Abstract

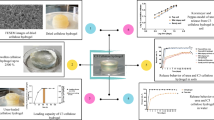

In the agricultural industry, biomass waste generated along with the production of food, is transformed into value-added products. Also, the demand for the slow or control release fertilizer is increasing to reduce the cost of maintaining the agricultural land. These issues are tackled by converting biomass waste to a slow fertilizer release vehicle and biodegradable water retention material that could reduce the cost for fertilizer application and simultaneously preserved the soil from dryness. A series of carboxymethyl sago pulp (CMSP) hydrogels were prepared by electron beam irradiation. Slow release systems were evaluated by loading potassium nitrate (KNO3) and ammonium nitrate (NH4NO3) into the CMSP hydrogels. These CMSP hydrogels endow slow release property, biodegradability and a soil moisture preservation property that could find greener application in agricultural industries. The results indicate that CMSP hydrogels have a great potential as an agent for slow release of fertilizers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

New arable lands are being developed to increase the production of commercial plantation crops such as oil palm, paddy, cocoa, natural rubber, pepper and sago starch. A study made on the soil characteristics under crop farming found that the biggest problems faced were soil erosion and the effects of slope terracing on soils which, led to significant fertilizer loss with concomitant water pollution in lower lying areas (Pincus et al. 2016; Smith and Siciliano 2015; Wei et al. 2016). The leachates from conventionally applied agrochemicals are recognized to be a significant contributor to ground water contamination (Islami et al. 2011; Quirós et al. 2015). Additionally, the leachates cause changes in soil microbiological properties and a shift in soil microbial communities, which indicates soil stress that adversely influences the productivity of the farm (Gupta et al. 2017; Huang et al. 2014). The presence of nutrients such as phosphorus and nitrogen in ground water may also adversely affect biological attributes due to their toxicity and ability to bio-accumulate in the food chain (Mahdy et al. 2017; Zeinali and Lenjannezhadian 2017). As such there is a need for a more controlled application of agrochemicals to reduce the amounts of active ingredients at any given time without diminishing efficiency (Pourjavadi et al. 2011). The replacement of conventional agrochemical formulations by controlled-release systems helps to avoid treatment with excess amounts of active substances by maintaining a local concentration of active ingredients in the soil and reducing runoff, thereby providing a pragmatic solution to the various environmental problems caused by traditional water-soluble fertilizers (Pincus et al. 2016).

There are many approaches to providing a controlled-release environment. One way that shows promise is to take advantage of the interwoven characteristics associated with polymeric hydrogels, which by definition trap aqueous solvent within their lattice to produce the hydrogel characteristics. In a recent example where agrochemicals were trapped in the hydrogel by including them in the feed mixture undergoing radiation-based polymerization, their findings suggest the amount of swelling controlled the agrochemical release, i.e., when the swelling percentage is high, the amount of fertilizer release will also be higher. Similarly, release studies on CMC-g-polyacrylamide hydrogels loaded with 63% w/v aqueous potassium nitrate (KNO3) solution showed the fertilizer to have been fully released within 7 days. This is not appealing for agriculture use as the fertilizer needs to be retained for longer periods of time (Bajpai and Giri 2003). CMC-based superabsorbent hydrogels are also finding increasing interest as a result of their high biodegradable characteristics and high swelling capacity (El-Mohdy 2007).

The composition of the hydrogel is also vital to its practical use in an agricultural environment. For example, the degradation of polyacrylamide leads to the formation of acrylamide that creates potential environmental hazards such as contamination of surface and ground water systems and health risks such as nerve toxins (Chadwick et al. 2015; Smith et al. 1997). The concerns of both government and public opinion regarding environmental conservation have diverted manufacturers toward producing more sustainable cellulose-based superabsorbent hydrogels from renewable organic resources, which biodegrade completely and safely (Marcì et al. 2006).

Superabsorbent hydrogels can also be added as a soil conditioner, to reduce soil water loss and allowing a sustained release of water to the soil and the plant roots. Simultaneously, it promotes the formation of soil aggregates and enhances the soil microbial activity that increase crop yield (Li et al. 2014). The use of the hydrogel on a large scale might have a revolutionary impact on water resources management, particularly in arid areas (Demitri et al. 2013).

In 2015, the global fertilizers and agricultural chemicals market forecast a volume of 186.4 million metric tons, an increase of ~ 13% since 2010 (Datamonitor June 2011). The slow release fertilizer (SRF)/control release fertilizer (CRF) annual growth rate in the period 2010–2015 was predicted to be 2.6%. Asia–Pacific accounts for 53.5% of the global fertilizers and agricultural chemicals market value followed by Americas (26.3%), Europe (16.5%), Middle East and Africa (3.7%). Coated CRFs have the highest demand in these countries. The interest in using CRFs in developing countries such as Malaysia, India and China is also increasing (Rahman 2004; Smith and Siciliano 2015). In 2012, China produced 1.35 million tons of SRF/CRF for its agricultural markets in corn, wheat and rice (Liu 2013). Chinese SRF/CRF consumption has been growing significantly in recent years and projected to grow 12.8% annually during 2014–2019 (Handbook February 2015).

The drive to use SRFs/CRFs in agricultural markets is to reduce labor costs, environmental concerns and maintaining high nutrient use efficiency (NUE). Increased usage could be achieved by producing new, less expensive technologies which could be derived using cheaper starting material, such as plant waste, and developing efficient application method unique to market needs (Carlos et al. 2009; Shaviv and Mikkelsen 1993). This approach to producing CMSP hydrogels from natural resources, such as sago pulp from sago waste, shows promise in our laboratory (Pushpamalar 2010). In this study, the hydrogels demonstrated SRF, water absorbing, soil conditioner properties and biodegradability.

