Abstract

Bioregeneration is a process of restoring the adsorptive capacity of the spent adsorbents through microbial action. In this study, the effects of acclimated biomass concentration, biomass acclimation concentration, dosage of granular activated carbon (GAC) and type of GAC on the bioregeneration efficiency (BE) of GAC loaded with phenol and p-nitrophenol (PNP), respectively, were investigated. The quantification was conducted by monitoring the time courses of adsorbed substrate amount during bioregeneration under the sequential adsorption and biodegradation approach. The mean BEs of phenol- and PNP-loaded GAC were found to be 78 ± 2 and 77 ± 1%, respectively. The results revealed that increasing acclimated biomass concentration and adsorbent dosage did not have an observable effect on the BEs of phenol- and PNP-loaded GAC. Additionally, the BEs were found to be almost the same for the bioregeneration of phenol-loaded GAC using biomass acclimated to 350 and 600 mg/L of phenol, respectively. The BEs of phenol-loaded GAC 830 (thermal-activated) and GAC 1240+ (thermal- and acid-activated) did not show any observable difference, but the BE of PNP-loaded GAC 1240+ was found to be greater than that of PNP-loaded GAC 830 indicating that the improvement of BE of spent GAC through further chemical activation was dependent on the type of adsorbate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phenolic compounds are a common group of toxic environmental contaminants and are widely present in the effluents of many industrial processes such as oil production, coal conversion, paper production, coal gasification sites and others (Aleksieva et al. 2002; Dąbrowski et al. 2005; Lin and Juang 2009). The presence of phenolic compounds even at low concentrations has resulted in noxious effects on health and ecology (Guerra 2001). Therefore, the treatment of phenolic compound-containing wastewaters is absolutely essential before the wastewaters are allowed to be discharged to the environment.

Activated carbon (AC) is the most frequently adopted adsorbent in the adsorption process due to its outstanding adsorption capacities towards target pollutants (Pan et al. 2003; Dąbrowski et al. 2005). However, as the AC becomes saturated with pollutants, it loses its adsorption capacity and needs to be either disposed of or regenerated. The disposal option is not eco-friendly as it causes secondary environmental pollution and is a waste of resources. Thus, great attention has been paid to the regeneration of spent AC for its reuse. Biological regeneration or bioregeneration, which is defined as the restoration of the adsorptive capacity of the adsorbents through microbial action, has emerged as the most eco-friendly technology as it avoids the generation of hazardous secondary wastes and is less energy-intensive.

In the literature, two different theories have been proposed to explain the bioregeneration process of AC (Çeçen and Aktaş 2011). One of the theories proposed that the bioregeneration was achieved through the biodegradation of target compounds following desorption caused by the concentration gradient built between the AC surface and the bulk liquid. Therefore, bioregeneration is less likely to occur if there is an increase in the concentration of target compound in the bulk solution. Second theory proposed that bioregeneration is due to exoenzymatic reactions. According to this theory, the desorption of organic matter is caused by the reactions catalysed by the extracellular enzymes of microorganisms in the pores with diameter larger than 10 nm, which excludes the micropores (ϕ < 2 nm) and some of the mesopores (ϕ: 2–50 nm). Compounds, such as phenol, which are mainly adsorbed at the pores with a diameter under 0.7 nm, are inaccessible for exoenzymatic reactions. Therefore, the bioregeneration of AC loaded with phenols is more likely to occur due to concentration gradient.

In order to bioregenerate the spent AC, the adsorbate must be a readily biodegradable substrate. Thus, in the case of toxic organic contaminants such as melamine (An et al. 2017) and ciprofloxacin (Yi et al. 2017) which are persistent in the conventional biological wastewater treatment system, bioregeneration would be unachievable. Aktaş and Çeçen (2007) reported that bioregeneration of 2-chlorophenol-loaded AC occurred only via desorption due to an initial concentration gradient between the loaded AC and the bulk liquid and no further desorption was observed due to its low biodegradability. In this study, biomass used to bioregenerate granular activated carbon (GAC) loaded with phenolic compounds was pre-acclimated to the target compounds using sequencing batch reactor system. In addition, bioregeneration is controlled by the reversibility of adsorption and desorption serves as prerequisite step for bioregeneration. It was reported that the occurrence of oxidative polymerization of phenol under aerobic condition has led to the increase in the fraction of irreversible adsorbed phenol and thus the low bioregeneration efficiency (Ng et al. 2009, 2010).

