Abstract

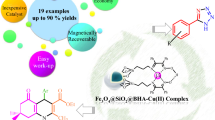

An effectual encapsulation–functionalization procedure for preparing high-activity magnetic Fe3O4@SiO2@Tannic Acid-Cu (Fe3O4@SiO2@TA-Cu) nanocomposite was described. Tannic acid-Cu complexes were uniformly protected on the surface of Fe3O4@SiO2 nanoparticles. The newly prepared catalyst was characterized by XRD, FT-IR, SEM, and EDX. The obtained nanocomposites showed excellent catalytic performance and good stability for the one-pot synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines via three-component condensations of aldehydes, malononitrile, and thiophenols in water. The catalyst was separated by a magnet and reused at least five times without remarkable degradation in the performance. The desired products were prepared in high yields by an easy workup procedure with this protocol.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Substituted pyridines are significant heterocyclic compounds, which have gained much attention in medicinal chemistry due to their extensive biological and pharmaceutical activities [1, 2]. Among them, the pyridine derivatives of 2-amino-3,5-dicarbonitrile-6-thio-pyridines were reported to display many pharmaceutical properties and are effective as anti-hepatitis B virus [3], antibacterial [4], anti-prion [5], anticancer agents [6], and as potassium channel openers for treatment of urinary incontinence [7]. In addition, with some of these heterocycles, the new drugs for Parkinson’s disease, hypoxia, asthma, epilepsy, and kidney [8] disease have developed. Several methods have been reported for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines. Recently, scientists have mainly applied the multi-component reactions (MCRs) as one of the most essential existing methods to synthesize 2-amino-3,5-dicarbonitrile-6-thio-pyridines via the cyclo-condensation of aldehyde, malononitrile, and thiol under various conditions.

Multicomponent reactions (MCRs) are effective in the synthesis of organic heterocyclics. Recently, the three MCRs have been interested since they provide high sustainability and eco-friendly conditions [9,10,11]. MCRs also have many advantages, such as simple purification, easy synthesis of compounds in one-pot, green conditions, high yields of products with heterogeneous catalysts, and the ease of workup [12,13,14,15,16,17,18,19,20].

Otherwise, the magnetic nanoparticles (MNPs), because of their essential properties such as practical reusability, simple preparation, high surface area, ease of functionalization, easy catalyst separation, and high loading capacity, has been extensively used as the heterogeneous catalysts for MCRs [21,22,23,24]. The combination of magnetic heterogeneous catalysts and MCRs is a new and helpful strategy for the synthesis of heterocycle systems [25].

The MCRs of aldehyde, malononitrile, and thiol for the synthesis of 2-amino-3, 5-dicarbonitrile- 6-thio-pyridines have been carried out under using various bases such as Et3N, DABCO, N,N-DIPEA, piperidine, 2,4,6-collidine, DMAP, N,N dimethylaniline, N,N-diethylaniline [26], WEB [27], DBU [28], silica-bonded N propyldiethylenetriamine [29], macrocyclic Schiff base ligand [25], KOH [30], K2CO3 [31], Na2SiO3 [32], TBAB/Cs2CO3 [33], MgO [34], ZrOCl2/NaNH2 [35], TBAF [36], KF/Al2O3 [37], molecular sieves 4 Å [38], CaO NPs [39], CH3COONa [40], 2-HEAA [41], [bmIm]OH [42], [bmim][Br] [43] and using a variety of Lewis acids such as ZnCl2, AlCl3, FeCl3, I2, Cu (OTf)3, InCl3, BF3.Et2O [44], Sc(OTf)3 [45], y-Fe2O3-2-HEAS [46], silica NPs [47], CuI NPs [48], boric acid [49], phosphotungstic acid/CTAB [50], Zn(II), and Cd(II) MOFs [51].

However, some of these reported methods contain some faults such as using toxic catalysts or solvents, difficult reaction conditions, the performance of the side reactions, and low yield of desired product despite the longer reaction time. So, it is significant to develop an improved method for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines.

Following the above-mentioned significance, and the values of substituted pyridines as unique medicinal compounds, herein, we wish to report a novel, efficient, and green strategy for the synthesis of these classes of compounds. For this purpose, a new tannic acid-Cu modification process onto the surface of Fe3O4@SiO2 nanospheres was developed for the catalytic application. Tannic acid-Cu coordination complexes were coated onto the surface of Fe3O4@SiO2 nanospheres.

