Abstract

Functionalized nanostructures such as, boehmite, salicylate alumoxane (Sal-A) and p-hydroxybenzoate alumoxane (PHB-A), were studied in varying amounts with respect to curing behavior, thermal stability, hardness and fracture surface morphology of their corresponding epoxy-based nanocomposites, emphasizing on the dispersabilities of the nanostructures in the epoxy matrix and the potential mechanisms of the interactions between various species. TG–DTA, Vickers hardness test and SEM were used to characterize the composite specimens. Addition of nanostructures into the epoxy matrix accelerated the curing process. The experimental tests proved that Sal-A acted most effectively as a co-curing agent through the autocatalytic curing process of the epoxy resin and also produced the highest values of Vickers hardness in its corresponding nanocomposites. The presence of the nanostructures also lowered the heat of reaction in curing process with an exception of PHB-A containing nanocomposites. Thermal stability of the nanocomposites was improved due to existence of the functionalized nanostructures. Mechanisms are proposed for the possible interactions between various species, constructing the three types of nanocomposites, divided into positive and negative types. The functional groups on the surfaces of the nanostructures not only facilitated chemical interactions with the polymer matrix but also improved their dispersion in the epoxy matrix. Dispersability tendency of the nanostructures in the epoxy matrix was of the order: boehmite < PHB-A < Sal-A. Extent of agglomeration of the nanostructures in the epoxy matrix depended on the types of the functional groups on their surfaces and consequently, their interactions with the epoxy matrix and hardener.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Application of polymer nanocomposites as engineering materials has become state of the art so that, improvement of their properties is most important for further development of high performance nanocomposites [1]. Incorporation of rigid inorganic fillers into various polymers is a well-known technique to reduce the cost and to modify the specific properties of polymers such as modulus, toughness, thermal, electrical, viscosity and so on [2–4]. The effect of fillers on properties of composites depends on their level of loading, shape, particle size, aggregate size, surface characteristics and degree of dispersion. Flame-retardant epoxy resin nanocomposites reinforced with silica nanoparticles were prepared at different nanoparticle loading levels. The surface functionality of the silica nanoparticles was manipulated by the phosphoric acid (H3PO4)-doped conductive polyaniline (PANI) via a surface initiated polymerization (SIP) method. The heat release rate peak of the epoxy filled with functionalized silica nanoparticles dropped dramatically with increases in functionalized silica particle loadings, comparable with flame-retardant performance from the phosphoric acid-doped PANI [5]. Magnetic graphene (Gr) nanocomposites (Gr nanosheets coated with iron core and iron oxide shell nanoparticles, named Gr/Fe@Fe2O3) successfully served as nanofillers for obtaining magnetic epoxy resin polymer nanocomposites (PNCs) to be compared with the epoxy nanocomposites with pure graphene [6]. Carbon-coated iron (Fe@C) nanoparticles functioned as nanofillers for obtaining magnetic epoxy resin polymer nanocomposites (PNCs). A reduced viscosity was observed in liquid suspensions of 1.0 wt% Fe@C/epoxy resin and the viscosity was increased with further increases in Fe@C nanoparticle loading. Introduction of the Fe@C nanofillers resulted in lower onset decomposition temperature of the PNCs. Also, a reduced flammability was observed in PNCs due to the easier char formation from epoxy matrix induced by the Fe@C nanoparticles. Enhanced storage modulus was observed in PNCs with 20.0 wt% Fe@C nanoparticles. Due to the cavities initiated by nanoparticles, the PNCs with 5.0 wt% Fe@C nanoparticles showed an increased tensile strength up to 60 % compared with pure epoxy. The Fe@C nanofillers efficiently increased the electrical conductivity of the epoxy matrix, and a chain of particles observed in the SEM image of fracture surface indicated the formation of percolated Fe@C nanoparticles in the epoxy matrix [7]. Preparation of epoxy PNCs filled with both barium titanate (BaTiO3) (500 and 100 nm) and conductive polyaniline (PANI) stabilized BaTiO3 nanoparticles (NPs) with high dielectric permittivity and reduced flammability were reported [8]. Flame-retardant electrical conductive nanopolymers based on bisphenol-F epoxy resin reinforced with both fibril and spherical polyaniline (PANI) nanostructures were fabricated [9]. Presence of the PANI nanofillers reduced the heat-release rate and increased the char residue of epoxy resin. The critical PANI nanofiller loading for the modulus and T g was different, i.e., 1.0 wt% for the nanofibers and 5.0 wt% for the nanospheres. Nanofibers reached the percolation threshold at a lower loading (3.0 wt%) than the PANI nanospheres (5.0 wt%). High performance multi-walled carbon nanotubes (MWNTs) reinforced epoxy PNCs were synthesized with different MWNT contents [10]. The surface functionalization of MWNTs with conductive polyaniline was achieved by using a facile surface initiated polymerization