This forms oxygen vacancies. Thus, when a water droplet is placed on the surface, it reacts with oxygen vacancies resulting in complete spreading of the water droplet.

Figure 2 shows the trends of the WCA variations on Cp TiNT surfaces prepared using LWHF and HWLF electrolytes. Initially, 2 days after anodization, the two different Cp TiNT morphologies showed similar hydrophilicity. This later showed variation in the hydrophilic to hydrophobic transition as a function of aging. In the case of nanotubes prepared using HWLF electrolyte, the surface became hydrophobic after 20 days. On the contrary, nanotubes prepared using LWHF electrolyte maintained hydrophilicity even after 20 days. The non-anodized control Cp Ti foil surfaces showed a WCA of 64° (not shown in figure) which reduced to 14° on both types of nanotubular surfaces representing hydrophilic behavior upon anodization. This reduction in WCA after fabrication of the nanotubes could also be because of the increased surface area of the separated nanotubes along with formation of TiOH on the surface.

Previous studies reported that reversible switching between hydrophobic and hydrophilic states is an effect defined by surface chemical composition and roughness [14]. The chemical composition provides a photosensitive surface, which can be switched between the two wetting states. Figure 3 shows representative pictures of droplets on non-sonicated and sonicated alloy TiNT surfaces. The trends of the contact angle variations are presented in Fig. 4. The contact angle measurements were conducted before and after irradiating with UV light. The effect of indirectly induced UV photocorrosion was not considered within the scope of this study, and the possibility of oxygen vacancy formation which directly affects the hydrophobicity was considered. The following phenomena were observed. The first, in the case of non-sonicated alloy TiNTs, the wetting transition from hydrophilic to hydrophobic is mildly irreversible with the largest effect after 60-day aging. The second is, aging effect dominated in sonicated alloy TiNTs as compared to non-sonicated, due to oxidation of TiNTs in ambient conditions during storage. These results suggest that with more intense UV irradiation the wettability degenerate and photo-induced wettability effect cannot be achieved with short duration. The sharp increase in contact angle in non-sonicated alloy TiNT surfaces represented a much faster hydrophobic transition between 40 and 60 days, whereas in case of sonicated alloy TiNT surfaces, a much faster transition in first 20 days.

3.4 Effect of Thermal Annealing on Chemical Composition and Wettability

The compositional and wettability changes of TiNT surfaces upon annealing were studied. The TiNT surfaces were annealed at 350 °C to achieve the amorphous to anatase phase transformation. As-anodized TiNTs showed strong residual fluorine content. Reduction or elimination of fluorine may be advantageous because the presence of fluorine could alter the properties of the surface in biomedical devices [15]. Excessive levels of fluorine can also lead to skeletal fluorosis with the first indications being increased bone density and loss of calcium.

For Cp TiNTs anodized with HWLF electrolyte, which could also produce nanotubes on thermal plasma-sprayed implants, the chemical composition was studied before and after annealing for 1, 2, 3 and 4 h at 350ºC. From EDS wt% data, the graph in Fig. 5 shows the decreasing trend of fluorine in TiNTs with respect to annealing time. The fluorine concentration gradually decreased from 4.11 wt% in as-anodized TiNTs to 0.77 wt% upon annealing for 4 h.

Figure 6 shows wettability changes as effect of annealing at 350 °C for 3 h on control and TiNT surfaces. The alloy and Cp TiNT surfaces became super-hydrophilic upon annealing. Annealing caused adsorption of water representing hydrophilic surface. In case of unannealed amorphous nanotubes, the contribution of tube walls to generate photocurrent is very less [16]. The reason is the amorphous structure of tubes possesses more defects. The annealed nanotubes represent better photocurrent, because by conversion to anatase the tube walls become activated and contribute to photocurrent [16]. These annealed surfaces can become hydrophobic upon aging, and these can be exposed UV to make them hydrophilic again.

3.5 TiNT on Cp TPS Implant Surfaces

Nanotubular implant surfaces, providing nanoscale 3-D topographies with more surface area than flat surfaces, demonstrated enhanced osseointegration in rats [17]. In vivo studies of thermal plasma-sprayed (TPS) implants in a rabbit model showed higher percentage of bone contact, accelerated bone formation [18].

