Abstract

Arsenic, iron and nitrate coexist in groundwater at a wide range of concentrations in various regions of the world. This study aims at investigating the concurrent arsenic and iron removal by combining the advantages of nitrate removal in a sulphidogenic bioreactor. A laboratory-scale suspended growth reactor was used to assess the performance of mixed bacterial culture at different arsenic, iron and nitrate concentrations. A semi-batch reactor (SmBR) was operated for more than 400 days in anoxic conditions at 30 ± 4 °C with different influent arsenate (250–1000 µg/L as arsenic), iron (2.0 mg/L) and nitrate (100–250 mg/L) concentrations in simulated groundwater and HRT of 3–6 days. Effects of different electron donors to deliver removing power on arsenic, iron and nitrate were also investigated. Nitrate was completely removed at all tested concentrations, while concentration of arsenic and iron met drinking water standards. The reactor was also charged with actual groundwater containing arsenic (up to 226 µg/L) as well as iron (up to 8.3 mg/L) and was able to remove both the contaminants below drinking water standards after addition of sufficient amount of sulphate. Toxicity characteristics leaching procedure results indicated that leachate arsenic concentrations were below the maximum United States Environmental Protection Agency guideline value for arsenic and biosolids which did not impose any environmental hazard.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The arsenic enrichment of groundwater is a grim problem in many parts of the world. Naturally occurring groundwater arsenic is associated with significant health risks including various type of cancers (skin, kidney, lung and bladder) and other harmful effects (ATSDR 2000; Sarkar and Paul 2016). Because of the health issues related to high arsenic concentration, regulatory organizations have recommended maximum contaminant limit (MCL) of 10 µg/L in drinking water (BIS:10500 2012; USEPA 2002). A more stringent MCL of 7 µg/L and 5 µg/L has been imposed by Australia and New Jersey (USA), respectively (Barringer and Reilly 2013). Iron is commonly co-occurring with arsenic in groundwaters due to geochemical conditions in many parts of the world. For instance, up to 106.0 µg/L arsenic and 4.28 mg/L iron were found in groundwater of Assam (India) and Jamshoro (Pakistan) (Baig et al. 2009; Chaturvedi et al. 2014). The MCL for iron in drinking water is 0.3 mg/L (BIS:10500 2012), because regular intake of high iron containing groundwater may cause hemochromatosis, liver cirrhosis and siderosis (Chaturvedi et al. 2014).

There are reports on coexistence of nitrate along with arsenic and iron in groundwater of many parts of the world (Giménez et al. 2013; Mayorga et al. 2013; Venkataraman and Uddameri 2012). For instance, up to 200 mg/L nitrate, 1990 µg/L arsenic and 2000 µg/L iron were detected in the groundwater of Chaco Plain, Argentina (Giménez et al. 2013), which exceeded MCL of nitrate, arsenic and iron. Excessive use of nitrogenous fertilizers, sewage irrigation, and unsafe discharges of domestic and industrial wastewaters may increase nitrate concentration in drinking water sources (Bhatnagar and Sillanpaa 2011). Due to harmful effects of nitrate, the USEPA has set the drinking water MCL for nitrate at 10 mg/L as nitrogen. Conventional method for iron removal from groundwater includes aeration and rapid sand filtration (Teunissen et al. 2008), whereas arsenic is removed by adsorption on to the iron or aluminium hydroxides (Attinti et al. 2015). There are many other methods practiced for arsenic and nitrate removal from drinking water, for example chemical methods, ion-exchange, electrochemical and membrane techniques (Abass et al. 2016; Ghanbari et al. 2014; Jadhav et al. 2015; Wang et al. 2018).

Stricter drinking water standards have inspired researchers to develop new and effective technologies that can provide simultaneous removal of multi-pollutants in a single system in affected areas. Biological processes for arsenic removal are one of the most active research fields in recent years (Briones-Gallardo et al. 2017). Sulphidogenic bioprocesses employing sulphate-reducing bacteria have been extensively examined for their arsenic removal abilities from mining metallurgical and waste waters (Altun et al. 2014; Liu et al. 2018). These systems offer potential alternatives to existing technologies practiced for arsenic sequestration from potable water sources. The main advantages of using sulphidogenic system for arsenic removal from contaminated waters are generation of low volume of arsenic-laden sludge and stable nature of biogenic sulphide phases under changing environmental conditions (Onstott et al. 2011).

However, few studies have investigated the arsenic and nitrate removal, yet concurrent removal of arsenic, nitrate and iron from groundwater in a single system has not been studied. Upadhyaya et al. (2010) studied the performance of a train of two fixed-biofilm reactors and found that mixed bacterial culture could achieve 100% and 90% nitrate and arsenic removal at an empty bed contact time of 40 min (20 + 20 min) from 50 to 200 µg/L, respectively. Snyder et al. (2016) observed removal efficiency of only 50% from 200 µg/L initial arsenic concentration at an HRT of 4.4 days from synthetic water using an anaerobic biosand filter under sulphidogenic conditions. These systems, however, achieved complete nitrate removal but never met drinking water standard for arsenic. Recently, few studies have investigated the simultaneous arsenic and nitrate removal using single bacterial species of anaerobic Fe(II) oxidation denitrifying (AFODN) bacteria. Li et al. (2015) was first to use pure culture (Citrobacter freundii) for removal of nitrate and arsenite and observed 44% nitrate and 28% arsenic removal from 496 mg/L to 1024 µg/L initial concentration, respectively, in 6 days. The major limitation of these systems is use of pure culture, which often imposes several limitations in natural environment those prevailing in real field (Kleerebezem and van Loosdrecht 2007) and failing to meet drinking water standards. Furthermore, the filtration performance of fixed-film reactors is often limited by biomass sloughing with treated water, separation of solids from liquid, filter ripening, frequent need of backwashing and down-time during filter ripening (Amburgey and Amirtharajah 2005; Lee et al. 2001). Almost all the earlier studies used synthetic groundwater or synthetic mine water for the performance evaluation of various biological systems. To our best knowledge, no study has been conducted to evaluate the performance of sulphidogenic reactors while treating real groundwater and stability of reduced arsenic-laden biosolids. Hence, there is a need to develop a treatment system for groundwaters containing arsenic along with iron and nitrate. The present study focuses on performance evaluation of a suspended growth bioreactor for concurrent nitrate, arsenic and iron removal from simulated and actual groundwater under various operating conditions. The arsenic- and iron-laden reduced biosolids were also tested under varying environmental conditions for their stability against leaching.

