Abstract

Biochar has been reported to improve soil fertility and growing medium performance. However, the role that biochar plays in plant nutrition is not completely understood, especially in plants grown under nutritional stress. Recent research indicates that the addition of biochar increases produce yield of tomato grown under salinity stress and drought; however, little information is available about the effects of biochar on fruit quality parameters. The use of biochar as a growth substrate in an intensive greenhouse cropping system may have the capacity of replacing non-renewable and less sustainable growing media like peat and in addition being a strategy to optimize chemical fertilisation. This work aimed to investigate the effects of biochar, as a potential candidate to replace peat, on tomato growing in soilless conditions under nutritional stress. Plant biomass accumulation, leaf fluorescence and chlorophyll, fruit yield and fruit quality parameters were measured as performance indicators. Biochar increased the green biomass, but it did not significantly affect yield or most quality parameters, apart from potassium content in ripe fruits. These results suggest that biochar has great potential as a peat alternative material and plant growth promoter, but no ability to improve tomato yield, under nutritional stress.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Tomato is one of the most cultivated and consumed vegetables in the world, and its rate of cultivation and consumption has been continuously increasing over the last past decades (FAOSTAT 2019). The high annual per capita consumption of tomato is considerably higher than that of other vegetables, and the reason mainly lies in its beneficial effects on human health (Frusciante et al. 2007; Martí et al. 2016). Tomato fruits are important sources of vitamins, minerals, and natural antioxidants, including ascorbic acid, carotenoids and, particularly, lycopene and phenolic compounds (Bahonar et al. 2017). The content of these bioactive compounds depends on genetic, agronomic and environmental factors, such as cultivar, harvest time and method, fertilisation, cropping system, soil/growing medium characteristics and climate (Ciaccheri et al. 2018; Dumas et al. 2003; Rouphael et al. 2018; Toor et al. 2006).

Tomato grows optimally in both the field and greenhouse, achieving maximum production levels in soilless culture. In intensive cultivation systems, the supply of inorganic nutrients at high rates is one of the most effective and common practices to achieve high produce yield (De Pascale et al. 2018; Lao and Jiménez 2004). Many strategies have been developed in recent years to optimize chemical fertiliser application and management within tomato production systems (Le Bot et al. 2001; Massa et al. 2010). Some works showed that the use of organic amendments—such as manure, compost and green manures, and organic fertilisers—in soil and potting media can improve soil physical properties and biological characteristics (Celik et al. 2004; Marinari et al. 2000).

The use of biochar as growing medium has been proposed as a possible strategy to support a more sustainable production of different greenhouse crops (Dunlop et al. 2015; Fascella et al. 2018). Biochar is a carbon-rich material obtained from thermochemical conversion of biomass in an oxygen-limited environment. Biochar is a material with high porous structure, large surface area and high ion-exchange and water holding capacities (Atkinson et al. 2010; Sohi et al. 2010) that can change with time due to degradation phenomena (Liu et al. 2013). Although many previous studies have highlighted the effects of biochar on crop yield and soil fertility, the results are currently not conclusive under greenhouse or field environments. The reports are variable, showing no significant differences in crop yield or quality, or soil quality (Jeffery et al. 2011; Mukherjee and Lal 2014; Subedi et al. 2017). The heterogeneity of “biochar-crop system” responses depends on several factors, such as: (1) type of raw organic materials and temperature conditions in the pyrolysis process that the final biochar properties and characteristics depend on; (2) soil characteristics; (3) environmental conditions; (4) strategy of biochar application; (5) cultivated species.

Interestingly, the use of biochar as a growth medium for soilless cultivation appears to offer a concrete opportunity to increase the economic and environmental sustainability of these intensive cropping systems through the replacement of non-renewable materials like peat moss. In soilless culture, in fact, the root zone can be precisely controlled in terms of physico-chemical composition and nutrient and irrigation management, thus limiting the many interactions that occur in the root zone of open-field soil cultivation. Indeed, the use of biochar is a strategy worth pursuing for the valorisation of waste from the perspective of circular horticulture (Dunlop et al. 2015).

The main objectives of this work were to evaluate biochar produced from poplar as a growing medium for soilless tomato production and to study the effects of biochar on produce yield and the quality of plants grown under normal and limiting nutrient conditions.

2 Materials and methods

2.1 Growing media, nutrient solutions and treatments

The experimental treatments consisted of two substrate mixtures tested with two different nutrient solutions. Plants were grown in the P (peat) substrate composed of brown peat (H 4–5) and pumice (peat:pumice, 50:50 v/v) or in the PB (peat and biochar) substrate composed of brown peat (H 4–5) pumice and biochar (peat:pumice:biochar, 40:40:20 v/v).

Biochar was obtained from poplar (Populus spp.) wood chips cultivated in a short-rotation forest in northern Italy (Po Valley, Gadesco Pieve Delmona (CR), Lombardy, 458100 1300 N, 108060 0100E). The forestry harvest age was 5 years. The AGT (Advanced Gasification Technology, Arosio, Italy) gasification process was applied. Briefly, feedstock thermal conversion into syngas and biochar (10% initial biomass) was obtained at 1200 °C and atmospheric pressure after a period of 30–40 min of permanence in the reactor. Routine analyses for poplar biochar characterization are reported in Table 1.