Immobilizing metal nanoparticles on magnetic substrates can improve their dispersity and magnetically separating the catalyst, thereby facilitating the recycling and reuse of it. But, to improve the comprehensive performance and the stability of magnetic substrates, magnetic substrates have been encapsulated through inorganic or organic layers or functionalized with active functional groups. A suitable substrate for this purpose is Tannic acid (TA) [52,53,54]. Tannic acid (TA) is a green and polyphenolic compound widely available in nature. The active phenolic hydroxyl groups dedicate TA with metal ion chelating ability [55, 56]. In this work, we fabricated the Fe3O4@SiO2@TA-Cu nanoparticles as a new, facile, non-explosive, economic, green, and environmentally friendly catalyst with uniformly dispersed and easily recoverable NPs. The newly prepared catalyst was characterized by XRD, FT-IR, SEM, and EDX. The synthesized Fe3O4@SiO2@TA-Cu nanoparticles were successfully used as a magnetically recyclable heterogeneous catalyst for the one-pot synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines via three-component condensations of benzaldehydes, malononitrile, and thiophenols in water.

Experimental

Materials and instrumentation

All reagents were bought from Merck Company and used without further purification. Fourier-transform infrared spectra (FT-IR) were recorded on an Avatar 370 FT-IR Thermal Nicolet spectrometer. XRD patterns were recorded by an X-ray diffractometer, model X'Pert Pro. Holland (Panalytical). Morphology of the nanocatalyst was observed by a Mira 3-XMU FE-SEM. The reaction products were purified by column chromatography. The purity determining of the product was checked by TLC on silica gel Polygram STL G/UV 254 plates. The melting point is determined with an Electro-Thermal Type 9200 melting point apparatus. The 1H NMR (400 MHz) and 13C NMR (100 MHz) spectra were recorded on a Bruker Avance DRX-400 Fourier transformer spectrometer (Peoria, IL). Chemical shift values were brought in ppm at room temperature using CDCl3 or DMSO-d6 as a solvent and reported in ppm downfield from TMS. The mass spectra were gained on a Varian Mat CH-7 instrument at 70 eV in electron impact (EI) mode.

Preparation of the silica-coated Fe3O4 magnetic nanoparticles (Fe3O4@SiO2)

Fe3O4@Silica was prepared according to the reported procedure [57]. The mixture of the Fe3O4 nanoparticles (0.045 g) with distilled water (15 mL) and ethanol (100 mL) was dispersed under ultra-sonification for 30 min. Ammonium hydroxide 25% solution (2 mL) was added to the suspension under continuous stirring. After that, the tetraethylorthosilicate (TEOS, 0.1 mL) was added drop wise into the suspension. The stirring was continued at room temperature for 24 h to silica was formed on the surface of Fe3O4 nanoparticles by the hydrolysis and condensation of TEOS. The silica-coated Fe3O4 nanoparticles were separated from the mixture using an external magnet and washed with deionized water three times. It was then dried under vacuum at 80 °C overnight.

A typical procedure for the synthesis of Tannic Acid-Cu-modified Fe3O4@SiO2 nanoparticles (Fe3O4@SiO2@TA-Cu nanoparticles)

A solution of tannic acid (10 mL, 0.1 M) in EtOH was added to a suspension of the.

obtained Fe3O4@SiO2 NPs in EtOH (0.2 gr) with a vigorous stirring. After 10 min, the copper acetate solution (10 mL, 0.1 M) in EtOH was added dropwise into the suspension of nanoparticles. The stirring was continued at room temperature for 4 h. After completion of the reaction, the nanoparticles were washed with deionized water several times and once with absolute ethanol. Then were separated from the mixture by an external magnet and finally dried in the oven at 60 °C for 6 h.

General procedure for the synthesis of 2-amino-3,5-dicarbonitrile-6- thio-pyridines in the presence of Fe3O4@SiO2@TA-Cu nanoparticles

A mixture of benzaldehyde (1 mmol), malononitrile (2 mmol), thiophenol derivative (1 mmol) and H2O (5 mL) in the presence of the Fe3O4@SiO2@TA-Cu NPs (0.05 gr) was stirred at room temperature. After the completion of the reaction (The progress of the reaction was monitored by TLC, hexane/ethyl acetate), the magnetic catalyst was separated from the mixture using an external magnet and reused. The reaction mixture was filtered and the obtained solid washed with cold H2O (2 × 10 mL). The collected product was poured by recrystallization in EtOH. The isolated compounds were characterized by their melting points, FT-IR, 1H NMR, 13C NMR, and mass spectrometry (MS).

Spectral data for known 2-amino-3,5-dicarbonitrile-6-thio-pyridines 2-Amino-4-phenyl-6-(phenylthio)pyridine-3,5-dicarbonitrile (4a)

White solid; mp 218–220 °C; FT-IR (KBr, disk) ν: 3479, 3351, 3215, 3064, 2220, 1623, 1522, 1441,1263,1033 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.84 (br, 2H, NH2), 7.62–7.59 (m, 7H, Ar), 7.53–7.50 (m, 3H, Ar); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 166.64, 160.10, 159.14, 135.23, 134.50, 131.01, 130.18, 129.90, 129.15, 128.93, 127.65, 115.80, 115.52, 93.88, 88.00. MS, m/z (%): 328 [M+].

