Abstract

Low carbon bainitic steel derives the high strength mainly from high density of dislocations rather than carbon and alloy element content, so it tends to evolve into equilibrium microstructure with low density of dislocations under thermal disturbance. In the present investigation, granular bainite and lath-like bainitic ferrite were produced respectively in Mo-free low-carbon steels by changing cooling rate. It has been found that granular bainite possesses a lower strength at room temperature than bainitic ferrite, but it exhibits a slower decrease of strength with temperature increasing. Dislocation density in both granular bainite and bainitic ferrite decreases via recovery and recrystallization at high temperature. However, when reheating of bainite is carried out at temperature below 600 °C, a long time will be needed for incubation of recrystallization, during which the hardness of bainite maintains stable. The property makes bainite, especially granular bainite, become a potential microstructure for matrix of high strength fire-resistant steel.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Strengthening of fire-resistant steel mainly relies on precipitation of molybdenum carbides [1–4], and little attention was put on the microstructures of steel matrix. The microstructures in current fire-resistant steel are mainly ferrite and pearlite, which do not possess high strength. It is natural to conceive that if ferrite in fire-resistant steel is replaced by bainite, combined strengthening effect of precipitates and microstructures will be achieved. As secondary microstructure, bainite does occur in some modern fire-resistant steel, though strengthening mechanism of bainite at high temperature is not clear yet [5–7]. A main problem for utilization of bainite in fire-resistant steel is the thermal stability of it. Bainite derives its high strength mainly from high density of dislocations, which means it is metastable microstructure. The high density of dislocations in bainite comes from bainitic transformation, which results in effective strengthening at room temperature [8, 9]. The strengthening effect will reduce with increased temperature due to possible recovery and recrystallization [10].

Granular bainite and lath-like bainitic ferrite are two types of main microstructures with obviously distinct mechanical properties in low carbon bainitic steel [11, 12]. So far, there has ever been lacking investigation on respective behaviors of granular bainite and bainitic ferrite at high service temperature.

The yield strength of common low alloy steel at 600 °C is obviously lower than half of that at room temperature [13], while fire-resistant steel can maintain more than 2/3 of its room temperature yield strength at 600 °C for 3 h [14–16].

Compared to bainitic steel with higher carbon content, bainitic transformation occurs at higher temperature in low carbon steel, which means more stable microstructures formed in the steel. Thus, it is possible to achieve the stability to meet the need of fire-resistant steel. The present investigation aims to explore evolution of microstructures in low carbon bainitic steel held at high temperature and evaluate their stability.

2 Experimental

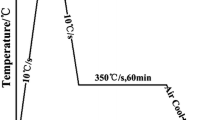

The experimental steel was melted in a vacuum induction furnace. The chemical composition (in wt%) is 0.060 C, 0.33 Si, 1.51 Mn, 0.052 Nb, 0.0019 B, 0.025 Ti with the balance of Fe. After forging and rolling, the steel was reheated up to 1,000 °C and held for 30 min and then quenched into oil to form bainite. Two oils with different cooling rates were used, based on continuous cooling transformation (CCT) curve determined with a Baehr DIL805A thermal dilatometer. Metallographic and SEM examinations were carried out on polished samples etched with 4 vol% Nital using Olympus BX51M microscope and ZEISS Ultra 55 transmission scanning electron microscopy. Bainite forming at different cooling rates was also contrasted with instrumented Charpy V-notch pendulum impact tests according to GB/T 19748-2005. The dimension of specimen is 55 mm × 10 mm × 5 mm.

To investigate the variation of strength of bainite with temperature, tensile tests at room temperature and high temperature were carried out according to GB/T 228.1-2010 and GB/T 4338-2006, and proof strength R p0.2 was used to evaluate strength. By calculating the ratios of R p0.2 at high temperature and room temperature, thermal stability of strength was evaluated. Using polygonal ferrite in samples with same chemical compositions as a reference, strengthening effect of bainitic transformation can be calculated approximately by subtracting strength of polygonal ferrite from strength of bainite. The relation between strengthening effect of bainitic transformation and temperature was analyzed. In addition, to investigate variation of strength of bainite with holding time at high temperature, high-temperature tensile tests were carried out after the samples had been isothermally treated for different times.

