Abstract

A novel halo-alkali and thermo-tolerant chitinase was obtained from an isolated strain found in the Caspian Sea. The effects of media composition and various fermentation conditions for the optimization of chitinase production were studied one factor at a time and by response surface methodology. The novel strain, which is designated as strain DC14 and phylogenetically related to the genus Pseudoalteromonas, produced chitinase after 72 h under the following optimal conditions: glucose 1 % (w/v), ammonium sulphate 0.2 % (w/v), chitin 1.07 % (w/v), pH 8, NaCl 10 % (w/v), inoculums size 2.5 % (v/v), temperature 30 °C, CaCl2 3 mM and MgCl2 4 mM. Using the statistical optimization method, chitinase production was found to increase from 2.30 to 21.90 U/dl. The enzyme showed maximum activity at 40 °C, pH 9 and 10 % NaCl. It was stable in a wide range of temperature from 15 to 65 °C, pH from pH 7 to 11 and NaCl concentration from 0 to 15 % (w/v). The molecular weight of the enzyme was estimated by SDS-PAGE to be about 65 kDa. With regard to the halo-alkali and thermo-stable properties of this enzyme, it has potential industrial activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chitin, a poly-β(1,4) linear-linked N-acetylglucosamine (GlcNAc), is the second most abundant biopolymer on earth after cellulose (Khoushab and Yamabhai 2010). Chitin polymers are mostly present in the exoskeleton components of arthropods and in the cell walls of fungi (Herring 1979; Souza et al. 2011). Chitinases (E.C. 3.2.1.14) are a group of enzymes capable of hydrolysing insoluble chitin to its oligo (chitosan and chitobiose) and monomeric (N-acetylglucosamine) components (Bhattacharya et al. 2007). Chitinases occur in a wide range of organisms including viruses, bacteria, fungi, insects, higher plants and animals for offensive, defensive, morphogenetic or nutritional purposes (Park et al. 1997; Dahiya et al. 2006).

Although chitin can be obtained as a cheap renewable biopolymer, especially from marine sources, the chitinase hydrolytic products are an expensive and valuable natural material for a wide variety of biotechnological and industrial applications (Dahiya et al. 2006; Chen et al. 2010). Moreover, chitinases have attracted interest as biocontrol agents due to their ability to degrade chitin in the fungal cell wall and insect exoskeleton (Tsujibo et al. 2003; Mostafa et al. 2009). It has been estimated that the annual production of chitin in aquatic systems is roughly equal to 1010–1011 metric tons (Beier and Bertilsson 2013). In spite of the continuous production of chitin in the marine ecosystems, there is a low level of chitin accumulation in these environments (Alldredge and Gotschalk 1990). Chitinolytic bacteria, which are very abundant and widely distributed in marine environments, are responsible for rapid degradation of chitin in aqueous systems (Keyhani and Roseman 1996). Accordingly, there are numerous reports about the isolation of bacterial chitinase from marine environments (Tsujibo et al. 1998; Itoi et al. 2007; Stefanidi and Vorgias 2008). Because most industrial processes are carried out in harsh physicochemical conditions, which may not be definitively adjusted to the optimal conditions required for the activity of the available enzymes, it would be of great value to have enzymes that demonstrate optimal activities in wide ranges of salinity, temperature and pH values.

In this paper, we describe the characteristics of a halo-alkali and thermo-tolerant chitinase obtained from Pseudoalteromonas sp. DC14 isolated in the Caspian Sea and its production optimization.