Our current research is focusing on CMSP hydrogels that are prepared by using CMSP from sago pulp and irradiated under electron beam irradiation without the use of cross-linking agents. In this paper, we are reporting on the investigations of slow release properties, swelling and soil biodegradability of our CMSP hydrogels.

Materials and methods

Biodegradation of CMC hydrogels in garden soil

Sago pulp was isolated from sago waste (PPES Sago Industries (Mukah) Sdn Bhd., Sarawak) and converted to CMSP with different degrees of substitution (DS), and the CMSP solutions were irradiated using EB radiation to form the CMSP hydrogels as mentioned in our earlier published work (Pushpamalar et al. 2006, 2013b). The biodegradation behavior of the CMSP hydrogels of DS 0.4, 0.6 and 0.8 with %GFs of 25, 35 and ≥ 40% in garden soil (Plant Lover brand, Selangor) was studied. Perforated transparent plastic cups were prepared by drilling holes in the wall of the plastic cups (holes are 1 cm apart from each other) to allow water movement, and the labels were sealed separately to avoid water penetration. The black garden soil (pH 6–7) used in this study is a six-in-one commercial organic potting mix (supplied by Plant Lover, Selangor) with the reported the properties of promoting plant growth. The black garden soil contained coco peat, burnt soil, river sand, burnt husk, rich humus and charcoal powder which reduced the acidity of soil and prevented pests. Half of the cups were filled with black garden soil, and the label was inserted near the inner wall of the cup to allow the label to be seen from outer part of the cup. The pre-weighed hydrogel samples were then inserted, and the cups filled fully with the black garden soil and pressed. A land area of 4 m2 was dug to a depth of 30 cm and filled to a 5 cm height with black garden soil. The cups were then arranged to open downwards in the plot area, and the plot was filled with black garden soil to bury the plastic cups. After a period of 1–16 weeks, plastic cups were taken out at regular intervals, and the samples were washed carefully with water, dried in the oven at 70 °C and then weighed. All the periodically weighed hydrogel samples were averages of three replicates. Percentage of biodegradation (BP) of the hydrogel was calculated using the following Eq. (1):

where W 0 and W 1 were the weights of the hydrogel in the plastic cups before and after degradation (Nie et al. 2004).

Loading of the model fertilizers potassium nitrate (KNO3) and ammonium nitrate (NH4NO3)

Loading of CMSP hydrogels of DS 0.4, 0.6 and 0.8 with %GFs of 25, 35 and ≥ 40% was achieved by allowing the dry hydrogel (0.1–0.2 g) to swell in aqueous KNO3 solutions of 10 and 20% w/v concentration and aqueous NH4NO3 solutions of 20 and 40% w/v concentration. The swollen hydrogels were washed with distilled water, dried at 40 °C for 3 days and stored under vacuum at 27 °C in polyethylene bags. The percentage loading of KNO3 and NH4NO3 in the hydrogel was calculated by the following Eq. (2) (Bajpai and Giri 2002):

Assay on KNO3 and NH4NO3 release

In a typical release experiment, KNO3- and NH4NO3 -loaded CMSP hydrogels of DS 0.4, 0.6 and 0.8 with %GFs of 25, 35 and ≥ 40% of known weight and percentage loading were placed in distilled water (50 ml) as a release medium under diffusion (unstirred) conditions. The concentration of released KNO3 and NH4NO3 was estimated by measuring the conductivity of the release medium using a conductivity meter (Bajpai and Giri 2002). A HANNA model HI9635 conductivity meter was used to measure the conductivity of the fertilizers. The concentration of KNO3 and NH4NO3 released was quantified using calibration curves of R 2 = 0.9906 and 0.9933, respectively. The equilibrium concentration (M ∞ ) of released KNO3 and NH4NO3 was determined by measuring the conductivity of the release medium after 9 days. Kinetic analysis of the release data was made using the following Eq. (3); moreover, the diffusional release kinetic mechanism exponent (n) was evaluated graphically (Bajpai and Giri 2002).

where F denotes the fraction of model fertilizer diffused out of the hydrogel at time t, k is the diffusion ratio factor, n is diffusional release kinetic mechanism exponent, and W t and W ∞ are the amounts of accumulation release of model fertilizer at time t and equilibrium time, respectively.

These hydrogels were characterized to study the surface morphology, crystallinity and the biodegradation in garden soil.

Scanning electron microscopy (SEM) observation

Observation of exterior/surface and interior morphology of CMC hydrogels of DS 0.4, 0.6 and 0.8 with % GFs of 25, 35 and ≥ 40% were investigated using SEM model Quanta 400 ESEM. For preparation of dried hydrogel, the swollen hydrogel was dried in the oven 2 days at 70 °C and transferred to a freezer for a day and freeze-dried for 2 days until all the non-bound water was removed. The dried hydrogel was mounted onto an aluminum stud and sputter-coated with gold.

X-ray diffractometry analysis

Powder X-ray diffraction patterns of sago pulp and CMCs with DS 0.4, 0.6 and 0.8 were obtained by using diffractometer PHILIPS 1729 model in the scanning range of θ = 1° to 60° with the following operating conditions: 40 kV and 25 mA with CuKα radiation at 1.54059 Å. The K β radiation can be eliminated by using a nickel foil as the filter. The diffractometer is equipped with 1° divergence, 1° receiving, 1° scatter, a graphite monochromator and proportional detector. The sample for analysis was prepared by using a quartz plate applied with Vaseline, and the sample was sprinkled on to it (Pushpamalar 2010).

