Abstract

Cationic surfactant (CS) is one of the alarming emerging contaminants often found in municipal and industrial wastewater. Various research articles have already reported about the toxicity of CS. In the current research work, sustainable and green alginate (Ag) and alginate composite beads with xanthan gum (AgX) are explored for the adsorptive elimination of model CS, cetylpyridinium chloride (CPC) and cetyltrimethylammonium bromide (CTAB), from wastewater. The composite (AgX) beads showed relatively better performance than Ag beads in terms of mechanical strength and equilibrium time. Studies on FTIR spectra, SEM analysis, size distribution, pHzpc measurement, and elemental analyses were conducted in order to characterize the adsorbent and to get an insight into the adsorption phenomenon. At the end of 8 days’ equilibrium time, the maximum adsorptive retention capacity of the AgX beads was obtained as ~ 310 mg/g with an initial CPC concentration of 600 mg/L, using an adsorbent dose of 1.5 g/L. A layered isotherm with varying slopes was obtained, indicating different stages of CPC adsorption. CPC uptake by hydrogel beads was associated with significant shrinkage of the beads. Removal of CPC from real wastewater was possible with good efficiency. The effect of pH and interfering ions on CPC removal was examined. The results showed that the pH range of 5.5–6 was the optimum, and there was no interference from Co(II), Ni(II), and Mg(II) ions. The results showed good reproducibility with a relative standard deviation (RSD) < ± 10%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactants are defined as surface active agents consisting of a hydrophilic and a hydrophobic moiety. They are one of the most important ingredients often required in our modern life. Detergents, soaps, toothpaste, shampoos, floor cleaners, etc., are all composed of different types of surfactants. It is one of the inevitable items of cosmetic and personal care products (Bezerra et al. 2018). They have wide applications in food industries for the stabilization of emulsions (Kralova and Sjoblom 2009). Due to the unique structure of the surfactant molecules, they are often adopted by industries for cleaning purposes (Collivignarelli et al. 2019). Hence, its importance is immense in domestic as well as in industrial activities. Surfactants are commonly classified as anionic surfactants (AS), cationic surfactants (CS), non-ionic and zwitterionic surfactants depending on the charge carried by them. Anionic surfactants are widely used for manufacturing detergents and soaps. On the other hand, CS is widely used in the preparation of shampoos (Chattaraj and Das 1992), cosmetics (Oztekin and Erim 2005), fabric softeners (Biswas and Pal 2020a), etc.

Although surfactants find different important applications, it is a severe environmental pollutant. After different industrial activities, when the wastewater containing surfactants in high concentration is discharged, it poses a severe environmental threat. Surfactants are considered as highly challenging emerging contaminants. Effluents, especially coming from the laundry units, usually contain very high concentrations of AS (> 8000 mg/L) (Adak et al. 2005a). They often cause problems, such as creating foam in wastewater treatment plants. They have the potential to deteriorate the settling quality of the sludge and hence can adversely affect the quality of the effluent (Liwarska-Bizukojc and Bizukojc 2006). As surfactants possess a long hydrocarbon chain, it is often found difficult in wastewater treatment plants to completely degrade these molecules in a short aeration period (Khoshravi et al. 2020). Their presence in water bodies is often responsible for the solubilization of other hydrophobic pollutants such as oil, grease, and organic solvents posing negative impacts on aquatic lives. Moreover, quaternary ammonium CS are poorly biodegradable under ambient conditions (Nalecz-Jawecki et al. 2003). Hence, their removal from water bodies is one of the major challenges in environmental engineering. Surfactant removal has been achieved through adsorption (Adak et al. 2005a), ion exchange (Schuricht et al. 2017), membrane bioreactor process (Gonzalez et al. 2007), and advanced oxidation process (Arslan et al. 2018). Among all the processes, adsorption is found to be the simplest and most versatile technique. However, the development of a low-cost adsorbent with high adsorption capacity and high regeneration ability is still a major issue. Reported studies are available in the literature regarding surfactant removal by alumina (Adak et al. 2005a), silica (Koner et al. 2010) and rubber tire granules (Purakayastha et al. 2005). Bae et al. (2012) explored the potential of pyrites for CS removal. Recently, Shami et al. (2019) explored dolochar for the removal of sodium dodecyl sulfate (an AS) from aqueous medium. In the current decade, biosorption has been considered as a green and sustainable technique for wastewater remediation. CS removal by magnetic-alginate beads has been conducted by Obeid et al. (2014). Das and Pal (2016) removed high concentrations of AS by hydrogel chitosan beads. We have recently reviewed the surfactant removal by adsorption techniques using biopolymers (Biswas and Pal 2021a). Biopolymers such as alginate, chitosan, tannin, and pectin have shown promising results in pollutant abatement in the recent past.

In the present article, cetylpyridinium chloride (CPC), a model CS, has been selected as the target pollutant. It is often present in real wastewater. In our study, hydrogel alginate (Ag) and alginate-xanthan (AgX) composite beads were applied for the removal of CPC present at a high concentration in synthetic and CPC-spiked real wastewater. Apart from CPC, the adsorbent also showed promising performance toward another CS, cetyltrimethylammonium bromide (CTAB). Xanthan gum has been used as the reinforcing agent because the bare alginate beads are very soft and brittle in nature. Adsorption experiments were carried out in three different set-ups, viz., in 15 mL glass vials, 200 mL glass beakers, and in a fabricated reactor of volume ~ 1.5 L. Additionally, like our previous studies, in this case, the adsorption of surfactant was carried out under static conditions, i.e., without the aid of any shaking instrument. It will undoubtedly make the process energy efficient (Das and Pal 2016). The effects of operational parameters such as variation of dose of adsorbent, initial concentration of CPC and pH of the solution on adsorption performance were investigated. The cost involved in the treatment of real wastewater containing CS has also been computed. The effect of interfering cations, which commonly occur in the water medium, was studied. As alginate and xanthan gum are both biopolymers, their capability to introduce microorganisms in the wastewater as a secondary pollutant was checked. All the experiments were performed at the Civil Engineering Department, IIT Kharagpur, within the period 1.1.2022–30.6.2022.

Materials and methods

Reagents and apparatus

Alginate powder and CTAB were purchased from Loba Chemie. On the other hand, xanthan gum was obtained from Urban Platter, a local company. The molecular weight of the sodium alginate powder was determined following the method described in an earlier reported study (Sellimi et al. 2015), and it was found experimentally to be ~ 25 kDa. CPC was purchased from SRL Chemicals. Calcium chloride, NaOH, and HCl (37%) were bought from Merck. Millipore water was used throughout the study.

To justify the suitability of the adsorbent (hydrogel alginate-xanthan beads) for real wastewater treatment, the effluent coming out from a UASB reactor situated in IIT Kharagpur campus was used as a ‘real wastewater sample.’

