Abstract

Azo dyes are widely used in textile industry due to their easy production, high stability during washing and variety of colors. It raises concern over the ecosystem because of its structural features. Some advanced oxidation process that is tertiary treatment is one of the conventional treatment methods. Pollutants that cannot be removed by primary and secondary treatment are treated by tertiary treatment methods. Primary and secondary treatment methods are not generally sufficient for removal of azo dyes. For this reason, it has an important place in its treatment with advanced oxidation processes. The aim of this study is to investigate the effect of different parameters on color and COD removal yields of triple dye mixtures by Fenton method and to optimize with the Taguchi method. Moreover, the aim is to examine the relationship between these parameters and ORP by regression analysis, and the change of organic groups by FTIR analysis in the effluent. As a result of the study, it was observed that the parameters considered had different effects on COD and color removal. There was an increase in both color and COD removal only with the increase in H2O2 concentration. The highest COD and color removal yields were 95.8% and 99.3%, respectively. As a conclusion, Fenton process is a method that can be preferred in the treatment of textile dyestuffs since the chemicals used are non-toxic, abundant and economical, and therefore, the operation cost of the system is quite favorable, providing advantages to compete with other advanced oxidation processes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As a result of the continuous development in ready-made clothing and home textiles, there are excessive production and consumption. The textile sector has an important place for production and environmental pollution, and there are pollutants in wastewater such as dyestuffs, surface active agents, toxic and organic compounds, heavy metals, soap, detergent, salt in bleaching, dyeing and washing processes in textile sector. Therefore, it is the most polluted wastewater for parameters such as different pH, dyestuff/color, temperature and organic, in other words, chemical oxygen demand (COD). It was stated that 1.6 million m3 water was used in a textile factory for an average production of 8 tons. It is estimated that 7 × 105–10 × 105 tons of dyestuff is produced for use in the textile industry worldwide and 2.8 × 105 tons of textile wastewater is produced annually (Mahamallik and Pal 2017; Turkes 2019), and 280,000 tons of the dye (10–15%) is discharged with wastewater (Babaei et al. 2017). Discharge of wastewater produced by the use of dyes from hazardous substances into the water system affects photosynthetic and respiratory activities adversely and causes the degradation of the water ecosystem, deterioration of aesthetic appearance and the formation of toxic products by reductive cleavage of azo bond. These dyes cause also mutagenic and carcinogenic effects in humans (Khan et al. 2019). There are various synthetic dyes (cationic, anionic and non-ionic). Basic dyes (e.g., Astrazon dyes) are the most toxic due to their cationic structure delocalized along the chromophoric system around nitrogen atoms. Basic dyes are widely used in silk, wool, nylon and acrylic dyeing (Bayrak Tezcan et al. 2019). These dyes should be controlled before they are released to the environment since even small amounts of these dyes can cause negative effects on the environment (Khan et al. 2019). Azo dyes are often used in the textile industry and other industrial applications due to their low energy consumption, easy use and production, high stability during washing and color diversity. Due to sulfa and azo groups, azo dyes constitute the largest and most permanent class. These structures (sulfa and azo groups) do not occur naturally, in other words, they are synthetic, xenobiotic, resistant to oxidative-biological decomposition and toxic (Sennaoui et al. 2018; Eren et al. 2010). Moreover, azo dyes contain heavy metals. These structural features increase the concern on the ecosystem (Eren et al. 2010).

Conventional treatment processes are not sufficient for the removal of azo dyes in wastewater. Because either the efficiency is low or it results in the formation of secondary toxic waste products, in other words, they remain in the effluent or sludge (Sennaoui et al. 2018; Eren et al. 2010). In the literature, advanced oxidation processes (AOPs) have been reported to provide effective decomposition of these dyes. AOPs are chemical, photocatalytic and electrochemical methods that produce hydroxyl radical (\( {\text{OH}}^{ \cdot } \)). \( {\text{OH}}^{ \cdot } \) radical is the strongest oxidant after fluoride and has an equally high standard oxidation potential (2.8 V) that can react no selectively with stable organic compounds until final mineralization (Sennaoui et al. 2018). Fenton process is one of AOPs processes where OH∙ occurs during the reaction (reaction no. 1). It is an important and economical advanced oxidation process that is preferred since only the catalytic properties of Fe2+ are used and it can be removed from the solution easily; H2O2 is decomposed to non-toxic substances such as H2O and O2; and hydroxyl radicals have affectivity in mineralizing existing pollutants (Eren et al. 2010; Erat 2018).

