Abstract

To determine the parameters of the double-ellipsoidal heat source model (DEHSM) in welding simulations, a technique is developed to extract the parameters of weld pool shape from the simulation results. The technique is developed based on the knowledge of the isoparametric transformation and computer graphics, and its validity is verified by a graphic comparison. It is shown that the technique can effectively extract and reflect the shape of weld pools without interrupting the solution process of the DEHSM parameters. Second, using this technique in conjunction with the optimization method, an approach is proposed to determine the DEHSM parameters. Next, using the proposed method, the DEHSM parameters associated with four different welding conditions are determined. Finally, with these parameters, their corresponding weld widths and penetrations are compared with the measured ones. The results demonstrate that the proposed method can efficiently determine the DEHSM parameters with a relatively high accuracy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

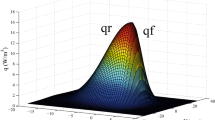

The double-ellipsoidal heat source model (DEHSM) [1], expressed by Eq. (1), utilizes two ellipsoidal heat sources (Fig. 1) to reflect the characteristics of steep and gentle welding temperature gradients in the front and rear of the heat source, respectively. The influence of arc stiffness on the penetration depth can also be considered by introducing a new parameter c. Thus, the DEHSM is especially applicable for the welding processes with large penetration depths, such as the groove welding and fillet welding.

where qf and qr [W/m3] are the power density distributions inside the front and rear ellipsoids, respectively. Q represents the effective heat power [W], and Q = ηUI. Here, η, U, and I represent the efficiency, welding voltage [V], and current [A], respectively; af, ar, b, and c represent geometric parameters of the front and rear ellipsoids [m]; x, y, and z are the local coordinates of the DEHSM [m]; and f1 and f2 denote the fractions of the heat power deposited in the front and rear half ellipsoids, respectively, and satisfying f1 + f2 = 2.

The DEHSM has been extensively used in numerical simulations of welding, such as gas shielded arc welding, submerged-arc welding, and electron beam welding. However, the determination of precise values of the DEHSM parameters is crucial for the simulation results of welding temperature [2], and it is also a prerequisite for obtaining precise simulation results of the welding residual stresses and distortions [3].

The procedure for determining the values of parameters of a welding heat source model (WHSM) commonly involves two aspects: (i) criteria for judging whether the values of the parameters are accurate, and (ii) a method for determining those values according to the criteria. In general, the criteria for verifying the values of the WHSM parameters can be classified into three categories: welding temperature, welding residual stress, and weld pool shape, as follows:

-

1.

Determination of WHSM parameters according to the welding temperature [4,5,6,7]. This approach aims at making the simulated welding temperatures to be consistent with the measured ones. In this way, the welding temperature can be directly associated with the WHSM parameters. However, because of the significantly high temperature in the weld pool, the thermocouples must only be installed at a location away from the weld itself, where the welding temperatures are significantly high and the welding residual stresses are the most concerned.

-

2.

Determination of WHSM parameters according to the welding residual stress [8]. According to this criterion, the simulated welding residual stresses are required to be in agreement with the measured ones. However, this method is seldom used because the lengthy computational time needed for simulating the welding residual stresses.

-

3.

Determination of WHSM parameters of according to the weld pool shapes [9,10,11,12,13]. By this criterion, the WHSM parameters are adjusted repeatedly until the calculated weld pool shape is approximately identical to the actual one. This criterion is the widely used standard to verify the values of the WHSM parameters owing to its high accuracy and efficiency. Therefore, in this study, this criterion is also employed to determine the DEHSM parameters.

According to the criteria above, the methods for determining the WHSM parameters can be generally divided into three categories: trial and error, regression analysis, and intelligent computing.

The trial and error method [6, 14, 15] determines the WHSM parameters through experience. Therefore, its efficiency and accuracy are heavily dependent on experience, which may result in extensive tentative calculations and lengthy computation time.

The regression analysis method generally consists of two steps [9, 10, 14,15,16]. In the first step, several samples of WHSM parameters are calculated with regard to weld pool shapes. Then, a regression analysis method is used to establish an explicit expression of those parameters about the shape parameters of weld pool. When the explicit expression is obtained, the WHSM parameters can be directly calculated with the weld pool shape parameters.