Materials and methods

Microorganism isolation and identification

Sampling was carried out at 30 m depth in a southern region of the Caspian Sea (36.46°N 51.02°E). A solid media was applied for the isolation procedure, which contained (g/l): (NH4)2SO4, 0.86; MgSO4·7H2O, 0.75; FeSO4·7H2O, 0.009; CaCl2·2H2O, 0.22; MgCl2·6H2O, 0.17; KCl, 0.13; NaCl, 9.1; peptone, 10; yeast extract, 5; glucose, 2; and agar, 15. The pH of the medium was adjusted to 8.2 with 2 M NaOH. Inoculated plates were incubated at 20 °C for 2 months. After successive cultivation, a pure isolate was obtained. The bacterial isolate was maintained on the slant above-mentioned solid media at 4 °C and broth media supplemented with 30 % (v/v) glycerol at −80 °C for short and long preservation, respectively. The genomic DNA of the strain was extracted by DNA extraction kit (Thermo Scientific, Lithuania) according to the manufacturer’s recommended procedure, and the 16S rRNA gene was amplified using the bacterial universal primers 27F and 1492R (Lane et al. 1985). The sequencing was conducted on an ABI 3730XL DNA sequencer at Macrogen (Seoul, South Korea). Phylogenetic analysis was performed using the software package MEGA version 6 (Tamura et al. 2013).

Preparation of colloidal chitin and primary screening

Colloidal chitin was prepared from purified chitin (Merck) by the modified method of Roberts and Selitrennikoff (1988). Briefly, 5 g of chitin powder was slowly added to 90 ml of concentrated HCl under vigorous stirring for 2 h. The mixture was added to 500 ml of ice-cold 95 % ethanol under vigorous stirring for 30 min and kept overnight at 25 °C. The precipitation was collected by centrifugation and washed with 0.1 M sodium phosphate buffer (pH 7) until the pH of the colloidal chitin became neutral. Qualitative chitinase assay was performed by spot inoculation of the bacterial strain on the solid isolation media containing 1.5 % (w/v) colloidal chitin. The chitinase activity was indicated by the clear zone around colonies after incubation for 2 weeks at 20 °C.

Measurement of chitinase production

Chitinase production was assayed with colloidal chitin as a substrate. The culture medium contained (g/l): (NH4)2SO4, 0.86; MgSO4·7H2O, 0.75; FeSO4·7H2O, 0.009; CaCl2·2H2O, 0.22; MgCl2·6H2O, 0.17; KCl, 0.13; NaCl, 9.1; yeast extract, 2; and colloidal chitin, 1.5 % (v/v). The pH was 8.2. The fermentation process was conducted in a 50-ml Erlenmeyer flask at 20 °C and 150 rpm for 72 h. The cultures were centrifuged at 10,000×g for 15 min at 4 °C, and the supernatant (crude enzyme solution) was used for chitinase assay. Enzyme solution (0.3 ml) was added to 0.3 ml of substrate solution, which contained a 0.5 % suspension of colloidal chitin in 100 mM sodium phosphate buffer (pH 8.0). The mixture was incubated at 30 °C for 45 min. After centrifugation, the amount of reducing sugar produced in the supernatant was determined by Schales’ method (Imoto and Yagishita 1971) and the dinitrosalicylic acid (DNS) method (Reissig et al. 1955) with N-acetylglucosamine as a reference compound. One unit of chitinase activity was defined as the amount of enzyme that produced 1 µmol of reducing sugars per minute.

Experimental design for enzyme optimization

To understand the effects of various conditions on the amount of chitinase production and identify the most important factors, a conventional ‘one-factor-at-a-time’ approach was applied. For this method, in each experiment we vary only one factor, while keeping others fixed. Various concentrations of NaCl (0–15 % w/v); different carbon sources (1 % w/v): glucose, fructose, maltose, saccharose and starch; different nitrogen sources (0.2 % w/v): peptone, yeast extract, casein, urea and ammonium sulphate; chitin substrate (0–5 % w/v); various concentrations of pH (6.0–10.0), inoculum size (0.5–4.5 % v/v), temperature (15–35 °C); and metal ions (0–4 mM) of calcium, magnesium, zinc, manganese and copper were chosen as the critical variables. To evaluate the combinatorial effects of variables and optimum condition for the chitinase production, Box–Behnken response surface methodology (RSM) was applied. Optimization studies were carried out by studying the effect of four major variables including NaCl, chitin, pH and temperature at three levels. The behaviour of the system is explained by the following empirical second-order polynomial model:

where Y is the predicted enzyme activity; x i , x j , …, x k are the input variables, which affect the response Y; \(x_{i}^{2} , \, x_{j}^{2} , \ldots , \, x_{k}^{2}\) are the square effects; x i x j , x i x k and x j x k are the interaction effects; β 0 is the intercept term; β i (i = 1, 2, …, k) is the linear effect; β ii (i = 1, 2, …, k) is the squared effect and β ij (i = 1, 2, …, k; j = 1, 2, …, k) is the interaction effect. Coded levels for independent variables are presented in Table 1.