method with the aid of the oxidations of CNTs and subsequent anilines by hexavalent chromium (Cr(VI)) oxidant. The glass transition temperature (T g) of the cured epoxy PNCs filled with functionalized MWNTs was increased by about 6–25 °C compared with cured pure epoxy. Tensile strength and thermo-stability of the PNCs reinforced with functionalized MWNTs were also improved. Magnetic epoxy PNCs reinforced with magnetite (Fe3O4) nanoparticles (NPs) were prepared at different particle loading levels. The particle surface functionality tuned by conductive PANI was achieved via a SIP approach. The glass transition temperature (T g) of the cured epoxy filled with the functionalized nanoparticles shifted to higher temperature compared with that of the cured pure epoxy. Tensile properties of the cured epoxy PNCs filled with the functionalized nanoparticles were also enhanced compared with those of the cured pure epoxy and cured epoxy PNCs filled with as-received NPs. The magnetic epoxy PNCs exhibited good magnetic properties [11]. Epoxy resin nanocomposites reinforced with various loadings of core–shell structured nanoparticles (Fe@FeO) were prepared using a surface wetting method. Nanoparticle loading effect on the viscosity of epoxy monomers was well correlated to the cross rheological model. The glass transition temperature was increased by 10 °C with the addition of nanoparticles, being independent of particle loadings. The saturation magnetization (M s) of the 20 wt% Fe@FeO/epoxy nanocomposites was 17.03 emu/g, being about 15.8 % of that of the pure nanoparticles. The electrical conductivity percolation was about 5–10 wt%, where the resistance of the nanocomposites sharply decreased by six orders of magnitude [12]. Carbon nanofibers (CNFs)-suspended epoxy resin nanocomposites and the corresponding polymer nanocomposites were fabricated. The surface of CNFs was functionalized with amine terminated groups by silanization route, which reacted with epoxy monomers in situ. This reaction favored the CNFs dispersion and improved the interfacial interaction between CNFs and monomers. A decreased viscosity with a better dispersion was explained in terms of the improved filler dispersion quality. The enhancement of tensile properties and storage modulus was related to the better dispersion and the introduced strong interfacial interaction [13]. In order to make a successful nanocomposite, it is very important to disperse the filler material thoroughly throughout the matrix to maximize the interaction between the intermixed phases [2]. In fact, this has been verified by several researchers that inorganic nanoparticles possess the ability to reinforce thermoplastics effectively as well as the thermosetting polymers [2, 14, 15]. Epoxy-based composite materials are being increasingly used as structural components in aerospace and automobile industry due to their excellent high-adhesion, low-weight and good chemical/corrosion-resistance [16, 17]. The gelation times of the phenol novolac epoxy resins, containing alumina (Al2O3) fillers were longer than those of the corresponding unfilled epoxy resins, indicating that Al2O3 fillers delayed the curing reactions of epoxy resin [2, 18]. Addition of untreated alumina nanoparticles into the epoxy had an accelerating effect on curing process and a converse effect on the polymer network formation, but did not change the autocatalytic cure reaction mechanism of the epoxy/amine hardener system. The presence of alumina nanoparticles also did not improve thermal stability of the nanocomposites considerably, due to possible weak secondary interactions occurred between nanoparticles and the epoxy matrix [2]. Though, surface functionalization of the alumina nanoparticles can considerably change the surface chemistry of these nanoparticles and result in chemical interactions between these functionalized nanoparticles and epoxide groups of the polymer matrix. A specific group of functionalized alumina nanostructures known as carboxylate-alumoxanes have been synthesized and attracted much attention in various applications [19, 20]. Carboxylate-alumoxanes are synthesized from the reaction of boehmite (γ-AlOOH) with carboxylic acid (HO2CR). Carboxylate-alumoxanes are in fact alumina nanostructures whose surface is covered with covalently bound carboxylate groups [19]. Boehmite also, is the oxide–hydroxide phase of aluminum with differing water contents and crystallite size [21]. Carboxylate-alumoxanes used as inorganic fillers for epoxy resins were chemically bound to the matrix, resulting in significant increase in thermal stability and tensile strength for both the hybrid and composite resin systems [22, 23]. The aim of this work was to fabricate three types of epoxy-based nanocomposites with three different types of nanostructures [boehmite, p-hydroxybenzoate alumoxane (PHB-A) and salicylate alumoxane (Sal-A)], each with a unique morphology and surface chemistry, to study the effect of these organic–inorganic functionalized materials in various amounts, on cure behavior, thermal stability, hardness and fracture surface morphology of the corresponding nanocomposites, emphasizing on the dispersing tendencies of the nanostructures in the epoxy matrix and the potential mechanisms of the interactions between various species, constructing the three types of nanocomposites.