Results and discussion

Biodegradation test

The series of CMSP hydrogels were tested for biodegradability in the black garden soil, the loading of the model fertilizer was determined, and the release kinetic characteristics of the model fertilizers were studied.

Dried CMSP hydrogels of DS 0.4, 0.6 and 0.8 with %GF 25, 35 and ≥ 40 were buried in a perforated cup to allow the samples to be exposed to microorganisms and moisture within the soil. The hydrogels were swollen by the soil humidity, and the soils loosely adhered to the gels. Interestingly, the hydrogels taken out after 2 months were covered with soil and grass roots that grew into the remnant network of the hydrogels.

The soil burial test was conducted over for 4 months with the average daily temperature around 29–32 °C, falling to 20–25 °C with heavy rain over the winter months. Figure 1a shows the percentage biodegradation of the hydrogel with DS 0.4, 0.6 and 0.8 with %GF 25, 35 and ≥ 40 against time of exposure. The degradation of CMSP hydrogel of DS 0.4 was the fastest of all CMSP hydrogels to degrade by this measure with each %GF completely degraded within 3 months. Within experimental error, there appear to be differences in the rates of degradation for hydrogels of different GF and DS values. The deterioration of the hydrogels, however, was proportional to the DS with DS 0.6 (88% w/w) more prone to degradation than DS 0.8 (72% w/w). Here, too, the %GF did trend with 25% GF > 35% GF > 46–48% GF. Figure 1b shows the rate of degradation of the hydrogel with DS 0.4, 0.6 and 0.8 with %GF 25, 35 and ≥ 40. The rate of biodegradation of CMSP hydrogels with DS 0.8 is about 3–4% (w/w)/week, DS 0.6 is about 5% (w/w)/week, and DS 0.4 is 8–12% (w/w)/week. What we can conclude is that CMSP hydrogels with higher DS are more resistant to microbial attack. It also appears that CMSP hydrogels with higher %GF, with their higher cross-linking density, degrade slower. The biodegradability of the CMSP hydrogel in the soil is an essential requirement to use the CMSP hydrogels as a carrier for slow release fertilizer and it is an effective polymer for environmental conservation. A complementary study on enzymatic degradation on CMC hydrogel formed using gamma irradiation also showed cross-linked CMC hydrogels degraded by the action of cellulase and thereby was classified as an environmentally friendly polymer (Wach et al. 2001). In other work, the rate of biodegradation the CMC hydrogel was enhanced by the addition of nutrient element, especially by the addition of urea. The results of biodegradation in different soils indicated sand soil was favorable for hydrogel degradation (Nagasawa et al. 2004; Nie et al. 2004).

Loading and release of fertilizers

In this study, we investigated CMSP hydrogels entrapped with model fertilizers (KNO3 and NH4NO3). It is expected that when the fertilizer-loaded CMSP hydrogel is allowed to contact an aqueous release medium, the water would penetrate the surface of hydrogel releasing the KNO3 and NH4NO3. The effect of KNO3 and NH4NO3 concentration on the CMSP hydrogels loading is shown in Fig. 2. It indicates that the percentage of KNO3 and NH4NO3 loading (w/w %) on CMSP hydrogel increased with increasing KNO3 and NH4NO3 concentration. This is a result of increasing of KNO3 and NH4NO3 diffusion rate inside the CMSP hydrogel matrix (El-Mohdy 2007). From Fig. 2a, the CMSP hydrogels of DS 0.8 with %GF of 25, 35 and 48 (w/w %) were immersed in aqueous 10% w/v KNO3 solution resulting in a KNO3 loading of 660, 730 and 900% (w/w %), respectively. CMSP hydrogels treated with an aqueous 20% w/v KNO3 resulted in 1450, 1900 and 2100% (w/w %), respectively. The CMSP hydrogels of DS 0.6 with %GF of 25, 35 and 46 (w/w %) immersed in aqueous 10% w/v KNO3 resulted in lower percentages of KNO3 loading and even lower with DS 0.4. Overall, the loading of KNO3 increased with increasing DS and %GF. It is to be noted that the percentage of KNO3 loading obtained in swelling in aqueous 10–20% w/v KNO3 is much higher (600–2100% w/w) for different CMC hydrogels prepared than the percentage of KNO3 loading with 3% (w/v) KNO3 into CMC/polyacrylamide hydrogels (El-Mohdy 2007). The high KNO3 loading property is critical in slow release fertilizer as the highly KNO3-loaded hydrogel will release higher amounts of KNO3 where more KNO3 nutrient will be supplied to the plants and the CMC hydrogel could be subjected for more days in the soil as the biodegradation period for the different CMC hydrogels are from 1–4 months as reported in the biodegradation study.

The effect of NH4NO3 concentration on the CMSP hydrogel loading is shown in Fig. 2b. Here, the percentage of NH4NO3 loading (w/w %) within the CMSP hydrogel increases with increasing NH4NO3 concentration, a trend similarly observed for the potassium nitrate loading. The CMSP hydrogels of DS 0.8 with %GF of 25, 35 and 48 (w/w %) were immersed in aqueous 20% w/v NH4NO3 solutions resulted in a percentage of NH4NO3 loading of 1800, 2400 and 2600% (w/w %), respectively, and with aqueous 40% w/v NH4NO3 resulted in 4100, 4400 and 5200% (w/w %), respectively. The CMSP hydrogels of DS 0.6 and 0.4 absorbed proportionately less with %GF of 25, 35 and 40–46 (w/w %) showing the general trend of loading 25 < 35 < 40–46%.