The feasibility of bioregeneration process in prolonging the service life of adsorbents, in particular GAC, has been reported previously (Aktaş and Çeçen 2006, 2007, 2009; Oh et al. 2011; Toh et al. 2013; Kew et al. 2016; Leong et al. 2017). In these studies, the bioregeneration of GAC loaded with different type of phenolic compounds was carried out using suspended or immobilized biomass and was quantified at various operation conditions under the sequential adsorption and biodegradation (two-step) or simultaneous adsorption and biodegradation (one-step) approach. With regard to quantification, it should be noted that information on the time course of the amount of substrate adsorbed on the adsorbent is important as mere monitoring of the substrate concentration in solution would not be able to pinpoint the time of completion of bioregeneration. Determination of the amount of substrate adsorbed on the AC can be achieved by direct measurement through reloading of the bioregenerated activated carbon (Klimenko et al. 2004; Aktaş and Çeçen 2006, 2009, 2010; Oh et al. 2011, 2013; Al-Amrani et al. 2012) and solvent extraction (Ha et al. 2000; Leong et al. 2017). To date, studies to monitor the time courses of the amount of substrate adsorbed onto the adsorbent during bioregeneration and information on the effects of the factors on the bioregeneration efficiency (BE) of phenolic compound-loaded GAC under the two-step approach are still very lacking.

In the light of the above observations, the objectives of this research are to investigate the effects of (a) acclimated biomass concentration, (b) biomass acclimation concentration, (c) adsorbent dosage and (d) type of GAC on the bioregeneration of phenol- and PNP-loaded GAC, respectively, by direct measurement under the two-step approach which reflects the regeneration of spent GAC by biological treatment. Additionally, the effect of biomass acclimation concentration on bioregeneration under one-step approach was also investigated for comparison with that under two-step approach.

Materials and methods

Preparation of adsorbents

The adsorbents used in this study were the commercially available activated carbon Norit GAC 830 and 1240+ obtained from the Norit Company, the Netherlands. Norit GAC 830 is a steam-activated coal-based carbon, whereas Norit GAC 1240+ is an acid-washed GAC produced by steam activation of selected grades of coal. The detailed specifications of the GACs are shown in Table 1. The GACs were ground and sieved to the size of 0.42–0.84 mm (20–40 mesh). The sieved GACs were dried in an oven at 104 °C and stored in the desiccator until use.

Culturing of phenol- and PNP-acclimated biomass in sequencing batch reactors (SBRs)

The activated sludges were cultured in three-replicate 5-L SBRs, namely R1, R2 and R3 following the operation periods of FILL, REACT, SETTLE, DRAW and IDLE in the time ratio of 2:18:1:1:2 for a cycle time of 24 h. The base mix with the following composition (in mg/L): bacto-peptone (188), sucrose (563), FeCl3·6H2O (18.8), CaCl2 anhydrous (40), MgSO4 (49), NaHCO3 (354), (NH4)2SO4 (212), K2HPO4 (180) and KH2PO4 (32) was fed into the reactors until the steady state was attained in 2 months. For R1 and R2, bacto-peptone and sucrose were slowly replaced by phenol as the sole carbon source. For instance, when the biomass in R1 was fed with phenol in gradually increasing concentration from 50 to 600 mg/L, the concentrations of bacto-peptone and sucrose were reduced from 188 to 563 mg/L, respectively, to zero. The final acclimation phenol concentrations for R1 and R2 biomass were 600 and 350 mg/L, respectively. The acclimation period took about 9 months. For reactor R3, the biomass was gradually acclimated to 280 mg/L of PNP following similar procedure as described above and about 11 months were required for the acclimation period. A fixed volume of 333 mL mixed liquor was wasted from all reactors at the end of REACT period to yield a sludge age of about 15 days. After the attainment of the steady state as indicated by relatively constant mixed liquor suspended solids (MLSS) concentration and chemical oxygen demand (COD) removal from one cycle to the other, the phenol- and PNP-acclimated biomass was used in the subsequent experiments. For this purpose, acclimated biomass was withdrawn at the end of REACT period from the respective reactor to ensure negligible amount of carbonaceous substrates.

Bioregeneration studies under different operating conditions

Batch bioregeneration studies were conducted to determine the BEs of phenol- and PNP-loaded GAC under two-step approach. The effects of physico-chemical factors, namely type and dosage of GAC, and biological factors, namely biomass concentration and biomass acclimation concentration on the BEs, were investigated.