UV–visible spectrophotometer (Agilent, Cary 360) was used to record the absorption spectra. FTIR spectrophotometer (Thermo Nicolet USA) was utilized to record the FTIR spectra. An atomic absorption spectrometer (AAS) was used to quantify Ca(II) ions in water medium. The morphological analysis was done in a Scanning Electron Microscope (Merlin). It is to be noted that FTIR and SEM analyses were done with dried beads. However, the adsorption experiments were performed with hydrogel beads. Elemental analyses of the hydrogel beads before and after CPC loading were done by CHNS analyzer (Euro EA Elemental Analyzer). The size distribution of the hydrogel beads was found via Image j software. The MALDI-TOF–MS analysis was performed using a MALDI-TOF–MS analyzer (Ultraflextreme) in order to find out the intermediate products. Viscosity measurement was done with the help of a Rheometer (Anton Paar, model: MCR 102) and Brookfield viscometer. An electronic balance (Afcoset, India) was used to measure the weight. For the measurement of pH, a digital pH meter was utilized (Systronics, India). The conductivity of the water samples was measured using a conductivity meter (Toshcon Industries Pvt. Ltd. Hardwar).

Analytical techniques

CPC exhibits a strong absorption peak at 258 nm. The absorbance at this peak for different concentrations of CPC was noted down for developing the calibration curve. In the supplementary section, Fig. S1 represents the spectra, along with the calibration curve. The equation of the developed calibration curve was

The equation was used to find out the concentration of CPC remaining in the solution after adsorption. The CPC concentration in the water after adsorption was also checked with another spectrophotometric method which has been developed by us recently. The results obtained from these two methods were comparable. However, to determine the CTAB concentration, the spectrophotometric method was used (Biswas and Pal 2020a).

Synthesis of hydrogel beads

Synthesis of alginate hydrogel beads

Alginate (Ag) beads in hydrogel condition, were synthesized according to our previously reported study (Biswas and Pal 2021b) with some modifications. In a 100 mL glass beaker, sodium alginate powder (0.2 g) was mixed with 20 mL water (Millipore). In another 600-mL glass beaker, 2 g of CaCl2 was dissolved in 50 mL Millipore water. The alginate suspension was kept under magnetic stirring at 500 rpm for 3 h. After the solution became homogeneous, it was added drop-wise using a 5-mL micropipette into the previously prepared CaCl2 solution. Alginate hydrogel beads formed slowly in the CaCl2 solution through crosslinking. The beads thus formed were designated as Ag beads. They were allowed to stay in the CaCl2 solution overnight. After that, the beads were thoroughly washed with Millipore water and kept dipped under Millipore water for further use.

Alginate is an anionic biopolymer containing mannuronic acid (M) and guluronic acid (G) as the main component. Guluronic acid has a strong affinity for calcium ions, and therefore, beads are formed by crosslinking when sodium alginate solution is dropped in the calcium chloride solution. Depending upon the M/G ratio, the alginate beads are classified as soft or rigid hydrogels. The M/G ratio of the sodium alginate powder used in our study was experimentally determined following the reported method (Sellimi et al. 2015) and it was found to be 0.73,. As the M/G ratio is less than 1, the hydrogels can be called rigid hydrogels.

Synthesis of alginate-xanthan hydrogel beads

Alginate-xanthan (AgX) beads in hydrogel condition were prepared according to a procedure that resembles with the preparation procedure of alginate hydrogel beads. The only difference is that, instead of sodium alginate, in this case, alginate and xanthan powder, each of 0.2 g was mixed with 20 mL of water (Millipore). The AgX suspension was allowed to stay under magnetic stirring at 500 rpm for 3 h. After the solution became homogeneous, the AgX solution was poured drop by drop using a 5-mL micropipette into the previously prepared CaCl2 solution. The hydrogel beads soon started forming as they came in contact with the CaCl2 solution. The hydrogel beads thus formed were named as AgX beads (Fig. S2; Step 1). AgX beads were ovular in shape, and they were less transparent as compared to the Ag beads. They were much stronger in comparison to the bare alginate beads (as it can be realized simply by pressing by hand).

Adsorption study in CPC-spiked synthetic wastewater and CPC-spiked real wastewater

AgX composite beads were utilized for the uptake of CPC (Fig. S2; Step 2) from both CPC-spiked Millipore water and CPC-spiked real wastewater. Adsorption study in CPC-spiked Millipore water was conducted in three reactors having three different sizes (containing 10 mL, 100 mL and 1000 mL volume having CPC solutions) at ambient temperature (24 ± 2℃). On the other hand, an adsorption study for CPC-spiked real wastewater was carried out in a solution of 1000 mL volume. During performing the experiment, every time the desired number of AgX beads of hydrogel nature were inserted into the CPC solution, and the whole setup was allowed to remain at rest with occasional handshaking. At certain time intervals, the concentration of CPC left in the solution after adsorption was monitored spectrophotometrically at λmax = 258 nm. The removal percentages of CPC and the maximized adsorption capacity of the hydrogel beads were obtained using the following Eqs. (1&2):

Here, C0 denotes the initial concentration of CPC in mg/L before the start of the adsorption, Ce denotes the concentration of CPC left in the solution phase after uptake by the beads at equilibrium (mg/L), qe marks the maximum uptake capacity at equilibrium (mg/g), and M is the adsorbent dose in g/L.

So basically, there are two steps in the whole work. In Step 1, the hydrogel beads were prepared, and in Step 2, CPC was removed using the AgX composite. The schematics of the work using AgX are shown in Fig. S2.

Statistical analysis

Statistical analyses such as relative standard deviation (RSD) and standard deviation (σ) were found to check the consistency of the results obtained experimentally. The formula of standard deviation is represented through Eq. (3):

Here, xi stands for a particular reading from a set of readings, \(\overline{x }\) denotes the mean value of all such readings, and n denotes the number of experimental runs.

RSD is obtained using Eq. (4):

Results and discussion

CPC adsorption study

Behavior of Ag and AgX hydrogel beads toward time dependant CPC adsorption at its various concentrations

The efficiency of the Ag beads and AgX beads of hydrogel nature toward CPC adsorption was compared. For this, both (Ag and AgX) beads were tested for CPC adsorption under the same experimental condition. Briefly, five Ag and AgX beads (hydrogel) were inserted separately into a 10 mL CPC solution with different initial concentrations ranging from 100–600 mg/L, each taken in 15 mL glass vials. Hence, the dose of Ag and AgX beads (hydrogel) remained at 1 g/L and 1.5 g/L, respectively. Experiments were conducted at ambient conditions (24 ± 2℃) for four initial concentrations of CPC, viz., 100 mg/L, 200 mg/L, 300 mg/L, and 600 mg/L. The amount of CPC adsorption onto the hydrogel beads was recorded at the end of 1, 4, 7, and 8 days. Results have been compiled in Fig. 1. At the end of 7 days, at a higher concentration of CPC, the adsorption capacity for the AgX composite showed a somewhat higher value. Moreover, the equilibrium time required by the AgX composite for CPC adsorption was nearly 8 days, while it was much larger for the Ag beads, as it is clear from Fig. 2. After a retention time of 8 days, both the beads (Ag and AgX) got shrunk significantly. Additionally, at the end of 13 days (equilibrium time for Ag), the beads showed extremely poor mechanical strength, and they were unfit for further use. With the increase in the initial concentration of CPC, the shrinking effect was enhanced. Upon CPC adsorption, the strength of both beads seemed to be decreasing. However, the Ag beads were more deteriorated compared to the AgX beads, which can be felt by hand pressing. Hence, for detailed study, AgX beads (hydrogel) were chosen.