To date, several studies have been conducted to determine the WHSM parameters by using a regression analysis method. Wang et al. [13] assumed that the DEHSM was made up of several point heat sources, and calculated the distribution of welding temperature by using a theoretical formula proposed by Rosenthal [16]. Subsequently, the authors established an expression of the DEHSM parameters with respect to weld width (W) and penetration (D). However, the prediction error of their expression can reach up to 30%; thus, further improvement may be necessary for obtaining more accurate results. Li and Lu [11] established an expression of the DEHSM parameters with respect to W and D for submerged-arc welding. After that, Guo et al. [12] carried out a similar study for CO2-gas shielded welding. Rouquette et al. [17] performed a nonlinear least square analysis to predict the parameters of a Gauss heat source model for electron beam welding. Jia et al. [18] investigated the effects of the DEHSM parameters on W, D, and the maximum welding temperature (Tp). Subsequently, the multiple regression and partial least squares regression method were both used to establish the expressions of the DEHSM parameters with respect to the weld pool shape parameters.

Using the regression analysis method, when the parameters of a weld pool are known, the WHSM parameters can be easily obtained with the regression expression. However, for a given regression expression, it is only applicable for a specific weld joint which is deposited by a specific welding process. If the welding process or dimensions of weldment change, a series of parametric analyses is required again for deriving a new regression expression. For example, the formula established by Li and Lu [11] can only be suitable for the butt joint with a dimension of 600 mm × 300 mm × 22 mm and deposited under the welding condition of 1000 A and 32 V. Certainly, more parameters can be introduced into the regression formulas to solve this problem, such as geometric parameters and welding process parameters. Nonetheless, this will also greatly raise the number of the parametric analyses and increase the complexity of the regression formulas.

To overcome the limitation of the regression analysis method, Li and Lu [19] employed intelligent computing techniques, i.e., the artificial neural network and support vector machine [19], to predict the DEHSM parameters without the limitations of the welding processes. However, this method has two shortcomings as follows.

-

1.

A large number of samples of various welding process parameters with regard to W and D are required. In a previous study [19], 18 measurements were performed to obtain the samples of W and D under different values of welding voltage (U) and current (I); however, the measurements of the W and D require complex processes, such as grinding, polishing, and acid etching.

-

2.

In general, this approach can only be used for the weldments with specific dimensions. For example, all 18 samples of W and D used in the previous study [19] were obtained from one type of weldment, and all the weldments had a specific dimension of 600 mm × 300 mm × 16 mm; therefore, the intelligent computing techniques based on these samples are only applicable for the welded joints with the same dimension. For taking into consideration the weldment dimensions, more measurements of W and D versus various welding processes are required.

To address the above-mentioned problems, an approach based on optimization methods was developed in this study to determine the DEHSM parameters. In the proposed method, neither extensive parametric analyses nor large amount of samples of W and D were required. Moreover, when the W and D of a weld joint are known, the DEHSM parameters can be determined automatically by the proposed method, without the limitations of weld dimensions and welding conditions.

2 Numerical simulation of welding temperature

2.1 Parametric modeling of butt joint

Taking the butt joint shown in Fig. 2 as an example, for its finite element model to be suitable for different welding conditions, the butt joint was modeled parametrically with the ANSYS parametric design language. The ANSYS parametric design language is a scripting language very similar to FORTAN but can only be compiled in ANSYS. The butt weld was modeled with first-order hexahedral elements (SOLID70). For the radiative and convective boundary conditions to be defined effectively, a layer of surface effect element (SURF152) was overlaid on the surface of the finite element model.

A grid convergence study was performed and demonstrated that relatively fine meshes were required through the thickness of the plate in or adjacent to the weld. For the 16-mm-thick plate used, 16 layers of elements were required through thickness to achieve a relatively accurate result of welding temperature in the weld areas. The size of elements located in these areas is less than 1 mm × 1 mm × 4 mm. In the areas away from the weld, the welding temperature gradient is significantly smaller. Therefore, coarse meshes, with sizes greater than 4 mm, were adopt to reduce the numbers of degrees of freedoms. The element size used in the longitudinal direction of the specimen is 4 mm. All the meshes are defined as first-order hexahedral elements, and every element has a single degree of freedom, temperature, at each node.