In related work, a new synthetic hydrogel formed by free radical copolymerization of acrylamide, acrylic acid, hydroxypropyl acrylate and glycidyl methacrylate was studied for its NH4NO3 release. (Wang et al. 2007) This hydrogel was loaded with NH4NO3 solutions (20 and 40% w/v) and resulted in 180 and 360 wt% NH4NO3 loading, respectively. The release rate of the higher loaded hydrogel was faster than that of the lower loaded hydrogel. It indicates that the release rate of NH4NO3 is influenced substantially by the difference in loading concentration. Encouragingly, the 20 and 40% NH4NO3 solutions subjected to the different CMC hydrogels prepared in this study resulted in 1000–2500% w/v NH4NO3 and 4000–5200% w/v NH4NO3 loading, respectively. This is much higher than that of acrylamide, acrylic acid, hydroxypropyl acrylate and glycidyl methacrylate hydrogels, all synthetic hydrogels, in 20–40% NH4NO3 immersion solution. Similar to the KNO3 case, the high KNO3 loading property is vital in slow release fertilizer where the highly KNO3-loaded hydrogel will increase the release rate and the amounts of KNO3 nutrient to the plants.

Assay of released KNO3 and NH4NO3

An important factor in the use of CMSP hydrogels as the carrier of fertilizer is the effect of percent loading on the rate of fertilizer release. Aqueous 10 and 20% w/v loaded KNO3 CMSP hydrogels release profiles are shown in Fig. 3. At a superficial level, the amount of KNO3 released increases with time and then levels off after 50 days. The profile appears to have three phases. KNO3 released increases significantly for the first 10 days (6.5–8.5%/day) and gradually increases for the next 50 days (1.5–2.5%/day) and then levels off up to 200 days. About 50% KNO3 release was achieved in 2 days under our conditions, 60–70% KNO3 release made in less than 10 days, and 80–90% KNO3 release achieved in 50 days, with no further release of KNO3 release beyond 90%. These results are not optimal as the major release over 10 days could lead to an accumulation of KNO3 in the soils, which could lead to KNO3 release exceeding the crop demand and the point of crop response, and when crop recovery of the applied KNO3 is low.

Interestingly, on the 18th day of the release study, there is a sudden high release of KNO3 from the 10% KNO3-loaded CMSP hydrogels with DS 0.4 %GF 25, CMSP HG DS 0.6 %GF 25 and %GF 35 and CMSP HG DS 0.8 %GF 35. The same type of significant KNO3 release was also observed from 20% KNO3-loaded of the CMSP HG DS 0.4 %GF25, CMSP HG DS 0.6 %GF25 and CMSP HG DS 0.8 %GF35 and 48. In these cases, the fertilizer release is due to the molecules (water and fertilizer) diffusion and polymer network degradation (Klinger and Landfester 2012). The degradation could occur due to the cleavage of the backbones or cross-linking points of the network-forming CMSP. The cleavage of cross-linking points leads to decreasing cross-linking density and increasing pore size. The diffusivity of the fertilizer is no more constant but increases with propagating polymer network degradation. This propagation of polymer network degradation increases with time and to a certain point where the network collapses and releases the fertilizer in an uncontrolled manner.

The aqueous 20 and 40% w/v NH4NO3-loaded CMSP hydrogel release profiles are shown in Fig. 4. The results are similar to those for potassium nitrate. All the CMSP hydrogels achieved about 50% NH4NO3 release in 2 days and 60–85% NH4NO3 release in under 10 days. Higher levels of 86–92% NH4NO3 release were achieved within 50 days. As a result of the rapid release, the NH4NO3 could accumulate in the soils, and this could lead to NH4NO3 release exceeding the crop demand (Snyder et al. 2009). Consistently and in alignment with the KNO3 study, Fig. 4 shows that within a narrow range (ca. 20–30th day) of the release study there is sudden high release of NH4NO3 from the CMSP HG DS 0.4 %GF 35, CMSP HG DS 0.6 %GF 35 and GF46 and CMSP HG DS 0.8 %GF 35 and 48. This may be attributed to the “burst effect” phenomena which arise when loaded CMSP hydrogels are put in the release medium, and the biodegradation of the CMSP hydrogel takes place and releases the significant amount of the entrapped KNO3 and NH4NO3 (Bajpai and Giri 2002).

Both the profiles show that the release of KNO3 and NH4NO3 increases with the increase in DS but decreases with the increase in the %GF. The average molecular weight of CMSP increases with increasing DS as a result of an increase in the number of –CH2COONa groups per glucose unit and, as a result, higher cross-linking could occur and more surface area available for KNO3 and NH4NO3 loading (Nomura et al. 1990; Pushpamalar 2010). The increase of %GF could have caused the macromolecular chain to become dense with the increase in cross-linking and form a tight network that restricts the flexibility of the macromolecular chain and leads to difficulty for the water molecule to penetrate out from the CMSP hydrogel, causing the slow release kinetics of KNO3.

All our prepared CMSP hydrogels have degraded after a maximum release of KNO3. Within experimental error, the results show that the CMSP hydrogels did not attain full (100%) release over the period. His can be explained by denitrification from the following pathway:

The conversion of NO3 − to N2 can be complete but small and variable portion of the nitrogen is often emitted as an N2O gas. Emissions of N2 and N2O gases are sporadic, occurring before, during and after the plant growing season. Flushes of these gases can happen in aerated soils which have become moistened or saturated from precipitation or irrigation (Kim et al. 2013; van der Weerden et al. 2016).