Effect of xanthan gum in alginate matrix

The two biopolymers used in this study, i.e., alginate and xanthan gum, both are anionic in nature. Sodium alginate is capable of bead formation by means of crosslinking with Ca(II) ions in water. However, the beads thus formed are often found brittle, and they are difficult to be used as an adsorbent. Hence, they are used in the form of composite beads with other organic and inorganic materials. Studies were conducted using xanthan gum as the reinforcing agent to impart strength and to improve the performance of the alginate beads toward wastewater treatment (Zhang et al. 2013, 2014). It is also worth noting that xanthan gum is a water-soluble biopolymer but cannot form hydrogel beads like alginate.

In the present study, the main reason for imparting the xanthan gum in the alginate matrix was to enhance the physical strength of the hydrogel beads. Also, in the case of AgX hydrogel beads, the time needed to reach equilibrium was less compared to that of Ag hydrogel beads. Moreover, after CPC removal, the deformation of AgX beads was found to be less than that of the Ag hydrogel beads.

Variation of proportion of alginate and xanthan gum in the prepared beads

Apart from the variation of concentration of CPC for the adsorption study, the amounts of alginate and xanthan gum were changed to find its influence on the physicochemical properties of the beads and further on removal efficiency. In the current work, for most of the studies, in the composite beads, the proportion of alginate and xanthan gum was kept same. However, preparation of hydrogel beads was also attempted with two other proportions. In one solution, the amount of alginate has been kept twice that of xanthan gum, while in another solution, the amount of alginate has been kept half of that of xanthan gum. When the content of xanthan gum was twice that of alginate, then production of bead was not found feasible owing to the high viscosity of the mixture. Instead of stable hydrogel beads, some unsteady, flaky structures were noticed. So, this proportion of alginate and xanthan was discarded in our experiments. On the other hand, when xanthan gum was kept as half of that alginate (Alginate: Xanthan = 1:0.5), then formation of beads took place without any difficulty. Spherical beads were obtained.

The CPC uptake capacity of both types of beads was tested under the same experimental conditions. In the beginning, the concentration of CPC was maintained at 600 mg/L, and the dose of adsorbent was maintained at 1.5 g/L. In the case of the beads where the content of alginate and xanthan gum has been kept the same, the maximum uptake capacity has been found to be 310 mg/g. On the other hand, in the case of the beads where xanthan gum content has been kept at half that of alginate, the maximum adsorption capacity reached 285 mg/g. It was found that in the post CPC removal phase, both beads lose a portion of their mechanical strength. However, the beads, where xanthan gum content was higher, were stronger as realized by pressing by hand. Before the beads’ synthesis, the viscosity of the solutions having Alginate: Xanthan = 1:1 and another one having Alginate: Xanthan = 1:0.5 was compared. The result showed that viscosity of the solution containing more xanthan gum was thrice viscous than the other. Therefore, it can be concluded that beads containing excess xanthan gum would be more durable than the other. So, Alginate: Xanthan with a ratio of 1:1 was chosen for preparing bead needed for the rest of the studies.

Characterization of beads (hydrogel)

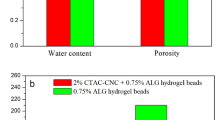

Physico-chemical properties of the beads

Alg hydrogel beads were nearly spherical in shape, while Alg-Xan hydrogel beads had an ovular structure. Besides the size distribution, the dry weights of the beads were also measured. Hydrogels are often defined as water-retaining structures. Hence it was essential to measure the dry weight of the beads, and, thereby to calculate the moisture content. The results are presented in Table 1. After CPC adsorption, the dry weight of the hydrogel beads was reduced significantly. Similar results were also observed in our previous studies (Pal and Pal 2017, 2019). Briefly, the dry weight of the Ag, AgX and AgX-CPC hydrogel beads were recorded as follows: In a petri dish, 30 wet beads were taken, and the weight of the petri dish along with the wet beads was taken using an electronic weighing balance. After that, the complete setup (wet beads + petri dish) was inserted into the hot air oven and dried for 3 h at a temperature of ~ 60℃. On being completely dried, the petri dish containing the dried beads was weighed again. The average of three sets of values was used for calculating moisture content, and the weight of the empty petri dish was also measured.

Size distribution of AgX hydrogel beads

After CPC adsorption, the AgX hydrogel beads shrunk excessively. Digital images were taken, and size distribution was analyzed for AgX beads (hydrogel) both before and after CPC adsorption. In both cases, 20 beads were taken for analysis. The beads were not completely spherical but were ovular in shape. Hence, dimensions of both length (larger one) and width (smaller one) have been chosen for the demarcation of their dimensions. Before the adsorption of CPC, the average length and width of the hydrogel beads were approximately 6.9 ± 0.77 mm and 4.85 ± 0.41 mm, respectively. However, after CPC adsorption, their average length and width were reduced to 3.9 ± 0.6 mm and 2.65 ± 0.46 mm, respectively (Table S1). The digital images of the AgX beads (hydrogel) before and after CPC adsorption have been presented in Fig. 3, and the size distribution is shown in the supplementary section (Table S1). A similar report on the shrinking of hydrogel beads after surfactant adsorption has also been documented by other research groups (Obeid et al. 2014; Wang and Wang 2010; Wang et al. 2013). Due to CPC adsorption, Ca(II) ions present in the hydrogel beads were released into the solution following the ion exchange mechanism. Due to the increase in the Ca(II) ion concentration in the solution, the osmotic pressure increased, which led to the shrinking of the beads. A detailed calculation was done to know the amount of Ca(II) ions released and the osmotic pressure, which is described in Sect. "Estimation of Ca(II) ions and osmotic pressure".

FTIR analysis

For getting better insight into the mechanism of adsorption, the FTIR spectra of CPC, AgX and AgX after CPC modification have been recorded and presented in Fig. S3. A broad band has been obtained in the region of 3366 cm−1 for CPC due to the presence of a characteristic OH group of adsorbed moisture. However, in the spectrum of AgX and CPC-loaded AgX, this peak shifted slightly toward a higher wavenumber (3421 cm−1). Peaks were observed in the range of 1600–1620 cm−1 due to the presence of carboxylates in the matrix of the alginate and xanthan. Pongjanyakul and Puttipipatkhachorn (2007) reported the appearance of a peak at 1615 cm−1 in alginate due to the asymmetric vibration of COO−. However, due to crosslinking with calcium, this peak may get shifted toward higher wavenumber. As in our case, a peak is obtained at 1635 cm−1 for all three materials. Liu et al. (2021) also mentioned the peaks at 1640 and 1470 cm−1 due to the stretching vibration of the pyridine ring. In pure CPC, a peak at 1176 cm−1 has been obtained. It is similar to the previously reported study (Liu et al. 2020). From the FTIR analysis, it is clear that the peaks at ~ 2850 cm−1 and ~ 2920 cm−1 appeared in the spectrum of CPC and CPC-loaded AgX composite due to the symmetrical and asymmetrical stretching vibration of –CH2 group of CPC (Liu et al. 2020). These peaks are absent in the FTIR spectrum of AgX.

