Abstract

The purpose of this study was to evaluate the biochar from fast pyrolysis of pine wood mixed with manure compost or vermicompost as a potential container substrate to replace peat moss. Seven biochar substrates were compared to the control (a commercial substrate; 0B) in container cultivation of bell pepper (Capsicum annuum L.): 100% biochar (100B), 90% biochar + 10% manure compost (90B10C; by volume), 80% biochar + 20% manure compost (80B20C), 70% biochar + 30% manure compost (70B30C), 90% biochar + 10% vermicompost (90B10V), 80% biochar + 20% vermicompost (80B20V), and 70% biochar + 30% vermicompost (70B30V). The physical characteristics of the container substrate (total porosity, container capacity, air space, and bulk density) were tested using NCSU porometers. The electrical conductivity (EC) and pH of container substrate leachates were measured according to the pour-through method on 34, 41, 62, and 83 days after planting (DAP). Growth index was measured on 34, 41, 48, 55, 62, 69, 76, and 83 DAP. Leaf SPAD value, net photosynthesis rate, total leaf area, and stem diameter were measured at week 11. Dry weight and yield were measured at the flowering (72 DAP) and harvesting (113 DAP) stages. The control showed the highest container capacity (59.2%) and the lowest air space (14.1%), with the opposite results observed on 100B. Control had pH values within 6.0–7.0 for optimum pepper growth, while container substrates with biochar resulted in a pH less than 6.0 from 41 to 83 DAP. EC in control at 34 DAP was approximately four times greater than values observed on the other substrates. EC of 70B30V slightly increased between 34 and 41 DAP, and the lowest EC was observed on 100B. SPAD value and net photosynthesis rate were the greatest on plants grown in control. The total leaf area, stem diameter, growth index, vegetative (stem + leaf) and flower dry weights, and yield were the highest in control, followed by 70B30V, 80B20V, and 90B10V, with the lowest in 100B.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Peat moss is a highly valued organic substrate for plant growth media over the last 30 years due to its low degradation, high water-holding capacity, cation exchange capacity, and low bulk density (Handreck and Black 2002). However, peat moss is a scarce and largely nonrenewable natural resource as the volume of the global peatland reduces at 0.05% annually. Although use of peat moss is not restricted in the US, peat exploitation has been banned or decreased in the most countries of Western Europe (Alexander et al. 2008) due to the increased cost of transportation and growing environmental concerns (Méndez et al. 2017). The increased greenhouse gas emissions and shrinkage of carbon (C) sink have led to environmental concerns and rising costs for peat moss (Méndez et al. 2017).

Biochar, a fine-grained porous by-product from pyrolysis, a slow-burning process under no or little oxygen, can be regenerated quickly, reducing atmospheric C (Glaser et al. 2002). However, numerous studies reported that biochar has both beneficial and adverse effects on the horticultural crop production due to the different types and means of processing of biochar mixed with various proportions of organic materials (Graber et al. 2010; Bruun et al. 2012; Méndez et al. 2017). Previous research has shown promising results when the biochar was incorporated in conventional container substrates (Gu et al. 2013; Choi et al. 2018; Guo et al. 2018).

Vermicompost, the product of composting using worms, could improve use efficiency of total quantity of carbon (C) and nitrogen (N) mineralized (Ngo et al. 2013; Doan et al. 2015). Similar to vermicompost, manure compost has fine texture, which may compensate the rigid structure of the biochar and improve physical properties of biochar-based substrate. Little information is available for combined effects of vermicompost/manure compost and the biochar manufactured from pine wood on plant growth in containers.

The objectives of this study were to assess the physical properties of the biochar-based substrates mixed with commercial vermicompost or manure compost and the feasibility of these biochar substrates (and proper portion) to replace peat moss in the container cultivation of bell pepper (Capsicum annuum L.).