This system should be operated under optimum conditions. Optimization of Fe2+ and H2O2 ratios as well as other parameters such as pH is very important for the effective operation of the system. Otherwise, hydroxyl radicals may be retained and their tendency to react may be reduced. Moreover, if Fe2+ ions are more than H2O2 ions, the mechanism of treatment can vary from oxidation to chemical coagulation.

There are some studies on Fenton removal of the most toxic azo dyestuffs, Astrazon dyes (Rahman et al. 2010; Rodrigues et al. 2012; Esteves et al. 2016; Erat 2018), and there are also limited studies on different dye mixtures (Hamoud et al. 2017). Esteves et al. (2016) carried out the treatment of Astrazon Blue FGGL 300% with heterogeneous Fenton under main operating conditions (H2O2–Fe+2 concentrations, temperature and contact time). Under best conditions, 62.7% color and 39.9% TOC removal were achieved. In the study conducted by Erat (2018), Astrazon Yellow 5GL dye was removed by Fenton process under main operation conditions (pH, H2O2, Fe+2, dye concentration). The highest color and COD removal percentages were 98.7% and 80.4%, respectively. Moreover, a limited study (Wu and Wang 2012; Yu et al. 2014) was conducted with the observation of pH and ORP in the Fenton process.

The aim of this study is to investigate the removal yield of triple dye mixture by Fenton method. For this purpose, operation parameters (pH, H2O2 and Fe+2 concentrations, reaction time, pollutant concentration) as well as parameters (temperature, salt, different dye mixtures, high dye concentrations) that consider the properties of real textile wastewater were taken into consideration. In many studies in the literature, color removal was mostly taken into consideration. COD removal should also be considered, as complete decolorization of the wastewater does not mean that the dye is completely decomposed. Therefore, the efficiency of the system under different operation conditions was determined by both color and COD, and oxidation–reduction potential (ORP) and FTIR parameters. Moreover, it was optimized with Taguchi method and regression analysis was performed.

Materials and methods

Materials

Astrazon Yellow 7 GLL 200% (AY), Astrazon Brilliant Red 4G 200% (AR) and Astrazon Black MBL 300% (AB) textile dyes used in the study were obtained from DyStar Inc. 1 g/L stock solutions were prepared. Spectrum scanning and COD analyses were performed to determine wavelength for each dye and organic content. The wavelengths and COD values of AY, AR and AB are 417 nm and 674 mg/L, 514 nm and 583 mg/L; and 613 nm and 3340 mg/L, respectively. The mixture of triple dye was prepared by taking equal volume of each dye solution. The wavelength, COD, pH, ORP and ion product of the triple dye mixture were determined as 430 nm, 1613 mg/L, 3.79, 199.1 mV and 4.13e−4 mol/L, respectively. Studies were carried out by diluting 2, 4 and 8 times. That is, COD concentrations are 806.5, 403.3 and 201.6 mg/L, respectively.

0.1 N NaOH and 0.1 N H2SO4 chemicals (Carlo Erba, 99% purity) were used for pH adjustment; H2O2 (30%) and Fe2SO47H20 (> 99.5%) supplied by Riedel-de Haën was used for Fenton process, and NaCl (Sigma Aldrich, 99.5%) was used to study the salt effect. All chemicals used in the study are laboratory quality (> 99% purity), and distilled water is used to prepare the required solutions.

Methods

Spectrum scannings, COD and color analyses were performed with Spectroquant Prove 300 Spectrophotometer (Merck). pH, ORP and ion product were measured with Mettler Toledo Seven Compact pH meter. COD analyses were performed (Merck Spectroquant TR320) by a closed reflux colorimetric method (5220-D) according to Standard Methods for the Examination of Water and Wastewater (APHA 2012). COD analyses were performed at 420 nm and 600 nm at concentrations less than 100 mg/L and concentrations above 100 mg/L, respectively.

Moreover, Fourier transform infrared spectrometer–attenuated total reflectance (FTIR–ATR) analysis was performed to determine the change in functional groups of dyes both in triple mixture dye and effluent sample formed as a result of optimum conditions.

Batch scale system

As a result of the literature review, the most effective levels of the operation parameters were selected. The experimental conditions established with Taguchi are given in Table 1. The reason for operation at two different temperatures is that the temperature in textile dyeing processes is about 50◦C (Eren et al. 2010). For this reason, it was studied at both room temperature 25 °C and 50 °C. High color concentration, different dye mixtures and salt content were considered to represent the real textile wastewater.

