Abstract

Physical characterization study is carried out on the Mansehra Granite, Hakale Granite, quartzite and dolerite from Mansehra area to explore their potential for utilization as construction materials. Laboratory tests reveal specific gravity (2.65–3.02), water absorption (0.32–0.38 %), Aggregate Impact and Aggregate Crushing values (17.26–27.01 % and 15.59–21.21 %), Flakiness and Elongation Index (6.01–7.80 % and 5.95–9.39 %), sulphate soundness (2.19–4.07 %) and Los Angeles abrasion value (28.13–35.70 %) of these rocks. Values of these parameters were compared with the ASTM and BS standards which indicate that Mansehra Granite, Hakale Granite, quartzite and dolerite can be the potential source for dimension stone, road and concrete aggregate. Stripping test indicates suitability of these rocks as aggregate for asphalt wearing course. Unconfined compressive strength of gneissic and massive Mansehra Granites varies from 61.50 to 66.20 MPa. Owing to lower unconfined compressive strength, higher flakiness and elongation index, aggregate impact and crushing values, the gneissic Mansehra Granite is not recommended as dimension stones, road and cement concrete. Petrographic studies indicate presence of strained quartz in Mansehra Granite, Hakale Granite and quartzite which suggest that these rocks are prone to alkali-silica reactivity potential and may not be used as cement concrete aggregate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In view of tremendous increase in demand of construction materials, it is imperative to carry out prospective research for the exploration of new resources. Geological materials occur as sedimentary, igneous and metamorphic rocks (Roberts et al. 1991). Among these, sedimentary rocks constitute major portion of construction materials in the form of gravels, pebbles, cobbles and crushed rocks. However, depending upon the suitability and transportation cost, igneous and metamorphic rocks can also be exploited as construction material. Granite and quartzite are most commonly used as aggregate source (McNally 1998). Granite is an intrusive igneous rock which can be an important source of aggregates for engineering projects. It can be used as dimension stone, flooring tiles and paving material. Due to its high durability and aesthetic qualities polished granite is a popular choice for kitchen counter tops. It shows consistency in colour and texture. It is thermally stable, impervious to weathering and air borne chemicals. Owing to negligible porosity (0.2–0.4 %), it has higher strength and excellent wear resistance.

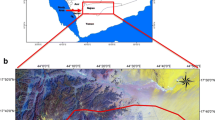

A variety of granitic rocks with varied colour, mineralogy, textural characteristics and mechanical properties are exposed in different parts of Pakistan but only few of them are being used as construction material. Mansehra Granite and associated rocks of Khyber Pakhton Khawa (KPK) (Fig. 1) may form a good source of construction material. Physical properties of the Mansehra Granite were investigated by Arif et al. (1999) but the study was confined to limited tests on three samples of the granite. The present study deals with the variety of tests carried out on the Mansehra Granite, Hakale Granite, quartzite and dolerite of the Mansehra area to explore their potential for road as well as concrete aggregates and dimension stones.

The objective of this work is to find out the potential of granite and other associated igneous rocks, present in the vicinity of Mansehra area, to be used as construction material.

2 Geology of the area

The Mansehra area is comprised of the Mansehra Granite, Hakale Granite, pegmatites and leucogranitic bodies (Shams 1961; Ashraf 1974). Mansehra Granite is the main plutonic rock which is whitish grey, jointed and assumes rounded appearance due to mass-exfoliation (Fig. 2a). The granite is medium to coarse-grained and porphyritic containing K-feldspar phenocrysts. Size and percentage of these phenocrysts vary from place to place. The granite is generally massive but gneissic at places in shear zones exhibited by stretched and augen shaped K-feldspar phenocrysts (Fig. 2b). Flow-foliation of phenocrysts is superimposed by tectonic foliation in shear zones. Pegmatite, aplite and leucocratic bodies are associated with the granite. Mansehra Granite is surrounded by Tanawal Formation of pre-Cambrian age (Baig et al. 1989). The formation is predominantly comprised of psammite, pelite, quartzite bands and schists. At some places dolerite dykes cut the Mansehra Granite (Fig. 2c). These dykes are up to 40 m thick.

The Hakale Granite is an oval shaped body about 3–8 km in length which is light colored, medium to coarse-grained, sub-porphyritic to non-porphyritic, containing tourmaline as ubiquitous mineral.