2 Materials and methods

2.1 Container substrate treatments and plant materials

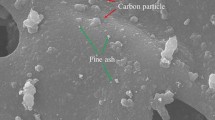

The biochar used in this experiment was the by-product of fast pyrolysis of pine wood at 450 °C (Gu et al. 2013), which was provided by the Department of Agricultural and Biological Engineering at Mississippi State University (Mississippi State, MS, USA). Particle size distribution was determined by passing 100 g of biochar through 2.0-, 1.4-, and 0.59-mm soil sieves, and weight was measured to determine the percentage of each particle size. Particle size distribution of the biochar was 15.7% of > 2.0 mm, 27.3% of 1.4–2.0 mm, 49.1% of 0.6–1.4 mm, and 7.9% of < 0.6 mm. The biochar had an initial pH of 5.4 and electrical conductivity (EC) of 0.2 dS m−1. The C, H, and N elemental compositions of the peat moss and biochar were analyzed by a CE-440 elemental analyzer (Exeter Analytical, Inc., North Chelmsford, MA, USA). C, N, and C:N ratio in the raw materials from the peat moss (Sunshine #1 Mix; Canadian Sphagnum peat moss amended with coarse perlite, starter nutrient charge (with gypsum), and dolomitic limestone; Sun Gro Horticulture Distribution, Inc., Bellevue, WA, USA) were 46%, 0.9%, and 51, respectively. C, N, and C:N ratio in the biochar were 48%, 0.4%, and 120, respectively.

Biochar at high incorporation rates (70, 80, 90, or 100% by volume) was mixed with two commercially available composts. One was manure compost (1N–0P–0K; Garden Magic® compost and manure, Michigan Peat Company, Sandusky, MI, USA), and the other was earthworm castings (1N–0P–0K; Wiggle Worm Soil Builder™ earthworm casting, UNCO Industries Inc., Gove, WI, USA). A commercial peat-moss-based substrate, Sunshine #1 Mix, was used as control. Eight container substrate treatments were used in this experiment: control (0B), 100% biochar (100B), 90% biochar + 10% manure compost (90B10C; by volume), 80% biochar + 20% manure compost (80B20C), 70% biochar + 30% manure compost (70B30C), 90% biochar + 10% vermicompost (90B10V), 80% biochar + 20% vermicompost (80B20V), and 70% biochar + 30% vermicompost (70B30V).

Bell pepper seeds (Capsicum annuum L. ‘Redskin’) were sown in commercial propagation mix (Sun Gro® Horticulture, Agawam, MA, USA) in 200-cell plug trays (cell depth, 4.5 cm; cell top length and width, 2.2 cm; volume, 10 mL) on 15 August 2015. On 11 September 2015, healthy and uniform seedlings with three true leaves were transplanted into plastic pots (15 cm high and 1250 mL volume). Plants were grown in a glass greenhouse at Texas A&M University (College Station, TX, USA). The average temperature, relative humidity, and daily light integral in the greenhouse, recorded by Watchdogs 450 (Spectrum Technologies Inc., Paxinos, PA, USA), were 27.2 °C day/20.4 °C night, 59.8%, and 8.8 mol m−2 day−1, respectively.

A water-soluble fertilizer (15N–2.2P–12.2K, Peters 15-5-15; Scotts Miracle-Gro Company, Marysville, OH, USA) was used in this experiment. The recommended feeding frequency of pepper was constant feeding at 200 mg L−1 N at every watering, initiated on 17 September 2015, 6 days after planting (DAP).

2.2 Experimental design and measurements

The physical characteristics of the container substrate, including total porosity, container capacity, air space, and bulk density, were tested in a laboratory, using NCSU porometers (North Carolina State University, Raleigh, NC, USA) according to the North Carolina State University Porometer Method (Fonteno et al. 1981). The EC and pH of container substrate leachates of each treatment were measured after watering according to the pour-through method (Wright 1986).