It has been established that a highly swelling hydrogel should release a greater amount of KNO3 entrapped within the hydrogel (Bajpai and Giri 2002). In this process, the release of solute from the loaded hydrogel involves the absorption of exogenous water into the matrix and simultaneous release of KNO3 through diffusion. We recently established that the diffusion of water out of the CMSP hydrogel is fastest for DS 0.4, and slowest for similar hydrogels with a DS of 0.8 (Pushpamalar 2010). Consistently, the diffusion of water is much slower in the CMSP hydrogel of %GF ≥ 40. This may be due to the higher cross-linking density in the CMSP hydrogel with higher %GF which reduces the size of the pores in the structure of CMSP hydrogel from which the water diffuses. This retardation leads to a decrease in swelling ratio and the diffusion coefficient (Amsden 1998; Pushpamalar et al. 2013b).

All the CMSP hydrogels in this paper studied for slow fertilizer release possess useful characteristics such as biodegradability in soil, loading and release of the model fertilizers (KNO3 and NH4NO3) was achieved, and significant swelling in water under a range of different conditions has been observed (e.g., temperature, pH, inorganic solutions). (Pushpamalar et al. 2013a, b) The order of best performance of our CMSP hydrogels in all slow release characteristics is: CMSP HG DS 0.8 %GF 48 > CMSP HG DS 0.8 %GF 35 > CMSP HG DS 0.8 %GF 25 > CMSP HG DS 0.6 %GF 46 > CMSP HG DS 0.6 %GF 35 > CMSP HG DS 0.6 %GF 25 > CMSP HG DS 0.4 %GF 40 > CMSP HG DS 0.4 %GF 35 > CMSP HG DS 0.4 %GF 25.

To determine the diffusional release rate coefficient (n), the percentage of release of KNO3 and NH4NO3 by a gram of the cross-linked CMSP hydrogel was plotted against the square root of immersion time (Pushpamalar 2010). The diffusional release rate coefficients are calculated from the linear slope for respective KNO3, and NH4NO3-loaded CMSP hydrogel and are listed in Tables 1 and 2, respectively.

As we know from previous discussions, increasing the concentration of KNO3 and NH4NO3 resulted in an enhancement of the percentage of KNO3- and NH4NO3-loaded (w/w %) within the CMSP hydrogel matrix. The increase in loading of KNO3 and NH4NO3 also increases the diffusional release rate coefficient as expected because of the larger the initial load; the faster is the movement of the KNO3 and NH4NO3 penetrating the surface of the loaded CMSP hydrogel. The rate of diffusional release coefficient in Tables 1 and 2 shows a decrease with increase in %GF. We have rationalized this as at higher %GF; the CMSP hydrogel has a greater cross-linking network and the CMSP macromolecular chains become dense which hinder the mobility of the KNO3 and NH4NO3 molecules to penetrate into the network, resulting in the decrease of KNO3 and NH4NO3 release (Bajpai and Giri 2002; El-Mohdy 2007).

The graph of lnF versus lnt for aqueous 10 and 20% w/v loaded KNO3 and aqueous 20 and 40% w/v loaded NH4NO3 CMSP hydrogels, respectively (not shown). Here the diffusional release kinetic mechanism exponent (n) of the KNO3 and NH4NO3 is determined from the slope of the straight lines and collected in Tables 3 and 4, respectively. This equation is applied to the initial stages of release and plots of lnF versus lnt yield straight lines for up to 2 days of immersion. For Fickian diffusion, n < 0.5, where the model fertilizer release process is controlled by diffusional transport, and non-Fickian diffusion n usually lies between 0.5 < n<1.0 where the polymeric matrix relaxation dominates the model fertilizer release process (Bajpai and Giri 2002; Francis et al. 2004; Saraydin et al. 1995, 1996)

The values of the diffusional release kinetic mechanism exponent (n) of CMSP hydrogels with DS 0.4 of aqueous 10% w/v loaded KNO3 and aqueous 20% w/v loaded KNO3 lies between 0.53–0.92 and 0.22–0.34, indicating both non-Fickian and Fickian behavior, respectively. It is observed that the transport mechanism for CMSP hydrogels loaded with aqueous 10% w/v KNO3 is non-Fickian except for CMSP hydrogel of DS 0.8 of %GF 35 and 48. For the aqueous 20% w/v loaded KNO3, the transport mechanism is Fickian except for CMSP hydrogel of DS 0.8 of %GF25. This type of transport mechanism observed may be due to the chain length increases with increasing DS of the CMSP. Such a system allows for a faster relaxation of the network, resulting in Fickian nature, where the KNO3 and NH4NO3 molecules transport become diffusion controlled. In the non-Fickian states, the diffusion of KNO3 and NH4NO3 molecules is much slower than the relaxation of the CMSP hydrogel, where the polymers chains are not sufficiently mobile to permit immediate penetration of the fertilizers out of polymer core.

The values of the diffusional release kinetic mechanism exponent of CMSP hydrogel with DS 0.4 of aqueous 20% w/v loaded NH4NO3 and aqueous 40% w/v loaded NH4NO3 are between 0.54–0.88 and 0.11–0.26, also indicating both non-Fickian and Fickian behavior, respectively. The similarity in results suggests that provided the nitrate use soluble; the cation has little effect on the rates of nitrate release. It is noticed that with the increase in loading of NH4NO3 the transport mechanism is shifted to Fickian in nature and this observation is due to the larger initial load, which resulted in a faster movement of the KNO3 and NH4NO3 penetrating the surface of the loaded CMSP hydrogels. A larger loading may also facilitate the relaxation of CMSP macromolecular chains and where the KNO3 and NH4NO3 transport becomes diffusion controlled (Bajpai and Giri 2002; El-Mohdy 2007).