2.2 Governing equation and boundary conditions

The governing equation for transient heat transfer analysis is given by:

where k is the temperature-dependent thermal conductivity [W/(m °C)], T is the temperature [°C], q is the internal heat generation rate [W/m3], ρ is the density [kg/m3], c is the specific heat [J/(kg °C)], t is the time, x, y, and z are the coordinates [m] in the reference system, and ∇ is the spatial gradient operator.

The general solution of temperature distribution is obtained by applying the following initial and boundary conditions:

where T0 is the initial temperature and assumed to be 25 °C.

where Nx, Ny, and Nz are the direction cosines of the outward drawn normal to the boundary, hc and hr are the convection radiation heat transfer coefficient [W/(m2 °C)], respectively. Ta is the ambient temperature and assumed to be 25 °C. qs is the boundary heat flux, here qs = 0. The radiation heat transfer coefficient is expressed as:

where σ is the Stefan-Boltzmann constant, ε is the effective emissivity.

Radiation losses are dominating for higher temperatures in the weld zones, while convection losses for lower temperatures away from the weld [20]. Therefore, a comprehensive heat transfer coefficient h was used to take into account both of convection and radiation:

Substituting Eq. (6) and qs = 0 to Eq. (4), the boundary condition can be rewritten as follows:

where h is temperature dependent and is given by Eq. (8) [21].

The comprehensive heat transfer coefficient h and other temperature-dependent material properties used in the simulation of welding temperature are illustrated in Fig. 3. In addition, the heat transfer due to fluid flow in the weld pool was taken into account by an artificial increase in thermal conductivity above the melting temperature. The latent heat of fusion was assumed to be 270 J/g between the solidus temperature of (1440 °C) and the liquidus temperature (1500 °C).

3 Determining the DEHSM parameters based on ANSYS optimizer tool

3.1 General description of ANSYS optimizer tool

ANSYS optimizer tool has been widely used to deal with the optimization problems in engineering, such as the topological optimization [22], optimum cross section of cantilever beams [23], and optimum initial configuration of grid structures [24]. As long as the optimization problems are modeled mathematically with appropriate variables and constraint conditions, the majority of optimization problems in engineering can be usually solved by the ANSYS optimizer tool. Therefore, the ANSYS optimizer tool was employed in this study to determine the DEHSM parameters. Therefore, the ANSYS optimizer tool was employed in this study to determine the DEHSM parameters.

The optimization variables and constraint conditions required by the ANSYS optimizer tool are defined with the design variables, state variables, and the objective function. The design variables are independent variables, which vary between their upper and lower bounds. The state variables are dependent variables, which change with the design variables to constrain the design requirements. The objective function is also a dependent variable that needs to be minimized. In summary, during the optimization process, the design variables will be adjusted automatically using optimization algorithms to minimize the objective function, under the constraints that the state variables are not greater than their limits. The designs variables, state variables, and objective function used to determinate the DEHSM parameters are detailed as follows:

-

1.

Design variables. For a given welding process, there are three parameters of the DEHSM that are known: the welding voltage U, current I, and efficiency η. However, there are six parameters needed to be solved: four geometric parameters (ar, af, b, c) and two fractions parameters (f1, f2). Of these six parameters, ar and af have little influence on weld widths and penetrations, while the influences of b, c, f1, and f2 are great [11]. Considering that there is only one independent parameter in f1 and f2 owing to f1 + f2 = 2, thus three parameters, i.e., b, c, and f1, were defined to be the design variables. Simultaneously, the other two parameters, ar and af, were assumed to be a half and double of the measured weld width (Wm), respectively: ar = 1/2Wm, af = 2Wm [1]. The initial values of b and c (described as b0 and c0, respectively) were assigned to be the measured weld width (Wm) and penetration (Dm), that is b0 = Wm and c0 = Dm. Because b and c are separately and closely related to the weld width and penetration (see Fig. 1), the intervals of b and c were assumed to be [0.8Wm, 1.2Wm] and [0.8Dm, 1.2Dm], respectively. The initial value of f1 was assumed as 0.6, and it can take values in the interval of [0.4, 0.7].

-

2.

State variable. The peak value of welding temperature Tp has a significant influence on the welding simulation results. A previous study [11] also took Tp as a criterion to verify the WHSM parameters. Therefore, in this study, Tp was chosen to be the state variable, and it must not exceed its upper bound. However, until now very few reports on the peak temperature in a weld pool have been published, except for a reference value of about 3000 °C provided by Radaj [25]. Therefore, the upper bound of Tp was assumed to be 3000 °C in the optimization process.