Strength variation results from microstructure evolution. Recovery of bainite was investigated using a Hitachi H8100 TEM with film samples. Recrystallization of bainite was investigated by corresponding hardness variation.

3 Results and Discussion

3.1 Microstructures and Mechanical Properties

CCT curves of the experimental steel are shown in Fig. 1. After austenitizing at 1,000 °C, bainite transformation in the experimental steel occurs in a wide cooling rate range of 5–80 °C/s. A little amount of quasi-polygonal ferrite can be found in the samples cooled at rate lower than 20 °C/s. With increasing of cooling rate, B s temperature (temperature of bainite transformation starting) (about 600 °C) changes slightly, whereas B f temperature (temperature of bainite transformation complete) decreases obviously. Proportion of bainitic ferrite to granular bainite, as well as hardness of the samples transformation products, increases with the increasing of cooling rate.

According to the CCT curves, two types of samples are prepared by using two different quench oils. Granular bainite (GB) steel, prepared with an average cooling rate between 20 and 30 °C, consists of chiefly granular bainite (see in Fig. 2a) and its hardness is 215 HV, which is characterized by M/A islands (see Fig. 2b). Bainite ferrite (BF) steel, prepared with an average cooling rate about 60 °C, consists of chiefly bainitic ferrite (see Fig. 2c) and its hardness is 280 HV, which is characterized by lath-like substructure (see in Fig. 2d).

Figure 3 shows the results of instrumented Charpy V-notch pendulum impact tests (GB/T 19748-2005) of GB-steel and BF-steel at room temperature. It is found that both GB and BF-steels exhibit stable crack extension and excellent toughness. GB-steel exhibits higher total impact energy while BF-steel possesses higher maximum force, which shows that granular bainite has higher toughness and bainitic ferrite has higher strength.

3.2 Variation of Strength of Bainite

As a reference to bainite, another sample named PF-steel consisting of polygonal ferrite (PF) (Fig. 4) is prepared by reheating BF-steel to 600 °C and holding for 192 h. Change in proof strength R p0.2 of GB-steel, BF-steel as well as PF-steel with temperature is shown in Fig. 5a. Room temperature strengths of PF-steel, GB-steel, and BF-steel are 315, 535, and 780 MPa, respectively. With temperature increasing, strength of PF-steel decreases approximately linearly, whereas strengths of GB-steel and BF-steel decrease slowly below 300 °C but fast above 400 °C. BF-steel exhibits a faster decrease of strength than GB-steel does above 400 °C. As shown in Fig. 5b, bainitic ferrite preserves 1/2 and 1/3 of the room temperature strength at 500 and 600 °C, respectively, whereas granular bainite preserves 2/3 and 1/2 of the room temperature strength at 500 and 600 °C, respectively. Strengthening effect of bainitic transformation can be calculated approximately by subtracting the strength of PF-steel from the strength of GB-steel or BF-steel, as shown in Fig. 5c. It is found that remained strengthening effect of BF-steel at 600 °C has a value about 150 MPa, while the value of GB-steel is a little higher. It can be seen from Fig. 5b that the strength of PF-steel decreases faster than that of bainite steel with increasing temperature even though its strength at room is the lowest.

Variations in the strength of experimental steels with temperature and holding time: a proof strength R p0.2 with temperature; b ratio of R p0.2 at high temperature to R p0.2 at room temperature with temperature; c remained strengthening effect of bainitic transformation with temperature; d R p0.2 with holding time during isothermal holding at 600 °C

The strength of bainite varies according to holding time at high temperature, as shown in Fig. 5d. During isothermal holding at 600 °C, the strength of GB-steel remains stable, while the strength of BF-steel decreases markedly after 48 h. The result indicates that granular bainite possesses a higher thermal stability of strength than bainitic ferrite does.

3.3 Evolution of Bainite Microstructure

Figure 6 shows the TEM images which denote microstructures of granular bainite and bainitic ferrite. Both granular bainite and bainitic ferrite consist of lath-like substructures divided by low angle grain boundaries, while high density of dislocations occurs inside the laths. However, laths in granular bainite are irregular whereas laths in bainitic ferrite are straight and show high aspect ratio.

