Abstract

One of the most valuable approaches to eliminate heavy metal ions from aqueous solutions is biosorption. Cobalt and nickel can be removed from aqueous solutions simultaneously using sodium chloride-treated Cystoseria indica, which is a kind of brown algae. Three parameters, including pH, initial concentration of heavy metals, and adsorbent mass, were designated to run batch adsorption experiments. The central composite design was employed to show the simultaneous change of all factors according to a pre-specified experimental matrix that creates a response model in which the interactions between the calculated responses and each variable as well as interaction influences, are revealed. R2 values for the computed model were 0.96 and 0.95 for the response surface 1 (cobalt) and 2 (nickel), respectively. Central composite design calculated the optimum adsorption process as pH, 5.9; biomass dosage, 0.06 g; initial nickel concentration, 91.94 mg/l; and initial concentration of cobalt 89.36 mg/l. The kinetic and isotherm models were engaged to evaluate the equilibrium data at the optimum condition. The biosorption of both heavy metal ions obeyed the intra-particle diffusion kinetic model best, with the equilibrium adsorption time at 80 min. The extended Freundlich isotherm model is better fitted for the equilibrium biosorption data of nickel and cobalt ions. The maximum biosorption of nickel and cobalt ions simultaneously at optimized condition was 69.99 and 75.21 mg/g, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Releasing heavy metals into the environment has turned into universal problematic matters. Many industries are a participant in unleashing toxic metals into the natural environment, which can result in the entering of heavy metals into the human and animal food chain. The accumulation of toxic heavy metals can endanger human health (Salehi and Madaeni 2014). Oil, gas, textile, battery industries evacuate heavy-metal contaminants like nickel (Ni) and cobalt (Co) (Luo et al. 2018; Xu et al. 2013). Heavy metal ions tend to accumulate in the human body and the natural environment (Park et al. 2015). Biosorption (based on the biological materials to remove the heavy metals) (Ozdemir et al. 2020), adsorption (mass conversion method) (Ojedokun and Bello 2016), reverse osmosis (based on the principle of size exclusion and charge exclusion) (Hosseini et al. 2016), chemical precipitation (adding chemicals to form metal precipitation) (Nas et al. 2019), ion exchange (substituting the ions with another) (Bila et al. 2013), and membrane filtration (pressure-driven separation technique) (Daraei et al. 2013) can be used to remove heavy metals from aqueous solutions. The biosorption process is regarded as one of the most effective ways of heavy metals removal for its outstanding features, including low-priced, eco-friendly, renewability and large biosorption capacity. Biosorption includes the passive binding to metabolic inactive materials stemmed from industrial or agricultural by-products, forestry, marine or terrestrial biological materials and microbe biomass. Macroalgae biomass is broadly available and comprises various active sites, including hydroxyl, carboxyl and amine, in its cell buildings that are reachable for heavy metal ions (Liang et al. 2019).

Many studies have reported that biosorbents comprising bacteria, fungi, algae have the exceptional capability to adsorb heavy metal ions (Kim et al. 2017; Taghi Ganji et al. 2005; Kajavian et al. 2019; Li et al. 2018).

Brown algae biomass has attracted much attention as a biosorbent because of non-toxic nature, renewability, abundance in the natural environment, and catalytic features in the adsorption process (Esmaeili and Aghababai 2015). The biosorption aptitudes of the brown algae, as macroalgae, can be ascribed to the presence of carboxylic acid, sulfonic acid, and amide groups (Akbari et al. 2015; Montazer-Rahmatia et al. 2011).

The northern coast of the Gulf of Oman is recognized as the most abundant source of macroalgae. Cystoseria indica (C. indica) is a subclass of brown algae that can be found plentifully in the Gulf of Oman (Sinaeia et al. 2018; Negm et al. 2018). Growing in huge dimensions and including alginic acid make the usage of C. indica reasonable in removing heavy metals from aqueous solutions (Rasool et al. 2015; John Babu et al. 2019). Oil–gas wastes and heavy metals discharging into the marine environment can impact the ecosystem of aquatic beings in the Gulf of Oman harmfully (Ferraz et al. 2015; Sinaei et al. 2018). Therefore, C. indica is an effective biosorbent to eliminate the contamination from the Gulf of Oman.

Current study focused on the optimization of simultaneous adsorption of two heavy metal ions (cobalt and nickel) to maximize the removal capacity of macroalgae, considering operational condition, and using central composite design. Not only, central composite design minimizes the number of experimental runs, but also displays the interaction between operational variables, and interaction among operational variables and removal efficiency. Sodium chloride was used to treat the surface of brown algae (Cystoseria indica), which is derived from the Oman Sea, to increase the steadiness and the heavy metal adsorption capacity of the brown algae. The optimum amount of pH, adsorbent mass, initial concentration of Co, and initial concentration of Ni was attained using the central composite design algorithm of Design-Expert software. ATR-FTIR spectrometer and scanning electron microscopy (SEM) were utilized to characterize the surface of C. indica. Moreover, isotherm and kinetic models were assessed suing biosorption equilibrium data at optimum conditions.