Materials and methods

Preparation of simulated groundwater and seed suspension

Arsenic, iron and nitrate containing simulated groundwater were prepared in distilled water and contained (mg/L): Na2HAsO4·7H2O (as As) 0.25–1.0; NaNO3 (as \({\text{NO}}_{3}^{ - }\)) 100–250; Na2SO4 (as \({\text{SO}}_{4}^{2 - }\)) 25; NaHCO3 (as \({\text{HCO}}_{3}^{ - }\)) 45–65; K2CO3 (as \({\text{CO}}_{3}^{2 - }\)) 1.5; NaCl (as \({\text{Cl}}^{ - }\)) 13; CaCl2 (as \({\text{Cl}}^{ - }\)) 13; MgCl2·6H2O (as \({\text{Cl}}^{ - }\)) 13; H3PO4 (as P) 0.5; CH3COOH (as C) 35–107. The chemicals Na2HAsO4·7H2O (> 98.5% assay), NaNO3 (> 99% assay), Na2SO4 (> 98.5% assay), NaHCO3 (> 99.7% assay), K2CO3 (> 99% assay), NaCl (> 99% assay), CaCl2 (> 93% assay), MgCl2·6H2O (> 99% assay), H3PO4 (> 88% assay) and CH3COOH (> 99.6% assay) used in this project were of analytical reagent (AR) grade and procured from HIMEDIA®. Fresh simulated groundwater was supplied with nitrogen gas for about 20 min to expel dissolved oxygen (< 1.0 mg/L). Acetate was supplemented as an electron donor for reduction in available electron acceptors (i.e. arsenate, dissolved oxygen (DO), nitrate and sulphate) in surplus (with safety factor of 1.5) of the carbon needed. The pH of the reactor content was maintained at 6.8 ± 0.2. Biomass used as seed sludge for the present study was mainly the sludge collected from the bottom of the sewage treatment plant of IIT Guwahati. This sludge of 3780 mg/L MLSS and 2560 mg/L MLVSS was mixed with sludge (< 5% as MLSS) collected from two nos. laboratory-scale bioreactors treating perchlorate and nitrate (Ghosh 2013) and sulphate (Brahmacharimayum 2014), respectively. This mixed bacterial culture was used as the seed suspension for inoculating semi-batch reactor.

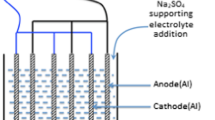

Experimental set-up and reactor operation

A laboratory-scale polypropylene reagent bottle (1000 mL capacity, 600 mL working volume) was used as a suspended growth anaerobic bioreactor. The reactor was wrapped with black film to stop phototrophic bacterial activity and algal growth before being mounted on magnetic stirrers and operated at 30 ± 4 °C in a temperature-controlled room. The working volume of the reactor was considered for the calculation of HRT. HRT of 6 day was maintained by removal of 200 mL of the supernatant (treated water after settlement of biomass) at an interval of 2 days and replacing the equal volume of untreated water. Similarly, HRT of 3 day was maintained by replacing 200 mL of the supernatant daily.

The bioreactor operation of 434 days is divided into three phases. Feeding and operating schedule of the reactor is given in Table 1. Before inoculation, the reactor content was deoxygenated by the supply of nitrogen gas. The reactor was filled up with 600 mL of fresh simulated groundwater. In phase 1, after inoculation, the semi-batch reactor (SmBR) was operated at an HRT of 6 days and finally at 3 days during setting up stage. After that, influent arsenic was increased stepwise from 250 to 1000 µg/L for assessing arsenic removal efficiency of mixed bacterial culture. In phase 2, influent nitrate concentration was gradually increased stepwise from 100 to 250 mg/L for evaluating the effect of nitrate on reactor performance in terms of nitrate and arsenic removal. In phase 3, reactor was supplemented with different carbon sources as electron donor to test the effectiveness of malate, succinate, lactate and glucose as the sole sources of carbon and energy on contaminants removal. During all phases, influent sulphate and iron were kept constant at 25 mg/L and 2 mg/L, respectively.

Actual groundwater collection and reactor operation

Actual groundwater (AGW) was collected from two locations at (26°16.45′N and 90°41.22′E; 26°16.53′N and 90°40.79′E, well depth 160 ft.) Bongaigaon district, Assam (India), in new high-density polyethylene containers (20 L) after adequate pumping (10–15 min). The characterizations of water quality parameters other than metals were analysed with non-acidified groundwater sample. The AGW for metal analysis was stored in pre-acidified containers with HCl at pH 2. To ensure oxygen-limited environment, filled-in containers were tightened with thread seal tape immediately and transported to the Environmental Engineering Laboratory, IIT Guwahati, within 6 h. The containers were supplied with nitrogen to bring DO below 1 mg/L, for preventing iron oxidation and stored at 10 °C prior to use in bioreactor experiments. A multi-parameter water quality analyser (Professional Plus: YSI, USA) was used for analysing AGW parameters (DO, ORP, pH and conductivity), while visual arsenic detection kit (Wagtech, WAG-WEI0600, UK) was used for onsite arsenic determination. The DO and ORP were measured in open environment after collection of pumped groundwater in a beaker. As the DO and ORP of AGW were measured in open environment, it might have caused oxygen dissolution into groundwater showing high values of DO and thereby ORP. Although the ORP and DO values were seem to represent an oxidizing environment, total arsenic and iron in groundwater sample collected for analysis would not have altered because of the following reasons: For analysis, samples were collected in pre-acidified bottles and final pH was below 2. At pH < 2, iron will not be oxidized, and therefore, arsenic removal with iron expected to be nil. The AGW quality parameters in detail are given in supplementary material (ESM 1). AGW containing 124 µg/L arsenic and 2.9 mg/L iron (type 1) and 226 µg/L arsenic and 8.3 mg/L iron (type 2) was fed sequentially in SmBR. Neither nitrate nor nitrite was present in AGW though 3–4 mg/L of sulphate was present. AGW type 1 was fed solely in SmBR for 9 days (from day 370) with the addition of sulphate, nitrate and COD at the rate of 25 mg/L, 50 mg/L and 150 mg/L, respectively. However, from day 379, AGW type 2 was fed for 13 days at an influent sulphate of 25 mg/L. Furthermore, for next 22 days (from day 393), SmBR was operated at increased sulphate and COD of 50 mg/L and 165 mg/L, respectively. From day 416, influent sulphate was escalated to 75 mg/L and COD was also increased to 180 mg/L to fulfil requirement of increased sulphate.

Water sample collection and analysis

The reactor was allowed to stand for 20 min without mixing, to allow biomass settling to prevent any loss of biomass during treated water collection. Treated water was directly collected in Erlenmeyer flasks which were made anoxic by purging nitrogen gas. Samples were filtered with nylon syringe filters with a pore size of 0.2 µm. Analysis for pH (Systronics µpH system 361, India), nitrate, nitrite (Varian, CARY50BIO, USA), sulphate (Systronics, Nephelo Turibidity Meter 132, India) and COD (Hach, Hach DRB 200, USA) were performed on the same day. In general, APHA (2005) has been followed for standard protocols unless otherwise specified. Nitrate and nitrite concentrations were determined by 4500 NO3−-B and 4500-NO2−-B, respectively. Sulphate concentration and chemical oxygen demand (COD) of samples were analysed by 4500 SO42−-E and 5220-C. The detection limits of nitrate, nitrite and sulphate were 1 mg/L, 25 µg/L and 1 mg/L, respectively.