CHNS analysis

The changes in the elemental composition of the beads before and after surfactant modification were investigated by the CHNS analysis of dried Ag, AgX, and CPC-modified AgX beads. It was noted that in comparison to the Ag beads, the AgX beads showed a higher percentage of carbon (Table S2). Again, after CPC adsorption onto the AgX beads, the carbon and nitrogen percentages were enhanced significantly. The ratio of carbon to nitrogen (C: N) in the molecular formula of CPC is 18, and after CPC modification of AgX, the C: N ratio in CPC-modified AgX is 19.1. The results indicated the incorporation of CPC into the hydrogel composite.

Determination of pHzpc measurement of AgX hydrogel beads

The pHzpc of the hydrogel AgX beads was determined following the previously described method (Biswas and Pal 2020b) with modification. Briefly, in a series of 50 mL glass beakers, 0.1 M NaCl solutions of 30 mL volume were taken. In each of them, fifteen AgX hydrogel beads were added, and the pH of the solutions varied in the range of 3–11. After insertion of the beads, the beakers containing NaCl solution and the hydrogel beads were kept at rest for 24 h. Unlike the previous method, the beakers were not subjected to shaking due to the fragile nature of the hydrogel beads. The plot of the difference between initial and final pH vs. initial pH is shown in Fig. S4. It is seen from the figure that the pHzpc of the hydrogel beads is around 6, which indicates that at a solution pH > 6, the surface of the beads will be negatively charged, and at pH < 6, it will be positively charged. Different research groups obtained pHzpc for various alginate composites. Abas et al. (2015) reported the pHzpc of mangrove-alginate composite beads as 5.41, while Pashaei-Fakhri et al. (2021) found the pHzpc of acrylamide/sodium alginate and acrylamide/graphene oxide alginate composite as 6.8 and 6.21, respectively.

Viscosity measurement

In the present research work, Ag and AgX hydrogel polymer beads have been prepared. It has already been mentioned in Sect. "Synthesis of alginate-xanthan hydrogel beads" that the AgX composite beads were stronger than the Ag hydrogel beads. However, the viscosity analysis of the two biopolymer solutions (sodium alginate in water and sodium alginate mixed with xanthan gum in water) may provide more quantitative information in this respect. Viscosity is an indirect measurement of the shear strength of fluid. Hence, the coefficient of viscosity of both Ag and AgX solution in water was measured using a Rheometer. The coefficient of dynamic viscosity for the Ag solution was found to be ~ 5.47 mPa-s, and that of the AgX solution was obtained as ~ 520 mPa-s. It is clear from the results that the AgX solution was more viscous (~ 100 times) than that of the Alg solution. Hence, in terms of shear strength, the AgX solution was more stable. Therefore, it can be concluded indirectly that, after the crosslinking, the AgX hydrogel beads will be more resistant to shear stress imparted by the fluid, i.e., water, in comparison to the Ag hydrogel beads. So, the usage of AgX hydrogel beads is more suitable from a practical point of view than using Alg hydrogel beads.

Apart from the above-mentioned characterization studies, the determination of critical micelle concentration (CMC) of CPC and the SEM analysis of the AgX dried beads were done and the results are presented in the supplementary section (sections S1 and S2; Fig. S5 and Fig S6).

Adsorption isotherm study

An adsorption isotherm study is conducted in order to find out the maximum adsorption capacity of the adsorbent. Isotherm is the other name of the graphical representation of adsorption capacity (qe) vs. concentration of solute at equilibrium (Ce). Adsorption isotherm study for CPC adsorption onto AgX hydrogel beads was conducted for a fixed dose of adsorbent at 1.5 g/L at ambient room temperature (24 ± 2℃), and the initial concentration of CPC was varied from 30 mg/L to 2000 mg/L.

In most of the adsorption studies reported in the literature, isotherm follows a particular model (Langmuir or Freundlich). However, in the case of surfactant adsorption, there are several reported studies where layered isotherms have been observed. Adak et al. (2005b) reported the layered isotherm for the adsorptive removal of SDS by neutral alumina. Das and Pal (2016) observed the same phenomenon for the removal of SDS by chitosan hydrogel beads. Koner et al. (2010) concluded a similar phenomenon for CTAB removal by silica gel. Pavan et al. (1998) thoroughly described the phenomenon of SDS adsorption by double-layered hydroxide systems. Mishra et al. (2003) also obtained the layered isotherm model while studying the adsorption of sodium dodecyl benzenesulphonate onto coal. Like all the above-mentioned reports, in this case, a layered isotherm was obtained, as shown in Fig. 4. Here, the whole isotherm can be roughly divided into four regions. A similar layered isotherm regarding the adsorption of CPC onto mag-alginate beads was also reported by Obeid et al. (2014). However, the nature was not exactly the same. It can be clearly seen from the isotherm plot shown in Fig. 4 that the slope of the graph starts changing from an initial concentration of CPC ~ 150 mg/L. The maximum adsorption capacity obtained in this region is 81.62 mg/g (Region I). After that, the slope of the curve starts rising at different segments, showing different slopes. However, at the region (Region III) spanning from 600–1100 mg/L of initial concentration of CPC, a flat plateau region in the isotherm curve is noticed. The plateau region begins at the initial concentration of CPC being ~ 540 mg/L and the CPC concentration remaining in the solution being ~ 87.8 mg/L. This result is similar to that reported by Obeid et al. (2014). Actually, CPC adsorption on the hydrogel surface occurred by two phenomena: electrostatic attraction and hydrophobic interaction. In the low concentration of CPC, adsorption occurred by the ion exchange mechanism with calcium ions. That is why the hydrogel beads got shrunk. However, at higher concentrations of CPC, the adsorption occurred by a combined effect of ion exchange and hydrophobic interaction. The first layer in the layered isotherm corresponds primarily to ion exchange between the cetyl group and Ca(II) ions of the gel bead matrix. The second and third layer refers to the combined Effect of electrostatic and hydrophobic interaction. After all the adsorption sites of the AgX bead matrix got exhausted, on further increasing CPC concentration, the surfactant molecules started self-assembling to form a micellar structure on the solid surface. After CPC adsorption, Ca(II) ions released into the solution were estimated by AAS. Roughly Ca(II) ions at a concentration of ~ 4.5 mmol/L (180 mg/L) were observed to remain in the final solution, corresponding to an initial concentration of CPC of 600 mg/L. The beginning of the plateau region denotes an adsorption capacity of ~ 310 mg/g. After the CPC’s initial concentration of 1100 mg/L, the adsorption uptake curve starts rising. The maximum uptake capacity was obtained as ~ 500 mg/g at an initial CPC concentration of 1900 mg/L.