Fifty milliliters of the dye mixture diluted in the appropriate ratio was taken into a 100-mL beaker, and pH was adjusted. Following FeSO47H2O, H2O2 and NaCl addition to the beaker, 5 min of rapid mixing (200 rpm) and slow mixing (50 rpm) for the remaining time were applied in the mixing apparatus. After rapid and slow mixing, pH was adjusted to 7–8 and the samples in the beakers were allowed to sediment for 60 min.

The main mechanism of Fenton is chemical oxidation and chemical coagulation (Güneş and Cihan 2015). The system was operated under acidic conditions, in other words, between pH 2 and 4. After adding Fe2+ ion (iron sulfate heptahydrate), hydroxyl radicals are formed by adding hydrogen peroxide. In the meantime, high-molecular organic materials are converted to smaller molecules by oxidation and Fe2+ is oxidized to Fe3+ ion. After the oxidation reaction is completed, neutralization process is carried out by sodium hydroxide and it is brought to the best sedimentation range of Fe3+ ions as pH 7 and 8. At the end of the waiting period determined for sedimentation of Fe3+ ions after neutralization, the upper phase of the sample is separated from the bottom sludge. The amount of sludge formed after sedimentation was recorded. The system used in the study is given in Fig. 1.

Optimization and statistical (regression) analyses with Taguchi method were performed by using Minitab 18 program. Taguchi method is an experimental design that uses orthogonal sequences. In this study, the L18 (2^1 and 3^6) orthogonal sequence consists of 2 levels of one (temperature) and 3 levels of others (pH, reaction time, salt, Fe+2, H2O2 and color concentration).

The results of the removal efficiency (%) obtained from the experiments have been converted to signal/noise ratio (S/N) and evaluated. S and N in the S/N ratio represent the signal factor and noise factor, respectively. The signal factor refers to the real value received from the system, and the noise factor refers to the factors that cannot participate in the design of the experiment but affect the result of the experiment. Noise sources are all variables that cause the performance characteristics to be obtained to deviate from the target value. Thus, the smaller the N value expressing the noise factors in the S/N ratio, the closer the desired target value is. So the purpose of this analysis is to maximize the S/N ratio. There are many S/N ratios in the literature. However, in this study, the “biggest best” (2) criterion was used for Nusselt (Serencam and Ucurum 2019).

where yi denotes the performance characteristic value (Nusselt number), and n denotes the number of Y values.

Results and discussion

Results

Effects of operation parameters on COD removal

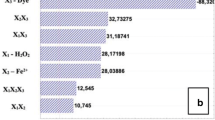

S/N ratios of the obtained data to investigate the effects of different parameters on COD removal yield are given in Fig. 2.

The highest values in Fig. 2 are optimum values since the largest is the best approach used for COD removal yield.

Since textile wastewater has high temperature, the effect of different temperatures was also studied. However, the high temperature decreased COD yield. Therefore, the optimum temperature for COD removal was determined as 25 °C. At temperatures above 40 °C, some \( {\text{OH}}^{ \cdot } \) radicals cannot have sufficient time to react/meet with pollutants, since rapid of radical reach and increase with increasing temperature via Arrhenius equation, resulting in decreasing of treatment efficiency. Furthermore, H2O2 may be decomposed into water and oxygen (in other words, radical formation decreases) (Dindar 2019), thus adversely affecting COD yield. It can be said that the high temperature is not suitable for these operation conditions since the main purpose of the Fenton process is the production of hydroxyl radicals, which are stronger oxidants. Salt content may also have a negative effect on the temperature. With the increase in temperature, the salt may have reduced the radicals in the environment. Thus, low yields can be obtained with increasing temperature.

In many studies, low dye concentrations were generally studied. But, low dye concentrations mean low COD. Perhaps this is why COD removal has not been considered in many studies. However, in fact, dye and COD concentrations of textile wastewaters are higher. In this study, three different concentration ranges were studied. There was no linear decrease or increase with the increase in concentration. A slightly higher S/N ratio was obtained at 1500 mg/L dye concentration compared to 375 mg/L dye concentration. But, no big difference has observed. Actually, as the dye concentration increases, COD removal efficiency is expected to decrease. The reasons for the absence of such a change are thought to be due to the triple dye mixture and other operation conditions.