Materials and methods

Materials

The stock solution of Co (Co(II)) and Ni (Ni(II)) was prepared by dissolving Co nitrate (Co (NO3)2.4H2O) and Ni nitrate (Ni (NO3)2·6H2O) in distilled water. The changed operational concentration of Co(II) and Ni(II) was arranged by dilution of Co(II) and Ni(II) stock solution with deionized water. The solution pH was changed using HCl (0.1 N) and NaOH (0.1 N). All of the chemicals in this study were acquired from Sigma-Aldrich.

Cystoseria indica preparation

Cystoseria indica (C. indica) collected from the Oman Sea were initially cleaned with deionized water to eliminate surface from salts and dirt. Sunlight was employed to desiccate the clean algal samples. Dried C. indica were sieved to the size of 0.5–1.0 mm, after drying with the sun for twenty-four hours. Afterward, the sieved C. indica were desiccated in an oven at 70 °C for twenty-four hours, after washing with deionized water. According to the previous studies, sodium chloride (NaCl) was used to treat the surface of C. indica macroalgae to raise its ability to adsorb heavy metals (Pinnola et al. 2019; Sari and Tuzen 2008).

Batch biosorption of Ni and Co from aqueous solution

According to the pretests and previous studies, pH (2–6), initial metal ion concentrations (30–150 mg/L), adsorbent mass (0.06–0.1 g), and contact times (180 min) were chosen to conduct the biosorption experiments at 25 °C. The algae were added to the containers, including 100 ml of Ni and Co solution, and stirred at 175 rpm for 5 h. After filtering algae, atomic absorption spectroscopy (PinAcle 500, PerkinElmer, USA) was applied to ascertain the residual metal ions concentrations in solutions at the end of adsorption experiments. Equation (1) (equation) calculated the concentrations of the metals adsorbed by C. indica (mg/L):

Ci and Cf (mg/L) are defined as the initial and, finally, heavy metal concentrations in the solution, respectively. V and m are described as the solution volume (L) and the mass of biosorbent (g), respectively. Input and output streams are stopped during the batch adsorption process, unlike the continuous process.

Experimental design

Adsorption process variables, including the initial concentration of Co, the initial concentration of Ni, adsorbent dose and pH, were optimized to maximize the adsorption capacity of C. indica for simultaneous adsorption of Co and Ni using the central composite methodology of Design-Expert Software (version 11.0.0). Limitations selected for each variable are existing in Table 1. According to the previous studies and the pretests, the level of variables was determined, as shown in Table 1.

The finest circumstances can be determined by optimizing variables to maximize the removal percentage (% removal) of Co and Ni simultaneously using C. indica algae. The overall explanation of the response surface is given in Eq. (2) (Khosravi et al. 2017):

In Eq. (2), y is correlated to the dependent variable, k is the number of inputs (independent) variables, β0 is a constant, and βii, βi, and βij are linear, quadratic, and interaction regression coefficients, respectively. Xi and Xj are independent factors, and ε is the standard error.

Biosorption isotherm study

The multiple-metal system can impede the adsorption process because heavy metals ions compete to gain active sites on the C. indica surface (Hadi et al. 2013). Numerous industries release their wastewaters in the form of multi-metal components, which is the main reason for this study to select the binary system (Villar da Gama et al. 2018). In this study, Langmuir and Freundlich isotherms were evaluated by the equilibrium data at a constant temperature (Sahan 2019; Gupta and Balomajumder 2015).

Langmuir isotherm study

Uniform and monolayer adsorption are the principles of the Langmuir isotherm. The extended Langmuir isotherm can be expressed by Eqs. (2) and (3):

KL1, KL2, qm1, qm2 are the Langmuir isotherm constants, and Ce1 (mg/L) and Ce2 (mg/L) are the residual concentration of Ni and Co at the end of the adsorption process, respectively. The equilibrium data for Ni and Co biosorption can be presented by qe1 (mg/g) and qe2 (mg/g), respectively (Putro et al. 2017; Gaikwad and Balomajumder 2017).