Characterization of partially purified chitinase

Optimized culture supernatants (crude enzyme) were spun in a centrifuge at 12,000×g for 20 min (4 °C) and then collected for ammonium sulphate precipitation (70 %, w/v). The precipitates were formed, kept overnight and collected by centrifugation at 12,000×g for 20 min (4 °C). They were then dissolved in a small amount of 50 mM Tris buffer (pH 8.0) and dialysed against the same buffer. Concentration of protein was estimated based on Bradford’s method using bovine serum albumin (BSA) as standard protein.

Effects of salinity on enzyme activity and stability

The optimum NaCl concentration for chitinase activity was determined by incubation of the partially purified enzymes with the substrates at the saline buffer that ranged from 0 to 20 % NaCl, under standard assay conditions. Salt stability was measured by pre-incubation of the enzymes without substrates in sodium phosphate buffer (50 mM, pH 8.0) supplemented with 0–20 % NaCl at 4 °C temperature for 30 min. Then, the remaining activity was measured under standard conditions.

Effects of temperature on enzyme activity and stability

The optimum temperature for chitinase activity was examined by incubation of the partially purified enzymes with the substrates at temperatures that ranged from 20 to 60 °C under standard assay conditions. Thermal stability was determined by pre-incubation of the enzymes without substrates in sodium phosphate buffer (pH 8.0) for 30 min at temperatures from 20 to 60 °C. The remaining activity was measured under standard conditions.

Effects of pH on enzyme activity and stability

The optimum pH of chitinase was investigated by the varied pH of the reaction buffers, ranging from 6.0 to 10.0; 50 mM of each buffer was used: acetate (pH 4.0–6.0), potassium phosphate (pH 7.0–8.0) and glycine–NaOH (pH 9.0–10.0). The enzymes were pre-incubated at various pH buffers that used the above systems at 4 °C for 30 min without substrates and then subjected to enzyme assays under standard conditions to determine the pH stability. All experiments were repeated at least three times.

SDS-polyacrylamide gel electrophoresis

SDS-PAGE analysis of proteins is carried out using 12.5 % (w/v) polyacrylamide gel at 120 V for 90 min. Solutions for preparing 12.5 % (w/v) resolving gel included H2O (6.4 ml), 30 % acrylamide mix (8.3 ml), 1.5 M Tris (pH 8.8, 5 ml), 10 % (w/v) SDS (0.2 ml), 10 % (w/v) ammonium persulphate (0.1 ml) and N,N,N,N′-tetramethylethylenediamine (0.008 ml) (Laemmli 1970).

Results and discussion

Marine environments encompass about 70 % of the earth’s surface, with countless marine microorganisms containing biochemical secrets which might provide new insights into and understanding of enzymes (Das et al. 2006). Marine bacteria have been attracting more attention as a resource for new bioactive compounds recently, as the soil-derived compounds have yielded high numbers of the previously described metabolites (Toledo et al. 2006; Bhatnagar and Kim 2010; Trincone 2011). The present study was conducted to optimize a marine bacterium chitinase production and examine its properties.