3 Materials and method

20 representative block samples of massive Mansehra Granite (MGm) and gneissic Mansehra Granite (MGg), Hakale Granite (HG), quartzite (QZ) and dolerite (DL) were collected from Mansehra, Susalgali-Khaki and Oghi-Darband areas (Fig. 1). Laboratory tests such as water absorption, specific gravity (bulk specific gravity, saturated surface dry and apparent specific gravity), Los Angeles abrasion (LA), aggregate impact value (AIV), aggregate crushing values (ACV), Asphalt adhesion and soundness tests were performed on these rocks to determine their suitability as construction material. Unconfined compressive strength (UCS) of the Mansehra Granite was also determined for its prospects as dimension stone. These tests were performed in accordance with the ASTM standards and the results are presented in Table 1. Petrographic studies were carried out for mineralogical composition and textural characteristics of these rocks.

4 Petrography

Mansehra and Hakale granites are principally composed of microcline, quartz, albite, biotite and muscovite. Microcline (25–45 %) is subhedral to anhedral, medium to coarse-grained which shows perthitic character and partly replaced by fine-grained muscovite. Plagioclase (albite) constitutes 15–25 % of the granites. Quartz (25–30 %) is fine to medium- grained which is variably strained showing wavy extinction and micro-fractures that indicate mild to intense marginal mylonization (Fig. 3a). Biotite and muscovite (3–12 %) are stretched, contorted, randomly oriented, broken, curves showing the effects of stress (Fig. 3b). This feature is well-marked in Mansehra Granite present in shear zones (Fig. 3c). Biotite enclosed euhedral to subhedral zircon crystals which are surrounded by dark haloes. The Hakale Granite has comparable mineralogy with that of Mansehra Granite with tourmaline (2–5 %) as ubiquitous mineral.

Dolerite is principally comprised of 55 % plagioclase (labradorite), 35 % pyroxene (predominantly augite), 5 % biotite and hornblende along with 5 % accessory minerals. These results are closely matched with those done by Shams (1961). Whereas quartzite is composed of fine to medium-grained, strained and fractured quartz grains which show wavy extinction indicating effect of stress.

5 Results and discussion

5.1 Specific gravity

Mean values of bulk specific gravity, saturated surface dry (SSD) and apparent specific gravity of the Mansehra Granite, Hakale Granite and quartzite vary within a narrow range i.e. 2.65–2.72, whereas, specific gravity of dolerite is relatively higher (3.01–3.02). These specific gravity values lie within the limits (minimum 2.6) specified in ASTM–127 for base, sub-base, wearing course of roads and cement concrete (Tables 2 and 4). Due to lower specific gravity of the gneissic Mansehra Granite (2.65) and quartzite (2.65) these rocks are not suitable as dimension stones (Table 3). However, massive Mansehra Granite, Hakale Granite and dolerite with specific gravity range 2.72–3.01 qualify as dimension stone.

5.2 Water absorption

Mean water absorption values (0.32–0.38 %) in Mansehra Granite, Hakale Granite, quartzite and dolerite suggest their comparable porosity characteristics. Higher water absorption values indicate more porosity of the rock which interferes with water-cement ratio. Pores absorb part of water needed for hydration of the cement rendering the weaker bond among aggregate fragments and adversely affect the strength of concrete. However, water absorption values of Mansehra Granite, Hakale Granite, quartzite and dolerite fall within limits (maximum 2.0 %) of ASTM–127 for concrete aggregate (Table 4). Owing to less than 0.4 % water absorption these rocks can be used as dimension stones.

5.3 Flakiness index and Elongation index

Particle shape plays an important role in the workability and deformation characteristics of the concrete. Flaky and elongated fragments tend to align themselves rendering anisotropic properties and reduce the strength of concrete. Mean Flakiness Index values in Mansehra Granite, Hakale Granite and dolerite range between 6.01 and 7.80 %. Relatively higher value of 7.80 % is due to gneissic character of the Mansehra Granite which has produced more flaky fragments. Since BS882 1992 recommends that flakiness index in crushed stone aggregate should not exceeds 40 % therefore these rocks can be used in cement concrete as well as road aggregate (Tables 2 and 4).

Mean Elongation Index values vary between 5.95 and 9.39 % in these rocks. Highest value (9.39 %) is due to the foliated nature of the Mansehra Granite. The gneissic Mansehra Granite tends to produce more elongated fragments.