2-Amino-6-(phenylthio)-4-(p-tolyl)pyridine-3,5-dicarbonitrile (4b)

Yellow solid, mp 213–215 °C; IR (KBr, disk) ν: 3473, 3325, 2213, 1622, 1542, 1258, 1020, 759 cm−1. 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.81 (br, 2H, NH2), 7.64–7.60 (m, 2H, Ar), 7.52–7.49 (m, 3H, Ar), 7.45 (d, J = 7.6 Hz, 2H, Ar), 7.40 (d, J = 8.0 Hz, 2H, Ar), 2.40 (s, 3H, CH3); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 166.01, 160.13, 159.22, 141.0, 135.57, 131.40, 130.24, 129.86, 129.60, 128.91, 127.62, 116.10, 115.65, 93.83, 87.40, 21.55; MS, m/z (%): 342 [M+].

2-Amino-4-(4-chlorophenyl)-6-(phenylthio)pyridine-3,5-dicarbonitrile (4c)

Yellow solid, mp 220–222 °C; IR (KBr, disk) ν: 3465, 3340, 2214, 1625, 1580, 1546, 1295, 780, 741, 690 cm−1. 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.88 (br, 2H, NH2), 7.66 (d, J = 8.4 Hz, 2H, Ar), 7.59 (d, J = 8.4 Hz, 4H, Ar), 7.54–7.51 (m, 3H, Ar); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 166.71, 159.90, 158.0, 135.84, 135.32, 133.21, 130.90, 130.33, 130.01, 129.40, 127.50, 115.77, 115.31, 93.79, 87.60; MS, m/z (%): 362 [M+].

2-Amino-4-(4-nitrophenyl)-6-(phenylthio)pyridine-3,5-dicarbonitrile (4d)

Yellow solid, m.p. 289–290 °C; IR (KBr, disk) ν: 3428, 3336, 3230, 2215, 1634, 1550, 1513, 1460, 1350, 1262, 780 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.50–7.58 (m, 5H, Ar), 7.84–7.95 (m, 4H, Ar, NH2), 8.35–8.39 (m, 2H, Ar); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 87.40, 93.45, 115.05, 115.39, 124.32, 127.37, 129.95, 130.22, 131.09, 135.25, 140.66, 149.05, 157.16, 159.91, 167.0; MS, m/z (%): 373 [M+].

2-Amino-4-(4-methoxyphenyl)-6-(phenylthio)pyridine-3,5-dicarbonitrile (4e)

Yellow solid, mp 240–242 °C, 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.78 (s, 2H, NH2), 7.65–7.50 (m, 7H, Ar), 7.17–7014 (d, J = 9 Hz, 2H, Ar) 3.87 (s, 3H, CH3); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 166.64, 161.35, 160.30, 158.81, 136.30, 130.75, 130.13, 129.93, 127.76, 126.30, 116.05, 115.79, 114.60, 93.91, 87.50, 55.85; MS, m/z (%): 358 [M+];

2-Amino-4-(4-hydroxyphenyl)-6-(phenylthio)pyridine-3,5-dicarbonitrile (4f)

Yellow solid, mp 312–314 °C, IR (KBr, disk) ν: 3400, 3367, 3335, 3247, 3117, 2217, 1650, 1632, 1572, 1479, 1295 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 4.10 (br, 2H, NH2), 7.29–7.45 (m, 9H, Ar), 10.05 (bs, 1H, OH); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 94.0, 96.92,

115.61, 116.05, 116.03, 124.55, 128.11, 129.89, 130.16, 130.85, 135.43, 158.90, 159.93, 162.05, 166.70; MS, m/z (%): 344 [M+].

2-Amino-4-(4-(dimethylamino)phenyl)-6-(phenylthio)pyridine-3,5-dicarbonitrile (4 g).

Brown solid, mp 288–290 °C, IR (KBr, disk) ν: 3415, 3335, 3117, 2310, 1625, 1568, 1521, 1387, 1205, 820 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 3.1–3.33 (m, 6H, CH3), 5.05 (bs, 2H, NH2), 7.45–8.12 (m, 9H, Ar); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 161.90, 160.10, 158.60, 155.14, 134.0, 119.22, 115.98, 115.91, 115.55, 115.0, 112.11, 69.26; MS, m/z (%): 371 [M+].

2-Amino-6-(phenylthio)-4-(thiophen-2-yl)pyridine-3,5-dicarbonitrile (4 h)

Yellow solid, mp 248–250 °C, IR (KBr, disk) ν: 3488, 3345, 3221, 3075, 2215, 1735, 1650, 1625, 1548, 1401, 1256 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.25–7.55 (m, 7H, Ar), 7.95–7.98 (m, 1H, Ar) 8.61 (br, 2H, NH2); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 87.31, 115.60, 115.93, 127.56, 128.35, 129.91, 130.16, 131.28, 132.04, 133.25, 133.29, 135.28, 151.37, 160.25, 167.13; MS, m/z (%): 334 [M+].