From the results obtained, we can conclude that these CMSP hydrogels could be applied as a slow release mechanism in the agricultural sector including vegetable, fruit, and paddy planting areas. In practicality, since most of the loaded KNO3 and NH4NO3 are being released within 50 days, it could be used as short time slow release agent. The CMSP hydrogels of DS 0.4 could be applied to the vegetable plantation as it would degrade within 3 months. CMSP hydrogel of DS 0.6 and 0.8 could be used in fruits and paddy plantations as they would need to release fertilizers over longer periods and it could also be used in vegetable plantations as these hydrogels degrade after 5 months.

Scanning electron microscopy (SEM) observations

Figure 5 shows the SEM photographs of cross-sectional interior structures of CMC hydrogels of DS 0.4, 0.6 and 0.8 with %GF 25, 35 and ≥ 40. These photographs show that CMC hydrogels form highly porous honeycomb-like structures at all levels of DS. The existence of the porosity confirms the three-dimensional structure of the hydrogel (Pourjavadi et al. 2011). The CMC hydrogels of DS 0.4 (Fig. 5a–c) show pores of irregular round shapes and sizes within a smooth overall superstructure. The CMC hydrogel with DS 0.6 %GF 25 (Fig. 5d and e) has a structure with large and small pores in the network. CMC hydrogel with DS 0.6 %GF 46 (Fig. 5f) shows more regular round pores with medium size and a few large pores and a more ordered arrangement formed with slightly more dense and compact superstructure. The CMC hydrogel of DS 0.8 (Fig. 5g–i) shows most regular pores, and the arrangement of the pores appears to be more ordered, much more dense and compact superstructure. From the SEM photograph taken, it is observed that the number of pores that appears in the network of CMC hydrogel is in the increasing order of DS 0.4, 0.6 and 0.8 and %GF 25, 35 and ≥ 40, respectively. From the SEM photographs of all the CMC hydrogels, it is observed that there is an increase in the order of arrangement of the pores, density and compactness of the structure in the increasing order of DS 0.4, 0.6 and 0.8 and %GF 25, 35 and ≥ 40, respectively. These could be attributed to a higher level of cross-linking in CMC hydrogels of higher DS and %GF (Sun and Chu 2006). These results also show that with increasing the degree of cross-linking density (%GF), the pore size decreased due to the decreasing distance between polymer chains. This porous structure is an advantage to micromolecules to diffuse into the interior of the hydrogel, and the size of the pores in the porous structure depends on the DS and %GF (Zhao and Mitomo 2009).

X-ray diffractometry studies on CMC hydrogels

X-ray diffraction analysis was carried out on the CMC samples to ascertain the changes in the crystalline structure upon cross-linking by electron beam irradiation. Figure 6 shows a representation of the x-ray diffractograms of CMC hydrogels of DS 0.4, 0.6 and 0.8, respectively. From this figure, it is observed that there is a diffraction peak observed in the range of 2θ = 19°–21° for all the CMC hydrogels. The CMC hydrogels with DS 0.4 have the highest intensity (counts) for all CMC hydrogels of %GF 25, 35 and ≥ 40 followed by the CMC hydrogels with DS 0.6 of %GF 25, 35 and 46 and then CMC hydrogels with DS 0.8 of %GF 25, 35 and 48, respectively. In the CMC hydrogels of DS 0.4, there are many hydroxyl groups available for H-bonding and therefore capable of forming a three-dimensional ordered structure, which results in higher crystalline phases relative to CMC hydrogels of DS 0.6 and 0.8. The electrostatic interactions between CMC polymers also will increase with the increase of DS which inhibits the formation of ordered structure. We can conclude that the higher the peak intensity, the higher is the chain orientation degree and hence the higher the crystallinity. This is consistent with the previously reported results in which it is summarized that the crystallinity of CMC decreases with the increase in the DS (Zia et al. 2009).

From these results, it is observed that the peak intensity decreases with the increase in the %GF for all the CMC hydrogels. The decreasing intensity of the crystalline peak with an increase in %GF may be due to increasing cross-linking which inhibits or prevents the close packing of the CMC macromolecular chains by reducing the degree of freedom in the 3D conformation and limiting the formation of the crystalline regions. This reduction of crystallinity would play a crucial role in influencing the CMC hydrogels biodegradability, water absorption and swelling, as it is exhibited by results in the following sections (Costa-Júnior et al. 2009). A study on developing novel polymer blends using chitosan and poly(vinyl alcohol) and chemically cross-linked by glutaraldehyde exhibited similar observations on x-ray diffractogram of the blend, whereby increasing the cross-linking in the blend decreased the intensity peak due to a reduction in crystallinity (Costa-Júnior et al. 2009).

Conclusion

We have prepared nine superabsorbent hydrogels based on sago pulp containing cellulose, lignin, and hemicellulose and have shown that they absorb large amounts of water and biodegrade completely over time. Nine different CMSP hydrogels were successfully prepared by EB irradiation by varying the irradiation dose (kGy) and % CMSP concentration. The nine CMSP hydrogels are CMSP HG DS 0.8 %GF 48, CMSP HG DS 0.8 %GF 35, CMSP HG DS 0.8 %GF 25, CMSP HG DS 0.6 %GF 46, CMSP HG DS 0.6 %GF 35, CMSP HG DS 0.6 %GF 25, CMSP HG DS 0.4 %GF 40, CMSP HG DS 0.4 %GF 35 and CMSP HG DS 0.4 %GF 25. All the CMSP hydrogels are susceptible to soil biodegradation with the rate of biodegradation, on average, 2.9 ± 0.4% per week. CMSP hydrogels of DS 0.4 completely degrade in 3 months and CMSP hydrogels of DS 0.6 and 0.8 in 5 months. The biodegradability of the CMSP hydrogel in the soil is an essential factor to use the CMSP hydrogels as a carrier for slow release fertilizer and it is an effective polymer for environmental conservation.