Experimental

The nanostructure fillers (boehmite, PHB-A and Sal-A) were synthesized in the laboratory, based on the methods published previously [20, 21].

Fabrication of nanocomposites

An appropriate amount of the epoxy resin and nanostructures (Table 1) were mixed thoroughly by a glass rod for 2 min. The beaker containing the mixture was then placed in a Sonrex ultrasonic bath (240 W–35 kHz, Digite C Ultrasonic bath, DT52 H model, by Bandelin, Germany), where it was sonicated for 1 h at room temperature to make a uniform mixture.

Then the hardener was added to the content of the beaker and mixed for 1 min by glass rod and later degassed in the ultrasonic bath for 5 min. The uniform mixture of each nanocomposite was immediately poured into the well-lubricated mold (using RENLEASE Z5 101 as the lubricating agent/releasing agent). The mold assembly was placed in a preheated air oven at 80 °C to pre-cure for 1 h and later post-cured for another 1 h at 110 °C. The samples were allowed to cool in the oven. For TG–DTA tests, each freshly prepared sample (as described above) was poured in an open aluminum pan, and placed in the DTA cell/oven. The nanocomposite samples were subjected to dynamic curing at the heating rate of 10 °C/min, using a Pyres Diamond TG/DTA analyzer under airflow of 200 mL/min. The variation of hardness (Vickers) as a function of time (indentation times: 30, 60 and 90 s) was performed on applying the load of 15.625 kgf. The fracture surface morphology of the nanocomposites was examined by a Hitachi S-4160 field emission scanning electron microscope.

Results and discussion

Figure 1 presents the molecular structure, surface chemistry and morphology of boehmite, Sal-A and PHB-A nanostructures. All the three nanostructures carry reactive functional groups on their surface, which enable them to interact chemically with the epoxy matrix. The cubic orthorhombic nanoparticles of boehmite with 10–30 nm in size are covered with hydroxyl groups on their surfaces. Nanosheets of Sal-A with the thickness of about 70 nm and length of some micrometers and the prism-like structures of PHB-A with the diameters of about 400 nm both have phenolic functional groups on their surfaces.

Thermal polymerization of nanocomposites

The cure reactions of epoxy resins are very complex because many reactive processes occur simultaneously, such as gelation (liquid-to-rubber) and vitrification (rubber-to-glass) phenomena. The autocatalytic effect in the early stages of curing, and the change from chemical control to diffusion control in the later stages of curing, can complicate the analysis [2]. The exothermic curing curves of the neat epoxy and epoxy nanocomposites containing 1, 2.5 and 5 wt% of the three types of nanostructures are shown in Fig. 2.