Plant height was measured weekly starting at week 5 after planting (5 WAP) from the cotyledonary node to the top of the plant. Two plant widths were measured across the widest plant canopy, and the perpendicular width and growth index (GI) were calculated as: GI = plant height/2 + (plant width1 + plant width2)/4.

At 11 WAP, the net photosynthetic rates were measured with a photosynthesis system (Li-6400, Li-COR Inc., Lincoln, Nebraska, USA) under 25 °C, 400 µmol s−1 CO2 flow rate, and 1200 µmol m−2 s−1 PPFD at 9:30–11:00 AM. Photosynthesis measurements were made on the first fully expanded leaves. Leaf greenness was quantified as SPAD readings using a chlorophyll meter (SPAD-502 Minolta Camera Co., Osaka, Japan) at the same time as photosynthesis measurement on three points of the same leaves.

The number of days from planting to first open flower was recorded. Four randomly selected plants of each treatment were cut at the cotyledonary node during flowering, 72 DAP. The number of flowers and fruits as well as the stem diameter were recorded. The leaf area was measured by scanning the leaves with a flatbed scanner (Epson Perfection V700 Photo, Epson America Inc., Long Beach, CA, USA). Then, the leaves, stems, flowers, and fruits were dried in an oven at 80 °C to a constant weight, and the dry weight (DW) was determined. At the stage of harvesting (113 DAP), four remaining plants of each treatment were cut at the cotyledonary node, the fruits were harvested, and fresh weights (FW) were recorded. The leaves, stems, flowers, and fruits were then dried in an oven at 80 °C to a constant weight, and the DW was determined.

2.3 Statistical analysis

The experiment was arranged in a completely randomized complete design with eight a single-factor, eight container substrate treatments. Each treatment had eight replications where one container with a single plant represented one replication. Statistical analysis was performed using GLM-ANOVA in SAS. When there was significant treatment difference, means were separated using Duncan’s multiple range test at p ≤ 0.05.

3 Results and discussion

3.1 Physicochemical properties of container substrate

Total porosity was not significantly different among the eight different substrates (Table 1). Control container substrate had the highest container capacity (59.2%) and the lowest air space (14.1%) and bulk density (0.104 g cm−1) (Yeager et al. 2007). On the other hand, 100B, 90B10C, 90B10V, and 80B20V had the lowest container capacity (54.8–55.3%), and 100B had the highest air space (19.6%), indicating lower water-holding capacity (Argo 1998). The results were not consistent with previous studies (Tian et al. 2012; Vaughn et al. 2015; Méndez et al. 2017) due to the different pyrolysis conditions and the particle size of biochar. Total porosity, container capacity, and air space of all the biochar substrates were within the suitable ranges (Yeager et al. 2007).

The pH was significantly different among the eight substrates (Fig. 1a). On both 62 and 83 DAP, pH of the control was higher than the biochar mixes, but pH levels of all the biochar substrates were above 5.1. Biochar substrates had increased alkali-soluble salts of due to pyrolysis process of the biochar and pH (Ahmad et al. 2012; Steiner and Harttung 2014), but substrates with biochar and compost resulted in pH levels less than 6.0 from 41 to 83 DAP. EC of control, which was above 1.0 dS m−1 on all DAPs, was approximately four times greater than values observed on the biochar substrates at 34 DAP, 2 days before fertigation was initiated (Fig. 1b). At 41 DAP, EC of control was still significantly higher than the biochar substrates at 62 DAP. EC of control was lower than the biochar substrates, while at 83 DAP, there was no significant difference. When initially fertilizing substrates with fertilizer solution and subsequently leaching 12 times, Altland and Locke (2012) observed a lower micronutrient release peak in substrates mixed with biochar but similar sum of released nutrients from the 12 leaching events, suggesting that the nutrient was retained by biochar and released more slowly. The lower EC of the biochar substrates at 41 DAP was probably caused by both the initial low EC (biochar substrates did not contain start charge as in many commercial substrates) and the nutrient-retaining property of biochar. The higher EC of the biochar substrates at 62 DAP may be caused by releasing the nutrient retained in the biochar from previous fertigation events. 70B30V container substrate slightly increased EC at 34 and 41 DAP compared to values observed on the other substrates with biochar, with similar results from the substrate containing biochar + peat (Steiner and Harttung 2014).