Slow release systems for agricultural fertilizers were designed by loading KNO3 and NH4NO3 physically into the CMSP hydrogels. The results show that the percentage of KNO3 and NH4NO3 loading (as a w/w %) on CMSP hydrogel enhances with increasing KNO3 and NH4NO3 concentration, respectively. The results from KNO3 and NH4NO3 released study shows that the diffusion rate of KNO3 and NH4NO3 is decreased with the increase of DS and %GF, and these CMSP hydrogels could be used as a slow release KNO3 and NH4NO3 in the agricultural sector. These CMSP hydrogels might be used in vegetable, fruit, and paddy planting areas. Since most of the loaded KNO3 is being released over 50 days, CMSP hydrogels could be used as short time slow release of KNO3 and NH4NO3 and obtain the benefits from the fertilizers treatment from the labor of a single application. The SEM micrographs reveal the highly porous honeycomb-like structure of the CMC hydrogels where the number of pores increases with the increase of DS and the size of the pores decreases with the increase of %GF. X-ray diffractograms of CMC hydrogels show that the crystallinity decreases with the increase of DS and %GF.

The results of the present work indicate that the cross-linked CMSP hydrogels are endowed with a slow release property, biodegradability and a soil moisture preservation property at the same time. The CMSP hydrogels are an example of a multifunctional water managing material which may find application in agricultural and in the renewal of arid and desert environments. These slow release CMSP hydrogels will be tested in the future for their effect on palm oil crops and other industrial plantations.

References

Amsden B (1998) Solute diffusion in hydrogels.: an examination of the retardation effect. Polym Gels Netw 6:13–43

Bajpai A, Giri A (2002) Swelling dynamics of a macromolecular hydrophilic network and evaluation of its potential for controlled release of agrochemicals. React Funct Polym 53:125–141

Bajpai A, Giri A (2003) Water sorption behaviour of highly swelling (carboxy methylcellulose-g-polyacrylamide) hydrogels and release of potassium nitrate as agrochemical. Carbohydr Polym 53:271–279

Carlos A, da Silva DB, Shepherd Andrew W, Jenane Chakib, Miranda-da-Cruz Sergio (2009) Agro-industries for development. CAB International and Food and Agriculture Organization of United Nations, Rome

Chadwick D, Wei J, Yan’an T, Guanghui Y, Qirong S, Qing C (2015) Improving manure nutrient management towards sustainable agricultural intensification in China. Agric Ecosyst Environ 209:34–46

Costa-Júnior ES, Barbosa-Stancioli EF, Mansur AA, Vasconcelos WL, Mansur HS (2009) Preparation and characterization of chitosan/poly (vinyl alcohol) chemically crosslinked blends for biomedical applications. Carbohydr Polym 76:472–481

Demitri C, Scalera F, Madaghiele M, Sannino A, Maffezzoli A (2013) Potential of cellulose-based superabsorbent hydrogels as water reservoir in agriculture. Int J Polym Sci 2013. doi:10.1155/2013/435073

El-Mohdy HA (2007) Water sorption behavior of CMC/PAM hydrogels prepared by γ-irradiation and release of potassium nitrate as agrochemical. React Funct Polym 67:1094–1102

Francis S, Kumar M, Varshney L (2004) Radiation synthesis of superabsorbent poly (acrylic acid)–carrageenan hydrogels. Radiat Phys Chem 69:481–486

Global Fertilizers and Agricultural Chemicals (2011) Datamonitor

Gupta S, Kumar M, Kumar J, Ahmad V, Pandey R, Chauhan N (2017) Systemic analysis of soil microbiome deciphers anthropogenic influence on soil ecology and ecosystem functioning. Int J Environ Sci Technol pp 1–10

Handbook IIHSCE (2015) Controlled and Slow Release Fertilizers. Colorado, United States

Huang J, Richard H, Zheng S (2014) Effects of nitrogen fertilization on soil labile carbon fractions of freshwater marsh soil in Northeast China. Int J Environ Sci Technol 11:2009–2014

Islami N, Taib S, Yusoff I, Ghani AA (2011) Time lapse chemical fertilizer monitoring in agriculture sandy soil. Int J Environ Sci Technol 8:765–780

Kim D-G, Hernandez-Ramirez G, Giltrap D (2013) Linear and nonlinear dependency of direct nitrous oxide emissions on fertilizer nitrogen input: a meta-analysis. Agric Ecosyst Environ 168:53–65

Klinger D, Landfester K (2012) Stimuli-responsive microgels for the loading and release of functional compounds: fundamental concepts and applications. Polymer 53:5209–5231

Li X, He J-Z, Hughes JM, Liu Y-R, Zheng Y-M (2014) Effects of super-absorbent polymers on a soil–wheat (Triticum aestivum L.) system in the field. Appl Soil Ecol 73:58–63

Liu G (2013) Brief introduction of slow/controlled release fertilizer industry of China and related standards. In: Third international conference on slow and controlled release and stabilized fertilizers, Rio de Janeiro, Brazil, 2013. International Fertilizer Industry Association (IFA)

Mahdy A, Elkhatib E, Balba A, Ahmed G (2017) Speciation and fractionation of phosphorus in biosolids-amended soils: effects of water treatment residual nanoparticles. Int J Environ Sci Technol 14(8):1729–1738

Marcì G, Mele G, Palmisano L, Pulito P, Sannino A (2006) Environmentally sustainable production of cellulose-based superabsorbent hydrogels. Green Chem 8:439–444