Textile wastewater includes chloride (CI−), sulfate, etc. salts. For this, NaCl salt was added and its effect on COD yield was studied. S/N ratio decreased as salt concentration increased. In other words, the presence of salt had a negative effect on COD removal in the Fenton process. The presence of CI− reduces the yield by causing the hydroxyl radical to be swept and forms stable complexes with Fe+2/Fe+3, which assume a reducing role in the environment (Khan et al. 2019). The use of Fe+2/Fe+3 with the exception of hydroxyl radical formation is not desirable in the Fenton process, since reaction of Fe+2 with H2O2 (hydroxyl radical formation) is reduced.

A reverse change was observed in Fe+2 and H2O2 concentrations. Fe+2 have a high S/N ratio at low concentration (2 mM), while H2O2 has a high S/N ratio at high concentration (160 mM). The increase in COD removal with increase in H2O2 shows that H2O2 concentration causes both more \( {\text{OH}}^{ \cdot } \) formation and oxidation. The decrease in yield with increasing Fe+2 may be due to depletion of hydroxyl radicals by excess of Fe+2 (reaction 3) (Ertugay and Acar 2017).

Ideal H2O2/Fe+2 ratios are recommended in 10–40 ranges (Güneş and Cihan 2015). In this study, the range of 5–80 was studied. The highest COD removal was obtained at a rate of 20.

The effect of pH in the Fenton process has been investigated in many studies, and it has been observed that the Fenton process is more efficient under acidic conditions. For this reason, 2.5, 3 and 3.5 values were studied in this study. It was observed that high S/N ratio was not obtained when pH was 2.5 and close S/N ratios were at pH 3 and 3.5. In many studies, pH 3 was determined as the optimum value (Kavitha and Palanivelu 2005; Eren et al. 2010; Ertugay and Acar 2017). pH is an important parameter affecting the oxidation mechanism of the dye. pH change is a parameter that affects Fe+2 concentration and thus the production rate of the \( {\text{OH}}^{ \cdot } \) radical. Fenton oxidation reaction speed is faster in acidic conditions. This is because the released OH− ion is neutralized by proton (H+) (reaction 4), so recycling is prevented and efficiency increases (Erat 2018). The low removal efficiency at pH < 2.5 is due to the formation of iron complex [Fe(II) (H2O)6]+2 or the sweeping of hydroxyl radicals (reaction 6) as a result of H3O2+ formation (reaction 5).

The reasons of low yield at high pH (> 4) are also Fe(OH)3 formation with low catalytic feature, degradation of H2O2 and difficult formation of \( {\text{OH}}^{ \cdot } \) as a result of low oxidation activity and formation of iron hydroxyl complexes (7–10 reactions), which has low activity after converting Fe+2 into Fe+3 and which do not react with H2O2 (Khan et al. 2019; Turkes 2019).

At different reaction times, S/N ratio increased with increasing time. This has a positive effect on COD removal since the length of time is mainly maintained by oxidation and coagulation. It also shows that the oxidation of the intermediate products formed by decomposition is difficult and requires longer time for complete oxidation.

Effects of operation parameters on color removal

S/N ratios of the obtained data to investigate the effects of different parameters on color removal yield are given in Fig. 3.

Wastewater temperature had a positive effect on color removal yield, and S/N ratio increased as temperature increased. It can be said that the radical formation reduces since H2O2 decomposes into water and oxygen at temperatures above 40 °C (Dindar 2019), and the formed oxygen is sufficient for color removal, but not for COD removal. The easy removal of the color does not mean that the dye molecules completely decompose. COD and FTIR results also show that complete mineralization of azo dyes with stable structure by Fenton may not be achieved.

There was a linear decrease in color removal yield with the increase in dye concentration. The highest S/N ratio was obtained at 375 mg/L dye concentration. It can be said that the color removal decreases as dye concentration increases due to the lack of sufficient hydroxyl radical in the environment. In the study conducted by Ertugay and Acar (2017), it was stated that color removal yield increases as dye concentration increases. In this study, there may not have increased in color removal since the treatment of high dye concentrations and different dye mixtures were performed instead of removal of low dye concentration and a single-type dye. In other words, high dye concentration may require a higher hydroxyl radical, i.e., oxidant. In some studies, it was stated that the higher the concentration, the higher the solubility of the dye is because of increase in the interaction between dye and \( {\text{OH}}^{ \cdot } \) (Wu et al. 2010; Ertugay and Acar 2017). This can be true for the low dye concentration range, but no such relationship was observed at high dye concentration.