Freundlich isotherm study

Heterogeneous systems can be defined by Freundlich isotherm. Equations (4) and (5) show extended Freundlich isotherm:

Ce1 and Ce2 are the residual concentrations of Ni and Co at the end of the adsorption process, respectively; the unit of Ce1 and Ce2 is mg/L. qe1 and qe2, respectively, can present the equilibrium adsorption values of Ni and Co; qe1 and qe2 are equal to mg/g. Suffixes 1 and 2 are utilized to signify Ni and Co, respectively.

x1, y1, z1, x2, y2, z2 are the Freundlich isotherm constants. KF1, KF2, n1, and n2 are the Freundlich isotherm constants (Fan Huan et al. 2008). The equilibrium data of the separately adsorbed Ni and Co by the C. indica were used to calculate Freundlich isotherm constants and are presented in Table 2. Nonlinear regression using MATLAB software was used to evaluate the model parameters. The favorability between the experimental data and the calculated data was measured by the coefficient of determination (R2), which is calculated using Eq. (7) (Chen et al. 2008; Yalçın et al. 2012). The closeness of R2 to 1.00 means a better fitting between the experimental data and the computed data.

2.8. Biosorption Kinetic of Ni and Co ions

The contact time of 300 min was determined as equilibrium time for the adsorption processes of Co and Ni using C. indica (Nuhoglu et al. 2002; Mudhoo et al. 2012). Pseudo-first-order, pseudo-second-order, and intra-particle diffusion kinetic models were used to describe biosorption kinetic of Co and Ni ions using C. indica.

The pseudo-first-order model

The pseudo-first-order model was used to explain the mechanism of the adsorption process. The pseudo-first-order equation can be described by Eq. (9) (Volesky 2001):

where qt (mg g−1) is Ni(II) and Co(II) uptake amount at time t (min), qe (mg g−1) is the Ni(II) and Co(II) uptake amount at equilibrium, k1 is the first-order reaction rate constant ( min−1).

The pseudo-second-order model

The pseudo-second-order model was utilized to compute pseudo-second-order model parameters, and can be described using Eq. (9) (Hamedy et al. 2000):

where qt (mg g−1) is Ni(II) and Co(II) adsorption amount at time t (min), qe (mg g−1) is the Ni(II) and Co(II) adsorption amount at equilibrium, and k2 signifies the second order reaction rate constant (g mg−1 min−1).

Intra-particle diffusion model

Intra-particle diffusion model was also employed to disclose the mechanism and influence of the rate-controlling step on the adsorption process for the biosorption of Ni and Co using C. indica and its linear form is given in Eq. 10 (Nagm et al. 2018).

Equation 10 shows intra-particle diffusion in which C (mg/g) is adsorption constant, and Kp (mg/g.min0.5) is described as the rate of intra-particle diffusion, respectively. qt (mg g−1) is Ni(II) and Co(II) uptake amount at time t (min).

Results and discussion

Characterization of brown algae

A scanning electron microscope (Hitachi SU-70, Japan) was utilized to characterize SEM micrographs of C. indica. A honeycomb structure, nonuniform pore distribution and high roughness could be observed using the SEM image of C. indica (Fig. 1).

The surface of C. indica comprises different functional groups, including hydroxyl, phenolic, aldehydic, ketonic, and carboxylic, which are the active sites for the adsorption of Ni and Co (Leng et al. 2015). Attenuated total reflectance-Fourier transform infrared (ATR-FTIR, Platinum, Bruker, Germany) analyses were utilized to study the surface of C. indica. Figure 2 shows the ATR-FTIR analysis of C. indica. The stretching vibration of O–H can be detected at 3400 1/cm, that can be ascribed to hydroxyl functional clusters (Leng et al. 2015). The peak of 2900 1/cm, 1640 1/cm, and 1100 1/cm showed up because of C–H, aromatic CC and, COC= ˗ ˗ bonds, respectively (Xiao et al. 2018; Liu et al. 2009). The high silica substance and oxygen-containing groups of the C. indica can be described at a peak of 1037 1/cm (Xiao et al. 2018; Abdulrazzaq et al. 2014).

Experimental design outcomes

Lessening the number of experimental runs and simultaneous evaluation of the interactions among the operating variables are the main advantages of optimizing according to the experimental design. The simultaneous separation of Co and Ni by C. indica was evaluated using batch adsorption experiments. Central composite design algorithm of the design expert software delivered the experimental runs, which were conducted several times to authenticate the validity of results. Experimental runs and surface responses are presented in Table 3. The surface responses were the removal of nickel and cadmium. Statistical significance of Co removal and the variance of the outcomes have been shown in Table 4. The effectiveness of variables on the model response could be detected from P values less than 0.05 than the other variables (Khosravi et al. 2017; Salehi et al. 2019; Askari et al. 2019). As shown in Table 4, A (pH), C (initial concentration of Co) and D (initial concentration of Ni) variable proposed a larger impact on the model response for both Co removal as response surface 1. ANOVA (analysis of variance) results can be seen in Table 4. It is evident from the results depicted in Table 4, R2 value for the calculated model is 0.96 for the response surface 1, which certifies the favorability of the model for describing the biosorption process behavior.