Nagasawa N, Yagi T, Kume T, Yoshii F (2004) Radiation crosslinking of carboxymethyl starch. Carbohydr Polym 58:109–113

Nie H, Liu M, Zhan F, Guo M (2004) Factors on the preparation of carboxymethylcellulose hydrogel and its degradation behavior in soil. Carbohydr Polym 58:185–189

Nomura H, Koda S, Hattori F (1990) Viscosity of aqueous solutions of polysaccharides and their carboxylate derivatives. J Appl Polym Sci 41:2959–2969

Pincus L, Margenot A, Six J, Scow K (2016) On-farm trial assessing combined organic and mineral fertilizer amendments on vegetable yields in central Uganda. Agric Ecosyst Environ 225:62–71

Pourjavadi A, Sadat Afjeh S, Seidi F, Salimi H (2011) Preparation of acrylated agarose-based hydrogels and investigation of their application as fertilizing systems. J Appl Polym Sci 122:2424–2432

Pushpamalar V (2010) Preparation and characterisation of carboxymethyl cellulose and carboxymethyl cellulose hydrogel from sago waste. Monash University Australia, Clayton

Pushpamalar V, Langford SJ, Ahmad M, Lim YY (2006) Optimization of reaction conditions for preparing carboxymethyl cellulose from sago waste. Carbohydr Polym 64:312–318

Pushpamalar V, Langford SJ, Ahmad M, Hashim K, Lim YY (2013a) Absorption characterization of Ca2+, Na+, and K+ on irradiation crosslinked carboxymethyl sago pulp hydrogel. J Appl Polym Sci 128:1828–1833

Pushpamalar V, Langford SJ, Ahmad M, Hashim K, Lim YY (2013b) Preparation of carboxymethyl sago pulp hydrogel from sago waste by electron beam irradiation and swelling behavior in water and various pH media. J Appl Polym Sci 128:451–459

Quirós R, Villalba G, Gabarrell X, Muñoz P (2015) Life cycle assessment of organic and mineral fertilizers in a crop sequence of cauliflower and tomato. Int J Environ Sci Technol 12:3299–3316

Rahman ZA (2004) Fertilizer use by crop in Malaysia. Food and Agriculture Organization of the United Nations, Rome

Saraydin D, Karadağ E, Güven O (1995) Adsorptions of some heavy metal ions in aqueous solutions by acrylamide/maleic acid hydrogels. Sep Sci Technol 30:3287–3298

Saraydin D, Karadağ E, Güven O (1996) Behaviors of acrylamide/maleic acid hydrogels in uptake of some cationic dyes from aqueous solutions. Sep Sci Technol 31:2359–2371

Shaviv A, Mikkelsen R (1993) Controlled-release fertilizers to increase efficiency of nutrient use and minimize environmental degradation-a review. Fertil Res 35:1–12

Smith L, Siciliano G (2015) A comprehensive review of constraints to improved management of fertilizers in China and mitigation of diffuse water pollution from agriculture. Agric Ecosyst Environ 209:15–25

Smith EA, Prues SL, Oehme FW (1997) Environmental degradation of polyacrylamides. Ecotoxicol Environ Saf 37:76–91

Snyder C, Bruulsema T, Jensen T, Fixen P (2009) Review of greenhouse gas emissions from crop production systems and fertilizer management effects. Agric Ecosyst Environ 133:247–266

Sun G, Chu C-C (2006) Synthesis, characterization of biodegradable dextran–allyl isocyanate–ethylamine/polyethylene glycol–diacrylate hydrogels and their in vitro release of albumin. Carbohydr Polym 65:273–287

van der Weerden T et al (2016) Nitrous oxide emissions from urea fertiliser and effluent with and without inhibitors applied to pasture. Agric Ecosyst Environ 219:58–70

Wach RA, Mitomo H, Yoshii F, Kume T (2001) Hydrogel of biodegradable cellulose derivatives. II. Effect of some factors on radiation-induced crosslinking of CMC. J Appl Polym Sci 81:3030–3037

Wang H, Wang Z, Zhu B (2007) Preparation and properties of new non-loading and superhigh ammonium nitrate loading hydrogels. React Funct Polym 67:225–232

Wei W, Yan Y, Cao J, Christie P, Zhang F, Fan M (2016) Effects of combined application of organic amendments and fertilizers on crop yield and soil organic matter: an integrated analysis of long-term experiments. Agric Ecosyst Environ 225:86–92

Zeinali M, Lenjannezhadian H (2017) Degradation of urea by entrapped cross-linked urease aggregates: a combinatorial approach to urease stabilization for environmental and industrial applications. Int J Environ Sci Technol. doi:10.1007/s13762-017-1337-8

Zhao L, Mitomo H (2009) Hydrogels of dihydroxypropyl chitosan crosslinked with irradiation at paste-like condition. Carbohydr Polym 76:314–319

Zia KM, Bhatti IA, Barikani M, Zuber M, Bhatti HN (2009) XRD studies of polyurethane elastomers based on chitin/1, 4-butane diol blends. Carbohydr Polym 76:183–187

Acknowledgements

Financial support from the School of Chemistry at Monash University, Clayton, Australia, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibiility: Tan Yigitcanlar.

Rights and permissions

About this article

Cite this article

Pushpamalar, J., Langford, S.J., Ahmad, M.B. et al. Eco-friendly smart hydrogels for soil conditioning and sustain release fertilizer. Int. J. Environ. Sci. Technol. 15, 2059–2074 (2018). https://doi.org/10.1007/s13762-017-1598-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-017-1598-2