Preloading of the fresh GAC with phenol or PNP

The adsorbent GAC 830 of 0.0200 g in weight was shaken with 20.0 mL of 1000 mg/L phenol or 800 mg/L PNP solution (equivalent to 1.0 g/L in GAC dosage) at 250 rpm in 110-mL amber glass reaction vessel for the respective contact time of 36 and 12 h. After shaking, the loaded GAC was easily separated from the supernatant by decantation. The supernatant was then analysed to determine the residual concentration of phenol or PNP, and the amount of phenol or PNP adsorbed, \(q_{o}\), can be calculated using Eq. (1) in which \(q_{t} = q_{o}\).

where C o and C t are the substrate concentrations in the solution (mg/L) initially and at time t, respectively, V the volume of the solution (L), W the adsorbent amount in the solution (g), and q t the amount of substrate adsorbed (mg/g) at time t. The experiment was repeated using 1.5 and 2.0 g/L of GAC 830, respectively. The same procedure was adopted for 1.0–2.0 g/L of GAC 1240+, but the concentrations of both phenol and PNP were changed to 1000 mg/L and the contact times to 12 and 4 h, respectively.

Bioregeneration process

The phenol- and PNP-loaded GAC at various dosages was re-suspended in 20.0 mL solution containing nutrients of the same composition as described in “Culturing of phenol- and PNP-acclimated biomass in sequencing batch reactors (SBRs)” section and 50 mg/L biomass acclimated to 600 mg/L phenol and 280 mg/L PNP, respectively. The reaction vessel was shaken at 250 rpm using an orbital shaker at 25 ± 1 °C. The determination of the residual concentration of phenol or PNP during bioregeneration was carried out at suitable time intervals for a period of 120 h.

Determination of the time courses of the amounts of phenol and PNP adsorbed, respectively, during bioregeneration was carried out by reloading GACs using phenol and PNP solutions having the same concentrations as those used for the loading of fresh GAC. These concentrations were sufficiently high to saturate the active sites of GACs. For phenol-loaded GAC, the reloading solution was adjusted to pH 2 using 0.1 M HNO3 to deactivate the microbial activity based on preliminary study result. At each time interval, a reaction vessel was withdrawn and GAC was separated from the sample solution by decantation. The GAC was immediately re-suspended in 20.0 mL of reloading solution and shaken for the respective duration as mentioned in the preloading of the fresh GAC with phenol or PNP. The amount of phenol adsorbed onto the bioregenerated GAC, \(q_{\text{reload}}\), was calculated using Eq. (1) in which \(q_{t} = q_{\text{reload}}\). Concurrently, the reloading solution was shaken with fresh GAC to determine the saturated amount of phenol adsorbed onto GAC, \(q_{o}\). In the case of PNP-loaded GAC, acidification was not required due to the inhibition effect towards microbial activity at the respective PNP concentration. The BE could be calculated using Eq. (2) as follows:

The abiotic desorption percentage of phenol or PNP was determined by repeating the regeneration experiment without biomass. The time courses of the amount of phenol or PNP desorbed from loaded GAC were monitored until desorption equilibrium was attained. The desorption percentage, %, was calculated using the following equation:

where \(C_{\text{des}}\) is the maximum phenol or PNP desorbed (mg/L) from phenol- or PNP-loaded GAC in the bulk solution, \(q_{e}\) the amount of phenol or PNP adsorbed on the GAC at equilibrium (mg/g), \(W\) the weight of the adsorbent (g), and \(V\) the working volume of the nutrients solution (L) in the desorption study.

The effect of biomass concentration on the BEs of phenol- and PNP-loaded GAC, respectively, was investigated by conducting the bioregeneration studies using 25–100 mg/L phenol-acclimated biomass and 50–200 mg/L PNP-acclimated biomass.

The studies on the effect of biomass acclimation concentration were carried out for phenol-loaded GAC 830 under both two-step and one-step approaches. In the former case, the experiment was conducted following the procedure as described above. In the latter case, GAC of dosages 1.0, 1.5 and 2.0 g/L was, respectively, mixed with 20.0 mL solution containing 600 mg/L of phenol, 50 mg/L of two types of phenol-acclimated biomass, one acclimated to 350 and the other 600 mg/L of phenol, and nutrients. The contents were shaken at 250 rpm at 25 ± 1 °C. The amount adsorbed and the residual phenol concentration were monitored at various time intervals. The bioregenerated GAC was then separated and reloaded with 1000 mg/L phenol at pH 2. The BE for the biomass acclimation concentrations of 350 and 600 mg/L, respectively, was calculated using Eq. (2).