Samples were acidified with 0.02 N HCl, prior to arsenic and iron determination, to solubilize precipitates (if any) and preserved at 4 °C for analysis. Total arsenic concentration was analysed using hydride generation atomic absorption spectrophotometer (VGA-77 and SpectrAA 55B, Varian, USA) having electrodeless discharge lamp at 193.7 nm wavelength (Behari and Prakash 2006). The detection limit of arsenic was 1 µg/L. Iron content was determined by 3500-Fe B with detection limits of 50 µg/L (APHA 2005).

Microbial community structure and population dynamics

To identify microbial community and predicted role of mixed bacterial population present in complex polybacterial population, metagenomic analyses of the bioreactor community were performed on V3–V4 variant regions of the 16S rRNA genes. After completion of performance study of SmBR, biomass suspension was collected in a polyethylene bottle. The bottle was filled up with \({\text{N}}_{2}\) gas (to avoid interference of oxygen) prior to biomass collection. It was sealed immediately after biomass collection and the sealed bottle was packed properly with an ice gel pack, which was then shipped to SciGenom Labs Private Limited, Kerala, India, for metagenomic sequencing. Genomic DNA was extracted using a DNA extraction kit (Purelink™, ThermoFisher Scientific, USA) as per manufacturer’s protocol. Extracted DNA was quantitatively and qualitatively analysed by Qubit™ double-stranded DNA High Speed Assay Kit with the Qubit® 2.0 fluorometer. The bacterial 16S rRNA gene was amplified using the following V3-specific primers: 314F (5′-CCTACGGGAGGCAGCAG-3′) and 518R (5′-ATTACCGCGGCTGCTGG-3′) annealing to the V3 region of the 16S bacterial gene. Two polymerized chain reactions (PCRs) were performed by using Master Mix in the following sequence: denaturation at 98 °C for 30 s followed by 15 cycles (denaturing at 98 °C for 10 s, annealing at 72 °C for 30 s, extension at 72 °C for 5 s) with 4 °C hold. Illumina MiSeq platform was used to sequence amplicons generated from the V3 region of the 16S rRNA gene (Illumina Inc., CA, USA).

Sequencing of amplicons was done by using the pair-end method, and the raw data generated from pyrotag sequencing were processed and analysed following QIIME platform. All unwanted sequences such as spacer, conserved region and primer were trimmed off from sequence reads to keep average quality score for each read above 20. Prior to operational taxonomic units (OTUs) identification, the de novo chimera removal method UCHIME was employed for Chimera removal. After the quality filtration, Uclust (QIIME) program was used for pooling and clustering these reads into OTUs based on their 97% sequence similarity. Taxonomic classification of the representative sequences was done using RDP classifier and Greengenes OTUs database based on the fixed similarity threshold of 80% confidence (DeSantis et al. 2006). Based on the obtained OTU, observed species, Shannon and Chao1 metrics calculation was used for computation of Alpha microbial diversity in the sample. QIIME software was employed for metric calculation. However, Beta diversity analysis for the given sample was not possible because it requires a minimum of three or more samples.

Biogenic precipitates separation

After completion of the experiments, the biogenic precipitates were recovered from the bottom of the reactor and characterized for their mineralogy. For this purpose, reactor contents were allowed to settle down for 1 h, and liquid medium was removed and transferred the precipitates and residual liquid into sterile 100-ml centrifuge tubes. The precipitates that formed at the bottom of the reactor were recovered by scraping with a sterilized spatula, homogenized and transferred to a centrifuge tube prefilled with nitrogen gas. The precipitates were centrifuged for 10 min at 6000 rpm to obtain wet paste followed by freeze drying at − 20 °C under 10 Pa vacuum for 1 day; under this cold and O2-free environment, oxidation of iron sulphides and arsenosulphides was negligible. The dried solids were preserved in sealed centrifuged tubes anaerobically at − 20 °C in zip-locked plastic bags for further analyses.

The precipitates were examined using field-emission scanning electron microscopy (FESEM) (Zeiss, Sigma, Germany) equipped with energy-dispersive X-ray microanalysis system (EDX) (INCA 300, Oxford, UK) for topographical characterization and elemental confirmation. Before the examination, the freeze-dried precipitates were lightly dusted onto the carbon tape of the FESEM stub surface and coated with gold using a Scancoat Six SEM sputter coater system. TEM and EDX studies were also carried out for precipitates to know the detailed morphology, microstructure and chemical composition of using a microscope (JEOL, JEM-2100, Japan), equipped with an EDX. An ultrasonic vibration method was used to prepare specimens for TEM observations. First, the precipitates were immersed in acetone solution and subjected to ultrasound vibration (Vibra-Cell model VC 505, Sonics, USA) to disperse the sample homogeneously. Then, one drop of the suspension was dropped with a micropipette to holey carbon supporting film (TEM grids). After being well dried under ambient conditions, the grid was mounted on the TEM specimen holder for examination.

Stability check of arsenic-laden biosludge against leaching

TCLP test

The TCLP test was conducted on stored freeze-dried arsenic-laden precipitates according to US EPA protocol (USEPA 1992) to assess their stability against leaching. In TCLP test, contaminants were extracted from 1 g of precipitate with an extraction solution at a liquid-to-solid (L/S) ratio of 20. USEPA protocol (method 9045d) was used to determine the pH of biosolids (USEPA 2004). Since pH of biosludge was below 10 (i.e. low alkaline range), CH3COOH (0.1 M) and NaOH (0.064 M) extraction solution buffered at pH 4.93 ± 0.05 was used for leaching. The sample and extraction fluid were placed in a screw-capped Teflon bottle (50 ml) and tumbled at 30 rpm for 84 ± 1 h at ambient laboratory temperature (30 ± 2 °C). The headspace of ambient air was kept minimal within the bottles. These samples were centrifuged followed by 10 min of settling and finally filtered through 0.45-µm glass fibre filter for analysis of soluble arsenic and iron concentration in the leachate.

Impact of DO on TCLP

TCLP study was also carried out at a constant leachant-to-solid (L/S) ratio of 20 at different headspace-to-leachant volume (Vair/VL) ratio to evaluate the impact of DO on arsenic leaching. The headspace in the bottles was varied to maintain Vair/VL ratios of 0.25, 0.50, 1.0 and 1.25. As TCLP test protocol did not specify the volume of the extraction vessels, Vair/VL ratios of 0.25, 0.50, 1.0 and 1.25 were maintained by using bottles of different volumes. After extraction period was over, filtrate was analysed for arsenic, iron and final DO concentration. A DO meter (DO 32A, TOA-DKK Corporation, Japan) was used to measure DO of the extraction mixture. A blank containing extraction solution without any test solids was also performed as duplicate.

pH batch leaching test

To investigate the effect of pH on arsenic leaching from biosolids, initial pH controlled tests were performed where de-ionized water (DW) was used as extraction fluid. One gram biosolids sample was mixed with 50 mL of DW that was adjusted to pH 3.0, 5.0, 7.0, 9.0 and 11.0 by adding either NaOH or HCl. The test vessels (100 ml polypropylene bottle) shaken at 30 rpm for 84 h. The pH values selected for this study were representative of most nature landfills (Hooper et al. 1998). After shaking, mixture was filtered and arsenic and iron were measured.