Figure 7 shows recovery inside laths in BF-steel with holding time at 600 °C. Before reheating, dislocations inside laths distribute randomly (Fig. 7a). After holding at 600 °C for 1 h, dislocations tend to rearrange as cell-like structures (Fig. 7b). After holding at 600 °C for 12 h, dislocation nets (Fig. 7c) and regular dislocation walls (Fig. 7d) can be observed. Besides recovery of dislocations inside laths, low angle grain boundaries between laths are also found to evolve at high temperature. As shown in Fig. 8, lath boundaries disappear partially and shape of lath becomes irregular after holding at 600 °C for 6 h, which show that straight boundaries between laths in BF-steel tend to contract.

Recrystallization of bainite occurs after holding at high temperature for a long time. Granular bainite has been found to have a much longer incubation period of recrystallization than bainitic ferrite does. As shown in Fig. 9, granular bainite is still in recovery stage after holding at 600 °C for 48 h (Fig. 9a), in which morphology details have been reduced considerably due to decomposition of M/A, but boundaries have not migrated. However, new recrystallized grains have been observed in bainitic ferrite after holding at 600 °C for 48 h (Fig. 9b).

3.4 Evolution Kinetics of Bainite

After isothermally held for different times at high temperature, BF-steels were cooled to room temperature to measure their hardness. Hardness variations of BF-steel during isothermal holding at 600 and 650 °C are shown in Fig. 10, by which evolution kinetics of bainite can be analyzed. Logarithmic time was selected as horizontal coordinate since recovery progresses linearly with logarithmic time in general. At 600 °C, hardness of BF-steel drops twice. The first hardness drop finishes within 1 h, and accounts for about 1/3 of the total hardness decline. The second hardness drop progresses during 8–256 h, and accounts for about 2/3 of the total amount. Between the two drops, there is a stable stage of hardness. At 650 °C, hardness of bainite drops twice too, but the stable stage shortens and the second drop accelerates. Hardness variation derives from microstructure evolution. Figure 11 shows the course of recovery and recrystallization of bainite during holding at 600 °C. After held for 15 min (Fig. 11a), morphology details of bainite have been reduced to some extent due to decomposition of M/A. After held for 16 h (Fig. 11b), morphology details of bainite have been reduced further but boundaries have not migrated yet, which shows that bainite is still in recovery. After held for 64 h (Fig. 11c), recrystallization has happened, and a part of bainite has evolved into polygonal ferrite. After 192 h (Fig. 11d), all bainite has evolved into polygonal ferrite. By contrasting hardness variation and microstructure evolution, it is concluded that the first hardness drop results from recovery and the second hardness drop results from recrystallization. Artificially, 1/10 of the second hardness drop is regarded as starting of recrystallization. Then it is determined in Fig. 10 that recrystallization starts at 24.5 h at 600 °C and 21.1 h at 650 °C, in which linear simulation is carried out with the following equation :

where t 1 and t 2 are incubation times for recrystallization at holding temperatures T 1 = 873 K and T 2 = 923 K, respectively, while R is gas constant and Q denotes activation energy of recrystallization. Using Eq. (1), activation energy Q of recrystallization is calculated to be 316 J/mol.

3.5 Discussion

Bainitic transformation of low carbon bainitic steel occurs in a wide range of cooling rate, as a result of low carbon content and addition of Nb and B [17, 18]. In low carbon steels, granular bainite and bainitic ferrite are two main types of bainite. Granular bainite has a higher transformation temperature than bainitic ferrite does. Consequently, granular bainite has a smaller deviation from equilibrium state and a lower driving force of recovery, which makes strength of granular bainite decreases more slowly at high temperature. In the present investigation, strength of bainitic ferrite at 600 °C drops to 1/3 of that at room temperature, while strength of granular bainite at 600 °C retains 1/2 of that at room temperature.

It can be seen from Fig. 5 that granular bainite not only possesses obviously higher strength than ferrite at high temperature, but also exhibits obviously higher ratio of high temperature strength to room temperature strength. The result indicates that ferrite, as equilibrium microstructure, might not be advantageous as matrix microstructure of fire-resistant steel, due to too low resistance to motion of dislocations.