Statistical significance of Ni removal and the variance of the results have been displayed in a Table 5. As shown in Table 5, A (pH), C (initial concentration of Co) and D (initial concentration of Ni) variable proposed a more significant impact on the model response for Ni removal as response surface 2, respectively. ANOVA (analysis of variance) results can be understood in Table 5. It is clear from the outcomes shown in Table 5, R2 value for the computed model is 0.95 for the response surface 2, which confirms the validity of the model for explaining the biosorption behavior of Ni ions using C. indica.

The effectiveness of variables was calculated via analysis of variance (ANOVA). Tables 4 and 5 show these variables and the outcome of the fitted model was uttered with accordance to the removal percentage of Co and Ni to define the regression model. Polynomial equations (Eq. 11, 12) were calculated to forecast the response after analyzing the multivariate regression system:

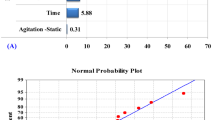

In Eq. (11), A, B, C, and D are attributed to pH, adsorbent mass, initial concentration of Co and initial concentration of Ni, respectively. A positive factor signifies that the amount of the response variable changes directly with changing of its vales. Figure 3 contrasts the model predicted and the experimental results surface response 1 (Co removal %) and shows the normal probability chart representing the favorability of points on the linear pattern for surface response 1 (Co removal %).

In Eq. (12), A, B, C, and D are attributed to pH, adsorbent mass, initial concentration of Co and initial concentration of Ni, respectively. Figure 4 compares the model calculated and the experimental outcomes of surface response 2 (Ni removal %) and displays the normal probability chart indicating the validity of points on the linear pattern for surface response 2 (Ni removal %).

Interactions of variables

Figure 5 illustrates the 3D charts of the two-component interactions of the variables on Co removal through the interaction charts. The interaction among removal, pH and the adsorbent mass to remove Co from solution is revealed in Fig. 5. Upregulating pH can increase the adsorption of Co. Low pH led metal cations and protons to contest for active sites, leading to low adsorption of metal ions. Furthermore, electrostatic repulsion between positively charged surface sites and positive metal cations causes to reduce the adsorption of Co. Increasing pH led to increasing the negativity of active sites that allured more positively charged metal ions for attachment. The biosorbent dosage could not affect the biosorption capacity of C. indica to adsorb Co while the more biosorbent dosage means the more active sites that this is due the fact that the process of C. indica treatment, using NaCl, did not saturate all of the sites accessible on the NaCl-pretreated C. indica.

Figure 6 explains the two-component interactions of the variables on Ni removal using the interaction charts. The interaction among removal, pH, and the adsorbent mass to remove Ni from the solution is exposed in Fig. 6. pH can upregulate the biosorption of Ni. Low pH led metal cations and protons to compete for active sites, resulting in low adsorption of Ni ions. Additionally, electrostatic repulsion between positively charged surface sites and positive metal cations leads to a decrease in the adsorption of Ni. Increasing pH caused to increase the negativity of active sites that trapped more positively charged metal ions for attachment. The more biosorbent dosage means the more active sites, but the biosorbent dosage could not influence the biosorption ability of C. indica to remove Ni. This is due the fact that the process of C. indica treatment, using NaCl, did not saturate all of the sites accessible on the NaCl-pretreated C. indica. The interaction among removal, pH and the initial concentration of Co to remove Co from solution is revealed in Fig. 5. Figure 6 shows the dealings among the removal of Ni, pH and the initial concentration of Co and Ni to eliminate Ni from aqueous solution.

The more initial concentration of Co and Ni, the more removal of Co and Ni. This is because the higher initial heavy metal concentration increases the driving force of the concentration gradient. Higher driving force means more collisions between the heavy metal ions and adsorbents. Also, with an increase in Ni concentration (Fig. 5), it can be seen that the Co removal decreased because of the competitive relationship between Ni and Co to acquire active sites. Figures 5 and 6 reveal that adsorbent mass does not affect the removal of Co when the initial concentration of Ni and Co is increasing.

Published research (Yalçın et al. 2012; De France et al. 2002; Nuhoglu et al. 2002) showed the concentrations ranging from 30 to 150 mg/l could cause the highest capacities of algal adsorption for Ni and Co removal in aqueous solutions when they are in the binary system. Figures 5 and 6 show the interferential effect of metal ions (Co2+ and Ni2+) on the removal of each other by C. indica.

Comparing Figs. 5 and 6 suggested that C. indica tend to adsorb more Co than Ni because Fig. 5 shows that with raising the initial concentration of Co in the presence of Ni, the removal of Co is increasing sharply, which leads to more adsorption of Co in comparison to Ni. But from Fig. 6, it can be seen that increasing the initial concentration of Ni in the presence of Co does not increase the removal of Ni, while the adsorption of Co is rising. Therefore, it can be concluded that Ni is a loser in competition with Co to acquire active sites on the C. indica macroalgae. Carboxyl, sulfonic acid and alginate are the main functional groups on the surface of C. indica [41]. These functional groups play a key role to adsorb heavy metal ion from aqueous solution. The synergistic effect of Ni and Co ions has been shown in Figs. 5 and 6. Co succeeded in acquiring more active sites on the surface of C. indica in the binary system. The higher Co removal can be attributed to the alginic acid component, which exists on the surface of C. indica (Mudhoo et al. 2012; Xiong et al. 2013). The characteristics of the adsorbent can be affected meaningfully by the metallic behavior in binary systems (Volesky and Naja 2011; A-Davisa et al. 2003; Senthilkumar et al. 2006).