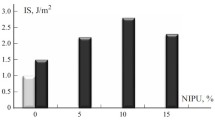

Addition of nanostructures into the epoxy matrix shifted the peak exothermic temperature (T p) of all the nanocomposites to lower temperatures (Fig. 2), indicating the accelerating effect of the nanostructures imposed on the curing process. The obtained data from DTA analysis are presented in Fig. 3. Lowering of the peak exothermic temperature in the range of 2–10 °C can be considered as a positive factor from the processing point of view, indicating the autocatalytic effect of the additive nanostructures.

The functional groups carried on the surfaces of all the three types of nanostructures can react with the epoxide groups to form covalent linkages as the curing proceeds, resulting in the formation of a three-dimensional network at the end of the curing process. Sal-A nanostructures, probably due to better dispersion in the polymer matrix, acted more effectively as a curing agent through the autocatalytic curing process of the epoxy resin. As the concentration of the nanoparticles increased, the peak exothermic temperature decreased with an exception of the system containing 5 wt% of PHB-A, probably due to agglomeration of the particles at higher concentration. Agglomeration of these particles weakened their autocatalytic effect on cure as well. We previously reported that, the presence of the passive alumina nanoparticles did not have a considerable effect on cure temperature [2]. However, the present work proves the active role of the functionalities of the nanostructures such as in boehmite and Sal-A, on reducing the peak exothermic temperature up to 10 °C. Figure 3 presents the decreasing effect of the presence of nanoparticles on heat of reaction during cure with an exception of PHBA containing resin systems, indicating lesser extent of cure as the amount of nanofillers increased. The observed decrease of the heat of reaction can be attributed to the increased viscosity of the resin mixtures as a result of the nanostructures presence, the exposed functional groups of which can react with the epoxide groups of the polymer matrix and thus, decrease the Brownian motion of the molecules. The epoxy/boehmite resin systems clearly exhibited the increasing trend of ΔH as the concentration of the nanoparticles increased. However, the decreasing trend of ΔH in the epoxy/Sal-A as a result of increasing the concentration of the nanoparticles can be attributed to the unexposed functional groups (Fig. 4a) of the nanoparticles to react freely with the epoxide groups.

Thus, as the concentration of the nanoparticles increased, the viscosity effect dominated. For epoxy-PHBA resin systems, the two factors; the effect of the presence of functional groups and effect of viscosity compete with one another. In PHB-A, the phenolic hydroxyl groups are exposed and highly reactive towards the three-membered epoxide rings as compared with those in the boehmite nanostructures, which is evident from the larger amount of heat released during the reactions of epoxy with PHB-A nanostructures. Figure 4b well illustrates the above-mentioned mechanisms. The acidic proton of phenol acts as an acid catalyst in the ring-opening mechanism of epoxide groups and the resulting phenolate nucleophile readily attacks the semi-opened epoxide rings. Whereas, with Sal-A, the phenolic groups are internal and not exposed, the same type of attacks are less common.

Thermal stability of nanocomposites

Thermogravimetric analysis (TGA) is the most powerful technique used to determine the thermal stability of materials. Figure 5 is the comparative TGA curves of epoxy-based nanocomposites containing various amounts of three types of nanostructures (0, 1, 2.5 and 5 wt%). A two-step change is observed in TGA curves of all the resin systems. The two-step behavior is believed to be due to the fact that, epoxy resins have a carbon ring structure. When epoxy resins are heated, all other chemical components except the carbon ring structures are initially burnt out. The inflection temperature for the neat epoxy system and all the nanocomposites are about 350 °C, which is believed to be the starting point of the charring of the carbon ring structure of the epoxy resin of the systems [2].