Taxonomic characteristics of chitinase-producing strain

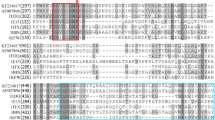

Strain DC14 was isolated from 30 m depth in the southern region of the Caspian Sea. The isolated strain was a gram-stain-negative, catalase- and oxidase-positive, non-motile rod-shaped bacterium. The clear zone was observed around the colonies on the chitin-containing solid media, which qualitatively indicated its chitinolytic activity (Fig. 1). The 16S rRNA gene sequence analysis revealed that strain DC14 is a member of the genus Pseudoalteromonas. The closest relatives of strain DC14 were Pseudoalteromonas lipolytica LMEB39T, Pseudoalteromonas donghaensis HJ51T and Pseudoalteromonas shioyasakiensis SE3T, with a 16S rRNA gene sequence similarity of 99.1, 98.4 and 97.4 %, respectively. Phylogenetic analysis using the neighbour-joining algorithm supports the view that the novel strain is a member of this genus (Fig. 2). Several bacterial strains from various genera of both soil and marine ecosystems were reported to contain chitinolytic activity. Bacterial strains from Aeromonas (Sashiwa et al. 2002), Alteromonas (Tsujibo et al. 1993; Orikoshi et al. 2005), Arthrobacter (Lonhienne et al. 2001; Wang et al. 2009), Bacillus (Alam et al. 1995; Sampson and Gooday 1998; Yuli et al. 2004), Entrobacter (Chernin et al. 1995), Flavobacterium (Campbell and Williams 1951), Microbulbifer (Howard et al. 2003), Micrococcus (Campbell and Williams 1951), Moritella (Stefanidi and Vorgias 2008), Nocardia (Bansode and Bajekal 2006), Pseudomonas (Wang and Chang 1997), Salinivibrio (Aunpad and Panbangred 2003), Serratia (Horn et al. 2006), Streptomyces (Tsujibo et al. 1993; Tsujibo et al. 2000; Tsujibo et al. 2003), Vibrio (Fukasawa et al. 1992; Osama and Koga 1995) and Virgibacillus (Essghaier 2012) were noted for their chitinolytic activity. Recently, Wang and co-workers reported the isolation of chitinase-producing Pseudoalteromonas. That enzyme showed its maximum activity at pH 8 and 20 °C (Wang et al. 2014).

Neighbour-joining phylogenetic tree based on 16S rRNA gene sequences showing the relationship of strain DC14T with other members of the genus Pseudoalteromonas. Accession numbers of the sequences are given in parentheses. The sequences of the Halopenitus malekzadehii CC65T (KC018183) was used as an outgroup. Bootstrap values (%) are based on 1000 replicates. Bar 0.05 substitutions per nucleotide position

Optimization of chitinase production by the one-factor-at-a-time approach

In order to identify the most relevant factors to chitinase production with Pseudoalteromonas sp. DC14, the one-factor-at-a-time method was conducted as described above. The effects of various factors/levels are presented in Table 2. It showed that the key parameters were NaCl (10 % w/v), glucose (1 % w/v), (NH4)2SO4 (0.2 % w/v), chitin (0.5 % v/v), pH 7, inoculums size (2.5 % v/v), temperature 30 °C, CaCl2 3 mM, MgCl2 3 mM. This resulted in the production of 8.50 U/dl chitinase after 72 h. Minimum amounts of ZnCl2, MnCl2 and CuCl2 completely inhibited the enzyme production. The experimental results clearly showed that the NaCl concentration, nitrogen source, inoculums’ size and temperature are the most effective parameters in chitinase production, with 27, 27, 52 and 62 % variations between their levels, respectively. This optimization enhanced the enzyme production more than 3.1 times. However, the OFAT approach has the limitation of ignoring the importance of the interaction of various physiological parameters. The statistical approach using response surface methodology for process optimization serves this purpose by finding out the optimal condition in any given system by a set of independent variables over a specific region of interest through establishing the relationship between more than one variable. It has proven to be a powerful tool in optimizing the fermentation condition (Box and Behnken 1960; Han et al. 2008).