-

3.

Objective function. In optimization analyses, the objective function is the variable that needs to be minimized. Therefore, the deviation between the measured and calculated weld pool shapes was defined as the objective function, as expressed in Eq. (9). In this case, the smaller the objective function is, the more similar the simulated weld pool is to the measured one.

where OBJ represents the objective function; Wc and Wm are the calculated and measured weld widths, respectively, and Dc and Dm represent the calculated and measured penetrations, respectively.

The Wc and Dc used to calculate OBJ and the state variable Tp are all extracted from the welding simulation results. However, it is necessary for the ANSYS optimizer tool to update the related parameters automatically, without interrupting its solution processes. In this case, the relevant parameters (Wc, Dc, and Tp) must be extracted automatically through a certain routine. Thus, the DEHSM parameters can be solved programmatically.

Of these three variables Wc, Dc, and Tp, the extraction of Tp from the simulation results is relatively simple and easy because it can be directly obtained from the nodal temperatures. However, the extractions of Wc and Dc are more complex and difficult, because their extracting procedure generally involves knowledge of the finite element method and computer graphics. For this issue, this paper presents a technique for extracting Wc and Dc by using a subroutine written in the ANSYS parametric design language. This technique will be described in the next section.

When all the steps mentioned above are completed, the optimization analysis can be executed using the command “OPEXE.” In this case, the design variables (b, c, and f1) will be adjusted automatically under the condition that the state variable (Tp) does not exceed its upper bound, and the objective function (OBJ) will be minimized until it is less than a given allowable tolerance (e). Here, e was assumed to be 1 mm. When OBJ < e, it indicates that the optimization process has converged. At this point, the b, c, and f1 obtained will be the most accurate parameters of the DEHSM. The whole solution processes of b, c, and f1 are implemented by optimization algorithms embedded in the ANSYS optimizer tool. The first-order optimization algorithm was used in this study, which has been elaborated by Beck [26]; the reader who wishes learn more could consult this report.

3.2 Extraction of the weld pool shape from simulation results

The extraction of the weld pool shape from the simulation results was indispensable for these approaches that determine WHSM parameters according to weld pool shapes. For this issue, Li [27] extracted Wc and Dc by using linear interpolation between two adjacent nodal temperatures. However, the interpolation function used was not linear, even if the finite element model was created with first-order hexahedral elements because the second- and third-order items exist in the interpolation function. As a result, the finite element model has to be meshed sufficiently fine, so that an accurate result can be achieved. Consequently, it will lead to a large finite element model and lengthy computation time.

For this problem mentioned above to be solved and for the parameters of weld shapes to be extracted automatically, a technique was developed in this study based on the knowledge of isoparametric transformation and computer graphics, which will be described in the paragraphs that follow.

Linear hexahedral elements with eight nodes, as shown in Fig. 4, were commonly used in the simulation of welding temperature, and their shape functions can be defined by Eqs. (10) and (11).

where ξi, ηi, and ζi denote the coordinates of node i in a natural coordinate system.

Supposing that the temperature of each node in the element shown in Fig. 4 is known, and for a node i, its temperature is denoted by Ti (i = 1, 2, …, 8), then the temperature at any point within the element can be obtained by using the shape function, as expressed as follows:

Considering that Dc and Wc have to be extracted on a cross section of a weld bead, then a layer of elements around the bead was isolated for further investigation, as shown in Fig. 5, where the shaded area represents the section to extract Dc and Wc. It is noteworthy that the shaded area should contain the node that has the peak value of temperature; otherwise, Dc and Wc will be inclined to the small side.

On the shaded area shown in Fig. 5, the ζ equals unity (ζ = 1). Thus, substituting ζ = 1 into Eq. (10) yields Eq. (13).

Subsequently, substituting Eq. (13) into Eq. (12) gives Eq. (14).

There is not any ζ-related item on the left side of the equal sign in Eq. (9), because ς ≡ 1 in the shaded area. Simultaneously, all ζ-related items on the right side of the equal sign are equal to zero. This is analogous to the situation in which a three-dimensional hexahedron element was simplified into a two-dimensional quadrilateral element.

Let T(ξ, η) in Eq. (14) be the material melting point Tm; then, the expression of the boundary curve of a weld pool can be obtained, as described in Eq. (15).

