Abstract

The effects of different ferrous sulfate (FeSO4) concentrations on the fatty acid profile of the blue-green alga Arthrospira platensis cultured in Zarrouk’s medium to produce biodiesel were studied. Different ferrous sulfate concentrations (0, 0.005, 0.01, 0.05, and 0.1 g/L) and 0.01 g/L were examined on the biochemical composition of the alga and fatty acids profile of A. platensis. Findings revealed that the highest and lowest yields of fatty acid were 0 and 0.1 g/L FeSO4, respectively. It was also noticed an increase of palmitic acid, oleic acid, linoleic acid, γ-linolenic acid, and docosahexaenoic acid when ferrous sulfate was between 0.05 and 0.1 g/L, while these fatty acids decreased at low concentration. Ferrous sulfate at a concentration of 0.1 g/L exhibited an increase and best yields in the following: growth rate and the shortest doubling time, chlorophyll-a, phycocyanin, allophycocyanin, phycobiliproteins, and carotenoids. Thus, increasing the FeSO4 concentration to 0.1 g/L has led to the increase in fatty acid individuals, which in turn, resulted in potential enhancement of the biodiesel production from A. platensis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The global population is expected to increase by 9 billion in 2050 [1], which will lead to more fossil fuel consumption with increasing greenhouse gas emissions (GHGs) [2]. Therefore, seeking another energy source is a necessity for reducing GHGs emissions, minimizing the dependence on fossil fuels, and maintaining environmental sustainability [3, 4]. Recently, there has been considerable attention to microalgae as a source of third-generation liquid biofuels. The utilization of microalgae for biofuel production offers several benefits. Firstly, they can grow in different waters [5], including wastewater, and double their biomass in periods as short as 3.5 h. Secondly, microalgae can be cultivated without the need for herbicides or pesticides application [6] due to their ability to live on non-arable lands [7]. Thirdly, they are employed in wastewater treatment to remove nutrients such as phosphorus, nitrogen, carbon, and other toxic compounds [8, 9]. Finally, different bio-products other than biofuel can be produced from microalgae, such as cosmetic products, animal feed, and valuable pharmaceuticals [10, 11]. Biofuels produced from microalgae are generated via processes, including ethanol production by carbohydrates saccharification [12,13,14,15], biodiesel production by lipid transesterification [16, 17], and crude bio-oil production by thermochemical conversion [18]. Researchers further investigated microalgae as a gas fuel source, such as biohydrogen [19] and biogas [20].

Biodiesel is a renewable and biodegradable fuel produced from animal fats or vegetable oils reactions with short-chain alcohol (methanol or ethanol) through the transesterification process in the existence of a catalyst. Catalysts are incorporated at 1.5 h and 60 °C under 101,325 Pa, in order to reduce response time and rising conversion rate [21]. Transesterification switches over fresh to dense microalgae lipids to decrease corrosive alkyl esters or the subatomic weight of fats, triacylglycerols, or safe unsaturated fats [22]. Several catalysts are employed in the process of transesterification such as alkaline, acid, enzymes, and heterogeneous inorganic catalyst [23]. In a comparison with conventional diesel, biodiesel can equilibrate the negative balance generated by the emission into the atmosphere. Further, it reduces carbon monoxide (CO), sulfur compounds (SOx), and particulate matter (PM) emissions and having better lubricity and renewability [24]; however, it contributes to increasing nitrogen oxide (NOx) emissions [25].

In the past few decades, microalgae species have been utilized to produce biodiesel. For instance, Chlorella vulgaris [26], Chlamydomonas reinhardtii [27], Scenedesmus dimorphus, Scenedesmus obliquus [28, 29], Nannochloropsis granulata, Nannochloropsis oculata [30], Scenedesmus dimorphus [31], and Caulerpa prolifera [13] were evaluated for biodiesel production with lipid content 6, 49–52, 10, 30–50, 28.5, 45, 14.71 ± 0.26, and 10%, respectively. However, several challenges are facing microalgal technologies despite their participation in global energy demand. It is essential to understand the optimum growth condition of the selected microalgae to enable a large-scale production system. Such condition enhances lipid accumulation or promotes high biomass production, which leads to a reduction in the production cost. Several studies have shown an effective method to enhance lipid accumulation via sulfur and nitrogen limitation [32, 33].

Arthrospira platensis (formerly Spirulina platensis) is a species of microalga with high protein content. A. platensis was first isolated by Turpin in 1827 [34]. It has a spiral-shaped trichoma with 100–110 μm long and 8–10 μmm wide. It is a vital microalga as it contains high protein, pigments, gamma-linolenic acid (GLA), vitamins, fatty acids, and other valuable metabolites [35]. It is worth mentioning that five fatty acids are most abundant in the A. platensis, namely palmitic acid, palmitoleic acid, oleic acid, linoleic acid, and γ-linolenic acid [36, 37]. Arthrospira platensis is extensively cultured at a mass commercial scale and is considered as one of the most famous blue-green algae or cyanobacteria [38, 39]. Worldwide, the production of Spirulina has increased to over 89 thousand tons in 2016 [40]. It is widely utilized in many biotechnological applications such as biofertilizers, pharmaceuticals, pigments, human food supplements, omega-3-fatty acids, and animal feed additives [38, 41,42,43,44].