Figure 6 depicts the comparative variation in decomposition temperatures with respect to percentage weight loss and shows the stronger effect of the addition of nanostructures on thermal stability of the nanocomposites compared to a neat epoxy system (in 1 % weight loss). The enhanced thermal stability can also be observed at higher percentages of weight loss with an exception of PHB-A-containing epoxy nanocomposites. As thermal degradation preceded at higher levels of weight loss percentages, the surface of PHB-A nanostructures with the exposed and thus, more active phenolic OH groups were more vulnerable to thermal decomposition as compared with internal OH groups of Sal-A nanostructures. Addition of all the three types of functionalized nanostructures to the epoxy resin increased thermal stability of each corresponding nanocomposite, unlike alumina nanoparticles [2], owing to the intensive chemical interactions between the epoxide and hydroxyl groups of the nanostructures.

Vickers indentation responses of nanocomposites

The time-dependent flow behavior of materials can be studied by simple hardness tests. Polymers can creep at temperature as low as room temperature. Therefore, it has been observed that hardness of polymers changes with time over which the load is applied on the indenter and can be used as an indication of the relative creep resistance of polymers. The time taken for reading hardness is thus important. During the loading of polymers, a small amount of elastic deformation occurs and is followed by viscoelastic flow. When unloading, spontaneous elastic recovery takes place and is followed by a time-dependent recovery of the deformation. The recovery of viscoelastic polymers depends on the material itself, temperature and the state of internal stresses. The elastic recovery usually results in a pyramidal indent having sides concave inwards or star-shaped. However, the elastic recovery in the direction of the diagonals is generally negligible or very small. Therefore, the measurement of diagonal lengths should give valid hardness values for viscoelastic rigid polymers [1, 2]. Vickers hardness number (H V) was calculated using Eq. 1:

where F is load (kg) and d is the diagonal length (mm).

Figure 7a–d present the obtained values of Vickers hardness of the nanocomposites at 30, 60 and 90 s indentation times.

Hardness increased due to the presence of boehmite nanoparticles in the corresponding nanocomposites, reaching its maximum value for 2.5 wt% boehmite-loaded system. Among the three types of nanocomposites studied, those containing Sal-A, showed the highest values of Vickers hardness. Vickers hardness also increased as the amount of Sal-A increased in the corresponding nanocomposites. These observations illustrate the dispersing tendency of the nanoparticles in the epoxy matrix, which on the basis of the molecular structure and surface chemistry of each type of nanoparticle was of the following order: boehmite < PHB-A < Sal-A (Fig. 7e). The surfaces of the PHB-A and Sal-A nanostructures are covered with aromatic phenolic groups, which is the reason for their higher tendency to disperse in the epoxy matrix as compared with boehmite nanostructures. On the other hand, the phenolic hydroxyl groups being more exposed on the surface of PHB-A compared with those of Sal-A nanostructures, explain the greater tendency of PHB-A nanostructures to agglomerate, compared to Sal-A. This also explains the lower Vickers hardness obtained for PHB-A containing nanocomposites than Sal-A containing ones. The boehmite and alumoxane nanostructures differ from alumina in containing functional groups on their surfaces. The results indicated that, the presence of functional groups and their reactions with the polymer matrix positively affected the hardness of the corresponding nanocomposites. Alumina can interact with the epoxy matrix only through physical means and not chemically. The functional groups on the surfaces of the nanoparticles, not only make the nanoparticles to interact chemically with the polymer matrix (through covalent bonds), but also improve the dispersion of the corresponding nanoparticles in the epoxy matrix. However, our previous work proved the minor improving effect of alumina nanoparticles on hardness in the 0.5 wt% alumina-loaded nanocomposite [2]. It was also shown that, alumina nanoparticles agglomerated, when higher concentration was used (3 wt%). Thus, the functional groups of alumoxane and boehmite nanoparticles caused the strong interactions of these nanostructures with the epoxy matrix to dominate the agglomeration tendency of the nanoparticles to a large extent. Figure 7f shows that the trend of the hardness values of the three types of nanocomposites follows a second order equation, which allows the prediction of the hardness of higher loaded corresponding nanocomposites. However, higher loading of nanoparticles increases their agglomeration simultaneously. Therefore, the curves in Fig. 7e are expected to behave as second order polynomial and not linear.