Upon expanding and rewriting Eq. (15), the expression of the boundary curve of a weld pool can be simplified as follows:

where

It is worth noting that the boundary of the weld pool described in Eq. (16) was established in a normalized coordinate system based on a regularly shaped element. However, Dc and Wc should be extracted in a global coordinate system for any arbitrarily shaped element. Therefore, the boundary of a weld pool expressed by Eq. (16) should be converted to a form that is applicable for arbitrarily shaped elements in the global coordinate system. This will be achieved using an isoparametric transformation which is elaborated as follows.

Figure 6 shows a diagram of the isoparametric transformation for a quadrilateral element, where the x-axis is perpendicular to the direction of welding, towards the weld toe, and in accordance with the Y-axis shown in Fig. 5. The y-axis is in accordance with the Z-axis shown in Fig. 5 and towards the weld root.

The normalized coordinates can be transformed into global coordinates using the following equations.

where xi and yi are the node coordinates in the global coordinate system.

On rearranging and expanding Eq. (18), it can be simplified as follows.

where

From Eqs. (19) and (20), it can be observed that both two expressions have the second-order item ξη. Thus, an explicit expression of the boundary of a weld pool as Eq. (16) cannot be obtained after the isoparametric transformation. Consequently, in the global coordinate system, it is not possible to calculate the Dc and Wc by the approach of solving extreme values with a partial derivative. For this issue, a series of characteristic points \( \left({\xi}_i^{\prime },{\eta}_i^{\prime}\right) \) were selected from the boundary described by Eq. (16) to represent the weld pool shape. After obtaining the coordinates of these characteristic points, Eqs. (19) and (20) were used to transform them into the global coordinate system. In this case, \( \left({\xi}_i^{\prime },{\eta}_i^{\prime}\right) \) will be transformed into \( \left({x}_i^{\prime },{y}_i^{\prime}\right) \). Finally, Dc and Wc can be obtained through the ranges of \( \left\{{x}_i^{\prime}\right\} \) and \( \left\{{y}_i^{\prime}\right\} \), respectively.

Based on the relevant theories mentioned above, the procedure for extracting Dc and Wc is summarized as follows.

-

1.

Extract information of elements.

A layer of elements in and adjacent to the weld bead was isolated and defined as a set of elements, which was denoted by E. Subsequently, for a given element in E, its element number and the first to the fourth node numbers were stored in the first to the fifth rows of ED, respectively. ED is an array parameter, which is N rows long and five columns wide; being N the total number of elements in E. For a given element i in E, its element number is stored in ED(i, 1) and its four node numbers are stored in ED(i, 2) to ED(i, 5), respectively.

-

2.

Extract node temperature.

For each element in E, the data stored in ED is used to extract its four node temperatures and assign them to TN × 4(i, 1) to TN × 4(i, 4). Here, T is an array parameter with a dimension of N times four.

-

3.

Judge whether the isotherm of T = Tm exists within an element in E.

For each element in E, the knowledge of computer graphics is used to judge whether there is an isotherm of T = Tm in a quadrilateral composed by its four nodes. The judging procedure commonly has two steps are as follows.

Assign a value to C(i, j) according to T(i, j). Here, C is a sign function, which is valued by Eq. (21).

where T represents the node temperature, Tm is the material melting point, i is the element number, and j denotes the j-th node in the element i.

For the element i, the sum of these four items of C(i, j) was denoted by Sum, as expressed in Eq. (22). When the temperature of each node in element j is greater than or less than Tm, the absolute value of Sum equals four, that is ∣Sum ∣ = 4. In this case, there is no isotherm of T = Tm in the element i, as shown in Fig. 7a. Otherwise, ∣Sum ∣ ≠ 4, in this case, there is an isotherm in the element i, as shown in Fig. 7b.

For each element in E, determine whether an isotherm of T = Tm exists according to these steps listed above. After this procedure is completed, define these elements with the isotherm of T = Tm as a new set of elements, which is denoted as E′.

-

4.

Extract the coordinates of characteristic points on the isotherm of T = Tm.

For each element in E′, a series of characteristic points in the isotherm of T = Tm were chosen to represent the weld pool shape. Assuming that the coordinates of characteristic points were described by \( \left({\xi}_{ik}^{\prime },{\eta}_{ik}^{\prime}\right) \) where the subscript i and k respectively denote the element number and characteristic point number, then \( \left({\xi}_{ik}^{\prime },{\eta}_{ik}^{\prime}\right) \) can be extracted by the following two steps.