Analytical methods

Phenol concentration

The phenol concentration was determined in the UV spectrum region using the peak area of 240–290 nm with λ max of 270 nm. The desired amount of sample was pipetted into a 25-mL volumetric flask and topped up with distilled water. The sample was measured using a UV–Vis double beam spectrophotometer (Shimadzu UV-2600) with 1 cm quartz cell. The phenol concentration was then calculated from the calibration curve.

p-Nitrophenol (PNP) concentration

The PNP concentration was analysed spectrophotometrically according to the procedure described in Xing et al. (1999) with some modifications. The sample was stabilized and preserved by adjusting the pH to higher than 9.5 with 1 M NaOH (AR grade, System). Then, the sample was diluted to the mark in a 25-mL volumetric flask with distilled water. Visible absorbance measurement was carried out at the wavelength of 400 nm using a UV–Vis double beam spectrophotometer with 1 cm quartz cell. The concentration of PNP was determined from the calibration curve.

Results and discussion

Effects of biological factors on bioregeneration of phenol- and PNP-loaded GAC

Acclimated biomass concentration

The time courses of residual phenol and PNP concentrations during the bioregeneration of phenol- and PNP-loaded GAC 830 using different biomass concentrations at GAC dosages of 1.0, 1.5 and 2.0 g/L are shown in Figs. 1a, c, e and 2a, c, e, respectively. It was observed from both figures that the durations of complete phenol and PNP removal decreased with the increase in acclimated biomass concentration for all the GAC dosages studied. For instance, the removal of desorbed phenol from 1.5 g/L of phenol-loaded GAC using 25 mg/L of acclimated biomass concentration required a duration of 30 h, whereas only 8 h was needed when 100 mg/L of biomass was used (see Fig. 1c). In all cases, no obvious lag phase was observed indicating that the biodegradation proceeded without much inhibition since the biomass was acclimated to much higher concentrations of phenol and PNP, respectively, than the residual concentrations during bioregeneration.

Figures 1b, d, f and 2b, d, f, respectively, show the time courses of the amounts of phenol and PNP adsorbed during the bioregeneration of the respective GAC using different acclimated biomass concentrations at GAC dosages of 1.0, 1.5 and 2.0 g/L. In contrast to the time course of the amount adsorbed under abiotic (absence of biomass) condition, there was a distinct decrease in the amount adsorbed under biotic condition. This underscores the important role of the biomass in degrading the phenolic compound in the bulk solution, thereby inducing further desorption resulting in the regeneration of GAC. For each GAC dosage, it was observed that the amount of phenol or PNP adsorbed at the completion of bioregeneration (indicated by a near constant value of the amount adsorbed) was almost the same irrespective of the biomass concentration employed. Comparing the time courses of the residual substrate concentration and the amount of substrate adsorbed, it was evident that the completion of bioregeneration could not be ascertained based on the completion of the removal of phenolic compound as the degradation intermediates require further time to be removed.

Based on the final amounts of phenol and PNP adsorbed in the biotic experiments determined from the fairly constant region of the time course curves, the BE of phenol- and PNP-loaded GAC 830 is calculated using Eq. (2) and shown in Table 2. In the absence of biomass, the regeneration efficiencies of phenol- and PNP-loaded GAC were found to be in the ranges of 21–27 and 22–30%, respectively. In comparison, the BEs were 76–81 and 74–79%, respectively. The results in Table 2 indicate that increasing acclimated biomass concentration did not seem to have any observable effect on the BEs of phenol- and PNP-loaded GACs. This result was found to be in agreement with the results reported by Oh et al. (2013) that a change in the initial acclimated biomass concentration did not have an observed effect on the BE of 4-chlorophenol-loaded GAC, provided that there was no inhibition effect due to the substrate. As shown in Figs. 1 and 2, there was no observed lag phases in the time courses of residual phenol and PNP concentrations indicating no inhibition since the concentrations of desorbed phenol and PNP in the bulk solutions were much lower compared to the respective biomass acclimation concentration. Similar result on the effect of biomass concentration was reported by Al-Amrani et al. (2013) in the bioregeneration of mono-amine modified silica loaded with azo dye under the two-step approach. In this study, the mean BEs of phenol- and PNP-loaded GAC 830 were found to be 78 ± 2 and 77 ± 1%, respectively. These values were almost the same, indicating that the irreversibility of adsorption due to oxidative polymerization did not play an important part. In the case of phenol under the two-step approach, the build-up of the concentration gradient caused by the relatively low phenol concentration in the bulk solution reduced the contact time between phenol and GAC and thus the absence of oxidative polymerization. For PNP, it was documented that nitro group reduced the probability of PNP oxidation (Vidic et al. 1993). Similar result was observed by Ng et al. (2009).