Fracture surface morphology

Examinations on the fracture surfaces of epoxy nanocomposites by scanning electron microscopy (SEM) methods can often reflect detailed information on the cause and location of failure and also extent of dispersion of the nanoparticles. Several mechanisms of crack propagation and failure are commonly known to be applicable for filled epoxy resins [24]. Cracks may pass through the particles if the fillers are weak, known as trans-particulate fracture, or they may pass around, if the particles are strong enough. On the other hand, failure may occur by interfacial debonding or by cohesive failure of the matrix. The fracture surface may be roughly divided in two distinct regions: crack initiation zone and crack propagation zone. The crack initiation zone is distinguished by a relatively smooth area, which merges into the crack propagation zone [25]. The SEM micrograph (Fig. 8a) of the fractured surface belonging to the reference resin system shows that, fracture is nucleated at a minute flaw and it is propagated normal to the fracture axis. In the initial stages, the crack grew slowly, which produced a very smooth fracture surface, the mirror zone, denoted by A. A slightly rougher and less reflective region called the mist zone, denoted by B, surrounds the mirror region. The thin mist zone merges into a very rough surface called the hackle zone, denoted by C, which occurs when the crack reaches its limiting speed and excess stored energy was dissipated in bifurcation.

The size of the smooth region of the unfilled epoxy system is roughly the same as that of the nanocomposites. In order to allow conclusions to be drawn about the amount of dissipated energy during fracture, it is important to know in which way the traveling cracks pass through the material and how the particles influence the crack propagation. Cracks encounter particles as obstacles, which can deviate and branch the crack front or even pin it, forcing a higher energy absorption in the composite. A large amount of energy may also be consumed at the particle/matrix interface under strong bonding conditions. The interface plays a key role to the deformation behavior. As propagation of crack continues, the crack branching increases due to lowering of the crack energy as it proceeds. Further, on reducing the crack energy, there exist more chances of the cracks to be deviated on reaching the nanoparticles, as they do not have enough energy to break them and pass through them.

Figure 8 compares the fracture mechanism of neat epoxy (a) with that of the nanocomposites (b). It is clearly observed that, the cracks moved in straight lines for the neat epoxy, whereas in nanocomposites, cracks propagated as growing branches throughout the fractured surface.

The presence of nanoparticles in the polymer matrix was clearly the cause of branching the cracks, as they propagated, since the crack could not pass through the particles and thus, on reaching them, deviated and grew further through branches. The other observed phenomenon was that, nanoparticle agglomerates clearly acted as weak points in the structure of the nanocomposites, from where the cracks could start, as shown in Fig. 8a, b. The agglomerates are considered as weak points of the nanocomposites, where they cause local stresses in the polymer matrix and affect the nucleation and propagation of crack of the fracture mechanism.

Figure 9 presents the SEM micrographs of 1 wt% boehmite-containing nanocomposite at two different magnifications. Boehmite nanoparticles showed lower dispersion capability compared to other nanostructures used, and thus, greater tendency to agglomerate in the epoxy matrix, which in turn affected the mechanical property of their corresponding nanocomposites by lowering the hardness values. Extent of agglomeration of the nanoparticles in the epoxy matrix depended on the types of the functional groups on their surfaces and consequently, their interactions with the resin matrix and hardener.

Figure 10 proposes interaction mechanisms between various species, constructing the three types of nanocomposites studied. The interactions of nanostructures with the amine hardener used, had a negative effect, as the hydrogen type of interactions occurred between the amine groups of the hardener and the functionalities of the nanostructures, causing sudden agglomerations (coagulation) to occur, mostly in PHB-A-containing nanocomposites.