The first step is to determine the intersection points (P1 and P2, see Fig. 8) of the isotherm and element boundary. For a given element i, substitute ξ = 1, ξ = − 1, η = 1, and η = − 1 into Eq. (16), then four points will be obtained, which are (1, ηi1), (− 1, ηi2), (ξi1, 1), and (ξi1, − 1). However, only two of them are located at the boundary of the element. The two points can be determined by a judgment criterion, based on whether ∣ηi1∣, ∣ηi2∣, ∣ξi1∣, and ∣ξi2∣ is less than one. If it is, the associated point is located at the element boundary; otherwise, it is outside of the boundary. Here, the intersection points were assumed to be P1 (ξi1, 1) and P2 (ξi1, − 1), as shown in Fig. 8b.

The second step is to calculate the coordinates of the characteristic points. Supposing that the characteristic points were located at an equal interval along the ξ- or η-axis, the coordinates of these characteristic points can be calculated according to Eq. (16). Specifically, first calculate the ξ-coordinates of these characteristic points based on Eq. (23), which are denoted by \( {\xi}_{ik}^{\prime } \). After obtaining \( {\xi}_{ik}^{\prime } \), substitute it into Eq. (16), the related η-coordinate will be obtained. Here, assume that the coordinate of the point k of the element i is \( \left({\xi}_{ik}^{\prime },{\eta}_{ik}^{\prime}\right) \).

where i represent the element number; K is the total number of characteristic points.

For each element in E′, calculate its coordinates of characteristic points using the above steps.

-

5.

Coordinate transformation. Substituting \( \left({\xi}_{ik}^{\prime },{\eta}_{ik}^{\prime}\right) \) into Eq. (19), the corresponding coordinates in the global coordinate system, denoted by \( \left({x}_{ik}^{\prime },{y}_{ik}^{\prime}\right) \), will be obtained.

-

6.

Calculated Wc and Dc. After obtaining \( \left({x}_{ik}^{\prime },{y}_{ik}^{\prime}\right) \) for all elements in E′, Dc and Wc can be obtained from the following equations.

A flow chart was designed to help understand the procedure for extracting Wc and Dc from the simulation results, as shown in Fig. 9.

To verify the approach described above for automatically extracting the weld pool from simulation results, the welding temperature of a butt weld was first simulated. Then, the weld pool shape was extracted using the proposed approach and compared with that displayed by the ANSYS postprocessor, as shown in Fig. 10. The curve on the right side in Fig. 10a is the weld pool boundary that was extracted and sketched based on 180 characteristic points.

From Fig. 10a, it can be observed that the extracted boundary of the weld pool is consistent with that displayed by the ANSYS postprocessor. For further comparison, the right part of Fig. 10a was mirrored along the center line and then moved slightly to the right side, as shown in Fig. 10b. From Fig. 10b, it is can be observed that the inflections and configurations of the two boundary curves are highly consistent.

In summary, from the comparisons shown in Fig. 10, it can be determined that the proposed approach can precisely extract the shape of weld pools from the simulation results without interrupting or stopping the solution process of the DEHSM parameters.

3.3 Verification of the proposed method for determining the DEHSM parameters

To verify the proposed method for determining the DEHSM parameters, four sets of Dm and Wm, measured by Li [27], were used to determine the DEHSM parameters using the proposed method, and the calculated results are summarized in Table 1. The Dm and Wm in Table 1 were measured from four butt joints with a dimension of 600 mm × 300 mm × 16 mm, and the butt joints were deposited by submerged-arc welding with a welding speed of 16.67 mm/s and a power coefficient of 0.9 [23].

From Table 1, it can be determined that the deviations between the measured and calculated Dm and Wm are all less than 1 mm, and the relative errors are not greater than 6%. This indicates that the proposed method can be efficiently used to determine the DEHSM parameters.

Figure 11 shows a visual comparison between the simulated and experimental weld pools. From Fig. 11, it can be observed that: (i) The simulated weld widths and penetrations are in good agreement with experimented ones; (ii) The experimental weld widths shrink rapidly at a small depth from the weld surface, while the simulated weld pools are generally in the shape of an ellipse. Consequently, the experimental weld pools appear more slender than the simulated ones. This suggests that the ellipsoid-shaped DEHSM probably cannot capture the characteristics of rapid shrinkage of the weld width in the case of submerged-arc welding.