The optimal conditions were obtained as: pH of 5.9, the adsorbent mass of 0.06 g, initial concentration of Ni 91.94 mg/l and initial concentration of Co 89.36 mg/l, which lead to the maximum model-predicted removal percentage as 52.77% removal for Co and 47.33% removal for Ni. The batch adsorption experiment was re-performed at the obtained optimum settings. In this case, the experimentally-measured removal was measured 53.99% for Co and 46.01% for Ni. The outcome verified the rationality of the optimization and the advanced model.

Contact time experiments for Ni and Co adsorption

The impact of contact time on the adsorption of Ni and Co by C. indica is shown in Fig. 7. Optimal condition: pH of 5.9, adsorbent mass of 0.06 g, initial concentration of Ni 91.94 and initial concentration of Co 89.36 were used to conduct contact time experiments at 25 °C. Contact time changes from 10 to 180 min. Figure 7 shows that 90% of Ni and Co were adsorbed by C. indica in the first 70 min. This is because of the empty active sites on the surface of C. indica at the beginning of the adsorption process. Also, a high concentration of Ni and Co can raise the adsorption capacity of C. indica at the starting points of the adsorption process. At the end of the adsorption process, reducing the number of active sites causes the reduction of Ni and Co adsorption rate. Therefore, the contact time of 180 min was selected to perform equilibrium experiments. Similarly, 180 min contact time was authenticated by the previously published studies for Ni and Co biosorption using brown algae (Liu et al. 2009; Abdulrazzaq et al. 2014).

Isotherm study for Ni and Co adsorption

Table 6 shows the extended Langmuir and extended Freundlich isotherm parameters at the optimized conditions, including a pH of 5.9, the adsorbent mass of 0.06 g, initial concentration of Ni 91.94 mg/l and initial concentration of Co 89.36 mg/l. The isotherm parameters were conducted at a contact time of 180 min and a temperature of 25 °C. The more value of R2 signifies the better isotherm model for the adsorption of Ni and Co using C. indica. The parameter values of isotherms models for single-metal-component systems and binary-metal-component systems have been shown in Tables 2 and 6, respectively. The equilibrium data for C. indica better obeyed the extended Freundlich isotherm for both Co and Ni. Table 6 shows that the extended Langmuir isotherm calculates the maximum adsorption capacity of 67.09 and 71.13 for Ni(II) and Co(II), respectively. Therefore, the biosorption process occurs on heterogeneous surfaces and the concentration of adsorbed Co and Ni ions can affect adsorption capacity.

Alginate plays a pivotal role to adsorb heavy metal ions in the brown algae (Kumar et al. 2018). Figure 8 shows the molecular structure of alginate. The more selectively adsorption of Co by C. indica than Ni can be attributed to the direction, form and the gap between indents of glucuronic acid (G), which form a more appropriate complex with Co than mannuronic acid (M), that lead to allow Co ions to enter the structure (Hamedy et al. 2000).

The molecular structure of alginic acid (Pereira et al. 2017)

Based on the experimental data, curve-fitting for the extended Freundlich and extended Langmuir isotherms has been shown in Fig. 9. For both Co and Ni, the positive correlations between experimental data (q exp) and calculated-adsorption (q cal) were demonstrated by the extended Freundlich isotherm. The regression correlation coefficient (R2) values of extended Langmuir isotherm were 0.97 and 0.94 for Ni and Co, respectively, which are less than the values of the regression correlation coefficient (0.98) values of extended Freundlich isotherm for both Co (II) and Ni (II). Consequently, extended Freundlich is the best model for Co (II) and Ni (II) adsorption.

Adsorption process kinetics

The regression correlation coefficient value (R2) was 0.97 for both Ni and Co when using the intra-particle diffusion model, which is more than the calculated R2 of the pseudo-first-order and pseudo-second-order models for Ni and Co biosorption using C. indica. Therefore, the intra-particle diffusion model was obeyed more closely by the experimental data for both Ni and Co biosorption using C. indica. Table 7 shows that the intra-particle diffusion model determines the maximum adsorption capacity of 69.78 and 75.55 for Ni (II) and Co (II), respectively. Based on the principles of the intra-particle diffusion model, the biosorption process was distributed to three stages, including the rapid adsorption, the gradual inner diffusion step and the ending equilibrium step (Hubbe et al. 2019).