Recent studies have concluded that due to the high biomass and lipid productivity of A. platensis, it is considered one of the best feedstock for biodiesel production [39, 44,45,46]. As confirmed by literature, the extracted biodiesel from A. platensis is within the recommended specifications of the international standards of Europe (EN14214) and the USA (ASTM675103) [43, 44, 46]. For instance, the cultivation of A. platensis in an iron-enriched medium has been investigated by Cepoi et al. [47] who stated that the adaptation of the Spirulina’s biomass to copper-containing effluents was more noticeable in Cu/Fe systems since in multicomponent systems, the process was more complex and varied based on the metal type, amount, and concentration. The spectra of iron hydroxides in A. platensis biomass differed from those of iron complexes put into Zarrouk’s growth medium with ethylenediaminetetraacetic acid. The saturation limit of A. platensis trichomes with iron in the form of ferrihydrite in the culture medium was found to be 5 g/mL (0.09 mol/mL) Fe [48]. By utilizing Mössbauer spectroscopy, Wan et al. [36] identified the effects of iron on Chlorella sorokiniana growth and lipid synthesis, as well as the enzymes and metabolic pathways that may be altered in response to variations in iron levels in the environment. When compared to unsupplemented controls, the addition of iron up to 105 mol L−l boosted ultimate cell densities by approximately twofold at 2.3 107 cells/mL, growth rate by twofold, and the length of the exponential phase by 5 days, while 103 mol L−1 iron was hazardous. The lipid content increased from 12% for unsupplemented cultures to 33% at 10−4% mol L1 iron, with the maximum total lipid output of 179 mg L−1. To the best of our knowledge, studies have not fully investigated the effects of different ferrous sulfate concentrations on the fatty acid profile, biomass, and pigments of the blue-green alga Arthrospira platensis. Thus, this study evaluated A. platensis for biodiesel production by cultivating it in various ferrous sulfate (FeSO4) concentrations to find the optimal conditions. In addition, the assessment procedures involve studying the effects of the different cultivation conditions on some fatty acids profile, the growth rate, and the doubling time. Furthermore, the effect of FeSO4 on the biochemical composition of the alga as a nutritional source was evaluated.

2 Material and methods

2.1 Algal strain and medium composition

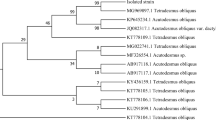

A kit of the blue-green alga, Arthrospira platensis, was purchased from Suncoast Marine Aquaculture (St. Petersburg, Florida). Arthrospira platensis was grown in Zarrouk’s medium [37]. To obtain the final medium, the solutions with the respective salts were sterilized by employing autoclaving for 15 min at a temperature of 121 °C. Then, they were mixed thoroughly [49]. For biomass production, A. platensis cells were inoculated at a concentration of 10% (Vinoculation/Vmedia) in 500-mL sterilized Erlenmeyer flasks containing 100 mL Zarrouk’s medium at 32 ± 1 °C, pH 9 using cool white fluorescent tubes (35 μEm2 s−1) with a photoperiod cycle of 12:12 h light/dark. They were shaken twice a day to allow air and nutrients circulation [50].

2.2 The design of the experiment

To study the effect of iron (in the form of ferrous sulfate) on the biochemical composition of the alga and fatty acids profile, A. platensis was cultured in Zarrouk’s medium supplemented with different iron concentrations (0, 0.005, 0.01, 0.05, and 0.1 g/L) and using 0.01 g/L as the control.

2.3 Biodiesel production

2.3.1 Direct in situ transesterification

Arthrospira platensis cells were centrifuged at 7500 rpm for 10 min. After that, samples were dried for 2 h at 55 °C and refrigerated at − 4 °C before analyses [51]. About 0.1 g was mixed with 8 mL of fresh reaction solution (HCl/CHCl3/CH3OH, 4:4:40 v/v/v) in Teflon-capped Pyrex tubes [52]. Then, suspended biomass was dehydrated for 1 h at 90 °C for the transesterification step. Then, the mixtures were cooled at room temperature. The upper extracted organic supernatant was collected, and the fatty acid methyl esters (FAMEs) were extracted twice. The final samples were then analyzed by gas chromatography [53].

2.4 Estimation of growth rate and doubling time

Using the UV–Vis spectrophotometer, the OD at 560 nm was converted to the cell density (cells/mL) according to the linear relationship between these two parameters and the culture medium [54]. The determination of the specific growth rate and doubling time was followed the past literature [55].

2.4.1 Chlorophyll

To determine the chlorophyll, Arnon’s method [56] was adopted. The algal cells were placed in 1 mL of 80% acetone, and then they were centrifuged. The collected supernatant was analyzed by using UV–Vis spectrophotometer at a wavelength of 663 nm and 645 nm with the following equation:

2.4.2 Carotenoids estimation

About 5 mL of A. platensis was centrifuged for 10 min at a speed of 4000 rpm. Samples were then washed with distilled water to remove any remaining salts. After that, about 5 mL of acetone was added until a white precipitate appeared. Then, samples were subjected to centrifugation for 15 min at a speed of 5000 rpm to separate the acetone extract. Following the steps reported by Jensen [57], the carotenoid content was determined with a spectrophotometer.

2.4.3 Phycobiliproteins estimation

The estimation was done by following the Bennett and Bogorad [58] method. About 10 mL of samples was centrifuged for 20 min at a speed of 4500 rpm. Then, samples were washed with distilled water. After that, samples were suspended in 10 mL phosphate buffer with further centrifugation at 4500 rpm for 10 min. The concentrations of phycocyanin, allophycocyanin, and phycobiliproteins (PBP) were determined in accordance with the equation from Devanathan and Ramanathan [59].