The occurrence of this sort of coagulation could inversely affect the mechanical properties of the nanocomposite. The phenolic groups of the alumoxanes on the other hand, went through interactions with the epoxy matrix, which can be considered as useful, positive interactions, which helped dispersion of the nanostructures in the polymer matrix. Boehmite showed lower extent of such interactions with the polymer matrix. The results obtained from the hardness tests, reflected these facts, as the presence of boehmite nanoparticles improved the hardness number less as compared with the alumoxane nanostructures. Sal-A, among the three types of nanostructures, proved to have dispersed most effectively in the epoxy matrix. Sal-A did not have any specific interaction with the hardener functionalities and thus, no coagulates formed due to its presence; and also interacted strongly with polymer matrix. Figure 11 compares the SEM micrographs of the nanocomposites, containing Sal-A and PHB-A nanostructures, showing more of PHB-A agglomerates than Sal-A ones and also that; the PHB-A nanostructures were not dispersed well in the polymer matrix. The fracture surface morphology of the 1 wt% Sal-A containing nanocomposite somewhat resembled that of the neat epoxy. This can be attributed to high level of dispersion and also useful interactions between the corresponding nanostructures and the epoxy matrix.

Conclusion

-

Epoxy-based nanocomposites were fabricated containing differing amounts of three types of nanostructures, namely, boehmite, Sal-A and PHB-A.

-

Addition of nanostructures to the epoxy matrix had an accelerating effect on the curing process.

-

Among the three types of functionalized nanostructures, Sal-A acted more effectively as a co-curing agent through the autocatalytic curing process of the epoxy resin.

-

Presence of the nanostructures also had a depreciating effect on heat of reaction during cure with an exception of PHB-A-containing nanocomposites.

-

Reaction mechanisms between epoxide with the exposed hydroxyl groups of boehmite and PHB-A nanostructures and also the unexposed hydroxyl groups of Sal-A were proposed.

-

Presence of the functionalized nanostructures increased thermal stability of the nanocomposites.

-

The Sal-A-containing nanocomposites showed the highest values of Vickers hardness, which also increased as the amount of Sal-A increased.

-

Dispersing tendency of the nanostructure in the epoxy matrix was of the order: boehmite < PHB-A < Sal-A.

-

The functional groups on the surfaces of the nanostructures, not only made them interact chemically with the polymer matrix (through covalent bond), but also improved their dispersion in the epoxy matrix.

-

Extent of agglomeration of the nanostructures in the epoxy matrix depended on the types of functional groups on their surfaces and consequently, their interactions with the resin matrix and hardener.

-

Mechanisms were proposed for the possible interactions between various species, constructing the three types of nanocomposites studied, which were divided into positive and negative types.

References

Ghorabi SH, Rajabi L, Derakhshan AA (2012) Epoxy/functionalized MWCNT nanocomposites: cure behaviour, thermal stability, mechanical properties and fracture morphology. J Nanoeng Nanomanuf 2:1–13

Rajabi L, Bostanipour M, Rostamabadi A, Derakhshan AA (2012) Cure behavior, thermal stability and mechanical properties of epoxy/alumina nanocomposites. J Nanoeng Nanomanuf 2:1–9

Hayashi K, Kurosaka Y, Osako Y, Ha J, Vacha M, Sato H (2005) Electrical properties of composites of TiO2-triphenylamine derivatives. Thin Solid Films 474:337–340

Vatanpour V, Madaeni SS, Rajabi L, Zinadini S, Derakhshan AA (2012) Boehmite nanoparticles as a new nanofiller for preparation of antifouling mixed matrix membranes. J Membr Sci 401–402:132–143

Gu H, Guo J, He Q, Tadakamalla S, Zhang X, Yan X, Huang Y, Colorado HA, Wei S, Guo Z (2013) Flame retardant epoxy resin nanocomposites reinforced with polyaniline stabilized silica nanoparticles. Ind Eng Chem Res 52:7718–7728

Zhang X, Alloul O, He Q, Zhu J, Verde MJ, Li Y, Wei S, Guo Z (2013) Strengthened magnetic epoxy nanocomposites with protruding nanoparticles on the graphene nanosheets. Polymer 54:3594–3604

Zhang X, Alloul O, He Q, Zhu J, He Q, Luo Z, Colorado HA, Haldolaarachchige N, Young DP, Shen TD, Wei S, Guo Z (2013) Iron core carbon shell nanoparticles reinforced electrically conductive magnetic epoxy resin nanocomposites with reduced flammability. RSC Adv 3:9453–9464