2-Amino-6-((4-chlorophenyl)thio)-4-henylpyridine-3,5-dicarbonitrile (4i)

White solid; mp 225–227 °C IR (KBr, disk) ν: 3438 (NH), 3315 (NH), 2203 (CN), 1600, 1291, 780; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.93 (s, 2 H, NH2), 7.69–7.59 (m, 9 H, Ar); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 167.0, 160.15, 159.0, 137.21, 135.28, 134.35, 130.98, 129.95, 129.24, 128.90, 126.53, 115.72, 115.46, 93.73, 87.0; MS, m/z (%): 362 [M+].

2-Amino-4-phenyl-6-(p-tolylthio)pyridine-3,5-dicarbonitrile (4j)

Yellow solid; mp 238–240 °C; IR (KBr, disk) ν: 3467, 3348, 2219, 2195, 1625, 1522; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 8.26 (br, 2H, NH2), 7.60–7.54 (m, 6H, Ar), 7.50–7.47 (m, 3H, Ar), 2.61 (s, 3H, CH3); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 20.98, 87.22, 96.03, 114.81, 115.25, 124.55, 128.48, 129.91, 130.11, 131.0, 134.22, 135.69, 142.37, 158.21, 159.30, 169.59; MS, m/z (%): 342 (M+).

2-Amino-6-((4-methoxyphenyl)thio)-4-phenylpyridine-3,5-dicarbonitrile (4 k)

Yellow solid, mp 228–229 °C; IR (KBr, disk) ν: 3430, 3340, 2210, 1629, 1591, 1248, 1130, 833, 755 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 7.99 (br, 2H, NH2), 7.59–7.54 (m, 5H, Ar), 7.50 (d, J = 8.6 Hz, 2H, Ar), 7.07 (d, J = 8.6 Hz, 2H, Ar), 3.83 (s, 3H, OCH3); 13C NMR (100 MHz, DMSO-d6, ppm) δ: 54.0, 86.12, 95.11, 114.04, 114.30, 114.63, 124.78, 128.27,

130.05, 131.96, 136.71, 159.30, 162.37, 168.54, 184.0; MS, m/z (%): 358 [M+].

2-Amino-6-((2-aminophenyl)thio)-4-phenylpyridine-3,5-dicarbonitrile (4 l)

Yellow solid, mp 225–227 °C; IR (KBr, disk) ν: 3465, 3358, 2920, 2213, 1610, 1264, 1158, 750 cm−1; 1H NMR (400 MHz, DMSO-d6, ppm) δ: 6.65 (br, 2H, NH2), 7.11–7.16 (m, 4H, Ar), 7.30–7.48 (m, 5H, Ar), 8.01(br, 2H, NH2); 13C NMR (100 MHz, DMSO-d6, ppm) δ:

88.25, 95.66, 115.23, 118.68, 119.0, 120.84, 128.39, 129.03, 130.95, 131.54, 136.73, 148.53, 159.59, 168.0; MS, m/z (%): 343 [M+].

Results and discussion

Characterization of magnetic Fe3O4@SiO2@TA-Cu nanocomposite

The construction process of the catalyst is schematically shown in scheme 1. The prepared Fe3O4 nanospheres were covered with SiO2. The SiO2 shell increased the chemical stability and acid resistance of the magnetic core. Then, Cu(OAc)2 was added to the solution of TA. When Cu(OAc)2 was added to the solution, Cu2+ was adsorbed onto the TA layer through static and coordination interactions. A uniform TA-Cu coordination-complex coating on the SiO2 shell was formed.

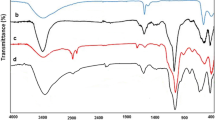

FT-IR analysis

Figure 1 presents the FT-IR spectra of Fe3O4, Fe3O4@SiO2 and Fe3O4@SiO2@TA-Cu nanoparticles. As shown in Fig. 1, for pure Fe3O4 (red color), the characteristic bands at 550 and 3358 cm−1 were belonged to the Fe–O bond and OH functional group [58, 59]. The FT-IR analysis of the Fe3O4@SiO2 also demonstrates a peak at around 540 cm−1, which is related to Fe–O vibration and the bands at approximately 1090, 800, and 470 cm−1 are from Si–O vibrations. In the case of Fe3O4@SiO2@TA-Cu, new bands were observed in the range of 700 to 1700 cm−1. The mentioned bands belonged to functional groups of tannic acid. Regarding TA-Cu and Fe3O4@SiO2 interactions, it is expected to observe a shift in bands of TA functional groups. Accordingly, characteristic bands of pure tannic acid and corresponded bands were reported in Table 1 [60, 61]. From Fig. 1, the wide and strong band was observed, which centered at 3356 cm−1, related to the overlapping of the OH functional group of TA and Fe3O4. The FT-IR analysis of the Fe3O4@SiO2@TA-Cu also demonstrates the bands at approximately 1090 cm−1, 800 cm−1, and 470 cm−1 are from Si–O vibrations.In Table 1 the Comparison FT-IR position of TA and Fe3O4@SiO2@TA-Cu was also demonstrated.