2.4.4 Total protein

Total protein was determined by the Bradford dye-binding assay method [60]. The main concept of this assay is relying on the binding of the dye Coomassie Blue G250 to protein. About 100 µL and 5 mL of Bradford dye reagent were added and mixed. Known dilutions of bovine serum albumin were prepared to calculate the protein.

2.4.5 Total carbohydrates

Arthrospira platensis was centrifuged at 5000 rpm for 30 min at 4 °C. Utilizing glucose as a standard, the Dubois et al. [61] method was employed to determine the carbohydrate content. A mixture of 1 mL of sample, 5% phenol, and 5 mL of 96% H2SO4 were added to the test tube. The tube was water bathed for 20 min at 25–30 °C. The total carbohydrate was determined by following the standard graph prepared by Nordin et al. [62].

2.5 Determination of fatty acid composition

To analyze the washed FAMEs, gas chromatography (Shimadzu, Japan) equipped with a flame ionization detector using the SP-2480 column was used. Furthermore, the carrier gas used in this study was helium. The temperatures at the injector port and the detector were 280 °C and 330 °C, respectively. The initial column temperature was started at 150 °C and gradually increased by 10 °C min−1 until it reached 300 °C. The FAMEs for the selected algae were identified by comparing the standard fatty acids retention time and sample peaks [63]. Five fatty acids (palmitic acid, oleic acid, linoleic acid, γ-linolenic acid, and docosahexaenoic acid) were used as the standard materials.

2.6 The analysis of fatty acid by gas chromatography

The fatty acid methyl esters (FAMEs) of A. platensis were examined by comparing the peak retention times with the standard one [63]. The gas chromatography was equipped with a flame ionization detector. The carrier gas in the SP-2480 column was helium. The injector temperature was 280 °C, and the initial column temperature was set at 150 °C, which raised to 300 °C at the rate of 10 °C min−1.

3 Results and discussion

3.1 The effect of FeSO 4 concentrations on growth rate and doubling time of A. platensis

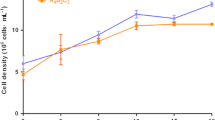

The growth rate (K) increased to 0.135 and 0.141 under the treatments of 0.05 g/L and 0.1 g/L, respectively, and decreased to 0.120 and 0.118 under the treatments 0.005 g/L and 0 g/L, respectively, as compared with 0.131 in 0.01 g/L (control). Figure 1 shows the growth rate (K) with and doubling time (d) of Arthrospira platensis at different FeSO4 concentrations. The maximum growth induction of 7.092% was recorded in 0.1 g/L, while the maximum growth inhibition of 9.923% was found in the 0 g/L treatment (Fig. 1). In 0.005, 0.01, and 0.05 g/L treatments, the doubling times (G) were 2.511, 2.297, and 2.228 days, respectively. The shortest doubling time was 2.136 days with the 0.1 g/L, while the longest was 2.547 days with the 0 g/L treatment (Fig. 1).

The different FeSO4 concentrations caused different biomass growth production for A. platensis. The growth rate was increased when iron concentration increased; meanwhile, the doubling time was decreased. The findings of this study agreed with Cheng et al. [64], who showed that increasing the concentration of iron in the growth medium stimulated the growth rate of Chlamydomonas reinhardtii. The mean cell abundance in the 2 × treatment (Fe = 92.4 μM) was observed to be significantly higher than the cell abundance in the 1/2 × treatment (Fe = 23.1 μM) on day 16 and significantly higher than the 1 × treatment (Fe = 46.2 μM) on day 23. Moreover, Glaesener et al. [65] concluded that C. reinhardtii cells displayed an increase in cell growth as the iron concentration in the medium increased.

3.2 The effect of FeSO 4 concentrations on carbohydrate and protein content of A. platensis

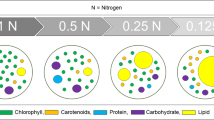

The treatment of A. platensis with FeSO4 concentrations of 0.05 and 0.1 g/L caused an increase in the total carbohydrate content, while decreasing FeSO4 concentrations to 0 and 0.005 g/L caused a decrease in the carbohydrate content. Figure 2 illustrates the carbohydrate and protein contents of Arthrospira platensis with respect to different FeSO4 values. As compared with the 37.077 mg/L carbohydrates in control (0.01 g/L FeSO4), the highest carbohydrate content (41.732 mg/L) was recorded with 0.1 g/L, and the lower carbohydrate content (34.435 mg/L) was recorded with 0 g/L (Fig. 2).

The increased FeSO4 concentrations of 0.05 and 0.1 g/L caused a significant reduction in the protein content, while the decreased FeSO4 concentrations of 0 and 0.005 g/L induced the increase of the protein content. The highest protein content (57.300 mg/L) was recorded with 0 g/L, and the lowest protein content (34.861 mg/L) was recorded with 0.05 g/L compared with 39.414 mg/L protein, which was recorded in 0.01 g/L (control) (Fig. 2). In this study, A. platensis exhibited a decline in the total protein contents when the concentrations of FeSO4 increased. This result is in accordance with the findings of Das et al. [66], who demonstrated that the carbohydrate content in Tetraselmis sp. increased with the increase of iron concentrations, while the increased iron in the culture decreased the protein content in the marine microalgae Tetraselmis sp. and Chlorocystis sp. Marrez and his colleagues have conducted a study on A. platensis cultured in different growth media. They concluded that the protein and carbohydrate of the selected algae were between 49.5 and 59.8% and between 12.4 and 22.8%, respectively [67]. Another study has reported that A. platensis has a protein content ranging between 50.2 and 58.6% [68]. Jaruwan et al. [69] reported that A. platensis has a lipid content between 4 and 16%. These variations in the lipid content may be due to different extraction methods, culture system, as well as other environmental conditions, or available nutrient limitations [38, 39, 70, 71].