In both P and PB substrates, plants were fed with a standard nutrient solution (i.e., close to nutrient concentrations commonly adopted for the cultivation of soilless tomato), or a nutrient solution with reduced concentration of macronutrients. The first nutrient solution for the standard fertilisation (SF) was: N-NO3 12.5 mmol L−1, N-NH4 0.5 mmol L−1, P–PO4 1.0 mmol L−1, K 7.5 mmol L−1, Ca 4.5 mmol L−1, Mg 1.5 mmol L−1, Na 0.9 mmol L−1, S–SO4 2.9 mmol L−1, Cl− 0.8 mmol L−1, Fe 15 µmol L−1, B 20 mol L−1, Cu 1 mol L−1, Zn 5 mol L−1, Mn 10 mol L−1, Mo 1 mol L−1. The second nutrient solution for the low fertilisation (LF) was calculated with the intent of inducing a nutritional stress and obtained by adding 1/3 the quantity of salts (only for macronutrients) as that used for the SF solution to irrigation water. Therefore, the nominal nutrient concentration of the LF solution was: N-NO3 4.3 mmol L−1, N-NH4 0.2 mmol L−1, P–PO4 0.3 mmol L−1, K 2.6 mmol L−1, Ca 1.8 mmol L−1, Mg 0.6 mmol L−1, S–SO4 1.0 mmol L−1, with no variation regarding saline ions (i.e., Na and Cl) or micronutrients. Nominal electrical conductivity (EC) was 2.18 dS m−1 for SF and 1.00 dS m−1 for LF. In both nutrient solutions, bicarbonates were neutralized using sulphuric acid with the aim of preserving 1 mol m−3 of HCO3; this allowed for the maintenance of stable pH with a target value of 5.6. Under operational conditions, mean EC values —calculated by measurements collected twice per week at the dripper— averaged 2.17 dS m−1 for SF and 0.97 dS m−1 for LF with coefficients of variation of 6.0% and 6.5%, respectively. The same criterion was used for monitoring pH that averaged 5.79 for SF and 5.72 for LF with coefficients of variation of 7.1% and 7.6%, respectively.

The different substrate mixtures and nutrient solutions were then combined to obtain the following treatments: (1) SFP, in which plants were fed with standard fertilisation (SF) and grown in the P substrate; (2) SFPB, in which plants were fed with standard fertilisation (SF) and grown in the PB substrate; (3) LFP, in which plants were fed with low fertilisation (LF) and grown in the P substrate; (4) LFPB, in which plants were fed with low fertilisation (LF) and grown in the PB substrate.

2.2 Greenhouse experiment and growing conditions

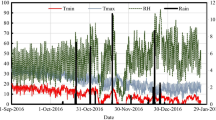

The experiment took place at the CREA Research Centre for Vegetable and Ornamental Crops, Council for Agricultural Research and Economics, Pescia (PT), Tuscany, Italy (lat. 43° 54′ N, long. 10° 42′ E) during the summer–autumn period of 2014. Plants were grown in a typical Mediterranean plastic greenhouse where a minimum air temperature of 9 °C was maintained by the internal heating system. Radiation, relative humidity, and air temperature were monitored over the whole experimental period by a portable data logger (Decagon Em50; Decagon Devices Inc., USA). Mean daily-averaged photosynthetic active radiation and accumulated daily global radiation were 136.7 µmol m−2 s−1 and 651.9 MJ m−2, respectively. Minimum, mean and maximum daily air temperature was 9.1, 20.2 and 41.5 °C, respectively. Air mean daily relative humidity averaged 80.2%.

Tomato plants (Solanum lycopersicum L., cv. Bodar F1) were transplanted on 11 August 2014 at the 5–6 true-leaf stage into plastic pots (24 Ø, 9.5 L) filled with the different substrate mixtures. Ten pots per replicate were arranged in a randomized complete block design with three replications per treatment for a total of 30 plants per treatment and a crop density of 3.3 plants/m2.

Nutrient solution treatments initiated 7 days after transplanting (DAT). The following expedients were adopted to prevent salt accumulation in SF or excessive depletion in LF treatments and to keep root zone conditions as close to the nutrient treatments as possible: (1) high irrigation frequency was imposed using FDR sensors (SM200; Delta-T Device, Cambridge, UK), which triggered irrigation automatically when roughly 1/3 of the easily available water (0.4 over 1.2 L/pot) was evapotranspirated from the pot; (2) high leaching fraction for each irrigation event (i.e. 25–30%); (3) highly homogeneous water distribution along the root zone profile using three drippers per pot.

Pots were placed on the ground and plants grown vertically (single stem). During the cultivation, auxiliary shoots were removed and weighed separately for each replicate. Each truss was pruned with the aim of having a target number of five fruits per truss. Flower pollination was facilitated using an electronic bee. The number of trusses was limited to five after top cutting at 65 DAT. All leaves below the first truss were removed after harvesting at 70 DAT and the same procedure was adopted for the second truss at 101 DAT. The greenhouse experiment lasted 126 DAT and concluded with a final destructive analysis.

2.3 Plant biomass analyses

All plant material removed from the cultivation systems was weighed (fresh and dry weight) and considered for the calculation of total (aboveground) biomass. During the cultivation, the following biometric parameters were measured: (1) plant height and node number on three plants per replicate twice per week; (2) leaf area index (LAI) by Accupar LP-80 ceptometer (Decagon Devices Inc., USA) for seven different periods (roughly once every 2 weeks). The latter measurements were carried out reading 10 different points per replicate, below the canopy, beside each plant and behind two plants for a total of 30 measurements per treatment.

Fruits were harvested twice per week at commercial maturity following the criteria proposed by the United States Department of Agriculture (2°–3° USDA colour class) and weighed for yield determination. Number and weight of marketable and unmarketable (i.e., small fruits < 60 g and fruits with cracking or blossom-end rot) fruit yield were determined for each truss. A sub-sample of five fruits, separated by truss and replicate, were dried (in a forced-air oven at 75 °C to constant weight) to determine dry biomass accumulated with fruits.