Zhang X, He Q, Gu H, Wei S, Guo Z (2013) Polyaniline stabilized barium titanate nanoparticles reinforced epoxy nanocomposites with high dielectric permittivity and reduced flammability. J Mater Chem C 1:2886–2899

Zhang X, He Q, Gu H, Colorado HA, Wei S, Guo Z (2013) Flame retardant electrical conductive nano-polymers based on bisphenol F epoxy resin reinforced with nano polyanilines. ACS Appl Mater Interfaces 5:898–910

Gu H, Tadakamalla S, Zhang X, Huang Y, Jiang Y, Colorado HA, Luo Z, Wei S, Guo Z (2013) Epoxy resin nanosuspensions and reinforced nanocomposites from polyaniline stabilized multi-walled carbon nanotubes. J Mater Chem C 1:729–743

Gu H, Tadakamalla S, Huang Y, Colorado HA, Luo Z, Haldolaarachchige N, Young DP, Wei S, Guo Z (2012) Polyaniline stabilized magnetite nanoparticles reinforced epoxy nanocomposites. ACS Appl Mater Interfaces 4:5613–5624

Zhu J, Wei S, Ryu J, Sun L, Luo Z, Guo Z (2010) Magnetic epoxy resin nanocomposites reinforced with core-shell structured Fe@FeO nanoparticles: fabrication and property analysis. ACS Appl Mater Interfaces 2:2100–2107

Zhu J, Wei S, Ryu J, Budhathoki M, Liang G, Guo Z (2010) In-situ stabilized carbon nanofibers (CNFs) reinforced epoxy nanocomposites. J Mater Chem 20:4937–4948

Wetzel B, Haupert E, Friedrich K, Zhang MQ, Rong MZ (2002) Impact and wear resistance of polymer nanocomposites at low filler content. Polym Eng Sci 42:1919–1927

Naganuma T, Kagawa Y (2002) Effect of particle size on the optically transparent nano meter-order glass particle-dispersed epoxy matrix composites. Compos Sci Technol 62:1187–1189

Frisch HL, Mark JE (1996) Nanocomposites prepared by threading polymer chains through zeolites, mesoporous silica, or silica nanotubes. Chem Mater 8:1735–1738

Park J, Jana SC (2003) Effect of plasticization of epoxy networks by organic modifier on exfoliation of nanoclay. Macromolecules 36:8391–8397

Akatsuka M, Takezawa Y, Amagi S (2001) Influences of inorganic fillers on curing reactions of epoxy resins initiated with a boron trifluoride amine complex. Polymer 42:3003–3007

Derakhshan AA, Rajabi L (2012) Review on applications of carboxylate–alumoxane nanostructures. Powder Technol 226:117–129

Derakhshan AA, Rajabi L, Karimnezhad H (2012) Morphology and production mechanism of the functionalized carboxylate alumoxane micro and nanostructures. Powder Technol 225:156–166

Rajabi L, Derakhshan AA (2010) Room temperature synthesis of boehmite and crystallization of nanoparticles: effect of concentration and ultrasound. Sci Adv Mater 2:163–172

Vogelson CT, Koide Y, Alemany LB, Barron AR (2000) Inorganic-organic hybrid and composite resin materials using carboxylate-alumoxanes as functionalized cross-linking agents. Chem Mater 12:795–804

Siparsky G, Luebben S (1998) Non-skid, non-flammable coating for navy applications. Report. TDA Research, Wheat Ridge

Wetzel B, Haupert F, Zhang MQ (2003) Epoxy nanocomposites with high mechanical and tribological performance. Compos Sci Technol 63:2055–2067

Zhang H, Tang LC, Zhang Z, Friedrich K, Sprenger S (2008) Fracture behaviours of in situ silica nanoparticle-filled epoxy at different temperatures. Polymer 49:3816–3825

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajabi, L., Marzban, M. & Derakhshan, A.A. Epoxy/alumoxane and epoxy/boehmite nanocomposites: cure behavior, thermal stability, hardness and fracture surface morphology. Iran Polym J 23, 203–215 (2014). https://doi.org/10.1007/s13726-013-0216-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-013-0216-5