3.3 The effect of FeSO 4 concentrations on chlorophyll a content of A. platensis

The chlorophyll-a (Chl-a) content in the control (0.616 mg/L), showed that a decrease in FeSO4 concentration to 0 and 0.005 g/L affected A. platensis. Figure 3 describes the influence of FeSO4 concentrations on the average of chlorophyll and carotenoid contents of Arthrospira platensis. The maximum reduction of Chl-a was 0.461 mg/L, while the maximum induction was 0.683 mg/L (Fig. 3).

The results showed that limiting FeSO4 inhibited photosynthetic pigments like Chl-a, PC, APC, PBP, and carotenoids. Iron is an important component in protein complexes that contributes to photosynthesis and acts as a redox cofactor [72]. The cyanobacterial photosynthetic system photosystem I (PSI) has considerable amounts of iron. In addition, intermediary electron transport complex cytochrome also contains iron. Therefore, with iron deficiency, these pigments can be synthesized in small amounts [73]. Researchers have further investigated the relationship between chlorophyll biosynthesis and iron. They concluded that iron deficiency leads to chlorosis as Fe is considered the most important element for the growth of spirulina with its ability as a limiting factor in pigment production [74, 75].

3.4 The effect of FeSO 4 concentrations on phycocyanin, allophycocyanin, and phycobiliproteins content of A. platensis

The comparison with the control, which supported 0.186 mg/L PC, 0.194 mg/L APC, and 0.381 mg/L PBP, showed that the increasing FeSO4 concentration to 0.05 and 0.1 g/L affected A. platensis by increasing the PC, APC, and PBP concentrations. Figure 4 shows the influence of ferrous sulfate concentrations on the average of phycocyanin, allophycocyanin, and phycobiliproteins contents of Arthrospira platensis. The maximum induction values of APC (0.274 mg/L) and PBP (0.578 mg/L) were recorded in the presence of 0.1 g/L FeSO4, while the maximum PC value (0.267 mg/L) was recorded with 0.05 g/L FeSO4. On the other hand, the minimum reduction values of PC, APC, and PBP were 0.140, 0.155, and 0.296 mg/L with FeSO4 concentration of 0 g/L (Fig. 4).

3.5 The effect of FeSO 4 concentrations on carotenoids content of A. platensis

As compared to control (0.01 g/L), which contain 0.008 mg/L of carotenoids, the data showed that carotenoids content increased to 0.009 and 0.010 mg/L at high FeSO4 concentrations (0.05 and 0.1 g/L), respectively (Fig. 3).

3.6 The effect of FeSO 4 concentrations on the fatty acid profile

The effect of different FeSO4 concentrations (0, 0.005, 0.01, 0.05, and 0.1 g/L) on the content of the individual fatty acids is recorded in Table 1 which describes the influence of different ferrous sulfate values on palmitic acid, oleic acid, linoleic acid, gamma-linolenic acid, and docosahexaenoic acid in Arthrospira platensis. According to the literature, the selected five fatty acids are the most abundant in A. platensis [76, 77]. The chromatograms of gas chromatography (GC) for palmitic acid, oleic acid, linoleic acid, γ-linolenic acid, and docosahexaenoic acid in A. platensis revealed that spirulina at higher iron concentrations has a major percent of fatty acids. The maximum content induction of palmitic acid, oleic acid, linoleic acid, γ-linolenic acid, and docosahexaenoic acid was 1.217, 2.060, 0.279, 19.213, and 44.469 mg/g, respectively, with FeSO4 concentration of 0.1 g/L, and their maximum reduction values were 0.234, 0.172, 0.026, 1.699, and 0.998 mg/g, respectively, with FeSO4 concentration of 0 g/L as compared to 0.366 mg/g (palmitic acid), 0.302 mg/g (oleic acid), 0.086 mg/g (linoleic acid), 3.237 mg/g (γ-linolenic acid), and 11.896 mg/g (docosahexaenoic acid) in 0.01 g/L FeSO4 (control).