Results and discussion

Onset of sulphate reduction leads to arsenic and iron removal

Figure 1 represents the performance of SmBR during phase 1 operation. Nitrate was totally removed from the very first day of reactor operation. Neither nitrite nor nitrate was detected in the treated water indicating complete removal of nitrate, and therefore, nitrate and nitrite profiles are not shown in Fig. 1. Low sulphate reduction efficiency was observed during the first 15 days (average values of 50%), which was improved to 76% in next 25 days. This might be due to the heterogeneous seed sludge used as source of inoculum and slower adaptation of SRBs in a mixed bacterial population containing system than other active microorganisms (Frunzo et al. 2012). However, only around 5–6 mg/L of sulphate remained in the treated water during last few days of this phase indicating no further sulphate reduction. Iron removal in the reactor started after onset of sulphate removal. Treated water iron reduced to below the drinking water permissible limits of 0.3 mg/L after 22 days and remained below detection limits after 38 days. Arsenic removal started gradually with onset of sulphate and/or iron reduction and reduced to below 10 µg/L after 27 days of operation. Some instability in the treated water arsenic and iron concentration observed in the initial periods (first 15 days) which might be associated with poor sulphate reduction in SmBR. After attainment of steady state in terms of arsenic removal, the HRT was changed to 3 days. The SmBR performance was not negatively affected due to reduction in HRT (to 3 days) might be due to better adaptation of microbial population and attainment of steady state in the reactor. The treated water COD values remained between 11 and 12 mg/L during last few days of this phase. A little increase in the pH (7.0–7.4) of the treated was observed as compared to that of raw water (6.8 ± 0.2) owing to alkalinity generation during sulphate and nitrate reduction (Altun et al. 2014).

Arsenic removal at low nitrate concentration

Figure 1 represents the performance of SmBR on the arsenic removal at low influent nitrate concentration of 100 mg/L. Arsenic concentration in the treated water was observed to be well below 5 µg/L regardless of influent arsenic addition (up to 1000 µg/L), indicating that increasing influent arsenic concentration did not hamper arsenic removal. Iron was also remained below detection limits in the treated water. Similarly, regardless of influent arsenic concentration, total nitrate was removed (from initial 100 mg/L) within the first 24 h of SmBR operation. Nitrite was not detected in treated water indicating complete nitrate removal in SmBR. The sulphate, COD and pH values in the treated water were 4–5 mg/L, 10–12 mg/L and 7.3–7.4, respectively. Hence, it is evident that increase in influent arsenic concentration did not influence the mixed bacterial culture performance in SmBR.

Arsenic removal at high nitrate concentration

Arsenic removal at varying influent nitrate concentrations of 100, 150, 200 and 250 mg/L is presented in Fig. 2. Based on the efficient performance of the SmBR on arsenic removal, initial arsenic was kept at 1000 µg/L during this phase of study. Influent COD was maintained at 150, 194, 240 and 285 mg/L, respectively, to meet carbon requirement at increased influent nitrate concentration. Complete nitrate removal was observed during this entire experimental period. Nitrate and nitrite were always remained undetected in treated water. Similarly, iron remained below the detection limit at all tested nitrate concentrations. Regardless of influent nitrate (up to 250 mg/L), the SmBR was able to remove arsenic below 10 µg/L from 1000 µg/L initial arsenic concentration. The pH of the water samples collected during this phase ranged between 7.30 and 7.75 for all nitrate concentrations tested; however, it never exceeded permissible limits of drinking water. This little increase in pH may be due to more alkalinity generation at initial nitrate of 200 and 250 mg/L. Furthermore, an increase in COD was observed for first few days after every increase in nitrate addition but never exceeded 21 mg/L (Fig. 2), possibly due to the supply of excess COD to meet higher influent nitrate. However, COD concentration gradually reduced and remained constant at 11–15 mg/L for all tested influent nitrate. Therefore, it is evident that influent nitrate concentration up to 250 mg/L did not influence the mixed bacterial culture performance in SmBR.

Arsenic removal with different electron donors

Figure 3 shows the performance of SmBR using different carbon sources as electron donors including acetate, malate, succinate, lactate and glucose. Based on the performance of SmBR at influent nitrate concentration up to 250 mg/L and arsenic of 1000 µg/L, the SmBR was operated with same initial nitrate and arsenic concentration during this phase. Similar to the results mentioned above (“Arsenic removal at high nitrate concentration” section), nitrate, nitrite and iron concentration remained below detection limits with all electron donors tested. It is clear from Fig. 3 that arsenic was removed to well below 10 µg/L with all electron donors mentioned above. However, compared with the experiments using other electron donors, the arsenic was below detection limits when SmBR was fed with lactate and glucose. Sulphate in the treated water was between 3.5 and 7.5 mg/L with the lowest of near about 1.5–3.0 mg/L during the operation of SmBR with lactate and glucose. The foregoing results demonstrated that the mixed bacterial culture effectively utilized all the electron donors for contaminants removal. Lactate, succinate and malate are reported as preferred carbon sources for SRB among organic acids under mesophilic operating conditions (Hao et al. 1996; Liamleam and Annachhatre 2007) and promote sulphate reduction at almost the same rates (Postgate 2013). However, in the present study glucose was found to be the best among other electron donors. This could be because sugar is easily reduced under anaerobic conditions and supports the growth of a wide variety of nitrate- as well as sulphate-reducing bacteria leading to increase in microbial diversity and treatment system resilience (Akunna et al. 1993; Mohseni-Bandpi et al. 2013).

SmBR performance with actual groundwater

Figure 4 presents the performance of SmBR with actual groundwater. Nitrate was never detected in the treated water. From AGW type 1, arsenic and iron were removed to well below permissible limits of drinking water. From day 379 to 392, when SmBR was fed with AGW type 2, 4.4–4.6 mg/L of iron appeared in treated water. During this period, only 4–5 mg/L of sulphate was detected, which indicates no further sulphate reduction is expected. As precipitation of biogenic iron sulphides is the only mechanism for iron removal in the present system, unavailability of sufficient sulphides could be the sole reason for higher iron in treated water. Therefore, influent sulphate concentration was elevated to 50 mg/L on day 393, which improved iron removal but leaving 0.6–0.7 mg/L of iron in treated water. The sulphate concentration in treated water was 4–5 mg/L. Owing to sulphide unavailability, influent sulphate was again elevated to 75 mg/L (day 416–434). The iron was removed to below 0.3 mg/L once again in the treated water and remained below detection limits. Although concentration of iron sometimes exceeded drinking water MCL (as discussed above), arsenic was always remained below detection limits in treated water during the entire study period with AGW. This could be due to the concomitant removal of arsenic as arsenic sulphide precipitation as well as adsorption and/or co-precipitation with iron sulphides (Altun et al. 2014). The sulphate, COD and pH values were 4.5–7.5 mg/L, 11.0–14.0 mg/L and 7.2–7.34, respectively, during treatment of AGW. Thus, it can be concluded that sufficient influent sulphate is necessary for arsenic and iron removal from AGW to meet permissible limits of drinking water.