Estimation of Ca(II) ions and osmotic pressure

The Ca(II) ions used up by the AgX beads for crosslinking and the amount of Ca(II) released into the effluent during CPC adsorption was estimated by AAS. The amount of Ca(II) loaded during the crosslinking to form the beads was estimated as ~ 8.3 mmol/g (332 mg/g). After CPC adsorption, the Ca(II) ions released into the effluent were also calculated using the same procedure. Three samples were tested, and the average Ca(II) concentration was determined as 4.5 mmol/L (180 mg/L). Before the insertion of the AgX hydrogel beads into the CPC solution, no Ca(II) ions were there in the water medium. Hence, the increase in osmotic pressure can be calculated as follows:

Here, π denotes the osmotic pressure, i represents Van’t Hoff factor, c represents molar concentration, R is the ideal gas constant, and T represents room temperature. Taking the value of i as 3, c as 4.5 mmol/L, R as 0.0821 LatmK−1 mol−1, and T as 300 K, the increase in osmotic pressure was obtained as 0.332 atm.

Variation of adsorbent (AgX hydrogel beads) dose

In an adsorption study, it is quite important to examine the effect of adsorbent dose on the adsorption phenomenon. In the present study, CPC adsorption was carried out using 2 beads and 5 AgX hydrogel beads per 10 mL of the surfactant solution (600 mg/L). Hence, the doses of the adsorbents remained at 0.6 g/L and 1.5 g/L, respectively. Readings were taken at different time intervals (up to 8 days). The CPC removal efficiency in the case of 5 beads was higher (~ 77%) in comparison to that of 2 beads (~ 50%). However, the adsorption capacity (mg/g) in the case of 2 beads obtained was higher (~ 1.46 times). The results have been shown graphically in Fig. 5. The maximum adsorption capacity for CS removal has been compared with various adsorbents reported in the literature (Table 2).

Kinetic study

The kinetic study is one of the most important areas of the adsorption process since the mechanism, as well as the trend of removal can be understood from it. Time-dependent plots of the remaining concentration of CPC using adsorbent dose of 1.5 g/L and 0.6 g/L have been shown in Fig. 6. Adsorption study was conducted at 24 ± 2℃ (ambient room temperature) under static conditions. It is interesting to observe that most of the removal in both cases (adsorbent dose 1.5 g/L and 0.6 g/L) took place within 4 days. The experimental data for the first 4 days can be well-fitted with the zero-order kinetic plot. After that, the trend seems to deviate from the zero-order kinetics and follow a mixed-order kinetic model.

Adsorption of CTAB

It is already stated that most of the adsorption studies have been performed with CPC as the target pollutant. However, in order to justify the potential of AgX hydrogel beads toward other CS, it was also tested against another model CS, i.e., CTAB. Adsorption experiments were done in a way similar to that of CPC adsorption. Briefly, in two 15-mL glass vials, 10 mL CTAB solutions having initial concentrations of 100 mg/L and 600 mg/L were taken separately. To each of them, 5 AgX hydrogel beads were inserted so that the dose of the adsorbent became 1.5 g/L. After keeping the setup at a static condition, at the end of 8 days (equilibrium time for CPC adsorption), the amount of CTAB remaining in the solution was determined by our previously reported method (Biswas and Pal 2020a). By mass balance, the adsorption capacity for initial CTAB concentrations of 100 mg/L and 600 mg/L were found to be ~ 58 mg/g and ~ 297 mg/g, respectively. The results are quite comparable with that of the CPC adsorption study. Hence, it can be concluded that the AgX hydrogel beads are also suitable for another CS adsorption.

CPC adsorption in large-scale batch reactors

Scaling up of laboratory reaction setup is of utmost importance to find out the applicability of the removal process in real-field. In the present study, first, the adsorption experiments were performed in 15-mL glass vials with an influent volume of 10 mL. Next, to see the size effect of the reactors, the volume of the reactor was increased to 200 mL, where 100 mL influent volume was considered to get 10 times scale up. Finally, with further scaling up, the adsorptive removal was studied in a small tank fabricated out of an acrylic glass reactor. The reactor had the appearance of a cuboid having dimensions of 36.5 cm × 9.3 cm. An outlet hole was drilled in such a way that the volume of the reactor became nearly 1.5 L. The setup of the fabricated reactor has been shown in the supplementary section (Fig. S7). The CPC solution used in this case was 1L. So, again, a scaling up by a factor of 10 was done. Hence, a total scale-up of 100 times was examined, and their performance was evaluated.

In all cases, the initial concentration of CPC was fixed at 600 mg/L and 5 beads were used for 10 ml solution, 50 for 100 mL solution and 500 for 1L solution. Hence, the dose (1.5 g/L) and initial concentration of CPC (600 mg/L) remained the same. The kinetics of CPC removal up to 8 days have been plotted in Fig. S8. It is quite interesting to observe that the removal efficiency remained almost the same even with the increment of the reactor size. Hence, AgX may be recommended for large-scale wastewater treatment containing emerging pollutants like CPC.

CPC uptake by the hydrogel beads took place through multiple mechanisms, including osmosis, ion exchange, diffusion, hydrophobic interaction, etc. The osmotic phenomenon is involved in the case of the hydrogel beads, as also indicated by other reported studies (Saber-Samandari et al. 2017). As osmosis is a slow process and diffusion is a fast process, therefore the overall process is slow in comparison to traditional adsorption studies. On the other hand, although bulk diffusion is a quicker process, diffusion inside the hydrogel beads is also a slow phenomenon, which also reduces the speed of CPC uptake. However, these beads are also suitable as a substrate for constructed wetlands, as also mentioned in our previous study (Biswas and Pal 2022).

Effect of coexisting cations on CPC removal

The presence of cations like Ca(II), Mg(II) are common in municipal wastewater. On the other hand, in industrial effluents, cations like Ni(II), Mn(II), Co(II) etc. are often encountered. Hence, a study is conducted to examine the effects of commonly occurring cations on CPC removal. For this study, cations like Mg(II), Ni(II), Co(II) were added to the CPC bearing Millipore water in such a way that in the final solution of CPC concentration remained at 600 mg/L and the metal ion concentration remained as 50 mg/L. The adsorption study was conducted in a 250 mL glass beaker containing 100 mL CPC solution (600 mg/L) and 50 AgX hydrogel beads. The percent CPC removal under different conditions (at the end of 8 days) is shown in Fig. S9. The CPC removal capacity of the hydrogel AgX beads in the presence of Co(II), Mg(II) and Ni(II) ions (50 mg/L) and in Millipore water (i.e., the control) was almost the same. It is quite clear that in the presence of 50 mg/L of different cations (Ni(II), Co(II), Mg(II)) almost no interference was observed on CPC removal by AgX hydrogel beads.