In this study, we anodized TPS implant surfaces of Cp titanium in HWLF electrolyte with two different anodization conditions on different implants to analyze nanotube morphology and their wetting behavior. Figure 7a–d shows TiNT surface fabricated at 30 V for 4 h. Figure 7e–h shows TiNT surface fabricated at 60 V for 40 min. It is evident that the nanotubes were anodized on the entire surface covering all the macroscopic roughness features. The TiNTs on the TPS substrate were vertically oriented, laterally spaced, structurally stable. This porous network of nanotubes showed strong scratch resistance representing good mechanical strength needed to sustain surgical loads. In prior work, Friedrich et al. [19] fabricated nanotubes into titanium alloy cancellous bone screws and subsequently inserted and removed them twice into pilot holes in bone simulant material. By measuring the insertion and removal torques and by FEM analysis, it was determined that the von Mises stress at the base of the nanotubes varied from 47.5 to 99.6 MPa depending on the nanotube morphology. The nanotubes were approximately 80–100 nm in diameter. The intertubular space between nanotube walls was ~10 nm. A similar type of nanotube morphology has been reported to have potential for bone implant material because of their ability to induce more osteoblast elongation with higher alkaline phosphate activity [20]. This type of morphology with interstitial spaces between tubes, even after cell adhesion, is reported to allow continued fluid flow of culture media and increased exchange spaces between tube walls for gas nutrients and cell signaling molecules, leading to enhanced performance of bioactivity on implant [21]. Controlled dimensional variation in tube diameter and length can be achieved using this HWLF electrolyte by changing anodization conditions.

Another desirable property of nanotubular structure is hydrophilicity for effective bioactivity. The greater cell adhesion by TiNTs, as compared to flat smooth control surfaces, is partly because of nano-topography and partly because of hydrophilicity of the TiNTs [21, 22]. Table 4 shows the WCA measurements on as-received and TiNT anodized surfaces of CpTPS implants using 1 μL DI water. The TiNT surfaces fabricated at 30 V for 4 h demonstrated retention of hydrophilicity even after aging up to 40 days, whereas nanotubes fabricated at 60 V for 40 min became hydrophobic after 20 days. The annealed TiNT surfaces on CpTPS implants demonstrated decrease in residual fluorine up to 85–93% compared to unannealed TiNT surfaces (Table 5).

4 Discussion

The morphological analysis of TiNTs indicates that as the ratio of NH4F to DI water was decreased, the nanotube density decreased and spacing between the nanotubes increased (Table 2). The shape and dimensions of nanotubes showed a strong correlation with composition of electrolyte. It is also interesting to note that the difference in the fluorine concentration in the two electrolytes has a pronounced effect on the amount of residual fluorine in the TiNT surfaces (Table 3).

The presence of TiOH on nanotube surface makes the surface hydrophilic in the as-anodized condition. The aging in air causes atmospheric contamination during dark storage makes the nanotubular surfaces more hydrophobic. In alloy TiNTs, much faster hydrophilic to hydrophobic transition of sonicated alloy TiNT surfaces in 20 days as compared to non-sonicated surfaces which occurred in 40 days (Fig. 4b) indicates that the surface aggregation of the non-sonicated TiNT surfaces has apparently protected the underlying nanotubes delaying TiO2 stabilization and slower aging. Our result shows that the rate of hydrophilic to hydrophobic transition (increase in contact angle values) was observed to be only 12% up to 40 days of dark storage in the case of non-sonicated alloy TiNT. This slower transition and retention of hydrophilicity up to 40 days, compared to sonicated alloy, could be important from a manufacturing, packaging and shelf life perspective for orthopedic implants with TiNT surfaces.

The UV-induced hydrophilic effect is not observed in alloy TiNT surfaces that were non-sonicated and sonicated. This can be explained as the presence of aluminum and vanadium oxides having higher band gap energy than titanium along with corresponding intermetallic compounds. This could not lead to reduction of metal ions and thus affected the process of formation of surface hydroxyls Ti(OH) upon UV.

In the case of TPS implant surface, the TiNTs fabricated with HWLF electrolyte at 60 V in 40 min showed major hydrophilic to hydrophobic transition in the first 20 days. This information is useful to determine short-term shelf life of Cp Ti nanotextured implant surfaces. The compositional and functional changes of TiNT surfaces upon annealing were studied. Our results showed that the residual fluorine in the TiNTs could be eliminated upon annealing.

5 Conclusions

The wetting transition from hydrophilic to hydrophobic is irreversible by UV irradiation for amorphous TiNTs using UV irradiation. The wettability of nanotubes is dominated by aging effect. Successful fabrication of super-hydrophilic nanotubes on Cp TPS implant is achieved, establishing reliable procedure for reproducible nanotubular surfaces needed for enhanced bioactivity. The elimination of residual fluorine by thermal annealing of the anodic TiO2 nanotubes is shown. As a result of annealing at 350 °C, release of fluorine was observed as a function of annealing time.