Bacterial community of the SmBR

After sequencing on Illumina MiSeq platform, 1064 OTUs were recognized from 728,574 reads generated. Alpha diversity was computed using observed species metrics with rarefied OTU table size of 100 (ESM 2). Figure 5 shows the taxonomic hits distribution at the phylum and class level of the abundant phylotypes in the SmBR. The phylum Proteobacteria represented about 53% of the total bacteria (Fig. 5a), and thus, it predominated the bacterial community in the SmBR. Not surprisingly, many identified denitrifying and sulphate-reducing bacteria (SRB) belong to the phylum Proteobacteria. Besides, the presence of Phylum Actinobacteria, Bacteroidetes, Firmicutes, Spirochaetes and TM6 was also detected at low abundance. A previous study also reported a functional role of Firmicutes, Bacterioidetes, Chlorobia, Actinobacteria and Chloroflexi members along with Proteobacteria in active denitrifying biofilms generated during acetate oxidation (Wrighton et al. 2010). The sequences with very less similarity or no similarity or whose V3 regions do not have any alignment hits against taxonomic database are categorized as “Unknown”. Among the four bacterial classes, the Beta subdivision was the most dominant Proteobacteria, followed by Delta, Gamma and Alpha subdivisions (Fig. 5b). The DsrAB catalyses the energy-conserving step during dissimilatory sulphate reduction pathway that is conserved in most SRB distributed in Deltaproteobacteria.

Sequences affiliated to genus Desulfosporosinus, Desulfovibrio, Desulfomicrobium and Desulfoglaeba were observed in SmBR. This observation was in accordance with the previous studies that observed SRB including Desulfomicrobium and Desulfovibrio (Altun et al. 2014) and Desulfosporosinus (Battaglia-Brunet et al. 2012) in arsenic-removing sulphidogenic bioreactors. Moreover, the Desulfosporosinus strains are capable of utilizing nitrate and arsenate as electron acceptors and are reported to play major role in precipitation of orpiment in sulfphidogenic systems (Battaglia-Brunet et al. 2012; Ramamoorthy et al. 2006). Other nitrate reducers detected in SmBR include Achromobacter, Burkholderia, Thiobacillus, Acinetobacter and Pseudomonas. Many denitrifying bacteria that are detected in full and pilot-scale groundwater denitrification bioreactors were related to Alpha-, Beta-,Delta- and Gamma-Proteobacteria, Bacteroidetes, Actinobacteria, Acidobacteria, Firmicutes and Bacterioidetes (Liu et al. 2008; Spain and Krumholz 2011). In addition, sequences related to taxa Acidothiobacillus, Geobacter and Burkholderia are also detected, which are proficient in utilizing more than one electron acceptors. The Burkholderia genus proved to contain genes responsible for arsenic reduction and resistance (Li et al. 2014). The capacity to utilize arsenic as electron acceptor allowed the denitrifying taxonomic groups to exist in the studied system. Thus, the presence of highly diverse microbial community suggests a much wider metabolic potential and occurrence of many diverse metabolic processes within the in SmBR.

Biosolids characterization

FESEM/EDX mapping observation of the precipitate was collected for elemental characterization (Fig. 6). FESEM-backscattered electron (BSE) image (Fig. 6a) shows homogeneous distribution of arsenic, iron and sulphur in the biosolids in substantial amount. Further EDX mapping was employed during FESEM characterization to confirm the elemental composition and distribution. The EDX elemental mapping indicated the homogeneous distribution of sulphur (Fig. 6b), arsenic (Fig. 6c) and iron (Fig. 6d) throughout the biosolids.

TEM analysis undertaken during this study indicates the presence of larger-size sulphide grain (Fig. 7a), which is consistent with the experimental analysis of Kirk et al. (2010). The corresponding selected area electron diffraction (SAED) revealed crystalline phases of the precipitate (Fig. 7b). Next, we performed EDX analysis of the precipitate showing that grains were chemically consisted of arsenic, iron and sulphur (Fig. 7c). The presence of Cu peaks is due to copper TEM grid used for TEM analysis. The morphology and elemental analyses of these grains suggested that they were precipitated in the SmBR as a result of microbial reduction. The presence of morphologically irregular grains of pyrite is more common in bioreactors than natural pyrite (Kirk et al. 2010). Thus, FESEM and TEM studies revealed arsenic precipitation in the form of arsenosulphide (As2S3) and its co-precipitation and/or adsorption with iron sulphides (FeS, FeS2 and FeAsS) are the main arsenic removal mechanism in the reactor (Altun et al. 2014; Liu et al. 2018).

Assessing the arsenic leaching potential of arsenic-laden biosludge

The stability of the arsenic-laden biosludge was evaluated, and its disposal options were examined by performing TCLP (Toxicity Characteristic Leaching Procedure) test. The arsenic and iron content in dried samples was determined by the total acid digestion method (USEPA 1996). A sum of 42.2 mg/kg arsenic and 102.6 mg/kg iron (on dry basis) was extracted from the biosludge of SmBR. As standard TCLP protocol for 18 h under estimates arsenic leaching (Hooper et al. 1998), TCLP extraction in this project has been conducted for longer period of 84 h (extended TCLP) as suggested by others (Clancy et al. 2013; Sima et al. 2015). The results showed that the TCLP-extracted arsenic and iron were 48 ± 12 and 412 ± 36 µg/L, respectively.

Effects of DO on TCLP leachability

The leachability of arsenic and iron at varying Vair/VL ratios is presented in Fig. 8 and Table 2. The leachate arsenic concentration was found to decrease from 24 to 3.7 µg/L (Fig. 8a), with an increase in Vair/VL ratio from 0.25 to 1.25. An increase in DO was also observed from 0.72 to 5.8 mg/L. Similarly, leachability of iron was also found to decrease from 442 to 3.7 µg/L (Fig. 8b), representing a decrease from 8.6 to 1.4% with an increase in Vair/VL ratio. This could be explained by dissolution of biogenic iron sulphides and subsequent oxidation of Fe(II) in biosolids in the presence of air which led to precipitation of iron(III) hydroxides. As iron(III) hydroxides are proven adsorbents of arsenic (III) and arsenic (V), lower arsenic leaching was observed at higher Vair/VL ratio. Data obtained in the present study and that reported by Meng et al. (2001) confirm this hypothesis.