At the end of the experiment, the total biomass of each plant was determined while a destructive plant analysis was carried out on three plants per replicate to determine tissue partitioning. Each plant was then divided into stems, rachides and leaves; the latter were also used to determine leaf area using a leaf area meter (WinDIAS Image Analysis System, Delta-T Devices, UK). Finally, each organ was weighed and dried in a forced-air oven at 75 °C to a constant weight to determine the dry matter percentage.

2.4 Phenological and physiological analyses

Plant phenology was monitored twice per week by recording the following parameters of each truss of three plants per replicate: (1) first and last (fifth) flower opening; (2) first and last (fifth) fruit set.

Leaf chlorophyll was indirectly evaluated using a portable SPAD meter (SPAD-502, Konica Minolta, Chiyoda, Japan) at 30, 45, 60, 75, 90, 105 and 120 DAT; nine healthy leaves from the bottom to the top of the plant were measured on five plants per replicate for a total of 135 measurements per treatment. At 120 DAT, chlorophyll fluorescence was measured with a Handy-PEA (Hansatech, King’s Lynn, United Kingdom). A fixed area of each leaf was illuminated with continuous light (650 nm peak wavelength, 3500 µmol photons m−2 s−1 light intensity) provided by LEDs. Each chlorophyll fluorescence induction curve was analysed using BiolyzerHP3 software in accordance with the so-called JIP-test (Strasser and Strasser 1995). The following parameters were calculated from the fluorescence measurements: (1) minimum fluorescence yield (F0 at 50 μs); (2) maximum fluorescence yield (Fm); (3) initial slope at the beginning of the variable fluorescence (Mo = 4·(F300 μs − F0)/(Fm − F0)); (4) net rate of the reaction centre closure; and (5) variable fluorescence at phase J (VJ = (FJ-F0)/(Fm-F0)), considered a good indicator of the PQ-pool redox state. The following flux ratios and parameters were calculated: (1) maximum quantum yield of PSII for primary photochemistry (Fv/Fm); (2) probability that a trapped photon, which triggers the reduction of QA to QA-, could move an electron further than QA—into the electron transport chain (ψ0 = 1 − VJ); and (3) the quantum yield of electron transport (φE0 = Fv/Fm·ψ0).

2.5 Fruit quality analyses

Trusses 1–2 and 3–4 were harvested, sub-samples of fruits at the full maturity stage (6° USDA colour class of maturity) were collected to determine fruit chemical characteristics. One fruit per truss of five plants per replicate was collected and slices from different fruits were put in a mixer. Part of the fruit was analysed immediately. In this case, the collected samples were centrifuged (10 min at 5000 rpm) and the supernatant solution analysed for pH, EC, total soluble solids (°Brix, by a portable refractometer), K concentration (by a Shimadzu AAA7000 atomic absorption spectroscope, Kyoto, Japan) and NO3 concentration according to Cataldo et al. (1975); finally, total acidity (g 100 mL−1 of citric acid) was determined through titration with NaOH 0.1 N in the presence of phenolphthalein.

The remaining part of the collected fruits was lyophilised (ALPHA 1–4 LD freeze dryer; Martin Christ, Osterode am Harz, Germany), homogenised and frozen at 80 °C prior to subsequent analyses. Total phenolics (TP) were extracted according to Petruccelli et al. (2015). The TP assay was performed using the Folin–Ciocalteu reagent as described by Luthria et al. (2006). Results were expressed as mg gallic acid equivalent (GAE) 100 g−1 lyophilized tomato powder. Standards of gallic acid and all reagents used were from Sigma (St. Louis, MO, USA). Flavonoids were extracted according to Dinelli et al. (2006). The content of total flavonoids was determined according to Lung et al. (2013) using rutin as the reference compound.

Total carotenoids were extracted from lyophilized tomato powder in a hexane:ethanol:acetone (2:1:1 v/v) mixture according to Olives Barba et al. (2006). Extracts were suspended in 2 mL of methanol and injected directly into a high-performance liquid chromatograph (HPLC) for analysis. The concentrations of individual carotenoids were assessed using a reversed-phase Beckman System Gold HPLC (module 125 solvent) equipped with a diode-array detector, model 168 Nouveau (Beckman Coulter Inc.), with a Luna C8 column (Phenomenex, Torrance, CA, USA), according to Van Heukelem and Thomas (2001). The peak identification and subsequent quantification of β-carotene, lycopene and lutein was achieved using the standard curve for each compound and their molar absorptivity coefficient. The carotenoid content was reported as mg per 100 g sample on a dry-weight basis. HPLC-grade extraction solvents were purchased from Sigma.

The free radical scavenging activity, measured using the 1,1 diphenyl-2-picryl-hydrazil (DPPH), was determined for tomato samples using the method proposed by Brand-Williams et al. (1995). Radical scavenging activity was calculated by the percentage of DPPH that was scavenged using the following formula: percent reduction = [(AB − AE)/AB] × 100, where AB is the absorbance of the blank sample and AE is the absorbance of the fruit extracts. The EC50 (effective concentration) values, defined as the amount of antioxidant required to scavenge a DPPH radical by 50%, were calculated from the results.

Each analysis was performed in triplicate. Only reagents from Sigma Aldrich were used for fruit analyses.

2.6 Statistics

The experiment was carried out in a randomized complete block design. Collected data were analysed by one-way ANOVA, using the GLM univariate procedure, to assess significant (p ≤ 0.05, 0.01 and 0.001) differences among treatments. Mean values were then separated by LSD multiple-range test (p = 0.05). Statistics and graphics were supported by the programs Statgraphics Centurion XV (Stat Point, Inc., Herndon, VA, USA) and Prism 5 (GraphPad Software, Inc., La Jolla, California USA).