The maximum induction of the total fatty acids was 76.371% in the 0.1 g/L treatment, while the maximum reduction of the total fatty acids was 80.304%, which was recorded with 0 g/L of FeSO4. In the desaturated molecule, the iron created a reactive complex with oxygen. However, oxygen reacted with carbon in the fatty acid chain and changed the single bonds to double bonds [78] Low iron concentration resulted in the decrease of the chlorophyll concentration, which has led to low biomass and lipid content [69]. With the increased iron concentration, reactive oxygen such as hydrogen peroxide and other oxidant compounds could be formed. In light of this, an interaction between lipids and other biochemical components and oxidant compounds may occur. Therefore, due to iron stress, the synthesis of lipid may be produced to counteract the reactive oxygen species [70]. A study conducted by Mostafa and his co-worker has concluded that A. platensis showed 89.6%, 6.2%, and 2.11% of saturated fatty acids (SFAs), monounsaturated fatty acids (MUFAs), and polyunsaturated fatty acids (PUFAs), respectively, as they have grown the algae indoor and enriched them with Zarrouk’s medium [39]. However, another study stated that the PUFAs of A. platensis might reach up to 30% of SFAs [38]. Other researchers have also concluded that lipid content in Botryococcus spp. and Scenedesmus obliquus increased when supplemented with high iron concentration [79, 80]. Moreover, treating the alga Chlorella vulgaris with ferrous sulfate (35 μM FeSO4.7H2O) resulted in a decrease in SFAs with percentages of 3% lower than the corresponding control (17 μM ferrous sulfate) [81]. In 2019, another study was done by Sahin, and his co-worker illustrated the growing diatoms under higher iron concentrations. The study has revealed a dramatic increase in lipid content. In Nitzschia sp., there was an increase between 37.7 ± 0.77% of the total lipid and between 37.44 ± 0.54% of the total lipid in Nanofrustulum shiloi. As a result, they were about 2.7 and 1.7 times higher than those obtained with the standard f/2 (13.8 ± 0.42%) and BG11 (21.71 ± 0.34%) media, respectively [82]. Additionally, C. vulgaris with ferrous sulfate (35 μM after 12 days of incubation) revealed the highest lipid content, whereas the corresponding control showed a lowering in the lipid content. This decrease may be shifted towards the bio-synthesis of the unsaturated fatty acids (UFAs) and vice versa. The study has reported that the predominant saturated and unsaturated fatty acids of C. vulgaris were C16:0 and C18: 2, respectively [83].

4 Conclusions

Recently, there has been considerable attention among the scientific community with regard to microalgae to produce third-generation liquid biofuels. The present study examined the potential of A. platensis to produce biodiesel. Therefore, five concentrations of FeSO4 (0, 0.005, 0.01 (control), 0.05, and 0.1 g/L) were utilized. The fatty acid profile of the A. platensis revealed that palmitic, oleic acid, linoleic acid, γ-linolenic acid, and docosahexaenoic acid were most prevalent. It was also found that the maximum-minimum yields of fatty acid individuals were achieved with 0.1–0 g/L FeSO4, respectively. The study indicated that when the concentrations of FeSO4 were between 0.05 and 0.1 g/L, palmitic acid, oleic acid, linoleic acid, γ-linolenic acid, and docosahexaenoic acid were increased, and at low concentrations, these fatty acids decreased. The maximum induction rate of the total fatty acids was obtained in the modified media with 0.1 g/L FeSO4. The results revealed that the highest growth rate and the shortest doubling time were recorded with the FeSO4 concentration of 0.1 g/L. The best concentration used to increase the yields of chlorophyll-a, phycocyanin, allophycocyanin, and phycobiliproteins is 0.1 g/L FeSO4, and carotenoids is 0.1 g/L FeSO4. Finally, increasing the FeSO4 concentration to 0.1 g/L has led to the increase in fatty acid individuals, hence, the potential enhancement of the biodiesel production from the point of view of quality and quantity.

References

Dutta K, Daverey A, Lin J-G (2014) Evolution retrospective for alternative fuels: first to fourth generation. Renew Energy 69:114–122

Berardi U (2017) A cross-country comparison of the building energy consumptions and their trends. Resour Conserv Recycl 123:230–241

Hu Y, Wang S, Li J, Wang Q, He Z, Feng Y (2018) Co-pyrolysis and co-hydrothermal liquefaction of seaweeds and rice husk: comparative study towards enhanced biofuel production. J Anal Appl Pyrolysis 129:162–170

Phwan CK, Ong HC, Chen W-H, Ling TC, Ng EP, Show PL (2018) Overview: comparison of pretreatment technologies and fermentation processes of bioethanol from microalgae. Energy Convers Manage 173:81–94

Salman JM, Hassan FM, Abdulameer SH (2018) Qualitative and quantitative study of epipelion algal community in Euphrates River (Al-Hussainya), Karbala Province-Iraq. Int J of Aquatic Science 9:30–37

Ortiz-Marquez JCF, Do Nascimento M, Zehr JP, Curatti L (2013) Genetic engineering of multispecies microbial cell factories as an alternative for bioenergy production. Trends Biotechnol 31:521–529

Winckelmann D, Bleeke F, Thomas B, Elle C, Klock G (2015) Open pond cultures indigenous algae grown on non-arable land in an arid desert using wastewater. Int Aquat Res 7:221–233

Goncalves AL, Pires JC, Simoes M (2017) A review on the use of microalgal consortia for wastewater treatment. Algal Res 24:403–415

Salman JM, Grmasha RA, Al-sareji OJ (2022) Potential efficiency of macroalgae Cladophora sp. to remove toxic industrial dye (safranin O) from aqueous solution. In AIP Conference Proceedings (Vol. 2386, No. 1, p. 020048). AIP Publishing LLC

Scott SA, Davey MP, Dennis JS, Horst I, Howe CJ, Lea-Smith DJ, Smith AG (2010) Biodiesel from algae: challenges and prospects. Curr Opin Biotechnol 21:277–286

Yahya NA, Attan N, Wahab RA (2018) An overview of cosmeceutically relevant plant extracts and strategies for extraction of plant-based bioactive compounds. Food Bioprod Process 112:6985

Ho S, Huang S, Chen C, Hausunuma T, Kondo A, Chang J (2013) Bioethanol production using carbohydrate-rich microalgae biomass as feedstock. Bioresour Technol 135:191–198

Ismail, M.M., Ismail, G.A., El-Sheekh, M.M., 2020. Potential assessment of some micro-and macroalgal species for bioethanol and biodiesel production. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 1–17.