3.4 Causes and countermeasures for the failures of the proposed method

It is worth noting that some failure may occur in the applications of the proposed method, such as problems when the object function OBJ exceeds a given tolerance, or that the state variable Tp exceeds its upper bound. For this issue, two possible causes and corresponding countermeasures will be discussed:

-

1.

The lower and upper bounds of the design variables were inappropriately defined. In the optimization analysis, the design variables (b, c, and f1) must vary in their domains to minimize the object function OBJ. However, it could happen that after traversing all the combinations of b, c, and f1 between their lower and upper bounds, there is still no combination of them that can make the OBJ be less than the given tolerance e. In this case, it will be judged by the ANSYS to be a situation of non-convergence. To overcome this issue, the bounds of b, c, and f shall be expanded, but c should not be larger than the thickness of the weldment.

-

2.

The constraint conditions used in the optimization process are too strict. If the tolerance of OBJ is so small that the optimization result can hardly be obtained. For example, if OBJ ≤ 0.1 mm, which means that the deviation of the measured and calculated D and W cannot be greater than 0.1 mm, then smaller element sizes (less than 0.2 mm) and additional computational time will be required. If the element sizes around the weld bead are less than 2 mm, it is advised that OBJ ≤ 1 mm, and a satisfying result will be obtained.

4 Conclusions

-

(1)

In this study, a method for determining the DEHSM parameters was proposed based on the ANSYS optimizer tool. A comparison of the simulated and experimental weld pool shapes demonstrates that the proposed method can efficiently determine the DEHSM parameters with a high accuracy. However, the effects of fluid flow on the weld pool shapes were not considered in the present study, therefore, the proposed method may be only valid for simulations that do not take the fluid flow into account.

-

(2)

In the optimization process of DEHSM parameters, too small range of design variables or too strict constraint conditions will result in the failure of the proposed method. In this case, expanding the limits of design variables or relaxing the constraint conditions may help to achieve an optimization results.

-

(3)

In the case of submerged-arc welding, although the weld width and penetration can be precisely simulated using the DEHSM, the ellipsoid-shaped DEHSM still cannot capture the characteristics of rapid shrinkage of the weld width. Therefore, it is necessary to develop a new heat source model that suitable for submerged-arc welding in future research.

References

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305. https://doi.org/10.1007/BF02667333

Mondal AK, Biswas P, Bag S (2017) Prediction of welding sequence induced thermal history and residual stresses and their effect on welding distortion. Weld World 61(4):711–721. https://doi.org/10.1007/s40194-017-0468-3

Gu Y, Li YD, Qiang B, Boko-Haya DD (2017) Welding distortion prediction based on local displacement in the weld plastic zone. Weld World 61(2):333–340. https://doi.org/10.1007/s40194-016-0418-5

Guo XK, Li PL, Chen JM, Lu H (2009) Inversing parameter values of double ellipsoid source model during multiple wires submerged arc welding by using Step Acceleration Method. Trans China Weld Inst 30(2):53–56+155. https://doi.org/10.3321/j.issn:0253-360X.2009.02.014

Guo XK (2009) Inversing parameter values of double ellipsoid source model during multiple wires submerged arc welding by using Pattern Search Method. Dissertation, Shanghai Jiaotong University

Gery D, Long H, Maropoulos P (2005) Effects of welding speed, energy input and heat source distribution on temperature variations in butt joint welding. J Mater Process Technol 167(2–3):393–401. https://doi.org/10.1016/j.jmatprotec.2005.06.018

Li PL, Lu H (2011) Influence of multi-wire submerged arc welding process on heat source parameters. Trans China Weld Inst 32(6):13–16+20

Price JWH, Paradowska A, Joshi S, Finlayson T (2006) Residual stresses measurement by neutron diffraction and theoretical estimation in a single weld bead. Int J Press Vessel Pip 83(5):381–387. https://doi.org/10.1016/j.ijpvp.2006.02.015

Joshi S, Hildebrand J, Aloraier AS, Rabczuk T (2013) Characterization of material properties and heat source parameters in welding simulation of two overlapping beads on a substrate plate. Comput Mater Sci 69:559–565. https://doi.org/10.1016/j.commatsci.2012.11.029