Conclusion

The initial concentrations of Ni and Co were the most affecting parameters on the adsorption Co and Ni ions using C. indica. Comparisons of Co and Ni biosorption capacity of treated brown algae, Cystoseria indica, indicate that the maximum sorption capacity for Co at an optimum pH of 5.9 was 75.21 mg/L, whereas the maximum Ni biosorption capacity at an optimum pH of 5.9 was 69.99 mg/L. The optimum conditions of the biosorption process were discovered, pH of 5.9, the adsorbent mass of 0.06 g, initial concentration of Ni 91.94 mg/l and initial concentration of Co 89.36 mg/l. The simultaneous biosorption of Ni and Co obeyed the extended Freundlich isotherm. The kinetic behavior of the equilibrium data for Ni and Co sorption by C. indica is best explained by the intra-particle diffusion kinetic model.

References

A-Davisa T, Volesky B, Mucci A (2003) A review of the biochemistry of heavy metal bio sorption by brown algae. J Water Res 37:4311–4330

Abdulrazzaq H, Jol H, Husni H, Abu-Bakr R (2014) Characterization and stabilisation of biochars obtained from empty fruit bunch, wood, and rice husk. J BioResources 9:2888–2898

Akbari M, Hallajisani A, Keshtkar A-R, Shahbeig H, Ghorbanian S-A (2015) Equilibrium and kinetic study and modeling of Cu(II) and Co(II) synergistic biosorption from Cu(II)-Co(II) single and binary mixtures on brown algae C. indica. J Environ Chem Eng 3:140–149

Askari M, Salehi E, Ebrahimi M, Barati A (2019) Application of breakthrough curve analysis and response surface methodology for optimization of a hybrid separation system consisting of fixed-bed column adsorption and dead-end depth filtration. J Chem Eng Process Process Intensif 143:107594

Bilal M, Shah JA, Ashfaq T, Gardazi SMH, Tahir AA, Pervez A, Haroon H, Mahmood Q (2013) Waste biomass adsorbents for copper removal from industrial wastewater—a review. J Hazard Mater 263:322–333

Chen Z, Ma W, Han M (2008) Biosorption of Ni and copper and to treated algae (Undriapinnatifida); Application of isotherm and kinetics study. J Hazard Mater 155:327–333

Daraei P, Madaeni SS, Salehi E, Ghaemi N, Sadeghi Ghari H, Khadivi MA, Rostami E (2013) Novel thin film composite membrane fabricated by mixed matrix nanoclay/chitosan on PVDF microfiltration support: preparation, characterization and performance in dye removal. J Membr Sci 436:97–108

De France F-P, Tavares A-P-M, Da Costa A-C-A (2002) Calcium interference with continuous bio sorption of Zinc by sargassum SP. (Phaeophyta) in tubular laboratory reactors. J Bioresour Technol 83:159–163

Esmaeili A, Aghababai Beni A (2015) Biosorption of Ni and Co from plant effluent by Sargassum glaucescens nanoparticles at new membrane reactor. Int J Environ Sci Technol 12:2055

Fan Huan H-J, Tsai Y-S, Furuya E (2008) Prediction of individual Freundlich isotherms from binary and ternary phenolic compounds mixtures. J Chemosphere 71:886–893

Pereira RF, Sousa A, Barrias CC, Bayat A, Granja PL, Bártolo PJ (2017) Advances in bioprinted cell-laden hydrogels for skin tissue engineering. J Biomanuf Rev 2:1

Ferraz AI, Amorim C, Tavares T, Teixeira JA (2015) Chromium (III) biosorption onto spent grains residual from brewing industry: equilibrium, kinetics and column studies. Int J Environ Sci Technol 12(2):1591–1602

Gaikwad M-S, Balomajumder C (2017) Simultaneous electrosorptive removal of chromium(VI) and fluoride ions by capacitive deionization (CDI): multicomponent isotherm modeling and kinetic study. J Separ Purif Technol 182:272–281

Gupta A, Balomajumder Ch (2015) Simultaneous removal of Cr(VI) and phenol from binary solution using Bacillus sp. immobilized onto tea waste biomass. J Water Process Eng 6:1–10

Hashim MA, Mukhopadhyay S, Sahu JN, Sengupta B (2011) Remediation technologies for heavy metal contaminated groundwater. J Environ Manage 92:2355–2388

Hosseini SS, Bringas E, Tan NR, Ortiz I, Ghahramani M, Alaei Shahmirzadi MA (2016) Recent progress in development of high performance polymeric membranes and materials for metal plating wastewater treatment: a review. J Water Process Eng 9:78–110

Hadi P, Barford J, McKay G-M (2013) Synergistic effect in the simultaneous removal of binary Co–Ni heavy metals from effluents by a novel e-waste- derived material. J Chem Eng 228:140–146