Effect of pH

In an adsorption study, it is pertinent to verify the Effect of the solution pH on the adsorption process. Firstly, the CPC solution (600 mg/L) was made acidic (pH ~ 2) by the application of dilute HCl when no color change was noticed. The spectrum also remained unchanged. After that, 5 hydrogel beads were inserted in 10 mL (dose remained as 1.5 g/L) CPC solution (600 mg/L) taken in a 15-mL glass vial and allowed to keep at rest for 8 days. The CPC concentration remaining in the solution was then measured and found that very little adsorption took place (~ 7%). The result is consistent with the obtained pHzpc of the AgX hydrogel composite beads. At solution pH < 6, the surface of the AgX hydrogel beads remained positively charged, and it repelled the positively charged CPC molecules. Similar results (32%) were mentioned for the low quantity of CPC adsorption on the mag-alginate beads (Obeid et al. 2014).

Adsorption capacity remained highest at near-neutral conditions (~ pH 5.5–6). But, in the alkaline pH range (pH ~ 8–10), the adsorption capacity of the hydrogel beads remained low. The CPC removal efficiency of AgX hydrogel beads at different pH conditions has been shown in Fig. 7.

Reproducibility studies

In order to make an adsorbent fit for practical purposes, its performance should be reproducible. In our case, the reproducibility study was tested with three initial concentrations of CPC: 100 mg/L, 600 mg/L and 1500 mg/L. The dose of the adsorbent was fixed at 1.5 g/L like the other studies, and the whole set-up was kept at rest for 8 days. Experiments were run in triplicates, and the results have been presented in Table S3. It can be clearly observed that the adsorption capacity obtained during three independent runs is quite close. The RSD values lie in the range of 2–9%

CPC removal from real wastewater spiked with CPC

The real sample was taken from the effluent from a wastewater treatment plant. The characteristics of the real sample have been compiled in a supplementary section (Table S4). The absorption spectrum of the raw wastewater was recorded to get an idea about the presence of CPC in it. However, no peak at 258 nm (characteristic of CPC) was observed.

Therefore, the real wastewater sample was spiked with CPC in different proportions, and it was checked with the calibration curve developed for the CPC solution in Millipore water. The results are compiled in the Supplementary section (Table S5). It was found that the recovered percentages closely correlated with the spiked amount, and the standard deviation was within ± 5%.

An adsorption study was conducted in a small fabricated reactor with the real wastewater spiked with CPC at a concentration of 600 mg/L. The removal efficiency obtained was very close to that obtained in Millipore water (~ 78% removal).

Such a high concentration of cationic surfactant is found in the effluent of some industries, for example, those producing mouth softeners. Hence, the AgX hydrogel biocomposite may provide a green and sustainable remediation technique for real wastewater treatment and can be considered a new-age material to control emerging pollutants.

Bacteriological test

As both the alginate and xanthan are biopolymers, there is a chance of biodegradation, which may cause unnecessary growth of microorganisms in the system, causing secondary pollution. Hence, a confirmatory test was done to check the possibility of bacterial growth in the samples containing alginate and alginate-xanthan solution. Hence,10 μL of sodium alginate and alginate-xanthan solution was spread separately on two nutrient agar plates and incubated at 30℃ for 2 days. At the end of 2 days, no growth of bacterial colony was observed in either of the alginate and alginate-xanthan spread plates. This concludes that there is less chance of the production of secondary pollutants (microorganisms) from these biopolymer beads.

The toxicity test was also conducted to confirm that when the developed method of CPC removal using AgX beads is applied to the real wastewater scenario, it may not affect the microorganism growth by posing toxicity. Typically, the test was started with the spreading of E. Coli bacterial strain on a nutrient agar medium. Two disks were bored on the Agar medium, as shown in Fig. S10. These two disks were filled separately with sodium alginate and sodium alginate-xanthan gum solution. If any toxic chemicals were leached from these two disks, then bacterial growth might be inhibited, and there would be a clear zone around these two disks. However, in this case, no such clear zones were visible. Hence, it was concluded that no toxic substances were produced from alginate-xanthan composites.

MALDI-TOF–MS analysis

MALDI-TOF–MS analysis was performed with the supernatant to find out the leaching of ions or chemicals from the AgX matrix during the adsorption of CPC, and the results were compared with those obtained with Ag solution, AgX solution, CPC solution. The results are shown in Fig. 8. In the spectra of Ag and AgX, a sharp peak has been found at a m/z value of 177. The monomeric unit of alginate is the mannuronic acid and guluronic acid, which has a typical peak at m/z equal to 176. Moreover, in previous studies, some peaks were reported to appear at m/z equal to 723 and 798 due to alginate (Aida et al. 2010). In our case, a very less intense peak has been found at 797 in the spectrum of Ag (Fig. 8a) and that of AgX (Fig. 8b). In the MALDI-TOF–MS spectrum of CPC (Fig. 8c), a sharp peak has been observed corresponding to the m/z ratio of 305 (Abdelhamid et al. 2017). After CPC adsorption, the peak at m/z value corresponding to 305 has been observed due to the remaining CPC in the effluent (Fig. 8d). Significant peaks corresponding to AgX are absent. Hence, the biopolymer composite (AgX hydrogel beads) can be considered to be stable, and no leaching took place.

Cost analysis

Cost computation is extremely necessary for the establishment of a new system for pollutant removal. In our case, the cost has been divided into two categories, viz. (i) materials cost and (ii) synthesis cost. Materials cost involves the cost of the chemicals used only i.e., sodium alginate powder, calcium chloride (fused), and xanthan gum powder. Synthesis cost involves the cost of water required for the production of the beads and also the electricity required during the blending process. However, some additional items, such as glass wares, and micropipettes are considered non-estimated (Dalvie et al. 2005). To include the cost of these, an additional 10% of the overall cost has been allotted. The cost computation has been provided in detail in the supplementary section (Table S6). To treat one liter of real wastewater, the price has been found to be nearly 9.22 INR. Considering 1 USD is equivalent to 80 INR, ~ 8.7 L of real wastewater containing 600 mg/L of CPC can be treated by spending $1.

According to the other reported study (Dadebo et al. 2023), the removal of 1 kg of COD from wastewater may add up to 0.15 $ which is approximately equal to 12 INR. COD of CPC has been estimated by using the following formula:

From the molecular formula of CPC, values of x and y are 21 and 38. Hence. By calculating, we get 314 mg/g CPC, which corresponds to 1043.31 mg/g of COD. So, for removing 1 kg of COD, roughly 1 kg of adsorbent (AgX-CPC) is required. In the case of other adsorbents, such as silica and pyrites, the amount to be spent will be higher as their adsorption capacity is less. Therefore, it can be concluded to get 12 INR profit, we have to spend 1 kg of AgX adsorbent which is lower in comparison to those other reported studies.