Effect of pH on arsenic release

Leachate arsenic and iron concentrations determined at different pH are presented in Fig. 8c. The DO concentration for all pH experiments remained at 5.0–6.0 mg/L. During an 84-h mixing period, slight change in pH was observed. The leachate arsenic and iron were significantly less than the total arsenic and iron concentrations and showed a great dependency on pH. A total of 54 ± 8 µg/L and 110 ± 12 µg/L arsenic were leached out at pH 3 and 5. At pH 7, 9 and 11, arsenic leaching was increased by a factor of 5, 8.5 and 14, respectively, to 274 ± 14 µg/L, 462 ± 26 µg/L and 778 ± 18 µg/L, relative to pH 3. A similar trend was observed for iron release, and a total of 186 ± 26 µg/L and 584 ± 42 µg/L were leached out at pH 3 and 5, respectively. The iron leaching was increased by a factor of 4.6, 6.8 and 9 at pH 7, 9 and 11, respectively. The arsenic and iron leaching from the biosolids is primarily associated with dissolution of less resistant biosolids or desorption of metals associated with biomass which are influenced by pH changes. Low arsenic release in acidic (pH 3 and 5) and circumneutral pH (pH 7) could be attributed to stability of arsenic minerals as well as the adsorption and/or co-precipitation with iron(III) hydroxides (Tabelin and Igarashi 2009). The increase in leachate arsenic under alkaline pH (pH 9 and 11) can be partly associated with hydroxyl ion replacement with arsenic on the sorption sites of iron(III) hydroxide, resulting in decreased adsorption of arsenic oxyanions (Shafiquzzaman et al. 2010; Tabelin et al. 2014). Results from TCLP tests conducted under different conditions suggested that arsenic concentrations in the leachate never exceeded maximum Australian (EA 2002) or USEPA (USEPA 1986) TCLP guideline values of 700 and 5000 µg/L, respectively. This result is expected for two reasons. First, sulphides of arsenic and iron in biosludge will remain stable as long as reducing conditions are maintained (Jong and Parry 2005). Second, if the biosludge is exposed to oxygen, the production of iron oxy-hydroxides will re-adsorb the leached arsenic, if any (Meng et al. 2001, Shakya et al. 2018). Based on the TCLP results, the sulphides of arsenic and iron in biosludge of SmBR do not qualify as hazardous materials.

Summary of reactor performance and mechanisms of arsenic and iron removal in SmBR

The present study primarily aims at performance evaluation of a suspended growth sulphidogenic bioreactor (SmBR) on concurrent arsenic, iron and nitrate removal from groundwater. The SmBR was found to be efficient enough to remove arsenic (250–1000 µg/L) and nitrate (100–250 mg/L) in the presence of 2.0 mg/L of iron from simulated groundwater, as well as arsenic (226 µg/L) and iron (8.3 mg/L) from real groundwater to meet drinking water standards. As chemo-heterotrophic bacteria gain energy during respiration, which involves an electron donor’s oxidation coupled with an electron acceptor’s reduction, and carbon from an organic carbon source, acetate was supplied as the electron donor cum carbon source for the mixed bacterial culture used in the SmBR. In a groundwater system where multiple number of electron acceptors are present, mixed bacterial culture utilizes available electron acceptors in sequential manner based on the thermodynamic favourability (Gibbs free energy) (Lovley and Chapelle 1995). As the pH of the content in SmBR varies between 6.8 ± 0.2, Gibbs free energy at pH 7 (ΔG°′) was calculated for different electron acceptors, which are given below.

From Eqs. (1–4), the expected preferential terminal electron acceptors would be Fe(III) > \({\text{NO}}_{3}^{ - }\) > As(V) > \({\text{SO}}_{4}^{2 - }\), provided adequate number of iron, nitrate, arsenate and sulphate reducers are present in the system. Bacterial community detected in SmBR also confirmed the presence of several genera capable of utilizing nitrate, sulphate, iron and arsenic as electron acceptors. Additionally, it is also important to mention that preferential use of an electron acceptor and formation of sulphides of arsenic and/or iron depends upon several other factors including amount of sulphate reduction. As sulphate and nitrate reduction generates alkalinity and high alkalinity retards formation of arsenosulphides precipitation (Henke, 2009), bioreactors treating high sulphate containing wastewater often leave high arsenic in the treated effluent (Altun et al. 2014). Importance of sulphate on arsenic removal in sulphidogenic bioreactors has been recently explained elsewhere (Shakya and Ghosh 2018a, b). Iron and arsenic removal in the present SmBR is expected mainly through one or more of the following mechanisms: (1) reduction in Fe(III), if any, to Fe(II) and precipitation as sulphides of iron, (2) reduction in AS(V), if any to As(III) and precipitation as sulphides of arsenic, (3) co-precipitation of arsenic with sulphides of iron and (4) co-precipitation of sulphides of arsenic with sulphides of iron (Altun et al. 2014; Shakya and Ghosh 2018b). The TEM/EDX studies on biosolids precipitated in SmBR indicated the presence of biogenic sulphides of arsenic and/or iron. Thus, removal of arsenic and iron in SmBR would have been through any one combination of the above-mentioned four mechanisms.

Although the bioreactor was found to be efficient enough to reduce target pollutants to meet drinking water standards, treated water contained 10–21 mg/L of COD which might be due to acetate addition in untreated water in excess to the stoichiometric requirement (“Preparation of simulated groundwater and seed suspension” section). Excess amount of acetate was added so that it should not be a limiting factor in overall biochemical process. Thus, residual amount of COD concentration (in treated water) could be possible to reduce further through its addition in raw water in lesser amount. The residual COD can also be removed in conventional water treatment units. Thus, the present study reveals that the suspended growth sulphidogenic bioreactor can be used as an additional treatment unit to a conventional water treatment plant, specifically where groundwater is contaminated with iron, arsenic and nitrate.

Conclusion

With the objective of concurrent nitrate, arsenic and iron removal, the present study demonstrated the feasibility of treatment of contaminated groundwater in an anaerobic suspended growth reactor system inoculated with a mixed bacterial culture indigenous to groundwater. The SmBR was able to achieve nitrate (100–250 mg/L), arsenic (250–1000 µg/L) and iron (2 mg/L) removal to meet permissible limits of drinking water. Additionally, the SmBR was able to remove both arsenic (226 µg/L) and iron (8.3 mg/L) simultaneously from AGW to below permissible limits of drinking water. When the SmBR was fed with AGW containing 8.3 mg/L iron, 4–5 mg/L of iron was observed in the treated water owing to deficit in the production of biogenic sulphide (at initial 25 and 50 mg/L of sulphate) necessitating addition of more sulphate (75 mg/L) in the untreated water. Metagenomic analysis confirmed the presence of diverse sulphate- and nitrate-reducing microbial community in the reactor after almost 14 months of operation. The use of analytical techniques indicates that biogenic sulphides effectively removed iron from the water, likely through the formation of iron sulphides, whereas precipitation of arsenosulphides, co-precipitation and/or adsorption on iron sulphides are the main arsenic removal mechanism. Furthermore, arsenic-laden biosludge was found to be stable against leaching under reduced as well as oxic environment and does not fall under a hazardous sludge. Therefore, the treatment technology and the residue management offer a sustainable technology for the treatment of groundwater contaminated with arsenic, iron and/or nitrate. However, further detailed studies on developing post-treatment processes including removal of excess COD from treated water, polishing unit for removal of arsenic precipitates and disinfection are necessary to validate the applicability of this aspect.