Additionally, the bands at 1612, 1067 cm−1 were attributed to the stretching and bending vibration of Cu–O [62].

XRD analysis

The XRD analysis was carried out to probe the structure of Fe3O4@SiO2@TA-Cu nanoparticles (Fig. 2). In form recorded pattern, a lack of the characteristic peaks of pure Fe3O4 was found. This trend can be explained by complex formation. Indeed, the thin layer of the Cu-tannic acid complex was appropriately formed on the Fe3O4@SiO2 surface. The peak at 25º indicated the nature of Tannic acid [63]. Additionally, 39, 53.5, and 65º showed diffraction patterns that can related to the Fe3O4 and TA-Cu complex.

FE-SEM and EDS analysis

Figure 3 illustrates FE-SEM images and EDS spectra of Fe3O4@SiO2@TA-Cu nanoparticles. The average size of coated particles was less than 100 nm and the spherical shape was changed due to complex coating. As can be seen, the characteristic peaks belonged to C, O, Fe, Si, and Cu elements which confirm the presence of Tannic acid and Cu on Fe3O4@SiO2 nanoparticles.

Magnetic characterization

The magnetic characterization of Fe3O4@SiO2 and Fe3O4@SiO2@TA-Cu nanoparticles was studied by vibrating sample magnetometer (VSM). The curves of magnetization are shown in Figs. 4. The magnetic properties were analyzed by room temperature vibrant sample magnetometer (VSM) with an applied – 15 to 15 KOe field. These magnetic nanoparticles have a lot of attention. The prepared MNPs are separated from the reaction mixture by applying an outer magnet. Figure 4 demonstrates that the saturation magnetization of Fe3O4@SiO2 and Fe3O4@SiO2@TA-Cu nanoparticles were found 70 and 49 emu/g, respectively.

The catalytic application of magnetic Fe3O4@SiO2@TA-Cu nanoparticles for the synthesis of 2-amino-3,5-dicarbonitrile-6- thio-pyridines derivatives

After characterization of the Fe3O4@SiO2@TA-Cu nanoparticles, we reported the synthesis of 2-amino-3,5-dicarbonitrile-6- thio-pyridines (4a-j) using a one-pot three-component reaction of benzaldehyde, malononitrile, and thiophenol in the presence of Fe3O4@SiO2@TA-Cu nanoparticles at room temperature (Scheme 2).

At first, we optimized different reaction parameters for the synthesis of 2-amino-4-phenyl-6-(phenylthio)pyridine-3,5-dicarbonitrile (4a) as the model reaction (Table 2). The first screening was done under solvent-free conditions. In the presence of the catalyst, the product was obtained in only 40% yield (Table 2, entry 1). When the reaction was performed using H2O as a solvent, in the absence of catalyst, the reaction did not proceed successfully even after a longer reaction time, in contrast, using the catalyst, the reaction times were decreased to 7 min and the desired product was obtained in excellent yields (Table 2, entries 2, 3). In continuation of our work, the catalytic activity of Fe3O4@SiO2@TA-Cu nanoparticles in some solvents was also investigated (Table 2, entries 4–8). Among the solvents, the best result has been obtained in H2O. The using solvent-free condition or solvents like toluene, EtOH, DMF, CH3CN, and CHCl3 gave a low yield of the product despite a longer time of reaction. Then, the condensation reaction occurred more successfully in the H2O as a safe solvent. One important case of green chemistry is the replacing of hazardous solvents with relatively nontoxic solvents. This is a great advantage of this new catalytic system concerning green chemistry since no toxic solvent is required to synthesis of desired products. We also studied the effect of the amount of catalyst loading (Table 2, entries 3, 9–11). The formation of 2-amino-4-phenyl-6-(phenylthio)pyridine-3,5-dicarbonitrile (4a) was done with an amount of 0.03 g, 0.05 g, 0.07 g, and 0.1 g of the catalyst. It was obtained that the 0.05 g of the magnetic Fe3O4@SiO2@TA-Cu nanoparticles was the optimal experimental amount (Table 2, entry 3). Increasing the amount of catalyst did not enhance the rate of reaction or the yield of the product (Table 2, entries 10, 11). In contrast, a lower amount of catalysts has decreased the yield of the product even after a longer reaction time (Table 2, entry 9). The effect of temperature on the reaction was also studied. It was found that at the high reaction temperature (at reflux condition, entry 12) the rate and yield of the reaction were not improved. To demonstrate the high catalytic effect of Fe3O4@SiO2@TA-Cu nanoparticles, the synthesis of (4a) was also performed using Cu(OAc)2, Fe3O4 NPs, and Tannic acid separately (Table 2, entries 13–15). As shown in Table 1, just 55% conversion was performed after 60 min in the presence of Cu(OAc)2 (Table 2, entry 13). When the Fe3O4 NPs and Tannic acid were taken separately as the catalyst, they gave the product in trace yield (Table 2, entries 14, 15). Therefore, the Fe3O4@SiO2@TA-Cu nanoparticles can be suggested as an efficient solid acid catalyst for the synthesis of 2-amino-3,5-dicarbonitrile-6- thio-pyridines.