There was no linear decrease or increase with the increase in salt concentration. A positive effect of the salt concentration of 500 mg/L on color removal was observed, and the highest S/N ratio was obtained at 500 mg/L. The high concentration of salt may have led to the reduction of the hydroxyl radical. Salt is a free radical scavenger, and it may have negatively affected the presence of sufficient \( {\text{OH}}^{ \cdot } \) in the environment for high concentration.

Fe+2 concentration did not show a linear change, whereas H2O2 concentration showed a linear change. The highest S/N ratio in Fe+2 concentrations was obtained at 8 mM. The highest S/N ratio in H2O2 concentration was obtained at 160 mM. The increase in color removal with the increase in H2O2 can be attributed to the formation of excess OH radical (Eren et al. 2010) and/or the presence of oxygen (oxidation). It indicates that the excess of H2O2 was not used. Because if it were excessive, HO2 radical would be formed (reaction 11) and removal yield would decrease due to its less activity (Schrank et al. 2007).

The excess Fe+2 increase the amount of sludge (amount of suspended solid matter), and non-precipitating iron causes color depending on its solubility (Matavos-Aramyan and Moussavi 2017). Therefore, a good adjustment of H2O2 and Fe+2 doses is of great importance. Adding too little leads to low efficiency, adding too much increases the cost (chemical cost, sludge amount and disposal) and possibly decreases removal yield (İlhan et al. 2017).

In the Fenton process, it was determined that pH had an effect on color removal yield and the highest S/N ratio was obtained at the lowest pH value (2.5). Since H2O2 and hydroxyl radical are oxidizing products under acidic conditions (İlles et al. 2019), pH 2.5 is determined as optimum for color removal. Optimum pH value is consistent with the results in the literature.

It was observed that color removal can occur in 30 min, and removal yield decreases as reaction time increases. The highest S/N ratio was achieved in 30 min. Unlike oxidation of organic intermediates (COD removal) that require longer time, color removal requires shorter time. Due to the homogeneous catalytic structure of the method, there is no mass transfer limit. This ensures that short reaction time is sufficient for color removal (Tunc et al. 2012).

It has been observed that the operation parameters of basic (cationic) dye mixtures representing a textile wastewater have different effects on COD and color removal. Low temperature (25 °C), high dye concentration (1500 mg/L), low salt concentration (0 mg/L-no), low Fe+2 (2 mM) and high H2O2 concentration (160 mM), high pH value (3.5) and longer time (60 min) optimum for COD removal, while high temperature (50 °C), low dye concentration (375 mg/L), medium salt concentration (500 mg/L), high Fe+2 (8 mM) and high H2O2 concentration (160 mM), low pH value (2.5) and shorter time (30 min) optimum for color removal. In other words, other parameters except for high H2O2 concentration had different effects. Therefore, if a Fenton process will be used for the treatment of textile wastewater, the effect of the parameters considered for color removal and/or COD removal should be optimized by separate studies. If the removal of two parameters will be considered, the optimal conditions of the process parameters should be determined according to the mineralization (COD removal yield), because it is much easier to obtain a high level of decolorization than the high level of mineralization (Papić et al. 2009).

Rank of parameters affecting COD, color and COD + color removal yield is given in Table 2. Temperature was last in terms of effect and in the same rank for all yields, while other parameters were generally in different ranks. The most important parameters affecting COD, color and COD + color removal were determined as salt content, dye concentration and H2O2 concentration, respectively. Salt content is a priority parameter in COD removal because the presence of chloride may cause COD interference and reduce radicals. Dye concentration is a priority parameter in decolorization because the mass transfer limitation is low/no in low concentration and requires more radicals in high concentration. And the concentration of H2O2 is the primary parameter in COD + decolorization because it is oxidizing by itself. In other words, it contributes to both COD and color removal.

Changes of the ORP and FTIR and removal yields

In this study conducted with the mixture of three different azo dyes, color removals after Fenton oxidation were measured using determined wavelengths. The yield of the mixture varies between 6.7 and 99.7%; the removal of AY, AR and AB dyes varied between 4–99.2%, 60–99.6% and 90–99.9%, respectively. COD removal was measured in the range from 2.8 to 95.8% (Table 3).