Abou-El-Souod GW, Morsy EM, Hassan L, El-Sheekh MM (2021) Efficient saccarification of the microalga Chlorella vulgaris and its conversion into ethanol by fermentation. Iranian Journal of Science and Technology, Transactions A: Science 46:767–774

Xu C, Zhu J, Yu H, Hu H, Yang Y, Fu Q, Zhan D, Wang Y, Wang H, Zhang Y, Li T, El-Sheekh MM, Peng L, Xia T (2021) Recyclable cascading of arsenic phytoremediation and lead removal coupled with high bioethanol production using desirable rice straws. In press, Biochemical Engineering Journal

Sivaramakrishnan R, Incharoensakhi A (2018) Microalgae as feedstock for biodiesel production under ultrasound treatment – A review. Bioresour Technol 250:877–887

El-Sheekh MM, Abomohra A, El-Adel H, Battah M, Mohammed S (2018) Screening of different species of Scenedesmus isolated from Egyptian freshwater habitats for biodiesel production. Renewable Energy 129:114–120

Cheng F, Cui Z, Chen L, Jarvis J, Paz N, Schaub T, Nirmalakhandan N, Brewer CE (2017) Hydrothermal liquefaction of high-and low-lipid algae: bio-crude oil chemistry. Appl Energy 206:278–292

Khetkorn W, Rastogi RP, Incharoensakdi A, Lindblad P, Madamwar D, Pandey A, Larroche C (2017) Microalgal hydrogen production–a review. Bioresour Technol 243:1194–1206

Sialve B, Bernet N, Bernard O (2009) Anaerobic digestion of microalgae as a necessary step to make microalgal biodiesel sustainable. Biotechnol Adv 27:409–416

Aresta M, Dibenedetto A, Carone M, Colonna T, Fragale C (2005) Production of biodiesel from macroalgae by supercritical CO2 extraction and thermochemical liquefaction. Environ Chem Lett 3(3):136–139

Rawat I, Kumar RR, Mutanda T, Bux F (2011) Dual role of microalgae: phycoremediation of domestic wastewater and biomass production for sustainable biofuels production. Appl Energy 88(10):3411–3424

Pavithra KG, Kumar PS, Jaikumar V, Vardhan KH, SundarRajan P (2020). Microalgae for biofuel production and removal of heavy metals: a review. Environmental Chemistry Letters, pp.1–19

Aransiola EF, Ojumu TV, Oyekola OO, Madzimbamuto TF, Ikhu-Omoregbe DO (2014) A review of current technology for biodiesel production: state of the art. Biomass Bioenergy 61:276–297

Hoekman SK, Robbins C (2012) Review of the effects of biodiesel on NOx emissions. Fuel Process Technol 96:237–249

El-Sheekh MM, Gheda S, Ab E-S, Abo Shady A, El-Sheikh M, Schagerl M (2019) Outdoor cultivation of the green microalga Chlorella vulgaris under culture stress conditions as a feedstock for biofuel. Environ Sci Pollut Res 26:18520–18532

Sachdeva N, Gupta RP, Mathur AS, Tuli DK (2016) Enhanced lipid production in thermotolerant mutants of Chlorella pyrenoidosa NCIM 2738. Bioresour Technol 221:576–587

El-Sheekh MM, El-Gamal A, Bastawess AE, El-Bokhomy A (2017) Production and characterization of biodiesel from the unicellular green alga Scenedesmus obliquus. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 38(8):783–793

Sajjadi B, Chen W-Y, Raman AAA, Ibrahim S (2018) Microalgae lipid and biomass for biofuel production: a comprehensive review on lipid enhancement strategies and their effects on fatty acid composition. Renew Sustain Energy Rev 97:200–232

Chua ET, Schenk PM (2017) A biorefinery for Nannochloropsis: induction, harvesting, and extraction of EPA-rich oil and high-value protein. Bioresour Technol 244:1416–1424

Bordoloi N, Narzari R, Sut D, Saikia R, Chutia RS, Kataki R (2016) Characterization of bio-oil and its sub-fractions from pyrolysis of Scenedesmus dimorphus. Renew Energy 98:245–253

Mizuno Y, Sato A, Watanabe K, Hirata A, Takeshita T, Ota S, Sato N, Zachleder V, Tsuzuki M, Kawano S (2013) Sequential accumulation of starch and lipid induced by sulfur deficiency in Chlorella and Parachlorella species. Biores Technol 129:150–155

Chia SR, Ong HC, Chew KW, Show PL, Phang SM, Ling TC, Nagarajan D, Lee DJ, Chang JS (2018) Sustainable approaches for algae in bioenergy production. Renewable Energy 129:838–852

Iwata K (1990) Effects of spirulina on plasma lipoprotein lipase activity in rats. Pub in Journal Nutr Sci Vitaminol 36:165–171

Glazer A (1999) Phycobiliproteins. In: Cohen Z (ed) Chemicals from microalgae. Taylor and Franchis Ltd., Philadelphia, pp 261–276

Wan M, Jin X, Xia J, Rosenberg JN, Yu G, Nie Z, Oyler G, Batenbaugh MJ (2014) The effect of iron on growth, lipid accumulation, and gene expression profile of the freshwater microalga Chlorella sorokiniana. Appl Microbiol Biotechnol 98:9473–9481

Zarrouk C, Contribution a letude d’une cyanophycee (1966) Influence de divers facteurs physiques. et chimiques sur la croissance et la photosynthese do Spirulina maxima, Ph.D. Thesis, University of Paris, France

Habib MAB (2008) Review on culture, production and use of Spirulina as food for humans and feeds for domestic animals and fish. Food and agriculture organization of the united nations.