Conclusion

A novel composite bead comprising alginate and xanthan has been fabricated, characterized and evaluated as an adsorbent to remove cationic surfactant (e.g., CPC, CTAB). The adsorbent served very well in the CPC concentration range of 100–600 mg/L, showing high adsorption capacity ~ 61–310 mg/g. The presence of coexisting ions in real wastewater has a negligible effect on the adsorption performance. The optimized pH for the adsorption has been found to be ~ 5.3, which is the pH of normal wastewater. Hence, pH adjustment is not required in most of the cases which is beneficial. The maximum CPC removal by the AgX hydrogel beads at a dose of 1.5 g/L has been found to be nearly 78% at 600 mg/L and 90% for 100 mg/L of initial CPC concentration. The beads are quite stable and biocompatible. The performance of CPC removal by AgX hydrogel beads has also been evaluated at different scaled-up reactors and for real wastewater. The results are quite promising.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abas SNA, Ismail MHS, Siajam SI, Kamal ML (2015) Development of novel adsorbent-mangrove-alginate composite bead (MACB) for removal of Pb(II) from aqueous solution. J Taiwan Inst Chem Eng 50:182–189. https://doi.org/10.1016/j.jtice.2014.11.013

Abdelhamid HN, Lin YC, Wu H (2017) Magnetic nanoparticle modified chitosan for surface enhanced laser desorption/ionization mass spectrometry of surfactants. RSC Adv 7:41585–41592. https://doi.org/10.1039/C7RA05982E

Adak A, Bandyopadhyay M, Pal A (2005a) Removal of anionic surfactant from wastewater by alumina: A case study. Colloids Surf A Physicochem Eng Asp 254:165–171. https://doi.org/10.1016/j.colsurfa.2004.12.004

Adak A, Bandyopadhyay M, Pal A (2005b) Adsorption of anionic surfactant on alumina and reuse of the surfactant-modified alumina for the removal of crystal violet from aquatic environment. J Environ Sci Heal A 40:167–182

Aida TM, Yamagata T, Watanabe M, Smith RL (2010) Depolymerization of sodium alginate under hydrothermal conditions. Carbohydr Polym 80:296–302. https://doi.org/10.1016/j.carbpol.2009.11.032

Arslan A, Topkaya E, Bingol D, Veli S (2018) Removal of anionic surfactant sodium dodecyl sulfate from aqueous solutions by O3/UV/H2O2 advanced oxidation process: Process optimization with response surface methodology approach. Sustain Environ Res 28:65–71. https://doi.org/10.1016/j.serj.2017.11.002

Bae S, Mannan MB, Lee W (2012) Adsorption of cationic cetylpyridinium chloride on pyrite surface. J Ind Eng Chem 18:1482–1488. https://doi.org/10.1016/j.jiec.2012.02.010

Bezerra KGO, Rufino RD, Luna JM, Sarubbo LA (2018) Saponin and microbial biosurfactants: potential raw materials for the formulation of cosmetics. Biotechnol Prog. https://doi.org/10.1002/btpr.2682

Biswas S, Pal A (2020a) Spectrophotometric determination of cationic surfactants in aqueous media using chrome azurol S as colour forming agent and 1-butanol as extracting solvent. Talanta 206:120238. https://doi.org/10.1016/j.talanta.2019.120238

Biswas S, Pal A (2020b) Visible light assisted Fenton type degradation of methylene blue by admicelle anchored alumina supported rod shaped manganese oxide. J Water Proc Eng 36:101272. https://doi.org/10.1016/j.jwpe.2020.101272

Biswas S, Pal A (2021a) Application of biopolymers as a new age sustainable material for surfactant adsorption: a brief review. Carbohydr Polym Technol Appl 2:100145. https://doi.org/10.1016/j.carpta.2021.100145

Biswas S, Pal A (2021b) Iron-oxide alginate-bentonite hydrogel beads as a green and sustainable catalyst for 4-nitrophenol reduction. Mater Today Commun 28:102588. https://doi.org/10.1016/j.mtcomm.2021.102588

Biswas S, Pal A (2022) Fabrication of a novel composite gel bead to reclaim methyl orange from a binary dye mixture: an active role of adsolubilization phenomenon. Mater Today Commun 33:104386. https://doi.org/10.1016/j.mtcomm.2022.104386

Chattaraj S, Das AK (1992) Indirect AAS determination of cationic surfactants in waste effluents and shampoos. Anal Lett 25:2355–2366. https://doi.org/10.1080/00032719208017967

Collivignarelli MC, Miino MC, Baldi M, Manzi S, Abba A, Bertanza G (2019) Removal of non-ionic and anionic surfactants from real laundry wastewater by means of a full-scale treatment system. Proc Safety Environ Protec 132:105–115. https://doi.org/10.1016/j.psep.2019.10.022

Dadebo D, Ibrahim MG, Fujii M, Nasr M (2023) Sequential treatment of surfactant-laden wastewater using low-cost rice husk ash coagulant and activated carbon: Modeling, optimization, characterization, and techno-economic analysis. Bioresour Technol Rep 22:101464. https://doi.org/10.1016/j.biteb.2023.101464

Dalvie MA, Sinanovic E, London L, Cairncross E, Solomon A, Adam H (2005) Cost analysis of ELISA, solid-phase extraction, and solid-phase microextraction for the monitoring of pesticides in water. Environ Res 98:143–150. https://doi.org/10.1016/j.envres.2004.09.002

Das D, Pal A (2016) Adsolubilization phenomenon perceived in chitosan beads leading to a fast and enhanced malachite green removal. Chem Eng J 290:371–380. https://doi.org/10.1016/j.cej.2016.01.062

Gonzalez S, Petrovic M, Barcelo D (2007) Removal of a broad range of surfactants from municipal wastewater—comparison between membrane bioreactor and conventional activated sludge treatment. Chemosphere 67:335–343. https://doi.org/10.1016/j.chemosphere.2006.09.056

Khosravi A, Karimi M, Ebrahimi H, Fallah N (2020) Sequencing batch reactor/nanofiltration hybrid method for water recovery from textile wastewater contained pthalocyanine dye and anionic surfactant. J Environ Chem Eng 8:103701. https://doi.org/10.1016/j.jece.2020.103701

Koner S, Pal A, Adak A (2010) Cationic surfactant adsorption on silica gel and its application for wastewater treatment. Desalin Water Treat 22:1–8. https://doi.org/10.5004/dwt.2010.1465

Kralova I, Sjoblom J (2009) Surfactants used in food industry: a review. J Disp Sci Technol 30:1363–1383. https://doi.org/10.1080/01932690902735561

Liu S, Chen M, Cao X, Li G, Zhang D, Li M, Meng N, Yin J, Yan B (2020) Chromium (VI) removal from water using cetylpyridinium chloride (CPC)-modified montmorillonite. Sep Purif Technol 241:116732. https://doi.org/10.1016/j.seppur.2020.116732