3 Results

3.1 Plant growth and biomass accumulation

Table 2 reports data collected on plant growth and development as determined during the cultivation cycle, through non-destructive methods, or in the final destructive analysis. Plant height and number of nodes measured at 65 DAT did not show any effect related to the presence of biochar in the growing medium, while both the above parameters were negatively affected by the reduced nutrient concentration in the nutrient solution (− 12.5% plant height and − 10.0% number of nodes). After 65 DAT, plants were trimmed to standardize the production at 5 trusses. Plant phenological monitoring, which consisted of recording the first and last (fifth) flower opening and first and last (fifth) fruit set, did not show any difference among treatments (data not shown).

All other parameters reported in Table 2 were enhanced by the presence of biochar in the potting mixtures except for the specific leaf area that was reduced in LFPB plants compared with the other treatments (− 13.8%). Measurements performed on tomato leaf area index (LAI) (Fig. 1) at successive growth stages revealed that LAI increased at a higher rate in plants grown with high nutrient concentration and biochar in the root zone compared with those grown with low fertilisation and peat control mixtures. The trends of data reported in Fig. 1 were supported by the estimation of LAI averaged over the whole crop cycle (Table 2); LF treatments reduced LAI by an average of 26.0% with respect to SF treatments, while PB treatments led to values 12.3% higher than P treatments. Tomato plants grown in the substrates containing biochar showed the highest LAI and total accumulated (i.e., aboveground) dry weight at the end of the experiment (Table 2). In particular, the LFPB treatment performed at the same level (not significantly different) as tomato grown with standard nutrient solution in SFP and SFPB treatments.

Leaf area index (LAI) measured during the cultivation cycle in tomato plants grown with standard fertilization in combination with the peat-pumice substrate (SFP) or in presence of biochar (SFPB), and low fertilization in combination with the peat-pumice substrate (LFP) or in presence of biochar (LFPB). Measurements are from non-destructive analysis carried out by Accupar LP-80 ceptometer, except for the first and last points determined through destructive analysis (see materials and methods for details). The first and second arrow show plant defoliation below the first and second truss, respectively, after harvesting. Points represent the average of replicates; mean standard deviation of measurements is reported in the top right side of the figure to avoid line overlapping

In summary, the total (aboveground) dry weight of tomatoes ranged from 351 to 516 g m−2 (Table 2). However, the addition of biochar only had positive effects on the vegetative organs of the plants, but not on fruit dry weight accumulation (Fig. 2). Figure 2 shows the plant dry weight partitioning of tomatoes as determined at the final destructive analysis. Leaf and stem biomass were greater in plants grown in the substrate containing biochar and significantly reduced only in plants fed with low nutrient concentration and grown in the peat control substrate (LFP). Total fruit dry weight was instead affected by nutrient solution concentration but not by the presence of the biochar (Fig. 2).

Biomass production determined in tomato plants grown with standard fertilization in combination with the peat-pumice substrate (SFP) or in presence of biochar (SFPB), and low fertilization in combination with the peat-pumice substrate (LFP) or in presence of biochar (LFPB). Biomass partitioning is reported in terms of dry weight of stems (dark grey), leaves removed by defoliation below the first and second truss (light grey), leaves at the end of the experiment (white), and total fruit (dotted white). Values are means of three replicates. Error bars represent the standard deviation for the total aboveground biomass accumulated at the end of the experiment. Statistical analysis was performed through one-way ANOVA; different letters within columns indicate significant differences for the same parameter according to LSD test (p = 0.05)

3.2 SPAD chlorophyll and leaf fluorescence

The experimental data collected for leaf chlorophyll and chlorophyll fluorescence are reported in Table 3. Low fertilisation rates (LFP and LFPB) significantly reduced SPAD chlorophyll compared with plants receiving the standard nutrient solution (SFP and SFPB). Neither the presence of biochar in the root zone nor different nutritional regimes had effects on the photosystem. In fact, none of the fluorescence parameters reported in Table 3 were significantly influenced by the different treatments, suggesting no damage to the photosynthetic apparatus.

3.3 Fruit yield and quality

Table 4 reports tomato yield accumulated at end of the cultivation period. The impact of biochar on harvested fruit was not significant. Total and marketable fruit yield were greater within standard fertilisation (SF) treatments compared with the low-fertilised plants with or without biochar addition. Low fertilisation led to a significant reduction of 16.1%, on average, in terms of total fresh weight, but not number of fruits compared with SF treatments. Mean fruit weight of LF plants was lower compared with fruits from the standard fertilisation but only in the LFP treatment (− 10.7%, on average), while the presence of biochar in the LFPB treatment led to yields no different from those of well-fertilised plants. Unmarketable yield was not significantly different among treatments and was composed of roughly 70% small fruits (i.e., < 60 g) and 30% fruits with cracking or blossom-end rot (data not shown).

Table 5 reports the quality parameters of ripe fruit collected from trusses 1–2 and 3–4 at harvest. The results did not show any difference in juice electrical conductivity, soluble solids (°Brix), pH, or nitrate concentration. The higher nutrient concentration in the root zone led to an increase in fruit dry matter percentage (5.8%) and total acidity (14.0%), but no effect was observed due to the presence of biochar in the growing medium. The taste index, calculated by combining °Brix and total acidity, did not significantly differ among the different treatments and ranged 0.82–0.85 (data not shown). The presence of biochar in the root zone enhanced K accumulation in tomato fruits compared with the peat control substrates; therefore, SFPB ranked first for K concentration, followed by LFPB and SFP, which performed at the same level.