Response surface methodology optimization

The four significant variables selected based on the results of OFAT design (NaCl, chitin, pH and temperature) were optimized using Box–Behnken response surface methodology. Experimental design and the actual yields of chitinase (response) obtained in the experiments are given in Table 3. The highest chitinase activity of 20.0 U/dl was obtained at the following condition after 72 h (run 4): NaCl 6.5 (% w/v), chitin (0.75 % w/v), pH 8 and temperature 20 °C. Based on the analysis of the results, the predicted optimized culture condition was at NaCl (10 % w/v), chitin (1.07 % w/v), pH 8 and temperature 20 °C. It was predicted to produce chitinase at 23.0 U/dl. The model was validated for the four variables within the optimized condition. The experiment resulted in 22.1 U/dl chitinase production, which was 2.6 times better than that observed with the one-at-a-time method. The ANOVA results of RSM optimization are given in Table 4. The P value serves as a tool for checking the significance of each of the coefficients and is indicative of the interaction strength of each independent variable. Four interaction coefficients, including AC (NaCl/pH), AD (NaCl/Temperature), BD (chitin/temperature) and CD (pH/temperature), are significant, as evidenced by low P and high F values. The response surfaces from the interactions are illustrated in Fig. 3. R 2 value for this model is 0.9795, which indicates that the variability in the observed response can be explained by the experimental parameters and their interactions. The fermentation process at the optimal conditions predicted by this approach resulted in an 8.2 times enhancement of the preliminary enzyme production. In this study, the chitinase production reached 22.1 U/dl in a 50-ml shake flask after incubating for 72 h (end of exponential growth phase) in the optimum fermentation medium (Fig. 4). The results for the reported chitinase production varied between 0.1 and more than 60 U/ml (Bhushan 2000; Vaidya et al. 2001; Singh et al. 2009; Souza et al. 2009). These variations were observed because of the strains and the level of enzyme purification. Our chitinase production is relatively low, and the application of recombinant DNA technology will be helpful to increase its production.

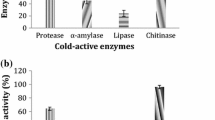

Effects of NaCl, pH and temperature on enzyme stability and activity

The effects of salinity, pH and temperature on the stability and activity of the chitinase from the marine-isolated strain Pseudoalteromonas sp. DC14 are shown in Fig. 5. The optimum NaCl concentration was 10 % (w/v), while the enzyme was stable in a wide range of salt concentration from 0 to 15 % (w/v). The maximum pH activity of the obtained chitinase was at pH 9, and it could be considered an alkali-stable enzyme which was stable at an alkaline pH between pH 8 and 11. The enzyme maintained more than 60 % of its activity in a broad range of temperature from 20 to 60 °C and showed its highest activity at 40 °C. In spite of the relatively low-level production, the enzyme showed very interesting properties. It was stable in a wide range of salinity, from 0 to 15 % (w/v), pH from pH 7 to 11 and temperature from 15 to 65 °C. There are some reports about halo (Essghaier et al. 2012), alkali (Sorokin et al. 2012) and thermo-tolerant (Bhushan 2000; Christodoulou et al. 2001; Dai et al. 2011) chitinase, but the poly-extremophilic features of the novel enzyme made it a good candidate for industrial applications. The halo-tolerant nature of the enzyme is important because most industrial waste has a high level of salinity. Furthermore, halo-tolerant chitinase may be applied as biocontrol agent to control disease in salt-tolerant plants (Essghaier et al. 2012). Chitinase with alkaline pH stability has major potential in insect biological control, as their chitinous gut environments have an alkaline pH condition (Bansode and Bajekal 2006). Alkaline chitinase also has benefits in the management of alkaline chitinous waste from some industries, like the food industry (Nawani and Kapadnis 2003). The isolated strain could produce chitinase at temperatures between 20 and 30 °C. The low producing temperature reduces the energy consumption in industry, and also the novel isolate may be applicable in field conditions against fungi and insect plant pathogens.

Molecular weight of chitinase

By the use of ammonium sulphate precipitation (70 % saturation), protein fraction was separated from theoretically optimized culture medium. Based on our process, specific activity in the culture medium was increased from 2.19 to 5.57 U/ml in precipitation stage. Our results also showed 2.54-fold purification (Table 5). The SDS-PAGE analysis of the purified enzyme revealed one protein band with an estimated molecular weight of 65 kDa (Fig. 6).

Conclusion

We elucidated the isolation of chitinolytic bacteria from the Caspian Sea for the first time. The results of phylogenetic analysis based on the 16S rRNA gene sequence analysis and phenotypic characterization showed that the novel isolate belongs to the genus Pseudoalteromonas. The overall results show that this bacterium has great potential capability to produce N-acetylglucosamine in a wide range of reaction conditions. The GlcNAc and its analogues could be used to produce biofuel and also valuable pharmacological compounds for the treatment of a wide variety of ailments. The novel strain could furthermore be applied as a biocontrol agent against fungi and insect plant pathogens.