Biomass acclimation concentration

Two-step approach

The bioregeneration of phenol-loaded GAC 830 was investigated using biomass acclimated to 350 and 600 mg/L of phenol, respectively, at GAC dosages of 1.0–2.0 g/L. The time courses of residual phenol concentration in the bulk solution during bioregeneration at these GAC dosages are shown in Fig. 3a, c and e. It was observed that the duration of complete phenol removal was prolonged using biomass acclimated to higher phenol concentration of 600 mg/L compared to the cases using biomass acclimated to lower phenol concentration of 350 mg/L at all GAC dosages. The duration of complete phenol removal was seen to increase from 1 to 4 h, 4 to 18 h and 8 to 18 h at 1.0, 1.5 and 2.0 g/L of GAC, respectively. These results could be explained by the degradation pathway of phenol at different concentrations. Lim et al. (2013) suggested that simultaneous activation of the enzymes, namely catechol-1.2-dioxygenase and catechol-2,3-dioxygenase, which promote ortho- and meta-cleavage pathways, respectively, was induced in the biodegradation of phenol at higher concentration (>630 mg/L). In contrast, at lower phenol concentration (<630 mg/L), phenol degradation was shown to follow meta-cleavage pathway only. In this study, a peak at λ max of 375 nm which is related to 2-hydroxymuconic semialdehyde (2-HMSA), an indicator for phenol degradation via the meta-cleavage pathway, was detected spectrophotometrically during the REACT period of the SBR for the culturing of biomass acclimated to 350 mg/L of phenol (data not shown). However, 2-HMSA was barely detected in the SBR for the culturing of biomass acclimated to 600 mg/L of phenol. Thus, it could be deduced that most of the phenol was degraded via the ortho-cleavage pathway in the latter case. During bioregeneration, the phenol concentration in bulk solution was much lower than 350 mg/L, implying that biomass acclimated to 350 mg/L of phenol would biodegrade phenol more easily. In contrast, biodegradation of phenol during bioregeneration by biomass acclimated to 600 mg/L of phenol required the activation of enzyme for meta- instead of that for ortho-cleavage pathway resulting in an increase in the duration for complete removal of phenol.

Figure 3b, d and f shows the time courses of amount of phenol adsorbed during the bioregeneration of phenol-loaded GAC 830 using biomass acclimated to 350 and 600 mg/L of phenol, respectively, at GAC dosages of 1.0, 1.5 and 2.0 g/L. It was observed that, for each GAC dosage, there was no pronounced difference in the amount of phenol adsorbed on completion of bioregeneration using both types of biomass, indicating that biomass acclimation concentration had no observable effect on the regeneration of spent activated carbon. Table 3 shows that the calculated BEs of phenol-loaded GAC 830 using biomass acclimated to 350 and 600 mg/L of phenol, respectively, at each GAC dosage were almost the same. In the bioregeneration of mono-amine modified silica loaded with azo dye under the two-step approach, Al-Amrani et al. (2013) reported similar results in which BEs were found to be relatively unchanged under different biomass acclimation concentrations.

One-step approach

The time courses of residual phenol concentration in the bulk solution at GAC dosages of 1.0, 1.5 and 2.0 g/L for the initial phenol concentration of 600 mg/L using biomass acclimated to 350 and 600 mg/L of phenol, respectively, are shown in Fig. 4a, c and e. The time courses of the abiotic run were also included for comparison. For the pattern of the time courses of phenol concentration in the bulk solution, a lag phase was observed for both biotic cases in which the biomass was acclimated to 350 and 600 mg/L of phenol, respectively, though the lag phase for biomass acclimated to 350 mg/L was longer. In contrast to what was observed under the two-step approach, the duration of complete phenol removal was shorter using biomass acclimated to 600 mg/L than 350 mg/L for all GAC dosages studied due to higher residual phenol concentration in the bulk solution.

Time courses of residual phenol concentration in the bulk solution and amount of phenol adsorbed during the one-step bioregeneration of phenol-loaded GAC 830 using biomass acclimated to 350 and 600 mg/L of phenol at GAC dosages of a, b 1.0, c, d 1.5 and e, f 2.0 g/L for initial phenol concentration of 600 mg/L

Figure 4b, d and f shows the time courses of the amount of phenol adsorbed onto GAC for the initial phenol concentration of 600 mg/L under abiotic and biotic conditions at GAC dosages of 1.0, 1.5 and 2.0 g/L. In biotic studies, a lag phase was observed for the time courses of the amount of phenol adsorbed for the time period commensurate with what was observed for the time courses of residual phenol concentration. Table 3 shows that the calculated BEs of phenol-loaded GAC 830 using biomass acclimated to 350 and 600 mg/L of phenol, respectively, were almost the same. Comparison of the BEs under the two approaches in Table 3 showed that the values were almost the same irrespective of the biomass acclimation concentration.