At the end of Fenton oxidation, sludge volumes of the samples were measured in the range of 1.5–8 mL. Excess sludge shows that there is excess Fe+2 in the environment. Fe+2 tend to precipitate by oxidizing to Fe+3. After precipitation, ORP and ion product were measured in the upper phase. ORP is oxidation–reduction potential, and it was measured between 16.7 and 135.9 mV (Table 3). Measurement of different values is due to different pH, Fe+2 and H2O2. H2O2 is the oxidizing agent and provides ORP to be high, while Fe+2 is the reducing agent and causes pH of the environment to increase by consuming H+ ions and ORP decreases (Yu et al. 2014).

The equations calculated for color removal, COD removal and ORP change as a result of regression analysis and obtained R2 values are given in Table 4. The minus (−) sign in the equation indicates that yield/ORP value decreases with increasing of that parameter, and the plus (+) sign indicates that yield/ORP value increases with increasing of that parameter. R2 values were obtained above 71%.

ORP had higher R2. This shows that the relationship between operation parameters and ORP is higher. pH and Fe+2 are the parameters that significantly affect ORP value. It was observed that pH, H2O2 and Fe+2 concentrations had a significant effect on initial ORP value in the treatment of actual printing and dyeing wastewater with Fenton (Wu and Wang 2012). ORP depends on many parameters and is a flexible and easy parameter to be used in the control of chemical wastewater treatment processes.

FTIR analysis was performed in the influent (triple mixture) and in sample numbered 3 with the highest removal yield (COD and color) (Fig. 4). Two main peaks were formed as a result of FTIR analysis. Only the density of these peaks in the influent and effluent has changed. The determination of the peaks in the influent and effluent shows the stability of these groups. Peaks were formed at 3604–3012 cm−1 and 1629 cm−1. These peaks can be attributed to N–H elongation vibration in amines and amides or O–H elongation vibration in phenols; and C=C elongation vibration in the alkene group or N–H bending vibration in amides, respectively.

Evaluation of Fenton process in terms of benefit, cost and risk criteria

The advantage of the Fenton process is that the chemicals used (Fe+2 and H2O2) are non-toxic. H2O2 turns into environmentally friendly products (H2O and O2). The operation and maintenance of the system are easy and simple. Mostly high yield is obtained (Khan et al. 2019). A wide range of pollutants (color, COD, etc. in wastewater, sludge and soil) can be removed by this method (GilPavas et al. 2019). It provides fast color removal (Rosales et al. 2018; Turkes 2019), because there is no mass transfer limit due to homogeneous catalytic structure (Tunc et al. 2012). Fe+2 and H2O2, which are abundant and less toxic, are cost-effective. Fenton method is effective for COD removal in wastewater with low BOD/COD ratio such as textile wastewater (İlhan et al. 2017).

The greatest risk in the Fenton process is the formation of sludge (even less compared to some methods) and the necessity of disposal of the sludge formed (Khan et al. 2019). But, as a result of physical, chemical, biological or thermal treatment, a waste (solid/liquid/gas) occurs, which needs to be treated/controlled. For this reason, it is of great importance to reduce sludge formation with the operation under optimum conditions. Another risk is the operation of system at low and narrow pH levels (2–4) to achieve high yield. It is not suitable for all paints/dyes (Turkes 2019). For example, low yield can be provided in reactive dyes (Dindar 2019). Also, low color removal efficiency is achieved generally in light-colored paints such as yellow, because Fe+2 in the environment as reducing agent can cause the effluent to be colored. The presence of salt in the sludge and the formation of foam in the system are other its disadvantages. If H2O2 remains in the effluent, it may increase system cost due to excessive use, cause incorrect COD results and damage beneficial microorganisms in the discharged environment (Canbolat 2019). Therefore, optimization of H2O2 is important.

It was stated that the investment and operation costs of a system at a flow rate of 250 m3/day in a 50 m3 reactor (12.5 m3/h, 20 h/day) are approximately 66,000 USD and approximately 435 USD/day, respectively (Canbolat 2019). In other words, the operation cost is 1.74 USD per m3. It is stated that the Fenton process can be selected when the flow rate is smaller than 50 m3/h, and TOC value is around 1000 mg/L in the method selection graph according to flow and TOC values (Dindar 2019). Treatment at higher concentrations may also realize, but it will result in greater chemical consumption, longer reaction time, and consequently increase in reactor volume.

It is a very convenient method in terms of operation cost due to the economy of the chemicals used. Determination of the optimization values of H2O2 and Fe+2 will prevent the increase in cost as a result of overuse.