Supplementary material

The Supporting Information provides details of the actual groundwater, bacterial genera detected in the system and Alpha microbial diversity within the samples.

References

Abass OK, Teng Ma, Kong S, Wang Z, Mpinda MT (2016) A novel MD-ZVI integrated approach for high arsenic groundwater decontamination and effluent immobilization. Process Saf Environ 102:190–203

Akunna JC, Bizeau C, Moletta R (1993) Nitrate and nitrite reductions with anaerobic sludge using various carbon sources: glucose, glycerol, acetic acid, lactic acid and methanol. Water Res 27:1303–1312

Altun M, Sahinkaya E, Durukan I, Bektas S, Komnitsas K (2014) Arsenic removal in a sulfidogenic fixed-bed column bioreactor. J Hazard Mater 269:31–37

Amburgey JE, Amirtharajah A (2005) Strategic filter backwashing techniques and resulting particle passage. J Environ Eng 131:535–547

APHA (2005) Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association, Washington, DC

ATSDR (2000) Toxicological profile for arsenic. US Department of Health and Human Services, Public Health Service Agency for Toxic Substances and Disease Registry, p 428

Attinti R, Sarkar D, Barrett K, Datta R (2015) Adsorption of arsenic (V) from aqueous solutions by goethite/silica nanocomposite. Int J Environ Sci Technol 12:3905–3914

Baig JA, Kazi TG, Arain MB, Afridi HI, Kandhro GA, Sarfraz RA, Jamal MK, Shah AQ (2009) Evaluation of arsenic and other physico-chemical parameters of surface and ground water of Jamshoro, Pakistan. J Hazard Mater 166(2):662–669

Barringer JL, Reilly PA (2013) Arsenic in groundwater: a summary of sources and the biogeochemical and hydrogeologic factors affecting arsenic occurrence and mobility. In: Current perspectives in contaminant hydrology and water resources sustainability. InTech

Battaglia-Brunet F, Crouzet C, Burnol A, Coulon S, Morin D, Joulian C (2012) Precipitation of arsenic sulphide from acidic water in a fixed-film bioreactor. Water Res 46:3923–3933

Behari JR, Prakash R (2006) Determination of total arsenic content in water by atomic absorption spectroscopy (AAS) using vapour generation assembly (VGA). Chemosphere 63(1):17–21

Bhatnagar A, Sillanpaa M (2011) A review of emerging adsorbents for nitrate removal from water. Chem Eng J 168:493–504

BIS:10500 (2012) Indian standard: drinking water: specification, 2nd revision. Bureau of Indian standard, New Delhi

Brahmacharimayum B (2014) Studies on sulfate reduction to elemental sulfur under anaerobic/microaerobic conditions. Ph.D. Thesis, Indian Institute of Technology, Guwahati

Briones-Gallardo R, Escot-Espinoza V, Cervantes-González E (2017) Removing arsenic and hydrogen sulfide production using arsenic-tolerant sulfate-reducing bacteria. Int J Environ Sci Technol 14:609–622

Chaturvedi R, Banerjee S, Chattopadhyay P, Bhattacharjee CR, Raul P, Borah K (2014) High iron accumulation in hair and nail of people living in iron affected areas of Assam, India. Ecotoxicol Environ Safe 110:216–220

Clancy TM, Hayes KF, Raskin L (2013) Arsenic waste management: a critical review of testing and disposal of arsenic-bearing solid wastes generated during arsenic removal from drinking water. Environ Sci Technol 47:10799–10812

DeSantis TZ, Hugenholtz P, Larsen N, Rojas M, Brodie EL, Keller K, Huber T, Dalevi D, Hu P, Andersen GL (2006) Greengenes, a chimera-checked 16S rRNA gene database and workbench compatible with ARB. Appl Environ Microbiol 72:5069–5072

EA (2002) Guidance on whether wastes containing metals or metal compounds are regulated under the Hazaradous Waste Act, 2nd edn. In: Information paper, no. 5, Department of Environment and Heritage, Australia, Environment Australia (EA), pp 1–22

Frunzo L, Esposito G, Pirozzi F, Lens P (2012) Dynamic mathematical modeling of sulfate reducing gas-lift reactors. Process Biochem 47:2172–2181

Ghanbari F, Moradi M, Mohseni-Bandpei A, Gohari F, Abkenar TM, Aghayani E (2014) Simultaneous application of iron and aluminum anodes for nitrate removal: a comprehensive parametric study. Int J Environ Sci Technol 11:1653–1660

Ghosh A (2013) Studies on microbial reduction of perchlorate in batch and continuous system. Ph.D. Thesis, Indian Institute of Technology, Guwahati

Giménez MC, Blanes PS, Buchhamer EE, Osicka RM, Morisio Y, Farías SS (2013) Assessment of heavy metals concentration in arsenic contaminated groundwater of the Chaco Plain, Argentina. Environ Chem 2013:1–12

Hao OJ, Chen JM, Huang L, Buglass RL (1996) Sulfate-reducing bacteria. Crit Rev Environ Sci Technol 26:155–187

Henke K (2009) Arsenic: environmental chemistry, health threats and waste treatment. Wiley, Chichester. https://doi.org/10.1002/9780470741122.ch2

Hooper K et al (1998) Toxicity characteristic leaching procedure fails to extract oxoanion-forming elements that are extracted by municipal solid waste leachates. Environ Sci Technol 32:3825–3830

Jadhav SV, Bringas E, Yadav GD, Rathod VK, Ortiz I, Marathe KV (2015) Arsenic and Fluoride contaminated groundwaters: a review of current technologies or contaminant removal. J Environ Manag 162:306–325

Jong T, Parry DL (2005) Evaluation of the stability of arsenic immobilized by microbial sulfate reduction using TCLP extractions and long-term leaching techniques. Chemosphere 60:254–265

Kirk MF, Roden EE, Crossey LJ, Brealey AJ, Spilde MN (2010) Experimental analysis of arsenic precipitation during microbial sulfate and iron reduction in model aquifer sediment reactors. Geochim Cosmochim Acta 74:2538–2555

Kleerebezem R, van Loosdrecht MCM (2007) Mixed culture biotechnology for bioenergy production. Curr Opin Biotechnol 18:207–212

Lee J, Ahn W-Y, Lee C-H (2001) Comparison of the filtration characteristics between attached and suspended growth microorganisms in submerged membrane bioreactor. Water Res 35:2435–2445

Li X, Zhang L, Wang G (2014) Genomic evidence reveals the extreme diversity and wide distribution of the arsenic-related genes in Burkholderiales. PLoS ONE 9:e92236

Li B, Pan X, Zhang D, Lee D-J, Al-Misned FA, Mortuza MG (2015) Anaerobic nitrate reduction with oxidation of Fe(II) by Citrobacter freundii strain PXL1: a potential candidate for simultaneous removal of As and nitrate from groundwater. Ecol Eng 77:196–201