Effects of physico-chemical factors on bioregeneration of phenol- and PNP-loaded GAC

GAC dosage

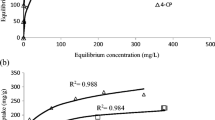

Previous studies on the effect of GAC dosage on bioregeneration efficiency were conducted under both saturated and unsaturated adsorbent conditions (Ng et al. 2009; Toh et al. 2013) which were defined based on the maximum adsorption capacity, q m , determined from the Langmuir isotherm. In this study, the BEs of phenol- and PNP-loaded GAC at various GAC dosages were all quantified under saturated adsorbent condition. For instance, the loading of GAC at the dosage of 2.0 g/L using phenol loading concentration of 1000 mg/L would lead to a saturated condition for GAC with adsorption capacity of 179 mg/g as q m was determined to be 189 mg/g. Table 2 shows that an increase in GAC dosage resulted in a decrease in desorption percentages of phenol and PNP in the abiotic studies with the values being the highest at the GAC dosage of 1.0 g/L followed by 1.5 and 2.0 g/L. According to Karanfil and Dastgheib (2004), the adsorption energy onto micropores is greater than those onto meso- and macropores. Thus, the desorption of phenols from mesopores, macropores and external surfaces was more favourable than from micropores, resulting in a higher percentage of desorption. Higher dosages of GAC therefore provide more micropores which favour strong adsorption of phenol and PNP leading to lower desorption efficiency.

In comparison, it is observed from Table 2 that variation in GAC dosage had little observed effect on the BEs of phenol- and PNP-loaded GAC using the same concentration of acclimated biomass. This indicates that biologically induced desorption is the dominating factor in bioregeneration.

Type of GAC

The effect of the type of GAC on BE was investigated using thermally-activated GAC 830 and acid-washed thermally-activated GAC 1240+ using 50 mg/L of acclimated biomass concentration. The time courses of residual phenol concentration in the bulk solution during the bioregeneration of phenol-loaded GAC 830 and GAC 1240+ at 1.0–2.0 g/L GAC dosages are shown in Fig. 5a, c and e. In all cases, the residual phenol concentration for phenol-loaded GAC 830 was found to be lower than that for phenol-loaded GAC 1240+. This was attributed to lower phenol uptake onto GAC 830 compared to that for GAC 1240+ (q m were found to be 189 and 203 mg/g for GAC 830 and GAC 1240+, respectively), leading to relative lower amount of phenol desorbed from GAC 830 during bioregeneration.

Figure 5b, d and f shows the time courses of the amount of phenol adsorbed at the GAC dosages of 1.0–2.0 g/L during bioregeneration. Based on the final amounts of phenol adsorbed determined from the time course plots, the BEs of GAC 830 and GAC 1240+ loaded with phenol were calculated using Eq. (2) and the results are shown in Table 4. It was observed that there was no significant difference (t test; p < 0.05) between the BEs of phenol-loaded GAC 830 and GAC 1240+.

Figure 6 shows the time courses of residual PNP concentration in the bulk solution and the amount of PNP adsorbed, respectively, during the bioregeneration of PNP-loaded GAC 830 and GAC 1240+. Similar to the observation for residual phenol concentration, the residual PNP concentration for GAC 1240+ was higher than that for GAC 830. This was due to higher PNP uptake for GAC 1240+ during loading process (q m were determined to be 316 and 246 mg/g for GAC 1240+ and GAC 830, respectively), resulting in greater amount of PNP desorbed thus higher residual PNP concentration in the bulk solution during bioregeneration. However, the duration for the complete removal of PNP in the bulk solution seemed comparable for both types of GAC.