Hamdy A (2000) Biosorption of heavy metals by marine algae. J Current Microbiol 4:232

Hubbe MA, Azizian S, Douven S (2019) Implications of apparent pseduo-second-order adsorption kinetics onto cellulosic materials: a review. J Bioresour 14(3):7582–7626

John Babu D, King P, Prasanna Kumar Y (2019) Optimization of Cu (II) biosorption onto sea urchin test using response surface methodology and artificial neural networks. Int J Environ Sci Technol 16:1885

Khajavian M, Wood D, Hallajsani A, Majidian N (2019) Simultaneous biosorption of nickel and cadmium by the brown algae Cystoseria indica characterized by isotherm and kinetic models. Appl Biol Chem 62:69

Khosravi R, Azizi A, Ghaedrahmati R, Gupta VK, Agarwal S (2017) Adsorption of gold from cyanide leaching solution onto activated carbon originating from coconut shell—optimization, kinetics and equilibrium studies. J Ind Eng Chem 54:464–471

Kim S-U, Owens V-N, Kim S-Y, Hong C-O (2017) Effect of different way of bottom ash and compost application on phytoextractability of cadmium in contaminated arable soil. Appl Biol Chem 60(4):353–362

Kumar M, Singh A-K, Sikandar M (2018) Study of sorption and desorption of Cd(II) from aqueous solution using isolated green algae Chlorella vulgaris. J Appl Water Sci 8:225

Leng L, Yuan X, Huang H, Shao J, Wang H, Chen X, Zeng G (2015) Bio-char derived from sewage sludge by liquefaction: characterization and application for dye adsorption. J Appl Surf Sci 346:223–231

Liang Y, Chen JQ, Mei J, Chang JJ, Wang QY, Wan GS, Yin BY (2019) Characterization of Cu and Cd biosorption by Pseudomonas sp. strain DC-B3 isolated from metal mine soil. Int J Environ Sci Technol 16:4035

Li J, Chen J, Chen S (2018) Supercritical water treatment of heavy metal and arsenic metalloid-bioaccumulating-biomass. J Ecotoxicol Environ Saf 157:102–110

Liu Y, Cao Q, Luo F, Chen J (2009) Biosorption of Cd2+, Cu2+, Ni2+ and Zn2+ ions from aqueous solutions by pretreated biomass of brown algae. J Hazard Mater 163:931–938. https://doi.org/10.1016/j.jhazmat.07.046.18755544

Luo Z, Wang Z, Yan Y, Li J, Yan C, Xing B (2018) Titanium dioxide nanoparticles enhance inorganic arsenic bioavailability and methylation in two freshwater algae species. J Environ Pollut 238(5):631–637

Montazer-Rahmatia MM, Rabbania P, Abdolalia A, Keshtkarb AR (2011) Kinetics and equilibrium studies on biosorption of cadmium, lead, and Ni ions from aqueous solutions by intact and chemically modified brown algae. J Hazard Mater 185(1):401–407

Mudhoo A, Garg V-K, Wang SS (2012) Heavy metals: toxicity and removal by biosorption. In: Lichtfouse E, Schwarzbauer J, Robert D (eds) Environmental chemistry for a sustainable world. Springer, Berlin, pp 379–442

Naseem K, Begum R, Wu W, Usman M, Irfan A, Al-Sehemi A, Farooqi Z-H (2018) Adsorptive removal of heavy metal ions using polystyrene-poly(N-isopropylmethacrylamide-acrylic acid) core/shell gel particles: Adsorption isotherms and kinetic study. J Mol Liquids 277:522–531

Nas SM, Calimli HM, Burhan H, Yilmaz M, Mustafo DS (2019) Sen F (2019) Synthesis, characterization, kinetics and adsorption properties of Pt-Co@GO nano-adsorbent for methylene blue removal in the aquatic mediums using ultrasonic process systems. J Mol Liq 296:112100

Negm NA, Abd El Wahed MG, Hassan ARA, Abou Kana MTH (2018) Feasibility of metal adsorption using brown algae and fungi: Effect of biosorbents structure on adsorption isotherm and kinetics. J Molliq 264(15):292–305

Nuhoglu Y, Malkoc E, Gurses A, Canpolat N (2002) The removal of cu (II) from aqueous solutions by Ulothrix Zonata. J Bioresour Technol 85:331–333

Ojedokun AT, Bello OS (2016) Sequestering heavy metals from wastewater using cow dung. Water Resour Ind 13:7–13

Ozdemir S, Kilinc E, Fatih S (2020) A novel biosorbent for preconcentrations of Co(II) and Hg(II) in real samples. Sci Rep 10:455

Park J-H, Ok Y-S, Kim S-H, Kang S-W, Cho J-S, Heo J-S, Delaune R-D, Seo D-C (2015) Characteristics of biochars derived from fruit tree pruning wastes and their effects on lead adsorption. J Korean Soc Appl Biol Chem 58(5):751–760