Conclusion

In this study, the change of different parameters (COD, color, ORP) in triple dye mixture has been optimized in terms of different operating conditions by Fenton oxidation. It was observed that the parameters considered in the study had different effects for COD and color removal. Increase in H2O2 concentration only resulted in an increase in both color and COD removal. Therefore, if the Fenton process is to be used in textile wastewater treatment, the operation parameters of the system should be optimized according to the aim (whether COD or color removal, or both). From the results of FTIR analysis, it was concluded that Astrazon dyes were very stable. Considering COD and color removal yield together, the highest COD removal yield and color removal yield were 95.8% and 99.3%, respectively, at 25 °C, 375 mg/L dye concentration, 1000 mg/L salt concentration, 8 mM Fe+2, 160 mM H2O2, pH 3.5 and 60 min reaction time.

The operation cost of the system is very favorable, since the chemicals used in the Fenton process are abundant, economical and non-toxic. High yields for COD and color removal were obtained by Fenton process.

References

APHA (2012) Standart methods for the examination of water and wastewater, vol 21. American Public Health Association, Washington DC

Babaei AA, Kakavandi B, Rafiee M, Kalantarhormizi F, Purkaram I, Ahmadi E, Esmaeili S (2017) Comparative treatment of textile wastewater by adsorption, Fenton, UV-Fenton and US-Fenton using magnetic nanoparticles-functionalized carbon (MNPs@C). J Ind Eng Chem 56:163–174

Bayrak Tezcan E, Ceylan Z, Acar FN (2019) Kinetics, isotherm and thermodynamic studies of the adsorption behavior of Basic Yellow 51 onto rice husk and burned rice husk. J Inst Sci Technol 1977–1988

Canbolat ÇB (2019) Treatment of membrane concentrates using a new technology based on hydrodynamic cavitation and advanced oxidation processes for water and salt reuse from textile wastewater. Ph.D. thesis, Gebze Technical University, Turkey. https://tez.yok.gov.tr/UlusalTezMerkezi/

Dindar N (2019) Implementation of advanced treatment processes in textile industry wastewaters for organic substance removal. Master thesis, Pamukkale University, Turkey. https://tez.yok.gov.tr/UlusalTezMerkezi/

Erat N (2018) Optimization of removal of Astrazon Yellow 5GL dye material from aqueous media by Fenton and UV/H2O2 processes using taguchi method. Master thesis, Ataturk University, Turkey. https://tez.yok.gov.tr/UlusalTezMerkezi/

Eren Z, Acar FN, Ince NH (2010) Fenton and Fenton-like oxidation of CI Basic Yellow 51: a comparative study. Color Technol 126:337–341

Ertugay N, Acar FN (2017) Removal of COD and color from Direct Blue 71 azo dye wastewater by Fenton’s oxidation: kinetic study. Arab J Chem 10:S1158–S1163

Esteves BM, Rodrigues CS, Boaventura RA, Maldonado-Hodar FJ, Madeira LM (2016) Coupling of acrylic dyeing wastewater treatment by heterogeneous Fenton oxidation in a continuous stirred tank reactor with biological degradation in a sequential batch reactor. J Environ Manage 166:193–203

GilPavas E, Dobrosz-Gomez I, Gomez-Garcia MA (2019) Optimization and toxicity assessment of a combined electrocoagulation, H2O2/Fe(2+)/UV and activated carbon adsorption for textile wastewater treatment. Sci Total Environ 651:551–560

Güneş E, Cihan MT (2015) COD and color removal from wastewaters: optimization of Fenton process. Pamukkale Univ J Eng Sci 21:239–247

Hamoud HI, Finqueneisel G, Azambre B (2017) Removal of binary dyes mixtures with opposite and similar charges by adsorption, coagulation/flocculation and catalytic oxidation in the presence of CeO2/H2O2 Fenton-like system. J Environ Manage 195:195–207

Ilhan F, Yetilmezsoy K, Kabuk A, Ulucan K, Coskun T, Akoglu B (2017) Evaluation of operational parameters and its relation on the stoichiometry of Fenton’s oxidation to textile wastewater. Chem Ind Chem Eng Q 23:11–19

Illes E, Mizrahi A, Marks V, Meyerstein D (2019) Carbonate-radical-anions, and not hydroxyl radicals, are the products of the Fenton reaction in neutral solutions containing bicarbonate. Free Radic Biol Med 131:1–6