The impact of the different treatments on secondary metabolites is summarized in Table 6. The higher nutrient concentration in the root zone led to a significant increase in total phenols, flavonoids, and lycopene, while β-carotene and lutein in tomato fruits did not vary among the different treatments. Total phenols values ranged from 3.51 mg GAE g−1 DW to 3.24 mg GAE g−1 DW, and lycopene contents were 20.8 mg 100 g−1 DW and 17.1 mg 100 g−1 DW in SFP and LFPB, respectively; the highest data variability was, however, observed for total flavonoids in the range of 0.79–1.85 mg RE d−1 DW. In general, the presence of biochar in the substrate had no effect on the accumulation of the compounds reported in Table 6 except for lycopene, which was reduced in the LFPB treatment.

4 Discussion

The growing conditions imposed on tomato plants in soilless culture induced a significant nutritional stress in plants fertirrigated with low concentrations of nutrients. Plants grown in the control substrate thus showed reduced biomass accumulation, plant development rate and yield when fed with nutrient solution containing a limited concentration of essential nutrients in the LFP treatment. In the present work, the above result supported the hypothesis that LF treatments caused a reduction in nutrient concentration in the root zone, which was apt to induce nutrient deficiency and, therefore, subnormal growing conditions. The negative effects of reduced fertiliser supply on agricultural crops are well known since mineral nutrients are essential for most bio-metabolic and physiological functions in plants (Marschner 2011). Symptoms like reduced LAI, plant height, biomass accumulation, tissues nutrient content, leaf chlorophyll content (namely SPAD index in the present work), and produce yield and quality were found relating to tomato crops with limited nutrient availability (Le Bot et al. 2001; Papadopoulos 1991; Passam et al. 2007; Tabatabaie et al. 2004). Most of the above effects were consistent with the results collected in the present work that compared SFP with LFP treatments. Although a severe stress was induced, no permanent damage to the leaf photosystem were observed, which revealed that the low nutrient concentration in the root zone limited plant performance without having permanent detrimental effects on the photosynthesis machinery.

Notwithstanding the reduced fertiliser supply, plants grown in the presence of biochar in the LFPB treatment showed increased biomass accumulation capacity, thereby performing at the same levels as well-fertilised plants. The better performance in terms of total (i.e., aboveground) biomass accumulation was also confirmed in the SFPB that ranked first compared with SFP. The above results agreed with Hossain et al. (2010)—the authors observed better performance (maximum plant height and dry weight) of tomato plants grown in soil when biochar was applied in combination with the fertiliser. The same biomass increase was observed for tomato plants when pine bark was replaced by biochar up to 40% in the growing medium (Choi et al. 2018). In the present work, biochar was tested in soilless conditions. Considering the chemical characteristics of the tested biochar (Petruccelli et al. 2015), its addition to the root zone led to more nutrients potentially available to the crop than in the peat control treatments. The amount of total nutrients delivered to the crop by fertirrigation was compared in this work with the possible nutrient contribution given by biochar addition. The above calculation led to the conclusion that the presence of biochar could nominally increase the availability of nutrients by 1.2 folds in SF treatments and 1.5 folds in LF treatments with minimal or no variation in total mineral N (N-NO3 + N-NH4), Ca and Mg, and larger variations in P and K. This extra budget of nutrients could be, at least partially, used in strategies to reduce the input of mineral fertilisers in container-grown plants.

Further reasons for the better tomato performance, in terms of biomass accumulation, likely lie in the positive interaction between biochar and plant nutrition, based on what was proposed in previous works with vegetable and ornamental crops (Chan et al. 2007; Graber et al. 2010; Agegnehu et al. 2017). In previous researches, the ameliorative action of biochar was found to be a consequence of a potential extra nutrient budget (Hossain et al. 2010; Vaccari et al. 2015) and/or indirect consequence of the improved physico-chemical (Liang et al. 2006; Chan et al. 2007; Rondon et al. 2007) and microbiological (Graber et al. 2010) characteristics of the root zone (Agegnehu et al. 2017).

Although remarkable, the higher biomass accumulation found in biochar-grown plants did not lead to enhanced yield. In fact, plants grown in biochar media showed a different organ partitioning trend compared with the peat control treatments that favoured the development of vegetative organs instead of fruit biomass accumulation. Similar results were previously reported for processing tomato grown in open field (Vaccari et al. 2015) and greenhouse (Graber et al. 2010) conditions with the addition of biochar in the root zone. It has been demonstrated that the increase in excess vegetative organs in tomato plants does not necessarily lead to higher yield (Heuvelink 1999). In fact, an unbalanced source/sink ratio can occur between vegetative and reproductive organs when the development of the former is stimulated. To this purpose, Kim et al. (2014) showed how the adoption of specific strategies for leaf removal can lead to higher yields in tomato crop.

The trends observed for produce yield were comparable to those observed for fruit quality. Most of the analysed parameters were in fact enhanced by the greater nutrient concentration in the root zone, while no effect was induced by the presence of biochar. Tomato plants generally react to environmental stress by accumulating protective molecules such as antioxidant compounds. In this case, the main driving variable behind the effects was likely the higher EC in the SF (2.17 dS m−1) with respect to LF treatments (0.97 dS m−1). Higher dry matter percentage, acidity, and content of antioxidant compounds in fruits are all well documented effects in tomatoes grown at increasing EC levels (Cuartero and Fernández-Muñoz 1999; Dorais et al. 2001; Dumas et al. 2003). However, the content of antioxidant compounds in tomato fruits was also found to increase when there was higher nutrient availability in the root zone (Montagu and Goh 1990). The only parameter that was positively related to both biochar application and nutrient concentration in the supplied nutrients was K content in tomato fruit. Potassium is a key element in human nutrition, and the role of vegetable crops for the assumption of this mineral is of primary importance in the diets of human beings and animals (Römheld and Kirkby 2010). Nonetheless, K nutrition is also fundamental for any plant species due to its key role in many metabolism processes; thus, the increased availability of this element in the root zone can be positively related to higher photosynthetic rate, leaf expansion, plant growth, and biomass accumulation (Römheld and Kirkby 2010), all of which were observed in this work for biochar-treated plants.