References

Alam MM, Nikaidou N, Tanaka H, Watanabe T (1995) Cloning and sequencing of chic gene of Bacillus circulans WL-12 and relationship of its product to some other chitinases and chitinase like proteins. J Ferment Bioeng 80:454–461

Alldredge AL, Gotschalk CC (1990) The relative contribution of marine snow of different origins to biological processes in coastal waters. Cont Shelf Res 10:41–58

Aunpad R, Panbangred W (2003) Cloning and characterization of the constitutively expressed chitinase C gene from a marine bacterium, Salinivibrio costicola strain 5SM-1. J Biosci Bioeng 96:529–536

Bansode VB, Bajekal SS (2006) Characterization of chitinases from microorganisms isolated from Lonar lake. Indian J Biotechnol 5:357–363

Beier S, Bertilsson S (2013) Bacterial chitin degradation—mechanisms and ecophysiological strategies. Front Microbiol 4:1–12

Bhatnagar I, Kim SK (2010) Immense essence of excellence: marine microbial bioactive compounds. Mar Drugs 8(10):2673–2701

Bhattacharya D, Nagpure A, Gupta RK (2007) Bacterial chitinases: properties and potential. Crit Rev Biotechnol 27:21–28

Bhushan B (2000) Production and characterization of a thermostable chitinase from a new alkalophilic Bacillus sp. BG-11. J Appl Microbiol 88:800–808

Box GEP, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

Campbell LL, Williams OB (1951) A study of chitin-decomposing micro-organisms of marine origin. J Gen Microbiol 5:894–905

Chen JK, Shen CR, Liu CL (2010) N-Acetylglucosamine: production and applications. Mar Drugs 8:2493–2516

Chernin L, Ismailov Z, Haran S, Chet I (1995) Chitinolytic Enterobacter agglomerans antagonistic to fungal plant pathogens. Appl Environ Microbiol 61:1720–1726

Christodoulou E, Duffner F, Vorgias CE (2001) Overexpression, purification, and characterization of a thermostable chitinase (Chi40) from Streptomyces thermoviolaceus OPC-520. Protein Expr Purif 23:97–105

Dahiya N, Tewari R, Hoondal GS (2006) Biotechnological aspects of chitinolytic enzymes: a review. Appl Microbiol Biotechnol 71:773–782

Dai DH, Hu WL, Huang GR, Li W (2011) Purification and characterization of a novel extracellular chitinase from thermophilic Bacillus sp. HU1. Afr J Biotechnol 10:2476–2485

Das S, Lyla PS, Khan SA (2006) Marine microbial diversity and ecology: importance and future perspectives. Curr Sci 90:1325–1335

Essghaier B, Hedi A, Bejji M, Jijakli H, Boudabous A, Sadfi-Zouaoui N (2012) Characterization of a novel chitinase from a moderately halophilic bacterium, Virgibacillus marismortui strain M3-23. Ann Microbiol 62:835–841

Fukasawa S, Arai M, Wada T, Shima H, Kurata M (1992) Some properties of a chitinase from a marine luminous bacterium, Vibrio fischeri strain COT-A136. Chem Pharm Bull 40:1631–1633

Han Y, Li Z, Miao X, Zhang F (2008) Statistical optimization of medium components to improve the chitinase activity of Streptomyces sp. Da11 associated with the South China Sea sponge Craniella australiensis. Process Biochem 43:1088–1093

Herring PJ (1979) Marine ecology and natural products. Pure Appl Chem 51:1901–1911

Horn SJ, Sørbotten A, Synstad B, Sikorski P, Sørlie M, Varum KM, Eijsink VG (2006) Endo/exo mechanism and processivity of family 18 chitinases produced by Serratia marcescens. FEBS J 273:491–503