Maximum permissible limits of Flakiness and Elongation Index for being road aggregate are less than 25 and 15 %, respectively. Hence these rocks qualify as road aggregate (Table 2). However, mean Flakiness and Elongation Index value are within limits (Flakiness and Elongation Index maximum values 25 %) BS-812: 105.1 and 105.2 (1990) for utilization in cement concrete (Table 4).

5.4 Los Angeles abrasion value (LAV)

Los Angeles abrasion values varied in the range of 28.13–35.70 % in Mansehra Granite, Hakale Granite, quartzite and dolerite. Mean values for gneissic and massive Mansehra Granite are 35.70 and 29.46 %. Owing to gneissic nature and fragile character the former has relatively higher Los Angeles abrasion value as compared with massive facies of the granite. Due to less shearing effects and sub-porphyritic to non-porphyritic nature the Hakale Granite shows mean value of 28–13 %. Since mean Los Angeles abrasion values of these rocks are less than 40 % which suggest their utilization as aggregate in base, sub-base and wearing course of roads (ASTM C-131) as presented in Table 2. However, mean Los Angeles abrasion value (LAV) for gneissic Mansehra Granite is more than the maximum permissible limit (30 %) of ASTM standard for cement concrete, therefore this facies of the granite is not recommended for utilization as aggregate in cement concrete (Table 4).

5.5 Aggregate impact and aggregate crushing values

Aggregate impact value (AIV) measures the resistance of an aggregate against sudden shock and impact (Smith and Collis 2001). Lower AIV means that the material has more resistance for mechanical impact. Aggregate Impact and Aggregate Crushing values of the Hakale Granite, quartzite and dolerite vary within narrow range (17.26–19.61 % and 15.59–18.54 %). However, relatively higher mean AIV (27.61 %) and ACV (21.21 %) of mylonized Mansehra Granite as compared with massive Mansehra Granite (14.81 and 16.51 %) indicates fragile nature of the former. Maximum limit described by BS-812: 112 is 30 % for cement concrete (Table 4). Moreover, AIV (BS-812: 112) and Aggregate Crushing values of the Mansehra Granite, Hakale Granite, quartzite and dolerite are within limits (IS:2386).

5.6 Stripping test

Chemistry and roughness of the aggregate surface are main contributory factors which affect the nature of bond between asphalt and aggregate. \(\hbox {SiO}_{2}\) is negatively charged hydrophilic (water-loving) mineral and usually considered to have non-adhesive characteristics (Abo-Qudais and Al-Shweily 2007). Stripping is a complex phenomenon which depends upon mineralogy and textural character of aggregate. Surface roughness ruptures the water film adhering on the mineral which may form bitumen bond with aggregate (Roberts et al. 1996). Rougher the surface texture better the adhesion. Dolerite qualify asphalt adherence test whereas Mansehra Granite, Hakale Granite and quartzite showed fair adherence characteristics. Mansehra Granite and Hakale Granite contain 40–65 % feldspar and plagioclase together with coarse-grained nature and surface roughness texture that may have rendered adequate bitumen bond. These materials may be used as aggregate for asphalt wearing course of roads.

5.7 Unconfined compressive strength

Mean Unconfined compressive strength (UCS) values of Mansehra Granite varied between 61.5 and 66.2 MPa. Relatively lower UCS (61.5 MPa) is attributed to the mylonized and fragile nature of the gneissic Mansehra Granite than the massive granite. UCS of the gneissic granite is just at the lower limit specified in ASTM C-170, which suggests that this rock may not be used as dimension stone (Table 3). Arif et al. (1999) have presented UCS of the Mansehra Granite which ranged from 1595 to 1725 PSI (11–11.89 MPa). These values are lower than UCS determined (61.5–66.2 MPa) in the present study.

The Hakale Granite has mean UCS values of 70.6 MPa which is relatively higher than Mansehra Granite strength because of the lesser shearing effects on the former. The Mansehra Granite is porphyritic and Hakale Granite is sub-porphyritic to non-porphyritic. Both these granites have relatively lower UCS which is most likely due to concentration of stress around K-feldspar phenocrysts and acted as stress raising agents at local level that helped in propagation of fractures and consequent failure at lower load imparting lesser strength to the granite.