Kavitha V, Palanivelu K (2005) Destruction of cresols by Fenton oxidation process. Water Res 39:3062–3072

Khan J, Tariq M, Muhammad M, Mehmood MH, Ullah I, Raziq A, Akbar F, Saqib M, Rahim A, Niaz A (2019) Kinetic and thermodynamic study of oxidative degradation of acid yellow 17 dye by Fenton-like process: effect of HCO3−, CO32−, Cl− and SO42− on dye degradation. Bull Chem Soc Ethiop 33:243

Mahamallik P, Pal A (2017) Degradation of textile wastewater by modified photo-Fenton process: application of Co(II) adsorbed surfactant-modified alumina as heterogeneous catalyst. J Environ Chem Eng 5(3):2886–2893

Matavos-Aramyan S, Moussavi M (2017) Advances in Fenton and Fenton based oxidation processes for industrial effluent contaminants control—a review. Int J Environ Sci Nat Resour 2:1–18

Papić S, Vujević D, Koprivanac N, Šinko D (2009) Decolourization and mineralization of commercial reactive dyes by using homogeneous and heterogeneous Fenton and UV/Fenton processes. J Hazard Mater 164:1137–1145

Rahman MM, Yusuf MA, Uddin MA, Islam MA, Saha R, Rahman MM, Haque MA, Hasnat MA (2010) Influence of irradiation on Fenton degradation of brilliant Red X-3B. Int J Chem Reactor Eng 8

Rodrigues CS, Boaventura RA, Madeira LM (2012) Application of Fenton’s reagent for acrylic dyeing wastewater decolorization, organic matter reduction and biodegradability improvement. J Adv Oxid Technol 15:78–88

Rosales E, Anasie D, Pazos M, Lazar I, Sanroman MA (2018) Kaolinite adsorption-regeneration system for dyestuff treatment by Fenton based processes. Sci Total Environ 622–623:556–562

Schrank SG, dos Santos JNR, Souza DS, Souza EES (2007) Decolourisation effects of Vat Green 01 textile dye and textile wastewater using H2O2/UV process. J Photochem Photobiol A 186:125–129

Sennaoui A, Alahiane S, Sakr F, Assabbane A, Addi EHA, Hamdani M (2018) Advanced oxidation of Reactive Yellow 17 Dye: a comparison between Fenton, photo-Fenton, electro-Fenton, anodic oxidation and heterogeneous photocatalysis processes. Portugaliae Electrochimica Acta 36:163–178

Serencam H, Ucurum M (2019) Performance evaluation of adsorption properties for Ni(II) removal with flying ash using taguchi experimental design. Omer Halisdemir Univ J Eng Sci 8(1):336–344

Tunc S, Gürkan T, Duman O (2012) On-line spectrophotometric method for the determination of optimum operation parameters on the decolorization of Acid Red 66 and Direct Blue 71 from aqueous solution by Fenton process. Chem Eng J 181–182:431–442

Turkes S (2019) Investigation of the treatability of textile industry wastewaters with Fenton and photo-Fenton processes. Master thesis, Çukurova University, Turkey. https://tez.yok.gov.tr/UlusalTezMerkezi/

Wu H, Wang S (2012) Impacts of operating parameters on oxidation-reduction potential and pretreatment efficacy in the pretreatment of printing and dyeing wastewater by Fenton process. J Hazard Mater 243:86–94

Wu Y, Zhou S, Qin F, Ye X, Zheng K (2010) Modeling physical and oxidative removal properties of Fenton process for treatment of landfill leachate using response surface methodology (RSM). J Hazard Mater 180:456–465

Yu R-F, Chen H-W, Cheng W-P, Lin Y-J, Huang C-L (2014) Monitoring of ORP, pH and DO in heterogeneous Fenton oxidation using nZVI as a catalyst for the treatment of azo-dye textile wastewater. J Taiwan Inst Chem Eng 45:947–954

Acknowledgements

I would like to thank Prof. Filiz Nuran Acar for allowing me to use laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author has declared no conflict of interest. The study has carried out by the author.

Additional information

Editorial responsibility: M. Abbaspour.

Rights and permissions

About this article

Cite this article

Adar, E. Optimization of triple dye mixture removal by oxidation with Fenton. Int. J. Environ. Sci. Technol. 17, 4431–4440 (2020). https://doi.org/10.1007/s13762-020-02782-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-02782-1