In previous studies, biochar application was found to improve the yield of vegetable crops (Chan et al. 2007; Hossain et al. 2010; Carter et al. 2013; Dunlop et al. 2015), including tomato (Nzanza et al. 2012; Vaccari et al. 2015). However, heterogenous scenarios—both increases and decreases, as well as no significant change—in produce yield and quality are also reported in the literature (Chan et al. 2007; Deenik et al. 2010; Mukherjee and Lal 2014; Dunlop et al. 2015; Subedi et al. 2017). Several mechanisms have been suggested to explain the positive and negative effects of biochar on crop growth and production, varying from chemical fertility (Vaccari et al. 2015; Li et al. 2018) to macro- and micro-nutrient immobilization (Subedi et al. 2017). The variability in the results is due to differences in cropping systems, climate conditions and biochar type that can differ heavily depending on raw material and processing (Keiluweit et al. 2010). Petruccelli et al. (2015), using biochar obtained from different feedstock (i.e., poplar wood chips, solid olive residues and wheat straw), observed that only poplar biochar was effective in improving fruit development of processing-type tomatoes while wheat straw biochar and olive residues biochar yielded negative effects on plant growth. Suthar et al. (2018) showed that the pyrolysis temperature induced changes in biochar properties that, in turn, could improve tomato growth and fruit quality. The authors highlighted that tomatoes grown in substrate amended with biochar produced at lower temperature had the largest growth index and potentially higher nutritional value. Based on what was observed in this work for tomato plants, the use of biochar indeed appears to be a valuable strategy for improving crop yield of leafy more than fruit vegetables, as is also highlighted by previous authors (Carter et al. 2013; Awad et al. 2017).

To the best of our knowledge, there are no previous works reporting the effects of biochar on the yield of fresh-market tomato grown in a soilless culture under limiting nutrient conditions. For soilless cultures, the choice of the correct growing medium is fundamental to reducing environmental impact since the spent substrates must be disposed of after use. Moreover, the production of many growing media highly impacts non-renewable (in the short-medium period) ecosystems, as in the case for peatlands. Biochar, however, is an industrial refuse that could be exploited as growing media and then landfilled after use. Replacing peat or other growing media with biochar appears to be a sustainable practice, in accordance with the concept of circular production chains in horticultural production.

Change history

29 October 2019

The original version of this article unfortunately contained a mistake. The first and last names of all authors were interchanged; the corrected author list is given above. The original article has been corrected.

References

Agegnehu G, Srivastava AK, Bird MI (2017) The role of biochar and biochar-compost in improving soil quality and crop performance: a review. Appl Soil Ecol 119:156–170. https://doi.org/10.1016/j.apsoil.2017.06.008

Atkinson CJ, Fitzgerald JD, Hipps NA (2010) Potential mechanisms for achieving agricultural benefits from biochar application to temperate soils: a review. Plant Soil 337:1–18. https://doi.org/10.1007/s11104-010-0464-5

Awad YM, Lee SE, Ahmed MBM, Vu NT, Farooq M, Kim IS, Kim HS, Vithanage M, Usman ARA, Al-Wabel M, Meers E, Kwon EE, Ok YS (2017) Biochar, a potential hydroponic growth substrate, enhances the nutritional status and growth of leafy vegetables. J Clean Prod 156:581–588. https://doi.org/10.1016/j.jclepro.2017.04.070

Bahonar A, Saadatnia M, Khorvash F, Maracy M, Khosravi A (2017) Carotenoids as potential antioxidant agents in stroke prevention: a systematic review. Int J Prevent Med 8:6–12. https://doi.org/10.4103/ijpvm.IJPVM_112_17

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28:25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Carter S, Shackley S, Sohi S, Suy TB, Haefele S (2013) The impact of biochar application on soil properties and plant growth of pot grown lettuce (Lactuca sativa) and cabbage (Brassica chinensis). Agronomy 3:404–418. https://doi.org/10.3390/agronomy3020404

Cataldo DA, Haroon M, Schrader LE, Youngs VL (1975) Rapid colorimetric determination of nitrate in plant-tissue by nitration of salicylic-acid. Commun Soil Sci Plant Anal 6:71–80

Celik I, Ortas I, Kilic S (2004) Effects of compost, mycorrhiza, manure and fertilizer on some physical properties of a Chromoxerert soil. Soil Tillage Res 78:59–67. https://doi.org/10.1016/j.still.2004.02.012

Chan KY, Van Zwieten L, Meszaros I, Downie A, Joseph S (2007) Agronomic values of greenwaste biochar as a soil amendment. Soil Res 45:629–634

Choi H-S, Zhao Y, Dou H, Cai X, Gu M, Yu F (2018) Effects of biochar mixtures with pine-bark based substrates on growth and development of horticultural crops. Hortic Environ Biotechnol 59:345–354. https://doi.org/10.1007/s13580-018-0035-x

Ciaccheri L, Tuccio L, Mencaglia AA, Sikorska-Zimny K, Hallmann E, Kowalski A, Mignani AG, Kaniszewski S, Agati G (2018) Prediction models for assessing lycopene in open-field cultivated tomatoes by means of a portable reflectance sensor: cultivar and growing-season effects. J Agric Food Chem 66:4748–4757. https://doi.org/10.1021/acs.jafc.8b01570

Cuartero J, Fernández-Muñoz R (1999) Tomato and salinity. Sci Hortic 78:83–125. https://doi.org/10.1016/S0304-4238(98)00191-5