Azar AS, As SK, Akselsen OM (2012) Determination of welding heat source parameters from actual bead shape. Comput Mater Sci 54:176–182. https://doi.org/10.1016/j.commatsci.2011.10.025

Li PL, Lu H (2011) Sensitivity analysis and prediction of double ellipsoid heat source parameters. Trans China Weld Inst 31(11):89–91+95+117

Guo GF, Wang Y, Han T, Jia PY (2013) Application of double-ellipsoid heat source parameters adjustment on prediction of pool size of in-service welding. Pressure Vessel Technol 30(1):15–19+39. https://doi.org/10.3969/j.issn.1001-4837.2013.01.002

Wang Y, Zhao HY, Wu S, Zhang JQ (2003) Shape parameter determination of double ellipsoid heat source model in numerical simulation of high energy beam welding. Trans China Weld Inst 24(2):67–70+1. https://doi.org/10.3321/j.issn:0253-360X.2003.02.018

Sharma A, Chaudhary AK (2009) Estimation of heat source model parameters for twin-wire submerged arc welding. Int J Adv Manuf Technol 45(11–12):1096–1103. https://doi.org/10.1007/s00170-009-2046-3

Wahab MA, Painter MJ, Davies MH (1998) The prediction of the temperature distribution and weld pool geometry in the gas metal arc welding process. J Mater Process Technol 77(1–3):233–239. https://doi.org/10.1016/S0924-0136(97)00422-6

Rosenthal D (1941) Mathematical theory of heat distribution during welding and cutting. Weld J 20(5):220–234

Rouquette S, Guo J, Le Masson P (2007) Estimation of the parameters of a Gaussian heat source by the Levenberg–Marquardt method: application to the electron beam welding. Int J Therm Sci 46(2):128–138. https://doi.org/10.1016/j.ijthermalsci.2006.04.015

Jia X, Xu J, Liu Z, Huang S, Fan Y, Sun Z (2014) A new method to estimate heat source parameters in gas metal arc welding simulation process. Fusion Eng Des 89(1):40–48. https://doi.org/10.1016/j.fusengdes.2013.11.006

Li PL, Lu H (2012) Hybrid heat source model designing and parameter prediction on tandem submerged arc welding. Int J Adv Manuf Technol 62(5–8):577–585. https://doi.org/10.1007/s00170-011-3829-x

Deng D, Murakawa H (2006) Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput Mater Sci 37(3):269–277. https://doi.org/10.1016/j.commatsci.2005.07.007

Brickstad B, Josefson BL (1998) A parametric study of residual stresses in multi-pass butt-welded stainless steel pipes. Int J Press Vessel Pip 75(1):11–25. https://doi.org/10.1016/s0308-0161(97)00117-8

Zhang X, Xiong J, Hao X, Lai R (2008) Topological optimization of slide of machining center based on ANSYS. Manuf Technol Mach Tool (6):67–70. https://doi.org/10.3969/j.issn.1005-2402.2008.06.020

Yoo HH, Cho JE, Chung J (2006) Modal analysis and shape optimization of rotating cantilever beams. J Sound Vib 290(1–2):223–241. https://doi.org/10.1016/j.jsv.2005.03.014

Yuan B, Ren FM, Zhong GQ, Zhou J (2011) Optimal design of spatial grid structure using group search optimization. Adv Mater Res 243-249(2011):6044–6048. https://doi.org/10.4028/www.scientific.net/amr.243-249.6044

Radaj D (2012) Heat effects of welding: temperature field, residual stress, distortion. Springer Science & Business Media

Beck A (2017) First-order methods in optimization, vol 25. SIAM

Li PL (2012) Study on the simulation of multi-wire submerged arc welding heat source model and appearance of weld. Dissertation, Shanghai Jiaotong University

Funding

The authors gratefully acknowledge the support provided by the National Natural Science Foundation of China (Grant Nos. 51708467 and 51378430) and the Doctoral Found of Southwest University of Science and Technology (Grant No. 16zx7134).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XV - Design, Analysis, and Fabrication of Welded Structures

Rights and permissions

About this article

Cite this article

Gu, Y., Li, Y.D., Yong, Y. et al. Determination of parameters of double-ellipsoidal heat source model based on optimization method. Weld World 63, 365–376 (2019). https://doi.org/10.1007/s40194-018-00678-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-00678-w