Owing to fractured nature the quartzite reveals comparable UCS (62.7 MPa) with that of Mansehra Granite. However, the dolerite exhibits highest UCS value of 86.3 MPa and qualifies as dimension stone (ASTM C-127) as presented in Table 3.

5.8 Petrographic characteristics

Petrographic study of the Mansehra Granite (massive and gneissic), Hakale Granite and quartzite reveal the presence of strained quartz which may be prone to Alkali-Silica reaction when used as aggregate in cement concrete. Therefore, it is suggested that these rocks may not be used in cement concrete aggregate.

5.9 Sulphate soundness test

Capability of a material to resist unusual change in volume in response to change in its physical environments is determined by soundness test. Weathering and alterations promote porosity which deteriorate strength and other mechanical properties of an aggregate. Higher soundness values indicate that the material is prone to alterations under changing environments. ASTM (C 88) recommends that the soundness values should be less than 12. Mean sulphate soundness values of the Mansehra Granite (gneissic and massive), Hakale Granite, quartzite and dolerite (2.19–4.07) are within limits for road aggregate (Table 2).

6 Conclusion

The laboratory tests performed on Mansehra Granite, Hakale Granite, quartzite and dolerite reveal that these rocks are potential source of dimension stones and road aggregates. However, due to lower specific gravity, LA and UCS values the gneissic Mansehra Granite is not recommended for utilization as dimension stone. Owing to presence of stained quartz in Mansehra Granite, Hakale Granite and quartzite these rocks are prone to alkali-silica reactivity potential and may not be used as aggregate in cement concrete. However, stripping tests indicate that these rocks can be utilized as aggregate in asphalt for wearing course of roads.

References

Abo-Qudais S, Al-Shweily H (2007) Effect of aggregate properties on asphalt mixtures stripping and creep behavior. Construct Build Mater 21:1886–1898

Arif M, Mulk A, Mahmood MT, Shah SMH (1999) Petrography and mechanical properties of the Mansehra granite, Hazara, Pakistan. Geol Bull Univ Punjab 32:41–99

Ashraf M (1974) Geology and petrology of acid minor bodied from Mansehra and Batgram area, Hazara district, Pakistan. Geol Bull Univ Punjab 11:81–88

ASTM C (2006) Standard test method for density, specific gravity and absorption of coarse aggregate. Annual Book of ASTM Standards 04(02):127–04

ASTM C 131–03 (2006) Standard test method for resistance to degradation of small-size coarse aggregate by abrasion and impact in the Los Angeles machine. Annual Book of ASTM Standards 04:02

ASTM C 88–05 (2006) Standard test method for soundness of aggregates by use of sodium sulfate or magnesium sulfate. Annual Book of ASTM Standards 04:02

ASTM C170 / C170M–09 (2013) Standard test method for compressive strength of dimension stone. Annual Book of ASTM Standards v. 04–07

Baig MS, Snee LW, La-Fortune RJ (1989) Timing of the Pre-Himalayan organic events in the Northwestern Himalaya: 40 Ar/39 Ar constraints. Kashmir J Geol 6&7:29–40

BS 812 105.1 (1989) Methods for determination of Flakiness index of coarse aggregate

BS 812 105.2 (1990) Method for determination of Elongation index of coarse aggregate

BS 882 (1992) Specification for aggregates from natural sources for concrete

I S 2386 - IV (1997) Methods for the determination of aggregate crushing and aggregate impact values of coarse aggregates. Bureau of Indian Standards, Manak Bhavan, 9-Bahadur Shah Zafar Marg, New Delhi-110002

McNally GH (1998) Soil and rock construction materials. E&FN Spon, London

Roberts FL, Kandhal PS, Brown ER, Lee DY, Kennedy TW (1996) Hot mix asphalt materials, mixture design, and construction. National Asphalt Pavement Association Education Foundation, Lanham

Shams FA (1961) A preliminary account of the geology of the Mansehra area, District Hazara, West Pakistan. Geol Bull Univ Punjab 1:57–67

Smith MR, Collis L (2001) Aggregates: Sand, gravel, and crushed rock aggregates for construction purposes. Sp. Pub. 17, Geological Society, London, p 339

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naeem, M., Khalid, P. & Anwar, A.W. Construction material prospects of granitic and associated rocks of Mansehra area, NW Himalaya, Pakistan. Acta Geod Geophys 50, 307–319 (2015). https://doi.org/10.1007/s40328-014-0087-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40328-014-0087-z