Howard M, Ekborg N, Taylor L, Weiner R, Hutcheson S (2003) Genomic analysis and initial characterization of the chitinolytic system of Microbulbifer degradans strain 2-40. J Bacteriol 185:3352–3360

Imoto T, Yagishita K (1971) A simple activity measurement of lysozyme. Agric Biol Chem 35:1154–1156

Itoi S, Kanomata Y, Koyama Y, Kadokura K, Uchida S, Nishio T, Oku T, Sugita H (2007) Identification of a novel endochitinase from a marine bacterium Vibrio proteolyticus strain No. 442. Biochim Biophys Acta 1774:1099–1107

Keyhani NO, Roseman S (1996) The chitin catabolic cascade in the marine bacterium Vibrio furnissii. Molecular cloning, isolation, and characterization of a periplasmic chitodextrinase. J Biol Chem 271:33414–33424

Khoushab F, Yamabhai M (2010) Chitin research revisited. Mar Drugs 8:1988–2012

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 277:680–685

Lane DJ, Pace B, Olsen GJ, Stahl D, Sogin M, Pace NR (1985) Rapid determination of 16S ribosomal RNA sequences for phylogenetic analyses. Proc Natl Acad Sci 82:6955–6959

Lonhienne T, Mavromatis K, Vorgias CE, Buchon L, Gerday C, Bouriotis V (2001) Cloning, sequences, and characterization of two chitinase genes from the Antarctic Arthrobacter sp. strain TAD20: isolation and partial characterization of the enzymes. J Bacteriol 183:1773–1779

Mostafa SA, Mahmoud MS, Mohamed ZK, Enan MR (2009) Cloning and molecular characterization of chitinase from Bacillus licheniformis MS-3. J Gen Appl Microbiol 55:241–246

Nawani NN, Kapadnis BP (2003) Chitin degrading potential of bacteria from extreme and moderate environment. Indian J Exp Biol 41:248–254

Orikoshi H, Nakayama S, Miyamoto K, Hanato C, Yasuda M, Inamori Y, Tsujibo H (2005) Roles of four chitinases (ChiA, ChiB, ChiC, and ChiD) in the chitin degradation system of marine bacterium Alteromonas sp. strain O-7. Appl Environ Microb 71:1811–1815

Osama R, Koga T (1995) An investigation of aquatic bacteria capable of utilizing chitin as the sole source of nutrients. Lett Appl Microbiol 21:288–291

Park JK, Morita K, Fukumoto I, Yamasaki Y, Nakagawa T, Kawamukai M, Matsuda H (1997) Purification and characterization of the Chitinase (ChiA) from Enterobacter sp. G-1. Biosci Biotechnol Biochem 61:684–689

Reissig JL, Strominger JL, Leloir LF (1955) A modified colorimetric method for the estimation of N-acetylamino sugars. J Biol Chem 217:959–966

Roberts WK, Selitrennikoff CP (1988) Plant and bacterial chitinases differ in antifungal activity. J Gen Microbiol 134:169–176

Sampson MN, Gooday GW (1998) Involvement of chitinases of Bacillus thuringiensis during pathogenesis in insects. Microbiol 144:2189–2194

Sashiwa H, Fujishima S, Yamano N, Kawasaki N, Nakayama A, Muraki E, Hiraga K, Oda K, Aiba S (2002) Purification of N-acetyl D-glucosamine from alpha-chitin by crude enzymes from Aeromonas hydrophila H-2330. Carbohydr Res 337:761–763

Singh AK, Mehta G, Chhatpar HS (2009) Optimization of medium constituents for improved chitinase production by Paenibacillus sp. D1 using statistical approach. Lett Appl Microbiol 49:708–714

Sorokin DY, Tourova TP, Sukhacheva MV, Mardanov AV, Ravin NV (2012) Bacterial chitin utilisation at extremely haloalkaline conditions. Extremophiles 16:883–894

Souza CP, Burbano-Rosero EM, Almeida BC, Martins GG, Albertini LS, Rivera IN (2009) Culture medium for isolating chitinolytic bacteria from seawater and plankton. World J Microbiol Biotechnol 25:2079–2082