In continuation, to study the general application of this procedure, the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines was investigated by various aldehydes and thiophenols under optimized reaction conditions (Table 3).

As is evident from the results shown in Table 3, this method is highly appropriate with many benzaldehydes with both an electron-donating and an electron-withdrawing group, such as chloro, nitro, methyl, methoxy, hydroxy, and N, N dimethylamine groups. All benzaldehyde derivatives gave the desired products in good to excellent yields (Table 3, entries 1–8). Similarly, the substituents on thiophenol show the same effects on the reaction: Chloro, methyl, methoxy, and amino-substituted thiophenols produced the corresponding pyridine derivatives in good to excellent yields using this catalyst. (Table 3, entries 8–12). However, with aliphatic aldehydes and thiols, the reaction was not efficient. The structures of all the products were confirmed from their spectral (FT-IR, 1H NMR, 13C NMR, and MS) data.

Then, the resultant nanocomposites exhibited excellent catalytic performance and good stability for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines. The excellent adsorption of TA is mainly due to the presence of large number of functional groups via hydrogen bonding and π–π interaction. Then, tannic acid-metal with surface binding affinity could activate the reactant through the strong chelating interaction between reactant groups and Cu ions and improved the rate and yield of the products [52, 64, 65].

In continuation, we compared the reported methods with the other catalysts recently reported for synthesis tetrazole derivatives in the literature. As it is found (Table 4), despite the merits of most of the previously reported methods, the Fe3O4@SiO2@TA-Cu NPs are the more efficient catalysts than many of the methods reported in the literature for this reaction.

The proposed mechanism for the preparation of 2-amino-3,5-dicarbonitrile-6- thio-pyridines is shown in Scheme 3. The first step of the mechanism involves the Knoevenagel condensation of an aldehyde with malononitrile to form the corresponding Knoevenagel product A. The reaction proceeds through the subsequent Michael-type addition of the second molecule of malononitrile to the Knoevenagel adduct A and thiolate addition to C≡N of the adduct and cyclization to produce dihydropyridine (B) [25, 29]. Aromatization of B under the reaction conditions gives desired pyridine derivatives. It is believed that the final step of the reaction mechanism for the synthesis of target molecules proceeded through vinylogous anomeric-based oxidation mechanism [66] (Scheme 3). In this mechanism, it is supposed that dual activation of aldehyde, malononitrile, and thiol by Fe3O4@SiO2@TA-Cu has also taken place.

Recycling of catalyst

Metal–organic frameworks (MOFs), are a class of emerging catalysts with many promising characters. These new heterogeneous catalysts usually are very stable and may be easily recycled and reused after the application [51]. The other advantage of this heterogeneous catalyst is that it can easily be recovered by an external magnet and can be reused without significant loss of catalytic activities. As shown in Fig. 5, when the reaction of benzaldehyde (1a), malononitrile (2), and thiophenol (3a) was done as a model reaction, the Fe3O4@SiO2@TA-Cu nanocatalyst reused for five cycles without almost considerable loss of the activity.

Conclusion

In summary, the surfaces of Fe3O4@SiO2 nanoparticles were successfully modified with a uniform thin layer of TA-Cu coordination complexes by a modification process for catalytic application. The results demonstrated that the Fe3O4@SiO2@TA-Cu nanoparticles are efficient, and recyclable catalysts for the synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines via three-component condensations of aldehydes, malononitrile, and thiophenols in water. This protocol provides several advantages such as the strong ability of catalyst to immobilize metal nanoparticles, high chemical stabilities of catalyst in the action mixture, high specific surface area of catalyst, uniformly dispersed and easily recoverable NPs, high yield of products, simple work up, simple separation of the magnetic catalyst, green method, avoiding hazardous organic solvent in the reaction environment.

References

T.L.S. Kishbaugh, Curr. Top. Med. Chem. 16, 3274 (2016)

M. Alrooqi, S. Khan, F.A. Alhumaydhi, S.A. Asiri, M. Alshamrani, M.M. Mashraqi, A. Alzamami, A.M. Alshahrani, A.A. Aldahish, Anticancer. Agents. Med. Chem. (2022). https://doi.org/10.2174/1871520622666220324102849

H. Chen, W. Zhang, R. Tam, A.K. Raney, PCT Int. Appl. WO 2005058315 A1 20050630, (2005).

S.B. Levy, M.N. Alekshun, B.L. Podlogar, K. Ohemeng, A.K. Verma, T. Warchol, B. Bhatia, T. Bowser, M. Grier, US Patent Appl. 2005124678 A1 20050609 (2005).