References

Baker EA (2016) Enhancing osseointegration of orthopaedic implants with titania nanotube surfaces. Open Access Dissertation, Michigan Technological University

Shin DH, Shokuhfar T, Choi CK, Lee SH, Friedrich C (2011) Wettability changes of TiO2 nanotube surfaces. Nanotechnology 22:315704

Von Wilmowsky C, Bauer S, Lutz R, Meisel M, Neukam FW, Toyoshima T et al (2009) In vivo evaluation of anodic TiO2 nanotubes: an experimental study in the pig. J Biomed Mater Res B Appl Biomater 89:165–171

Alexander V, Salisbury M, Fleischer M, Bhosle SM, Friedrich C, Paul FM (2016) Enhancing osseointegration of orthopaedic implants with titania nanotube surfaces. Foot Ankle Orthop 1:1

Macak JM, Tsuchiya H, Ghicov A, Yasuda K, Hahn R, Bauer S et al (2007) TiO2 nanotubes: self-organized electrochemical formation, properties and applications. Curr Opin Solid State Mater Sci 11:3–18

Balaur E, Macak JM, Taveira L, Schmuki P (2005) Tailoring the wettability of TiO2 nanotube layers. Electrochem Commun 7:1066–1070

Li B, Li Y, Li J, Fu X, Li C, Wang H et al (2014) Improvement of biological properties of titanium by anodic oxidation and ultraviolet irradiation. Appl Surf Sci 307:202–208

Ganesan B, Webster TJ (2006) A perspective on nanophase materials for orthopedic implant applications. J Mater Chem 16:3737–3745

Indira K, Mudali UK, Rajendran N (2014) In-vitro biocompatibility and corrosion resistance of strontium incorporated TiO2 nanotube arrays for orthopaedic applications. J Biomater Appl 29:113–129

Yang L, Zhang M, Shi S, Lv J, Song X, He G et al (2014) Effect of annealing temperature on wettability of TiO2 nanotube array films. Nanoscale Res Lett 9:621

Mazare A, Dilea M, Ionita D, Titorencu I, Trusca V, Vasile E (2012) Changing bioperformance of TiO2 amorphous nanotubes as an effect of inducing crystallinity. Bioelectrochemistry 87:124–131

Le Guehennec L, Soueidan A, Layrolle P, Amouriq Y (2007) Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater 23:844–854

Kontos AG, Kontos AI, Tsoukleris DS, Likodimos V, Kunze J, Schmuki P et al (2009) Photo-induced effects on self-organized TiO2 nanotube arrays: the influence of surface morphology. Nanotechnology 20:045603

Papadopoulou EL, Zorba V, Pagkozidis A, Barberoglou M, Stratakis E, Fotakis C (2009) Reversible wettability of ZnO nanostructured thin films prepared by pulsed laser deposition. Thin Solid Films 518:1267–1270

Regonini D, Jaroenworaluck A, Stevens R, Bowen CR (2010) Effect of heat treatment on the properties and structure of TiO2 nanotubes: phase composition and chemical composition. Surf Interface Anal 42:139–144

Beranek R, Tsuchiya H, Sugishima T, Macak JM, Taveira L, Fujimoto S et al (2005) Enhancement and limits of the photoelectrochemical response from anodic TiO2 nanotubes. Appl Phys Lett 87:243114

Smith GC, Chamberlain L, Faxius L, Johnston GW, Jin S, Bjursten LM (2011) Soft tissue response to titanium dioxide nanotube modified implants. Acta Biomater 7:3209–3215

Darimont GL, Cloots R, Heinen E, Seidel L, Legrand R (2002) In vivo behaviour of hydroxyapatite coatings on titanium implants: a quantitative study in the rabbit. Biomaterials 23:2569–2575

Friedrich CR, Kolati M, Moser T, Sukotjo C, Shokuhfar T (2014) Survivability of TiO2 nanotubes on the surface of bone screws. Surf Innov 2:60–68

Brammer KS, Oh S, Cobb CJ, Bjursten LM, van der Heyde H, Jin S (2009) Improved bone-forming functionality on diameter-controlled TiO2 nanotube surface. Acta Biomater 5:3215–3223

Brammer KS, Frandsen CJ, Jin S (2012) TiO2 nanotubes for bone regeneration. Trends Biotechnol 30:315–322

Hamlekhan A, Butt A, Patel S, Royhman D, Takoudis C, Sukotjo C et al (2014) Fabrication of anti-aging TiO2 nanotubes on biomedical Ti alloys. PLoS ONE 9:e96213

Acknowledgements

This work performed under the M-TRAC program was supported by Grant Case-48161 of the 21st Century Jobs Trust Fund received through the Michigan Strategic Fund from the State of Michigan. The M-TRAC program is funded by the Michigan Strategic Fund with program oversight by the Michigan Economic Development Corporation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhosle, S.M., Friedrich, C.R. Wetting Behavior and Chemistry of Titanium Nanotubular Orthopedic Surfaces: Effect of Aging and Thermal Annealing. J Bio Tribo Corros 3, 26 (2017). https://doi.org/10.1007/s40735-017-0085-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-017-0085-0