Mostafa SS, El-Gendy NS (2017) Evaluation of fuel properties for microalgae Spirulina platensis bio-diesel and its blends with Egyptian petro-diesel. Arab J Chem 10:S2040–S2050

United Nations Food And Agriculture Organization. 2018. The State of World Fisheries and Aquaculture 2018: Meeting the Sustainable Development Goals; Licence: CC BY-NC-SA 3.0 IGO; FAO: Rome, Italy,.

Hassan SM, Ashour M, Soliman AAF (2017) Anticancer activity, antioxidant activity, mineral contents, vegetative and yield of Eruca sativa using foliar application of autoclaved cellular extract of Spirulina platensis extract, comparing to NPK fertilizers. Journal of Plant Production 8:529–536

Shao W, Ebaid R, El-Sheekh M, Abomohra A, Eladel H (2019) Pharmaceutical applications and consequent environmental impacts of Spirulina (Arthrospira): an overview. Grasas Aceites 70:292

Wuang SC, Khaim MC, Chua PQD, Luo YD (2016) Use of Spirulina biomass produced from treatment of aquaculture wastewater as agricultural fertilizers. Algal Res 15:59–64

Kalsum L, Dewi E, Margarety E, Ningsih AS (2019) Lipid extraction from microalgae Spirulina Platensis for raw materials of biodiesel. In Journal of Physics: Conference Series, IOP Publishing. 1167:012051

Rahman MA, Aziz MA, Al-Khulaidi RA, Sakib N, Islam M (2017) Biodiesel production from microalgae S pirulina maxima by two step process: optimization of process variable. Journal of Radiation Research and Applied Sciences 10:140–147

Shirazi HM, Karimi-Sabet J, Ghotbi C (2017) Biodiesel production from Spirulina microalgae feedstock using direct transesterification near supercritical methanol condition. Biores Technol 239:378–386

Cepoi L, Zinicovscaia I, Rudi L, Chiriac T, Miscu V, Djur S, Strelkova L, Vorgel K, Nekhoroshkov P (2020) Growth and heavy metals accumulation by Spirulina platensis biomass from multicomponent copper containing synthetic effluents during repeated cultivation cycles. Ecological Engineering 142:105637

Perfiliev YD, Tambiev AK, Konnychev MA, Skalny AV, Lobakova ES, Kirpichnikov MP (2018) Mössbauer spectroscopic study of transformations of iron species by the cyanobacterium Arthrospira platensis (formerly Spirulina platensis). J Trace Elem Med Biol 48:105–110

Walter A, Carvalho JCD, Soccol VT, Faria ABBD, Ghiggi V, Soccol CR (2011) Study of phycocyanin production from Spirulina platensis under different light spectra. Braz Arch Biol Technol 54:675–682

Sarpal AS, Costa ICR, Teixeira CMLL, Filocomo D, Candido R, Silva PRM, Cunha VS, Daroda RJ (2016) Investigation of biodiesel potential of biomasses of Microalgaes chlorella, Spirulina and Tetraselmis by NMR and GC-MS techniques. Journal of Biotechnol Biomater 6:2

Uslu L, Icik O, Koc K, Goksan T (2011) The effects of nitrogen deficiencies on the lipid and protein contents of Spirulina platensis. Afr J Biotech 10:386–389

Lewis T, Nichols PD, Mcmeekin TA (2000) Evaluation of extraction methods for recovery of fatty acids from lipid-producing microheterotrophs. J Microbiol Methods 43:107–116

Li YR, Shue MF, Hsu YC, Lai WL, Chen JJ (2014) Application of factorial design methodology for optimization of transesterification reaction of microalgae lipids. Energy Procedia 52:377–382

Saranraj P, Stella D, Usharani G, Sivasakthi S (2013) Effective recycling of lignite fly ash for the laboratory cultivation of blue green algae-Spirulina platensis. International Journal of Microbiological Research 4:219–226

Fogg, G.E., Thake, B.1987. Algal culture and phytoplankton ecology [3rd Ed.]. University of Wisconsin Press, 267.

Arnon DI (1948) Copper enzymes in isolated chloroplasts Polyphenoloxidase in Beta vulgaris. Plant Physiol 24:1

Jensen, A. 1988. Chlorophylls and carotenoids. In: Handbook of phycological methods, physiological and biochemical methods. Hellebust J. A., Craigie J. S. (eds), 5970, Cambridge University Press, Cambridge.

Bennett A, Bogorad L (1973) Complementary chromatic adaptation in a filamentous blue-green alga. J Cell Biol 58:419–435

Devanathan J, Ramanathan N (2012) Pigment production from Spirulina platensis using seawater supplemented with dry poultry manure. Journal of Algal Biomass Utilization 3:66–73

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Dubois M, Gilles KA, Hamiton JK, Robers PA, Smith F (1956) Colorimetric method for determination of sugar and substances. Anal Chem 28:350–356

Nordin, N., Yusof, N., Samsudin, S. 2014. Microalgae biomass production and nitrate removal from landfill leachate. In Proceeding of International Conference On Research, Implementation And Education Of Mathematics And Sciences,73–82.