pH (a) and electrical conductivity (EC; b) in various container substrates for peppers in at 34, 41, 62, and 83 days after planting (DAP). *, **, ***Adjacent to each datum point for each sampling date indicate significant differences as determined by Duncan’s multiple range test at p ≤ 0.05, 0.01, or 0.001, respectively; ns not significantly different

3.2 Pepper growth

SPAD values were the greatest on the pepper plants grown in control, followed by 100B, with the lowest values on the substrates containing manure compost (Fig. 2a). 80B20C and 70B30C had significantly lower SPAD readings than the other biochar substrates (100B, 90B10C, 90B10V, 80B20V, and 70B30V). Three biochar mixes with the manure compost (90B10C, 80B20C, and 70B30C) had significantly lower net photosynthesis rates than the others, except 80B20V (Fig. 2b). The control had the greatest total leaf area, and the total leaf area for all the biochar substrates was approximately or less than half of that for control. Control had the greatest stem diameter, followed by 70B30V, and all the other biochar substrates had smaller stem diameter compared to control, with 100B being the smallest (Fig. 2c, d). Low water-holding capacity, slow-release nutrients, and possible presence of phytotoxic compounds in 100B with a high C:N ratio may have led to small leaf area, resulting in greater SPAD values and net photosynthesis rates due to more concentrated photosynthetic pigments and stem diameter (Dumroese et al. 2011; Bruun et al. 2012; Fryda and Visser 2015).

Leaf SPAD value (a), net photosynthesis rate (b), total leaf area (c), and stem diameter (d) of peppers grown in various container substrates at 11 weeks after planting (WAP). Different lower-case letters on each set of datum points for each phase indicate significant differences as determined by Duncan’s multiple range test at p ≤ 0.05

Growth index showed a sigmoid curve from 34 to 83 DAP, and both control and 70B30V had higher values than 100B (Fig. 3). The DW of vegetative and flower organs at both flowering and harvesting stages and the yield were the highest for control, followed by the biochar mixes with the vermicompost (70B30V, 80B20V, and 90B10V), with the lowest values observed on 100B (Table 2); this order was similar for the growth index (Fig. 3). At the flowering stage, DWs of both vegetative organs and all aboveground organs for plants in the biochar mixes with the vermicomposts were higher than the biochar mix with the manure compost or 100B. During the harvesting stage, two of the three biochar mixes with the vermicompost (70B30C and 80B20V) had higher DW in the stem, leaf, vegetative, and reproductive organs, all aboveground organs, and yield, compared to the biochar mix with the manure compost or 100B. Container sunflowers grown in 100% biochar (by volume) had lower biomass compared to those grown in 25% biochar, mostly due to the high C:N ratio from the biochar (Dumroese et al. 2011; Steiner and Harttung 2014). Vegetative DW was positively correlated to the flower DW (r2 = 0.987; data not presented), and the DW strongly affected fruit yield (r2 = 0.960; data not presented), as reported in pepper plants (Bowen and Frey 2002; Aminifard et al. 2012).