B.C.H. May, J.A. Zorn, J. Witkop, J. Sherrill, A.C. Wallace, G. Legname, S.B. Prusiner, F.E. Cohen, J. Med. Chem 50, 65 (2007)

M.T. Cocco, C. Congiu, V. Lilliu, V. Onnis, Eur. J. Med. Chem 40, 1365 (2005)

H. Harada, S. Watanuki, T. Takuwa, K. Kawaguchi, T. Okazaki, Y. Hirano, C. Saitoh, PCT. Int. Appl. WO 2002006237 A1 20020124, (2002).

B.B. Fredholm, A.P.I. Jzerman, K.A. Jacobson, K.N. Klotz, J. Linden, Pharmacol. Rev 53, 527 (2001)

C. Alonso, M. Fuertes, E. Martín-Encinas, A. Selas, G. Rubiales, C. Tesauro, B.K. Knudssen, F. Palacios, Eur. J. Med. Chem 149, 225 (2018)

A.R. Moosavi-Zare, H. Goudarziafshar, Z. Jalilian, Prog. Chem. Biochem. Res 2, 59 (2019)

M. Aghazadeh, Prog. Chem. Biochem. Res 2, 34 (2019)

J.D. Sunderhaus, S.F. Martin, Chem. Eur. J 15, 1300–1308 (2009)

B. Ganem, Acc. Chem. Res 42, 463 (2009)

S.K. Kundu, J. Mondal, A. Bhaumik, Dalton. Trans 5, 10515 (2013)

S.K. Kundu, A. Bhaumik, RSC. Adv 5, 32730 (2015)

S. Ray, P. Das, A. Bhaumik, M. Pramanik, C. Mukhopadhyay, Recycl. Catal 1, 34 (2014)

B. Borah, K. D. Dwivedi, L. Raju Chowhan, Polycycl. Aromat. Compd (2021). DOI: https://doi.org/10.1080/10406638.2021.1962923.

D. Bayramoğlu, M. Güllü, Polycycl. Aromat. Compd (2021). https://doi.org/10.1080/10406638.2021.1915806

S. Kamalifar, H. Kiyani, Polycycl. Aromat. Compd (2021). https://doi.org/10.1080/10406638.2021.1872656

B.R. Nemallapudi, D.R. Guda, N. Ummadi, B. Avula, G.V. Zyryanov, C.S. Reddy, S. Gundala, New Methods for Synthesis of 1,2,3-Triazoles: A Review. Polycycl. Aromati. Compound. (2021). https://doi.org/10.1080/10406638.2020.1866038

H. Thacker, V. Ram, P.N. Dave, Prog. Chem. Biochem. Res 2, 84 (2019)

K. Kamari, A. Taheri, J. Taiwan. Inst. Chem. Eng 86, 230 (2018)

Z. Ghadamyari, A. Khojastehnezhad, S.M. Seyedi, A. Shiri, ChemistrySelect 4, 10920 (2019)

F. Tajfirooz, A. Davoodnia, M. Pordel, M. Ebrahimi, A. Khojastehnezhad, Appl. Organomet. Chem 32, e3930 (2018)

H. Ebrahimiasl, D. Azarifar, J. Rakhtshah, H. Keypour, M. Mahmoudabadi, Appl. Organomet. Chem 34, e5769 (2020)

N.M. Evdokimov, A.S. Kireev, A.A. Yakovenko, M.Y. Antipin, I.V. Magedov, A. Kornienko, J. Org. Chem 72, 3443 (2007)

A. Allahi, B. Akhlaghinia, Phosphorus. Sulfur. Silicon. Relat. Elem 196, 328 (2021)

R. Mamgain, R. Singh, D.S. Rawat, J. Heterocycl. Chem 46, 69 (2009)

K. Niknam, A.R. Hosseini, J. Org. Chem. Res 3, 16 (2017)

M. Nasim Khan, S. Pal, T. Parvin, Lokman H. Choudhury, RSC. Adv 2, 12305 (2012).

M. Kidwai, R. Chauhan, J. Iran. Chem. Soc 11, 1005 (2014)

M.M. Heravi, M. Khorshidi, Y.S. Beheshtia, B. Baghernejad, Bull. Korean. Chem. Soc 31, 1343 (2010)

V.T. Kamble, S.T. Atkore, P.M. Pisal, M. Sadaf, R.V. Thakre, Iran. Chem. Commun 4, 186 (2016)

M. Kantam, K. Mahendar, S. Bhargava, J. Chem. Sci 122, 63 (2010)

M.R. Poor Heravi, F. Fakhr, Tetrahedron. Lett 52, 6779 (2011).