Uma VSS, Dineshbabu G, Deviram G, Arulananth D, Uma L, Prabaharan D (2016) Rapid, cost effective, enhanced lipid extraction from marine cyanobacteria in a biodiesel perspective. Int J Adv Biotechnol Res 7:976–2612

Cheng, J., Seo, J., Tang, F., Wagstaff, M.J. 2014. The effect of iron concentration on the growth rate of Chlamydomonas reinhardtii. The Expedition, 3.

Glaesener AG, Merchant SS, Blaby-Haas CE (2013) Iron economy in Chlamydomonas reinhardtii. Front Plant Sci 4:337

Das, P., Ibrahim Thaher, M., Abdul Quadir Mohd Abdul Hakim, M., Al-Jabri, H.M.S., Alghasal, G.S.H. 2019. Optimization of iron dosage for microalgal biomass production as a feedstock for biofuel. Biofuels 1–9.

Marrez DA, Naguib MM, Sultan YY, Daw ZY, Higazy AM (2014) Evaluation of chemical composition for Spirulina platensis in different culture media. Res J Pharm, Biol Chem Sci 5:1161–1171

N’djamena, C., (2012) Changes in the physico-chemical properties of Spirulina platensis from three production sites in Chad. Journal of Animal & Plant Sciences 13:1811–1822

Jaruwan, C., Wanida, P., Afrasiab, K., Imrana, N.S., Werasit, S., Pramuk, P. 2014. Screening of High-Lipid Content Microalgae for Biodiesel Production. TSB 16–18.

Miazek K, Iwanek W, Remacle C, Richel A, Goffin D (2015) Effect of metals, metalloids and metallic nanoparticles on microalgae growth and industrial product biosynthesis: a review. Int J Mol Sci 16:23929–23969

El-Sheekh MM, Hamouda R (2016) Optimization of lipids extraction from the green alga Ankistrodesmus falcatus using different methods. Rendconti Lincei-Scienze Fisiche e Naturali 27(3):589–595

Fujii M, Rose AL, Omura T, Waite TD (2010) Effect of Fe (II) and Fe (III) transformation kinetics on iron acquisition by a toxic strain of Microcystis aeruginosa. Environ Sci Technol 44:1980–1986

Fraser JM, Tulk SE, Jeans JA, Campbell DA, Bibby TS, Cockshutt AM (2013) Photophysiological and photosynthetic complex changes during iron starvation in Synechocystis sp. PCC 6803 and Synechococcus elongatus PCC 7942. PLoS One 8:E59861

Reinbothe C, El Bakkouri M, Buhr F, Muraki N, Nomata J, Kurisu G, Fujita Y, Reinbothe S (2010) Chlorophyll biosynthesis: spotlight on protochlorophyllide reduction. Trends Plant Sci 15:614–624

Briat JF, Curie C, Gaymard F (2007) Iron utilization and metabolism in plants. Curr Opin Plant Biol 10:276–282

Yasar D, Sevket G (2006) á-tocopherol and Fatty acids of Spirulina platensis biomass in Glass panel bioreactor. Pak J Biol Sci 9:2901–2904

Hadiyanyo H, Adetya NP (2018) Response surface optimization of lipid and protein extractions from Spirulina platensis using ultrasound assisted osmotic shock method. Food Science and Biotechnology 27:1361–1368

Chen L, Liu T, Zhang W, Chen X, Wang J (2012) Biodiesel production from algae oil high in free fatty acids by two-step catalytic conversion. Biores Technol 111:208–214

Yeesang C, Cheirsilp B (2011) Effect of nitrogen, salt, and iron content in the growth medium and light intensity on lipid production by microalgae isolated from freshwater sources in Thailand. Biores Technol 102:3034–3040

El-Baky HHA, El-Baroty GS, Bouaid A, Martinez M, Aracil J (2012) Enhancement of lipid accumulation in Scenedesmus obliquus by optimizing CO2 and Fe3+ levels for biodiesel production. Biores Technol 119:429–432

Battah M, El-Ayoty Y, Abomohra AF, El-Ghany SA, Esmael A (2013) Optimization of growth and lipid production of the Chlorophyte Microalga Chlorella vulgaris as a feedstock for biodiesel production. World Applied Sciences Journal 28:1536–1543

Sahin MS, Khazi MI, Demirel Z, Dalay MC (2019) Variation in growth, fucoxanthin, fatty acids profile and lipid content of marine diatoms Nitzschia sp. and Nanofrustulum shiloi in response to nitrogen and iron. Biocatal Agric Biotechnol 17:390–398

Battah MG, El-Ayoty YM, Esmael AE, El-Ghany SE (2014) Effect of different concentrations of sodium nitrate, sodium chloride, and ferrous sulphate on the growth and lipid content of Chlorella vulgaris. International Journal of Agricultural Technology 10:339–353

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Sheekh, M.M., Salman, J.M., Grmasha, R.A. et al. Influence of Fe+2 on the biomass, pigments, and essential fatty acids of Arthrospira platensis. Biomass Conv. Bioref. 14, 621–629 (2024). https://doi.org/10.1007/s13399-022-02470-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02470-9