Pinnola A, Formighieri C, Bassi R (2019) Algae: a new biomass resource. In: Kaltschmitt M (ed) Energy from organic materials (Biomass). Encyclopedia of Sustainability Science and Technology Series. Springer, New York, NY, pp 165–197

Putro J-N, Santoso S-P, Ismadji S, Ju Y-H (2017) Investigation of heavy metal adsorption in binary system by nanocrystalline cellulose e Bentonite nanocomposite: Improvement on extended Langmuir isotherm model. J Microporous Mesoporous Mater 246:166–177

Rasool K, Lee DS (2015) Characteristics, kinetics and thermodynamics of Congo Red biosorption by activated sulfidogenic sludge from an aqueous solution. Int J Environ Sci Technol 12:571

Şahan T (2019) Application of RSM for Pb(II) and Cu(II) adsorption by bentonite enriched with eSH groups and a binary system study. J Water Process Eng 31:100867

Salehi E, Gavari N, Chehrei A, Amani S, Amani N, Zaghi K (2019) Efficient separation of triglyceride from blood serum using Cinnamon as a novel biosorbent: adsorption thermodynamics, kinetics, isothermal and process optimization using response surface methodology. J Process Biochem 77:122–136

Salehi E, Madaeni SS (2014) Influence of poly(ethylene glycol) as pore-generator on morphologyand performance of chitosan/poly(vinyl alcohol) membrane adsorbents. J Appl Surf Sci 288:537–541

Sari A, Tuzen M (2008) Biosorption of Cadmium (II) from aqueous Solution by red argue (ceramiumvirgatum): equilibrium, Kinetic and thermodynamic studies. J Haz Mat 157(2–3):448–454

Senthilkumar R, Vijayaraghavan K, Thilakavathi M, Iyer PVR, Velan M (2006) Seaweeds for the remediation of wastewaters contaminated with zinc (II) ions. J Hazardous Mater 136(3):791–799

Sinaeia M, Loghmani M, Bolouki M (2018) Application of biomarkers in brown algae (Cystoseria indica) to assess heavy metals (Cd, Cu, Zn, Pb, Hg, Ni, Cr) pollution in the northern coasts of the Gulf of Oman. Ecotoxicol Environ Saf 164:675–680

Taghiganji M, Khosravi M, Rakhshaee R (2005) R. Int J Environ Sci Technol 1(4):265–271

Villar da Gama B-M, Nascimento G-E, Cesar D, Sales S, Rodríguez-Díaz J-M, de Menezes B, Barbosa C-M-B, Duarte M-M-M-B (2018) Mono and binary component adsorption of phenol and cadmium using adsorbent derived from peanut shells. J Cleaner Prod 201:219–228

Volesky B (2001) Detoxification of metal-bearing effluents: biosorption for the next century. J Hydrometall 59:203–216

Volesky B, Naja G-M (2011) Biosorption for industrial application biosorption process fundamentals and a pilot design. Biosorption Ind Appl 6:25

Xiao B, Dai Q, Yu X, Yu P, Zhai S, Liu R, Guo X, Liu J, Chen H (2018) Effects of sludge thermal-alkaline pretreatment on cationic red X-GRL adsorption onto pyrolysis biochar of sewage sludge. J Hazard Mater 343:347–355

Xiong Y, Xu J, Shan W, Lou Z, Fang D, Zang S, Han G (2013) A new approach for rhenium(VII) recovery by using modified brownalgae Laminaria japonica adsorbent. J Bioresource Technol 127:464–472

Xu L, Shen J, Marinova D, Guo X, Sun F, Zhu F (2013) Changes of public environmental awareness in response to the Taihu blue-green algae bloom incident in China. J Environ Develop Sustain 15(5):1281–1302

Yalçın S, Sezer S, Apak R (2012) Characterization and lead(II), cadmium(II), Ni(II) biosorption of dried marine brown macro algae Cystoseira barbata. Environ Sci Pollut Res 19(18):3118–3125

Acknowledgements

The authors thankfully acknowledge the support provided by Arak University and Tehran University (2018–2019).

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

MK and PG carried out heavy metal sampling, heavy metal solution analyses, and data organization. AH, MK, and PG participated in interpreting the obtained results and organizing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no competing interests.

Availability of data and materials

Not applicable.

Additional information

Editorial responsibility: Fatih ŞEN.

Rights and permissions

About this article

Cite this article

Khajavian, M., Hallajsani, A. & Ghelichi, P. Optimizing binary biosorption of cobalt and nickel ions on brown algae using a central composite design. Int. J. Environ. Sci. Technol. 17, 4759–4774 (2020). https://doi.org/10.1007/s13762-020-02761-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-02761-6