Liu L, Ge Y, Liu X, Ruan J, Cao J, Wei C, Fang P, Zhou J, Ma J, Tong Z (2021) One-pot ball-milling preparation of cetylpyridinium chloride/α-zirconium phosphate composite for simultaneous detection of ascorbic acid and dopamine. J Alloys Compd 860:157927. https://doi.org/10.1016/j.jallcom.2020.157927

Liwarska-Bizukojc E, Bizukojc M (2006) Effect of selected anionic surfactants on activated sludge flocs. Enzyme Microb Technol 39:660–668. https://doi.org/10.1016/j.enzmictec.2005.11.020

Mishra SK, Kanungo SB, Rajeev (2003) Adsorption of sodium dodecyl benzenesulfonate onto coal. J Colloid Interf Sci 267:42–48. https://doi.org/10.1016/S0021-9797(03)00553-8

Nalecz-Jawecki G, Grabinska-Sota E, Narkiewicz P (2003) The toxicity of cationic surfactants in four bioassays. Ecotoxicol Environ Safety 54:87–91. https://doi.org/10.1016/S0147-6513(02)00025-8

Obeid L, Kolli NE, Dali N, Talbot D, Abramson S, Welschbilig M, Cabuil V, Bee A (2014) Adsorption of a cationic surfactant by a magsorbent based on magnetic alginate beads. J Colloid Interf Sci 432:182–189. https://doi.org/10.1016/j.jcis.2014.06.027

Oztekin N, Erim FB (2005) Determination of cationic surfactants as the preservatives in an oral solution and a cosmetic product by capillary electrophoresis. J Pharm Biomed Anal 37:1121–1124. https://doi.org/10.1016/j.jpba.2004.07.050

Pal P, Pal A (2017) Enhanced Pb2+ removal by anionic surfactant bilayer anchored on chitosan bead surface. J Mol Liq 248:713–724. https://doi.org/10.1016/j.molliq.2017.10.103

Pal P, Pal A (2019) Treatment of real wastewater: kinetic and thermodynamic aspects of cadmium adsorption onto surfactant-modified chitosan beads. Int J Biol Macromol 131:1092–1100. https://doi.org/10.1016/j.ijbiomac.2019.03.121

Pashaei-Fakhri S, Peighambardoust SJ, Foroutan R, Arsalani N, Ramavandi B (2021) Crystal violet dye sorption over acrylamide/graphene oxide bonded sodium alginate nanocomposite hydrogel. Chemosphere 270:129419. https://doi.org/10.1016/j.chemosphere.2020.129419

Pavan PC, Gomes GA, Valim JB (1998) Adsorption of sodium dodecyl sulphate on layered double hydroxides. Micropor Mesopor Mater 21:659–665. https://doi.org/10.1016/S1387-1811(98)00054-7

Pongjanyakul T, Puttipipatkhachorn S (2007) Xanthan-alginate composite gel beads: molecular interaction and in vitro characterization. Int J Pharm 331:61–71. https://doi.org/10.1016/j.ijpharm.2006.09.011

Purakayastha PD, Pal A, Bandyopadhyay M (2005) Sorption kinetics of surfactant on to waste tire rubber granules. Sep Purif Technol 46:129–135. https://doi.org/10.1016/j.seppur.2005.04.011

Saber-Samandari S, Saber-Samandari S, Joneidi-Yekta H, Mohseni M (2017) Adsorption of anionic and cationic dyes from aqueous solution using gelatin-based magnetic nanocomposite beads comprising carboxylic acid functionalized carbon nanotube. Chem Eng J 308:1133–1144

Sanchez-Martin J, Beltran-Heredia J, Gibello-Perez P (2011) Adsorbent biopolymers from tannin extracts for water treatment. Chem Eng J 168:1241–1247. https://doi.org/10.1016/j.cej.2011.02.022

Schuricht F, Borovinskaya ES, Reschetilowski W (2017) Removal of perfluorinated surfactants from wastewater by adsorption and ion exchange-Influence of material properties, sorption mechanism and modelling. J Environ Sci 54:160–170. https://doi.org/10.1016/j.jes.2016.06.011

Sellimi S, Younes I, Ayed HB, Maalej H, Montero V, Rinaudo M, Dahia M, Mechichi T, Hajji M, Nasri M (2015) Structural, physicochemical and antioxidant properties of sodium alginate isolated from a Tunisian brown seaweed. Int J Biol Macromol 72:1358–1367. https://doi.org/10.1016/j.ijbiomac.2014.10.016

Shami S, Dash RR, Verma AK, Dash AK, Pradhan A (2019) Adsorptive removal of surfactant using dolochar: a kinetic and statistical modeling approach. Water Environ Res. https://doi.org/10.1002/wer.1193

Wang W, Wang A (2010) Synthesis and swelling properties of pH-sensitive semi-IPN superabsorbent hydrogels based on sodium alginate-g-poly(sodium acrylate) and polyvinylpyrrolidone. Carbohydr Polym 80:1028–1036. https://doi.org/10.1016/j.carbpol.2010.01.020

Wang Y, Wang W, Shi X, Wang A (2013) A superabsorbent nanocomposite based on sodium alginate and illite/smectite mixed-layer clay. Appl Polym Sci. https://doi.org/10.1002/APP.39141

Zhang S, Xu F, Wang Y, Zhang W, Peng X, Pepe F (2013) Silica modified calcium alginate-xanthan gum hybrid bead composites for the removal and recovery of Pb(II) from aqueous solution. Chem Eng J 234:33–42. https://doi.org/10.1016/j.cej.2013.08.102

Zhang W, Xu F, Wang Y, Luo M, Wang D (2014) Facile control of zeolite NaA dispersion into xanthan gum-alginate binary biopolymer network in improving hybrid composites for adsorptive removal of Co2+ and Ni2+. Chem Eng J 255:316–326. https://doi.org/10.1016/j.cej.2014.06.024

Acknowledgements

The authors are grateful to IIT Kharagpur for providing instrumental facilities and Ministry of Education, Government of India for providing financial support. Besides that, the authors would like to thank Miss Anuja Joseph (research scholar of School of Environmental Science and Engineering, IIT Kharagpur) for her help in bacteriological test.

Funding

None.

Author information

Authors and Affiliations

Contributions

SB was involved in the conceptualization, writing and original draft preparation, investigation. AN was involved in writing-reviewing and editing, conceptualization. AP was involved in supervision, writing-reviewing and editing, conceptualization. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval and consent to participate

No animals or human beings, human data or human tissue were used in this study.

Additional information

Editorial responsibility: Samareh Mirkia.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Biswas, S., Nath, A. & Pal, A. Fabrication of a novel alginate-xanthan biopolymer hydrogel bead for cationic surfactant removal from aqueous medium. Int. J. Environ. Sci. Technol. 21, 6663–6676 (2024). https://doi.org/10.1007/s13762-023-05421-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05421-7