Liamleam W, Annachhatre AP (2007) Electron donors for biological sulfate reduction. Biotechnol Adv 25:452–463

Liu X, Gao C, Zhang A, Jin P, Wang L, Feng L (2008) The nos gene cluster from gram-positive bacterium Geobacillus thermodenitrificans NG80-2 and functional characterization of the recombinant NosZ. FEMS Microbiol Lett 289:46–52

Liu F, Zhang G, Liu S, Fu Z, Chen J, Ma C (2018) Bioremoval of arsenic and antimony from wastewater by a mixed culture of sulfate-reducing bacteria using lactate and ethanol as carbon sources. Int Biodeterior Biodegradation 126:152–159

Lovley DR, Chapelle FH (1995) Deep subsurface microbial processes. Rev Geophys 33(3):365–381

Mayorga P, Moyano A, Anawar HM, García-Sánchez A (2013) Temporal variation of arsenic and nitrate content in groundwater of the Duero River Basin (Spain). Phys Chem Earth, Parts A/B/C 58–60:22–27

Meng X, Korfiatis GP, Jing C, Christodoulatos C (2001) Redox transformations of arsenic and iron in water treatment sludge during aging and TCLP extraction. Environ Sci Technol 35:3476–3481

Mohseni-Bandpi A, Elliott DJ, Zazouli MA (2013) Biological nitrate removal processes from drinking water supply-a review. J Environ Health Sci Eng 11:35

Onstott T, Chan E, Polizzotto M, Lanzon J, DeFlaun M (2011) Precipitation of arsenic under sulfate reducing conditions and subsequent leaching under aerobic conditions. Appl Geochem 26:269–285

Postgate J (2013) The sulfate-reducing bacteria: contemporary perspectives. Springer, Berlin

Ramamoorthy S et al (2006) Desulfosporosinus lacus sp. nov., a sulfate-reducing bacterium isolated from pristine freshwater lake sediments. Int J Syst Evol Microbiol 56:2729–2736

Sarkar A, Paul B (2016) The global menace of arsenic and its conventional remediation: a critical review. Chemosphere 158:37–49

Shafiquzzaman M, Azam MS, Nakajima J, Bari QH (2010) Arsenic leaching characteristics of the sludges from iron based removal process. Desalination 261:41–45

Shakya AK, Ghosh PK (2018a) Simultaneous removal of arsenic and nitrate in absence of iron in an attached growth bioreactor to meet drinking water standards: importance of sulphate and empty bed contact time. J Clean Prod 186:304–312

Shakya AK, Ghosh PK (2018b) Simultaneous removal of arsenic, iron and nitrate in an attached growth bioreactor to meet drinking water standards: importance of sulphate and empty bed contact time. J Clean Prod 186:1011–1020

Shakya AK, Rajput P, Ghosh PK (2018) Investigation on stability and leaching characteristics of mixtures of biogenic arsenosulphides and iron sulphides formed under reduced conditions. J Hazard Mater 353:320–328

Sima J, Cao X, Zhao L, Luo Q (2015) Toxicity characteristic leaching procedure over-or under-estimates leachability of lead in phosphate-amended contaminated soils. Chemosphere 138:744–750

Snyder KV, Webster TM, Upadhyaya G, Hayes KF, Raskin L (2016) Vinegar-amended anaerobic biosand filter for the removal of arsenic and nitrate from groundwater. J Environ Manag 171:21–28

Spain AM, Krumholz LR (2011) Nitrate-reducing bacteria at the nitrate and radionuclide contaminated Oak Ridge Integrated Field research challenge site: a review. Geomicrobiol J 28:418–429

Tabelin C, Igarashi T (2009) Mechanisms of arsenic and lead release from hydrothermally altered rock. J Hazard Mater 169:980–990

Tabelin CB, Hashimoto A, Igarashi T, Yoneda T (2014) Leaching of boron, arsenic and selenium from sedimentary rocks: II. pH dependence, speciation and mechanisms of release. Sci Total Environ 473:244–253

Teunissen K, Abrahamse A, Leijssen H, Rietveld L, Dijk HV (2008) Removal of both dissolved and particulate iron from groundwater. Drink Water Eng Sci Discuss 1:87–115

Upadhyaya G, Jackson J, Clancy TM, Hyun SP, Brown J, Hayes KF, Raskin L (2010) Simultaneous removal of nitrate and arsenic from drinking water sources utilizing a fixed-bed bioreactor system. Water Res 44:4958–4969

USEPA (1986) Hazardous waste management system; land disposal restriction. In: Appendix I to part 268: toxicity characteristics leaching procedure (TCLP), pp 40643–40654

USEPA (1992) Test methods for evaluating solid waste, physical/chemical methods, 3rd edn. In: SW-846, Method 1311. U S Government Printing Office, Washington, DC

USEPA (1996) Acid digestion of sediments, sludges and soils. Method 3050B. https://www.epa.gov/sites/production/files/2015-06/documents/epa-3050b.pdf. Accessed 23 Aug 2018

USEPA (2002) Office of ground water and drinking water implementation guidance for the arsenic rule EPA Report-816-D-02-005 (I3–I4) USEPA, Cincinnati, USA, 2002

USEPA (2004) SW-846 test method 9045D: soil and waste pH. https://www.epa.gov/sites/production/files/2015-12/documents/9045d.pdf. Accessed 23 Aug 2018

Venkataraman K, Uddameri V (2012) Modeling simultaneous exceedance of drinking-water standards of arsenic and nitrate in the Southern Ogallala aquifer using multinomial logistic regression. J Hydrol 458–459:16–27

Wang Z, Ma T, Zhu Y, Abass OK, Liu L, Su C, Shan H (2018) Application of siderite tailings in water-supply well for As removal: experiments and field tests. Int Biodeterior Biodegradation 128:85–93

Wrighton KC et al (2010) Bacterial community structure corresponds to performance during cathodic nitrate reduction. ISME J 4:1443–1455

Acknowledgements

The authors are thankful to Ministry of Drinking Water and Sanitation (MDWS), India [Project No. W-11017/44/2011-WQ], for partially supporting purchase of consumables, minor equipment and scholarship to the first author for certain period of time. The authors also highly acknowledge the help from the Central Instrument Facility (CIF), Indian Institute of Technology, Guwahati, for providing man power, various instrumental facilities, etc. Mr. L. Rahman, Mr. A. Das and other staff members of PHED, Bongaigaon, Assam, are duly acknowledged for helping in the collection of actual groundwater.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest. The help in any form received from any party has been acknowledged.

Additional information

Editorial responsibility: J Aravind.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shakya, A.K., Ghosh, P.K. Arsenic, iron and nitrate removal from groundwater by mixed bacterial culture and fate of arsenic-laden biosolids. Int. J. Environ. Sci. Technol. 16, 5901–5916 (2019). https://doi.org/10.1007/s13762-018-1978-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-018-1978-2