V. Pravin, B. Bapurao, S. Murlidhar, Chin. J. Chem 29, 1049 (2011)

B. Das, B. Ravikanth, A.S. Kumar, B.S. Kanth, J. Heterocycl. Chem 46, 1208 (2009)

P.V. Shinde, V.B. Labade, B.B. Shingate, M.S. Shingare, J. Mol. Catal. A Chem 336, 100 (2011)

J. Safaei-Ghomi, M.A. Ghasemzadeh, M. Mehrabi, Sci. Iran 20, 549 (2013)

M.S. Pandharpatte, H.A. Osman, A.M. Osman, G.M. Nazeruddin, Chem. Sci. Trans 6, 1 (2017)

S. Sobhani, M, Honarmand. C. R. Chim 16, 279 (2013)

B.C. Ranu, R. Jana, S. Sowmiah, J. Org. Chem 72, 3152 (2007)

A. Davoodnia, P. Attar, H. Eshghi, A. Morsali, N. Tavakoli Hoseini, A. Tavakoli-Nishaburi, Asian. J. Chem 23, 1273 (2011).

M. Sridhar, B.C. Ramanaiah, C. Narsaiah, B. Mahesh, M. Kumaraswamy, K.K.R. Mallu, V.M. Ankathi, PSh. Rao, Tetrahedron. Lett 50, 3897 (2009)

S.S. Kottawar, S.A. Siddiqui, S.R. Bhusare, Heterocycl. Commun 18, 249 (2012)

S. Sobhani, S.M. Honarmand, Appl. Catal. A: Gen 467, 456 (2013)

S. Banerjee, G. Sereda, Tetrahedron. Lett 50, 6959 (2009)

J. Safaei-Ghomi, M.A. Ghasemzadeh, J. Sulphur, Chem 34, 233 (2013)

P.V. Shinde, S.S. Sonar, B.B. Shingate, M.S. Shingare, Tetrahedron. Lett 52, 1309 (2010)

M.S. Su, X.J. Ji, B.B. Zhao, M. Tian, J.J. Ma, J. Chem. Soc. Pak 37, 1130 (2015)

M. Thimmaiah, P. Li, S. Regati, B. Chen, J.C. Zhao, Tetrahedron. Lett 53, 4870 (2012)

D. Li, X. Xu, X. Wang, R. Li, C. Cai, T. Sun, Y. Zhao, L. Chen, J. Xu, N. Zhao, ACS. Appl. Nano. Mater 2, 3510 (2019)

W. Zhou, Y. Zhou, Y. Liang, X.H. Feng, H. Zhou, RSC. Adv 5, 50505 (2015)

B.S. Kumar, A.J. Amali, K. Pitchumani, ACS. Appl. Mater. Interfaces 7, 22907 (2015)

H. Ejima, J.J. Richardson, K. Liang, J.P. Best, M.P. Koeverden, G.K. Such, J.W. Cui, F. Caruso, Science 341, 154 (2013)

J.L. Guo, Y. Ping, H. Ejima, K. Alt, M. Meissner, J.J. Richardson, Y. Yan, K. Peter, D. Elverfeldt, C.E. Hagemeyer, F. Caruso, Angew. Chem. Int. Ed 53, 5546 (2014)

A.R. Kiasat, J. Davarpanah, J. Mol. Catal. A Chem 373, 46 (2013)

S. Asgari, Z. Fakhari, S. Berijani, J. Nanostruct 4, 55 (2014)

Y.S. Lia, J.S. Church, A.L. Woodhead, J. Magn. Magn. Mater 324, 1543 (2012)

M.A. Pantoja-Castroa, H. González-Rodríguez, Rev. Latinoam. Quím. 39, 108 (2011)

K. Rajar, R. Ali Soomro, Z.H. Ibupoto, S.A. Balouch, Int. J. Food. Prop 20, 1359 (2017).

P. K. Raul, S. Senapati, A.K. Sahoo, I.M. Umlong, R.R. Devi, A.J Thakur, V. Veer, RSC. Adv 4, 40580 (2014).

R. Zhang, L. Li, J. Liu, RSC. Adv 5, 40785 (2015)

R. Kumar, M.A. Barakat, E.M. Soliman, J. Ind. Eng. Chem 20, 2992 (2014)

H. Veisi, M. Pirhayati, A. Kakanejadifard, P. Mohammadi, M.R. Abdi, J. Gholami, S. Hemmati, ChemistrySelect 3, 1820 (2018)

F. Karimi, M. Yarie, M.A. Zolfigol, Mol. Catal 497, 111201 (2020)

Funding

The authors gratefully acknowledge the Research Council of the University of Gonabad for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Rights and permissions

About this article

Cite this article

Karimian, A., Namvar–Mahboub, M., Binabaji, F. et al. Tannic Acid-Cu-modified Fe3O4@SiO2 nanoparticles (Fe3O4@SiO2@TA-Cu NPs): New recyclable magnetic catalyst for the three-component synthesis of 2-amino-3,5-dicarbonitrile-6-thio-pyridines. J IRAN CHEM SOC 19, 4397–4409 (2022). https://doi.org/10.1007/s13738-022-02608-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-022-02608-6