Souza CP, Almeida BC, Colwell RR, Rivera IN (2011) The importance of chitin in the marine environment. Mar Biotechnol 13:823–830

Stefanidi E, Vorgias CE (2008) Molecular analysis of the gene encoding a new chitinase from the marine psychrophilic bacterium Moritella marina and biochemical characterization of the recombinant enzyme. Extremophiles 12:541–552

Tamura K, Stecher G, Peterson D, Filipski A, Kumar S (2013) MEGA6: molecular evolutionary genetics analysis version 6.0. Mol Biol Evol 30:2725–2729

Toledo G, Green W, Gonzalez RA, Christoffersen L, Podar M, Chang HW, Hemscheidt T, Trapido-Rosenthal HG, Short JM, Bidigare RR, Mathur EJ (2006) High throughput cultivation for isolation of novel marine microorganisms. Oceanography 19:120–125

Trincone A (2011) Marine biocatalysts: enzymatic features and applications. Mar Drugs 9:478–499

Tsujibo H, Minoura K, Miyamoto K, Endo H, Moriwaki M, Inamori Y (1993a) Purification and properties of a thermostable chitinase from Streptomyces thermoviolaceus OPC-520. Appl Environ Microbiol 59:620–622

Tsujibo H, Orikoshi H, Tanno H, Fujimoto K, Miyamoto K, Imada C, Okami Y, Inamori Y (1993b) Cloning, sequence, and expression of a chitinase gene from a marine bacterium Alteromonas sp. Strain O-7. J Bacteriol 175:176–181

Tsujibo H, Orikoshi H, Shiotani D, Hayashi M, Umeda J, Miyamoto K, Imada C, Okami Y, Inamori Y (1998) Characterization of chitinase C from a marine bacterium, Altermonas sp. strain O-7, and its corresponding gene and domain structure. Appl Environ Microbiol 64:472–478

Tsujibo H, Hatano N, Endo H, Miyamoto K, Inamori Y (2000) Purification and characterization of a thermostable chitinase from Streptomyces thermoviolaceus OPC-520 and cloning of the encoding gene. Biosci Biotechnol Biochem 64:96–102

Tsujibo H, Kubota T, Yamamoto M, Miyamoto K, Inamori Y (2003) Characterization of chitinase genes from an alkaliphilic actinomycete, Nocardiopsis prasina OPC-131. Appl Environ Microbiol 69:894–900

Vaidya RJ, Shah IM, Vyas PR, Chhatpar HS (2001) Production of chitinase and its optimization from a novel isolate Alcaligenes xylosoxydans: potential in antifungal biocontrol. World J Microbiol Biotechnol 17:691–696

Wang SL, Chang WT (1997) Purification and characterization of two bifunctional chitinases/lysozymes extracellularly produced by Pseudomonas aeruginosa K-187 in shrimp and crab shell powder medium. Appl Environ Microbiol 63:380–386

Wang F, Gai Y, Chen M, Xiao X (2009) Arthrobacter psychrochitiniphilus sp. nov., a psychrotrophic bacterium isolated from Antarctica. Int J Syst Evol Microbiol 59:2759–2762

Wang X, Zhao Y, Tan H, Chi N, Zhang Q, Du Y, Yin H (2014) Characterisation of a chitinase from Pseudoalteromonas sp. DL-6, a marine psychrophilic bacterium. Int J Biol Macromol 70:455–462

Yuli PE, Suhartono MT, Rukayadi Y, Hwang JK, Pyun YR (2004) Characteristics of thermostable chitinase enzymes from the Indonesian Bacillus sp. 13.26. Enzyme Microb Technol 35:147–153

Acknowledgments

This work was supported by a grant from Ferdowsi University of Mashhad (27244/3).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Makhdoumi, A., Dehghani-Joybari, Z., Mashreghi, M. et al. A novel halo-alkali-tolerant and thermo-tolerant chitinase from Pseudoalteromonas sp. DC14 isolated from the Caspian Sea. Int. J. Environ. Sci. Technol. 12, 3895–3904 (2015). https://doi.org/10.1007/s13762-015-0848-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-015-0848-4