Growth index of peppers grown in various container substrates at 34, 41, 48, 55, 62, 69, 76, and 83 days after planting (DAP). Growth index was calculated as plant height/2 + (plant width1 + plant width2)/4. ***Adjacent to each datum point for each sampling date indicate significant differences as determined by Duncan’s multiple range test at p ≤ 0.001; ns not significantly different

Although the greatest GI was approximately 50% higher than the lowest one at 55 DAP (Fig. 3), the significant difference in vegetative growth reflected by GI did not result in too many days difference in the number of days from planting to initial flowering (Fig. 4). Flowering started to occur approximately on 55 DAP when the vegetative growth ceased. Flowering was advanced 1 to 2 days on the pepper plants grown in 70B30V compared to the other treatments. There was no significant difference on the number of days from planting to flowering on the other treatments. However, the DW of the highest flower organ in 0B was 9.3 times the lowest value in 80B20C at 72 DAP (flowering stage), and 2.7 times at 113 DAP (harvesting stage; Table 2). The biomass of the reproductive organ may be a better parameter to assess pepper plant response to the different substrates than the number of days to flowering. Conversa et al. (2015) found that incorporating 30% biochar increased both the number of flowers and the floral cluster DW in pelargonium at a high fertilization rate after 74 days; however, the number of days to flowering was not reported.

At high incorporation rates (70, 80, 90, and 100%; volume), the biochar mixes with either manure compost or vermicompost, did not perform as well as the commercial peat-moss-based substrate on container-grown bell pepper plants. This may be due to the accumulative effect caused by the starter nutrient charge in the commercial substrate (incorporated by the manufacture to give plants a nutrient boost) and the biochar’s nutrient-binding property (Altland and Locke 2012). Biochar mixes in this study did not contain any commercial substrate and thus have no starter nutrient. Altland and Locke (2012) found that peat:perlite substrates amended with 0, 1, 5, or 10% biochar had lower and delayed peaks in their nitrate release curves compared to the control without biochar. These two reasons could have caused lower nutrient availability and, thus, slower growth in pepper plants in the biochar mixes than the control at the beginning of the experiment. Altland and Locke (2012) also found that the sum of nitrate released from the mix with 10% biochar was 37.1 mg, compared to 44.7 mg after 12 leaching events, although this was not statistically significant. Biochar mixes in our experiment contained much higher biochar rates (70–100%) and the experiment lasted for 113 days, so the sum of total nitrate released from the biochar mixes may have been significantly lower than the control. For plants in mixes with high biochar rates to grow as well as the plants in the commercial substrate, a starter nutrient charge may need to be included and fertilization rate adjusted to compensate for the biochar’s nutrient binding. Plants in the biochar mixes with the vermicompost performed slightly better than the biochar alone or the biochar mixes with the manure compost. The vermicompost may be a better component than the manure compost to be mixed with the biochar in the container, although the reason was not investigated in this research.

References

Ahmad M, Lee SS, Dou X, Mohan D, Sung JK, Yang JE (2012) Effects of pyrolysis temperature on soybean stover- and peanut shell-derived biochar properties and TCE adsorption in water. Bioresour Technol 118:536–544

Alexander PD, Bragg NC, Meade R, Padelopoulos G, Watts O (2008) Peat in horticulture and conservation: the UK response to a changing world. Mires Peat 3:1–10

Altland JE, Locke JC (2012) Biochar affects macronutrient leaching from a soilless substrate. HortScience 47:1136–1140

Aminifard MH, Aroiee H, Nemati H, Azizi M, Khayyat M (2012) Effect of nitrogen fertilizer on vegetative and reproductive growth of pepper plants under field conditions. J Plant Nutr 35:235–242

Argo WR (1998) Root medium physical properties. HortTechnology 8:481–485

Bowen P, Frey B (2002) Response of plasticultared bell pepper to staking, irrigation frequency and fertigated nitrogen rate. J Hortic Sci 37:95–100

Bruun EW, Ambus P, Egsgaard H, Hauggaard-Nielsen H (2012) Effects of slow and fast pyrolysis biochar on soil C and N turnover dynamics. Soil Biol Biochem 46:73–79

Choi HS, Zhao Y, Dou H, Cai X, Gu M, Yu F (2018) Effects of biochar mixes with pine bark based substrates on growth and development of horticultural crops. Hortic Environ Biotechnol 59:345–354