Based on the final amounts of PNP adsorbed on GAC 830 and GAC 1240+, the BEs of both types of GAC are calculated and shown in Table 4. Unlike the case of phenol-loaded GAC, the BE of PNP-loaded GAC 1240+ was found to be significantly (t test; p < 0.05) greater than that of PNP-loaded GAC 830. This observation could be explained by the fraction of pore volume filled, F p, which is calculated using the following equation (Gusler et al. 1993; Haghseresht and Lu 1998):

where \(F_{p}\) is the fraction of the pore that is filled at equilibrium, \(V_{1}\) is the volume of adsorbate solution (mL), \(V_{\text{p}}\) is the specific pore volume of the adsorbent (cm3/g), Co and Ce are the initial and equilibrium concentrations (mg/L), respectively, W is the weight of GAC (g), and \(\rho\) is the density of the solute (g/cm3). The results in Table 4 show that for the cases of PNP, the values of F p were found to be greater for GAC 1240+ compared to those of GAC 830 at all dosages. This is equivalent to the higher amount of total adsorbed PNP onto GAC 1240+ in comparison with GAC 830. Since the percentage of micropore volume for both GACs was found to be comparable (Table 1), it can be deduced that the increase in the values of the fraction of pore volume filled by PNP in GAC 1240+ was due to more PNP being adsorbed in mesopores and macropores with larger pore width. Therefore, desorption of PNP from mesopores and macropores which were lower in adsorption energy was more favourable resulting in higher BE of PNP-loaded GAC 1240+. In contrast, Table 4 shows that the values of the fraction of pore volume filled by phenol for both GACs were generally comparable except at the dosage of 2.0 g/L. This could be explained by the fact that the molecular diameter of phenol (0.746 nm) was smaller than that of PNP (0.813 nm) (Daifullah and Girgis 1998), thus rendering phenol less restricted in micropore diffusion during adsorption and less affected by the increase in pore volume in GAC 1240+.

Conclusion

Investigation on the effects of biological and physico-chemical factors on the BEs of phenol- and PNP-loaded GAC showed that increasing acclimated biomass concentration and adsorbent dosage did not have an observable effect on the BEs of phenol- and PNP-loaded GAC which were found to be 78 ± 2 and 77 ± 1%, respectively. It was also observed that there was no significant difference (t test; p < 0.05) between the BEs of phenol-loaded GAC 830 and GAC 1240+. Unlike the case of phenol, the BE of PNP-loaded GAC 1240+ was found to be significantly (t test; p < 0.05) greater than that of PNP-loaded GAC 830. There was no observable difference in the BEs of phenol-loaded GAC using biomass acclimated to 350 and 600 mg/L of phenol, respectively.

References

Aktaş Ö, Çeçen F (2006) Effect of activation type on bioregeneration of various activated carbons loaded with phenol. J Chem Technol Biotechnol 81:1081–1092

Aktaş Ö, Çeçen F (2007) Adsorption, desorption and bioregeneration in the treatment of 2-chlorophenol with activated carbon. J Hazard Mater 141:769–777

Aktaş Ö, Çeçen F (2009) Cometabolic bioregeneration of activated carbons loaded with 2-chlorophenol. Bioresour Technol 100:4604–4610

Aktaş Ö, Çeçen F (2010) Adsorption and cometabolic bioregeneration in activated carbon treatment of 2-nitrophenol. J Hazard Mater 177:956–961

Al-Amrani WA, Lim P-E, Seng C-E, Wan Ngah WS (2012) Bioregeneration of mono-amine modified silica and granular activated carbon loaded with Acid Orange 7 in batch system. Bioresour Technol 118:633–637

Al-Amrani WA, Lim P-E, Seng C-E, Wan Ngah WS (2013) Effects of co-substrate and biomass acclimation concentration on the bioregeneration of azo dye-loaded mono-amine modified silica. Bioresour Technol 143:584–591

Aleksieva Z, Ivanova D, Godjevargova T, Atanasov B (2002) Degradation of some phenol derivatives by Trichosporon cutaneum R57. Process Biochem 37:1215–1219

An H, Li X, Yang Q, Wang D, Xie T, Zhao J, Xu Q, Chen F, Zhong Y, Yuan Y, Zeng G (2017) The behavior of melamine in biological wastewater treatment. J Hazard Mater 322:445–453

Çeçen F, Aktaş Ö, (2011) Activated carbon for water and wastewater treatment: Integration of adsorption and biological treatment, p 388. ISBN: 978-3-527-32471-2, Wiley-VCH

Dąbrowski A, Podkościelny P, Hubick Z, Barczak M (2005) Adsorption of phenolic compounds by activated carbon—a critical review. Chemosphere 58:1049–1070

Daifullah AAM, Girgis BS (1998) Removal of some substituted phenols by activated carbon obtained from agricultural waste. Water Res 32:1169–1177

Guerra R (2001) Ecotoxicological and chemical evaluation of phenolic compounds in industrial effluents. Chemosphere 44:1737–1747

Gusler GM, Browne TE, Cohen Y (1993) Sorption of organics from aqueous solution onto polymeric resins. Ind Eng Chem Res 32:2727–2735