Strength of bainite keeps stable for a long time at high temperature, which is attributed to high thermal stability. After recovery of bainite, there is a long incubation period of recrystallization, during which boundaries do not migrate and dislocations reserve in forms of dislocation cells and lath boundaries. Possibly owed to more stable configuration of lath boundaries, granular bainite shows higher thermal stability.

Even though for less stable bainitic ferrite, recrystallization activation energy of 316 kJ/mol is still much higher than that of cold-rolled pure iron [19], this means that the dislocation substrate in bainite possesses high thermal stability. It is expected that bainite, especially granular bainite, is possible to become main microstructure of high strength fire-resistant steels.

4 Conclusions

Both granular bainite and bainitic ferrite evolve via recovery and recrystallization at high temperature. After recovery of bainite, there is a long incubation period of recrystallization, during which boundaries do not migrate and dislocations reserve in forms of dislocation cells and lath boundaries, while strength of bainite maintains stable. Softening of bainite mainly results from recrystallization, and bainite possesses high activation energy of recrystallization. Granular bainite possesses a lower strength at room temperature than bainitic ferrite, but it exhibits a slower decrease of strength with temperature increasing.

References

W. Sha, F.S. Kelly, Mater. Sci. Technol. Lond. 20, 449 (2004)

W. Sha, B.R. Kirby, F.S. Kelly, Mater. Trans. 42, 1913 (2001)

K. Miyata, Y. Sawaragi, ISIJ Int. 41, 281 (2001)

W.B. Lee, S.G. Hong, C.G. Park, S.H. Park, Metall. Mater. Trans. A 33, 1689 (2002)

Y. Mizutani, K. Ishibashi, K. Yoshii, Y. Watanabe, R. Chijiiwa, Y. Yoshida, Nippon Steel Technol. Rep. 90, 45 (2004)

R.C. Wan, F. Sun, L.T. Zhang, A.D. Shan, Mater. Des. 35, 335 (2012)

J.H. Kong, L. Zhen, B. Guo, P.H. Li, A.H. Wang, C.S. Xie, Mater. Des. 25, 723 (2004)

H.K.D.H. Bhadeshia, Bainite in Steels, 2nd edn. (IOM Communications Ltd, London, 2001), p. 201

C.L. Qiu, L.Y. Lan, D.W. Zhao, X.H. Gao, L.X. Du, Acta Metall. Sin. (Engl. Lett.) 26, 49 (2013)

S.W. Yang, H.B. Wu, S.Q. Yuan, C.J. Shang, X.M. Wang, X.L. He, Mater. Sci. Forum 475–479, 125 (2005)

G. Krauss, S.W. Thompson, ISIJ Int. 35, 937 (1995)

H.F. Lan, L.X. Du, N. Zhou, X.H. Liu, Acta Metall. Sin. (Engl. Lett.) 27, 19 (2014)

M. Fushimi, H. Chikaraishi, K. Keira, Nippon Steel Technol. Rep. 66, 29 (1995)

R. Chijiiwa, Y. Yoshida, R. Uemori, H. Tamehiro, K. Funato, Y. Horii, Nippon Steel Technol. Rep. 58, 47 (1993)

R.C. Wan, F. Sun, L.T. Zhang, A.D. Shan, Mater. Des. 36, 227 (2012)

K.C. Yang, H.H. Lee, O. Chan, J. Constr. Steel Res. 62, 544 (2006)

K.Y. Zhu, C. Oberbillig, C. Musik, D. Loison, T. Lung, Mater. Sci. Eng., A 528, 4222 (2011)

Y.T. Zhao, C.J. Shang, S.W. Yang, X.M. Wang, X.L. He, Mater. Sci. Eng. A 433, 169 (2006)

F. Scholz, E. Woldt, J. Therm. Anal. Calorim. 64, 895 (2004)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://springerlink.bibliotecabuap.elogim.com/journal/40195

Rights and permissions

About this article

Cite this article

Sun, C., Yang, S. & Liu, G. Evolution of Microstructures of a Low Carbon Bainitic Steel Held at High Service Temperature. Acta Metall. Sin. (Engl. Lett.) 27, 436–443 (2014). https://doi.org/10.1007/s40195-014-0078-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-014-0078-7