Conversa G, Bonasia A, Lazzizera C, Elia A (2015) Influence of biochar, mycorrhizal inoculation, and fertilizer rate on growth and flowering of Pelargonium (Pelargonium zonale L.) plants. Front Plant Sci 6:1–11

Doan TT, Tureaux TH, Rumpel C, Janeau JL, Jouquet P (2015) Impact of compost, vermicompost and biochar on soil fertility, maize yield and soil erosion in Northern Vietnam: a three year mesocosm experiment. Sci Total Environ 514:147–154

Dumroese RK, Heiskanen J, Englund K, Tervahauta A (2011) Pelleted biochar: chemical and physical properties show potential use as a container substrate in container nurseries. Biomass Bioenergy 35:2018–2027

Fonteno WC, Cassel DK, Larson RA (1981) Physical properties of three container media and their effect on poinsettia growth. J Am Soc Hortic Sci 106:736–741

Fryda L, Visser R (2015) Biochar for soil improvement: evaluation of biochar from gasification and slow pyrolysis. Agriculture 5:1076–1115

Glaser B, Lehmann J, Zech W (2002) Ameliorating physical and chemical properties of highly weathered soils in the tropics with charcoal - a review. Biol Fertil Soils 35:219–230

Graber ER, Harel YM, Kolton M, Cytryn E, Silber A, David DR, Tsechansky L, Borenshtein M, Elad Y (2010) Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 337:481–496

Gu M, Li Q, Steele PH, Niu G, Yu F (2013) Growth of ‘Fireworks’ gomphrena grown in substrates amended with biochar. J Food Agric Environ 11:819–821

Guo Y, Niu G, Starman T, Volder A, Gu M (2018) Poinsettia growth and development response to container root substrate with biochar. Horticulturae 4:1–14

Handreck K, Black N (2002) Growing media for ornamental plants and turf. UNSW Press, Sydney, pp 1–542

Méndez A, Cárdenas-Aguiar E, Paz-Ferreiro J, Plaza C, Gascó G (2017) The effect of sewage sludge biochar on peat-based growing media. Biol Agric Hortic 33:40–51

Ngo PT, Rumpel C, Ngo QA, Alexis M, Vargas GV, Gil MLM, Dang DK, Jouquet P (2013) Biological and chemical reactivity and phosphorus forms of buffalo manure compost, vermicompost and their mixture with biochar. Bioresour Technol 148:401–407

Steiner C, Harttung T (2014) Biochar as growing media additive and peat substitute. Solid Earth 5:995–999

Tian Y, Sun X, Li S, Wang H, Wang L, Cao J, Zhang L (2012) Biochar made from green waste as peat substitute in growth media for Calathea rotundifola cv. Fasciata. Sci Hortic 143:15–18

Vaughn SF, Eller FJ, Evangelista RL, Moser BR, Lee E, Wagner RE, Peterson SC (2015) Evaluation of biochar-anaerobic potato digestate mixtures as renewable components of horticultural potting media. Ind Crop Prod 65:467–471

Wright RD (1986) The pour-through nutrient extraction procedure. HortScience 21:227–229

Yeager TH, Fare DC, Lea-Cox J, Ruter J, Bilderback TE, Gilliam CH, Niemiera AX, Warren SL, Whitwell TE, Wright RD, Tilt KM (2007) Best management practices: guide for producing container-grown plants. Southern Nurserymen’s Association, Marietta

Acknowledgements

This research was supported by Texas A&M AgriLife Extension Service, College Station, USA and Jiangsu Academy of Agricultural Sciences. Additional thanks go to the Department of Horticulture, Catholic University of Daegu, Gyeongsan, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, R., Gu, M., Huang, L. et al. Effect of pine wood biochar mixed with two types of compost on growth of bell pepper (Capsicum annuum L.). Hortic. Environ. Biotechnol. 60, 313–319 (2019). https://doi.org/10.1007/s13580-019-00133-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13580-019-00133-9