De Pascale S, Rouphael Y, Gallardo M, Thompson RB (2018) Water and fertilization management of vegetables: state of art and future challenges. Eur J Hortic Sci 83:306–318. https://doi.org/10.17660/eJHS.2018/83.5.4

Deenik JL, McClellan T, Uehara G, Antal MJ, Campbell S (2010) Charcoal volatile matter content influences plant growth and soil nitrogen transformations. Soil Sci Soc Am J 74:1259–1270. https://doi.org/10.2136/sssaj2009.0115

Dinelli G, Bonetti A, Minelli M, Marotti I, Catizone P, Mazzanti A (2006) Content of flavonols in Italian bean (Phaseolus vulgaris L.) ecotypes. Food Chem 99:105–114. https://doi.org/10.1016/j.foodchem.2005.07.028

Dorais M, Papadopoulos AP, Gosselin A (2001) Influence of electric conductivity management on greenhouse tomato yield and fruit quality. Agronomie 21:367–383. https://doi.org/10.1051/agro:2001130

Dumas Y, Dadomo M, Di Lucca G, Grolier P (2003) Effects of environmental factors and agricultural techniques on antioxidant content of tomatoes. J Sci Food Agric 83:369–382. https://doi.org/10.1002/jsfa.1370

Dunlop SJ, Arbestain MC, Bishop PA, Wargent JJ (2015) Closing the loop: use of biochar produced from tomato crop green waste as a substrate for soilless, hydroponic tomato production. HortScience 50:1572–1581

FAOSTAT (2019) Tomato world production. http://www.fao.org/faostat/en/#home. Accessed 10 Jan 2019

Fascella G, Mammano MM, D’Angiolillo F, Rouphael Y (2018) Effects of conifer wood biochar as a substrate component on ornamental performance, photosynthetic activity, and mineral composition of potted Rosa rugosa. J Hortic Sci Biotechnol 93:519–528. https://doi.org/10.1080/14620316.2017.1407679

Frusciante L, Carli P, Ercolano MR, Pernice R, Di Matteo A, Fogliano V, Pellegrini N (2007) Antioxidant nutritional quality of tomato. Molr Nutr Food Res 51:609–617. https://doi.org/10.1002/mnfr.200600158

Graber ER, Harel YM, Kolton M, Cytryn E, Silber A, David DR, Tsechansky L, Borenshtein M, Elad Y (2010) Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 337:481–496. https://doi.org/10.1007/s11104-010-0544-6

Heuvelink E (1999) Evaluation of a dynamic simulation model for tomato crop growth and development. Ann Bot 83:413–422. https://doi.org/10.1006/anbo.1998.0832

Hossain MK, Strezov V, Chan KY, Nelson PF (2010) Agronomic properties of wastewater sludge biochar and bioavailability of metals in production of cherry tomato (Lycopersicon esculentum). Chemosphere 78:1167–1171. https://doi.org/10.1016/j.chemosphere.2010.01.009

Jeffery S, Verheijen FGA, van der Velde M, Bastos AC (2011) A quantitative review of the effects of biochar application to soils on crop productivity using meta-analysis. Agric Ecosyst Environ 144:175–187. https://doi.org/10.1016/j.agee.2011.08.015

Keiluweit M, Nico PS, Johnson M, Kleber M (2010) Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ Sci Technol 44:1247–1253. https://doi.org/10.1021/es9031419

Kim SE, Lee MY, Lee MH, Sim SY, Kim YS (2014) Optimal management of tomato leaf pruning in rockwool culture. Hortic Environ Biotechnol 55:445–454. https://doi.org/10.1007/s13580-014-0049-y

Lao MT, Jiménez S (2004) Leaching of nutrients in greenhouse cultivation of tomato crop in the Mediterranean area under different fertirrigation managements. Food Agric Environ 2:370–375

Le Bot J, Jeannequin B, Fabre R (2001) Growth and nitrogen status of soilless tomato plants following nitrate withdrawal from the nutrient solution. Ann Bot 88:361–370. https://doi.org/10.1006/anbo.2001.1467

Li C, Xiong Y, Qu Z, Xu X, Huang Q, Huang G (2018) Impact of biochar addition on soil properties and water-fertilizer productivity of tomato in semi-arid region of Inner Mongolia, China. Geoderma 331:100–108. https://doi.org/10.1016/j.geoderma.2018.06.014

Liang B, Lehmann J, Solomon D, Kinyangi J, Grossman J, O’Neill B, Skjemstad JO, Thies J, Luizão FJ, Petersen J, Neves EG (2006) Black carbon increases cation exchange capacity in soils. Soil Sci Soc Am J 70:1719–1730. https://doi.org/10.2136/sssaj2005.0383

Liu Z, Demisie W, Zhang M (2013) Simulated degradation of biochar and its potential environmental implications. Environ Pollut 179:146–152. https://doi.org/10.1016/j.envpol.2013.04.030

Lung I, Soran ML, Tudoran C, Mǎruţoiu C (2013) Effect of microwave irradiation on polyphenolic compounds from Satureja hortensis L. Cent Eur J Chem 11:535–541. https://doi.org/10.2478/s11532-012-0188-x

Luthria DL, Mukhopadhyay S, Krizek DT (2006) Content of total phenolics and phenolic acids in tomato (Lycopersicon esculentum Mill.) fruits as influenced by cultivar and solar UV radiation. J Food Compos Anal 19:771–777. https://doi.org/10.1016/j.jfca.2006.04.005

Marinari S, Masciandaro G, Ceccanti B, Grego S (2000) Influence of organic and mineral fertilisers on soil biological and physical properties. Bioresour Technol 72:9–17. https://doi.org/10.1016/S0960-8524(99)00094-2

Marschner H (2011) Marschner’s mineral nutrition of higher plants. Academic Press, London