Ha SR, Vinitnantharat S, Ozaki H (2000) Bioregeneration by mixed organisms of granular activated carbon with a mixture of phenols. Biotechnol Lett 22:1093–1096

Haghseresht F, Lu GQ (1998) Adsorption characteristics of phenolic compounds onto coal-reject-derived adsorbents. Energy Fuels 12:1100–1107

Karanfil T, Dastgheib SA (2004) Trichloroethylene adsorption by fibrous and granular activated carbons: aqueous phase, gas phase, and water vapor adsorption studies. Environ Sci Technol 38:5834–5841

Kew S-L, Adnan R, Lim P-E, Seng C-E (2016) Bioregeneration of cresol-loaded granular activated carbon using immobilized biomass: effects of operational factors and chemical structure of cresol isomers. J Taiwan Inst Chem Eng 63:386–395

Klimenko N, Smolin S, Grechanyk S, Kofanov V, Nevynna L, Samoylenko L (2004) Bioregeneration of activated carbons by bacterial degraders after adsorption of surfactants from aqueous solutions. Colloid Surf A 230:141–158

Leong K-Y, Adnan R, Lim P-E, Ng S-L, Seng C-E (2017) Effect of operational factors on bioregeneration of binary phenol and 4-chlorophenol-loaded granular activated carbon using PVA-immobilized biomass cryogels. Environ Sci Pollut Res 24:20959–20971

Lim J-W, Seng C-E, Lim P-E, Ng S-L, Tan K-C, Kew S-L (2013) Response of low-strength phenol-acclimated activated sludge to shock loading of high phenol concentrations. Water SA 39:695–700

Lin S, Juang R (2009) Adsorption of phenol and its derivatives from water using synthetic resin and low-cost natural adsorbents: a review. J Environ Manag 90:1336–1349

Ng SL, Seng CE, Lim PE (2009) Quantification of bioregeneration of activated carbon and activated rice husk loaded with phenolic compounds. Chemosphere 75:1392–1400

Ng SL, Seng CE, Lim PE (2010) Bioregeneration of activated carbon and activated rice husk loaded with phenolic compounds: kinetic modeling. Chemosphere 78:510–516

Oh W-D, Lim P-E, Seng C-E, Sujari ANA (2011) Bioregeneration of granular activated carbon in simultaneous adsorption and biodegradation of chlorophenols. Bioresour Technol 102:9497–9502

Oh W-D, Lim P-E, Seng C-E, Mohamed N, Adnan R, Leong K-Y, Voon S-Y (2013) Effect of initial biomass concentration on bioregeneration of 4-chlorophenol-loaded granular activated carbon: kinetic and efficiency studies. J Chem Technol Biotechnol 88:1157–1163

Pan BC, Xiong Y, Su Q, Li AM, Chen JL, Zhang QX (2003) Role of amination of a polymeric adsorbent on phenol adsorption from aqueous solution. Chemosphere 51:953–962

Toh R-H, Lim P-E, Seng C-E, Adnan R (2013) Immobilized acclimated biomass-powdered activated carbon for the bioregeneration of granular activated carbon loaded with phenol and o-cresol. Bioresour Technol 143:265–274

Vidic RD, Suidan MT, Brenner RC (1993) Oxidative coupling of phenols on activated carbon: impact on adsorption equilibrium. Environ Sci Technol 27:2079–2085

Xing XH, Inoue T, Tanji Y, Unno H (1999) Enhanced microbial adaptation to p-nitrophenol using activated sludge retained in porous carrier particles and simultaneous removal of nitrite released from degradation of p-nitrophenol. J Biosci Bioeng 87:372–377

Yi K, Wang D, Yang Q, Li X, Chen H, Sun J, An H, Wang L, Deng Y, Liu J, Zeng G (2017) Effect of ciprofloxacin on biological nitrogen and phosphorus removal from wastewater. Sci Total Environ 605–606:368–375

Acknowledgements

Financial support from Universiti Sains Malaysia [Grant Number 304/PKIMIA/6313275] is gratefully acknowledged. One of the authors, Chan Poh Ying, would like to acknowledge the financial support of MyBrain 15 (MyPhD) programme.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Binbin Huang.

Rights and permissions

About this article

Cite this article

Chan, PY., Lim, PE., Ng, SL. et al. Bioregeneration of granular activated carbon loaded with phenolic compounds: effects of biological and physico-chemical factors. Int. J. Environ. Sci. Technol. 15, 1699–1712 (2018). https://doi.org/10.1007/s13762-017-1527-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-017-1527-4