Martí R, Roselló S, Cebolla-Cornejo J (2016) Tomato as a source of carotenoids and polyphenols targeted to cancer prevention. Cancers. https://doi.org/10.3390/cancers8060058

Massa D, Incrocci L, Maggini R, Carmassi G, Campiotti CA, Pardossi A (2010) Strategies to decrease water drainage and nitrate emission from soilless cultures of greenhouse tomato. Agric Water Manag 97:971–980. https://doi.org/10.1016/j.agwat.2010.01.029

Montagu KD, Goh KM (1990) Effects of forms and rates of organic and inorganic nitrogen fertilisers on the yield and some quality indices of tomatoes (Lycopersicon esculentum miller). NZ J Crop Hortic Sci 18:31–37. https://doi.org/10.1080/01140671.1990.10428067

Mukherjee A, Lal R (2014) The biochar dilemma. Soil Res 52:217–230. https://doi.org/10.1071/SR13359

Nzanza B, Marais D, Soundy P (2012) Effect of arbuscular mycorrhizal fungal inoculation and biochar amendment on growth and yield of tomato. Int J Agric Biol 14:965–969

Olives Barba AI, Cámara Hurtado M, Sánchez Mata MC, Fernández Ruiz V, López Sáenz De Tejada M (2006) Application of a UV–Vis detection-HPLC method for a rapid determination of lycopene and β-carotene in vegetables. Food Chem 95:328–336. https://doi.org/10.1016/j.foodchem.2005.02.028

Papadopoulos AP (1991) Growing greenhouse tomatoes in soil and in soilless media. Agriculture and Agri-Food Canada, Ontario

Passam HC, Karapanos IC, Bebeli PJ, Savvas D (2007) A review of recent research on tomato nutrition, breeding and post-harvest technology with reference to fruit quality. Eur J Plant Sci Biotechnol 1:1–21

Petruccelli R, Bonetti A, Traversi ML, Faraloni C, Valagussa M, Pozzi A (2015) Influence of biochar application on nutritional quality of tomato (Lycopersicon esculentum). Crop Pasture Sci 66:747–755. https://doi.org/10.1071/cp14247

Römheld V, Kirkby EA (2010) Research on potassium in agriculture: needs and prospects. Plant Soil 335:155–180. https://doi.org/10.1007/s11104-010-0520-1

Rondon MA, Lehmann J, Ramírez J, Hurtado M (2007) Biological nitrogen fixation by common beans (Phaseolus vulgaris L.) increases with bio-char additions. Biol Fertil Soils 43:699–708. https://doi.org/10.1007/s00374-006-0152-z

Rouphael Y, Kyriacou MC, Petropoulos SA, De Pascale S, Colla G (2018) Improving vegetable quality in controlled environments. Sci Hortic 234:275–289. https://doi.org/10.1016/j.scienta.2018.02.033

Sohi SP, Krull E, Lopez-Capel E, Bol R (2010) A review of biochar and its use and function in soil. Adv Agron 105:47–82

Strasser BJ, Strasser RJ (1995) Measuring fast fluorescence transients to address environmental questions: the JIP-test. In: Mathis P (ed) Photosynthesis: from light to biosphere. Kluwer, The Netherlands, pp 977–980

Subedi R, Bertora C, Zavattaro L, Grignani C (2017) Crop response to soils amended with biochar: expected benefits and unintended risks. Ital J Agron 12:161–173. https://doi.org/10.4081/ija.2017.794

Suthar RG, Wang C, Nunes MCN, Chen J, Sargent SA, Bucklin RA, Gao B (2018) Bamboo biochar pyrolyzed at low temperature improves tomato plant growth and fruit quality. Agriculture. https://doi.org/10.3390/agriculture8100153

Tabatabaie SJ, Gregory PJ, Hadley P (2004) Uneven distribution of nutrients in the root zone affects the incidence of blossom end rot and concentration of calcium and potassium in fruits of tomato. Plant Soil 258:169–178. https://doi.org/10.1023/B:PLSO.0000016548.84566.62

Vaccari FP, Maienza A, Miglietta F, Baronti S, Di Lonardo S, Giagnoni L, Lagomarsino A, Pozzi A, Pusceddu E, Ranieri R, Valboa G, Genesio L (2015) Biochar stimulates plant growth but not fruit yield of processing tomato in a fertile soil. Agric Ecosyst Environ 207:163–170. https://doi.org/10.1016/j.agee.2015.04.015

Van Heukelem L, Thomas CS (2001) Computer-assisted high-performance liquid chromatography method development with applications to the isolation and analysis of phytoplankton pigments. J Chromatogr A 910:31–49. https://doi.org/10.1016/s0378-4347(00)00603-4

Acknowledgements

The authors thank Mr. Paolo Bini for his technical support managing greenhouse equipment.

Author information

Authors and Affiliations

Contributions

Massa Daniele and Petruccelli Raffaella: design and conception of the experiment, part of laboratory analysis and greenhouse samplings, data collection, data analysis and elaboration, manuscript writing; Bonetti Alessandra and Cacini Sonia: fruit laboratory analyses; Faraloni Cecilia and Tuccio Lorenza: physiological analyses; Prisa Domenico: greenhouse sample collection, biometric and phenological measurements, destructive analysis; all authors: materials and methods writing and manuscript revision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Communicated by Young Yeol Cho, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: The first and last names of all authors were interchanged.

Rights and permissions

About this article

Cite this article

Massa, D., Bonetti, A., Cacini, S. et al. Soilless tomato grown under nutritional stress increases green biomass but not yield or quality in presence of biochar as growing medium. Hortic. Environ. Biotechnol. 60, 871–881 (2019). https://doi.org/10.1007/s13580-019-00169-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13580-019-00169-x