Abstract

The influence of mass transfer intensity on kinetics of catalytic oxidation of flax shives with oxygen to aromatic aldehydes and pulp was studied. The process was carried out in an autoclave in an aqueous-alkaline medium in the presence of CuO as the catalyst. Oxidation of flax shives into vanillin, syringaldehyde, and pulp was shown to proceed as a completely diffusion-controlled process under the studied conditions. Depending on the process conditions, it can be limited by stages of oxygen transfer through the gas–liquid interface as well as by oxygen transfer through the bulk of a Newtonian liquid phase and non-Newtonian suspension of the reaction mass. The results obtained on the influence of stirring speed and volume of the reaction mass on the rates of oxygen consumption and vanillin accumulation were described by a simple well-known model connecting the intensity of mass transfer and the stirring power density in the bulk of the liquid phase. It was shown that, despite the distinctly diffusion-controlled conditions of flax shives oxidation with oxygen, the vanillin yield was very close (70–83%) to the theoretical maximum of vanillin yield in the processes of lignin oxidation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Sustainable development is a challenge of modern civilization. First of all, development of new possibilities to substitute oil and other fossil resources with renewable plant raw materials is necessary. Agricultural waste is a huge renewable resource of lignocellulose materials but little used for chemical processing. Complete recycling of such waste in Russia can provide all the energy needs of agriculture [1].

The production of flax in Russia attains 600 thousand tons per year, and the main waste product (up to 70%) of the processing is flax shives. Shives are the lignified parts of the flax stem, mainly in the form of small straws, remaining after threshing stage. Usually, flax shives remain in the form of huge dumps or are burned for heating plants, but rational flax shives usage expands the possibilities to improve the efficiency of flax production [2, 3].

The intense development of processing plant biomass for fuels is due to the huge scale and importance of the problem, and against this background, processing of agricultural and forestry waste into value-added fine chemicals seems less noticeable. In the first place, aromatic aldehydes obtained by oxidation of various plant lignins, vanillin (4-hydroxy-3-methoxybenzaldehyde) and syringaldehyde (4-hydroxy-3,5-dimethoxybenzaldehyde), should be noted [4]. The world production of vanillin (prices per kilo of about $ 20) is 15–20 thousand tons per year [5]. Syringaldehyde can be an inexpensive source of trihydroxyphenyl derivatives used in pharmaceutics and other areas of fine chemical technology [6].

Attempts to combine processing of lignin from plant waste into aromatic aldehydes and carbohydrates into ethanol are quite promising, despite the different scale of technologies [7, 8]. Wood processing into pulp and vanillin provided the main production of the latter in the 1950s–1970s and still operates today [4, 5, 9].

The most promising methods for vanillin and syringaldehyde production are catalytic oxidation of lignins with oxygen. The oxidation of lignin with nitrobenzene (NB) usually produces slightly higher yields of aromatic aldehydes, but such processes are complicated due to the high NB price and the problems of byproduct utilization [4]. Kraft condensed lignins give relatively low yields of aldehydes during oxidation, and for this reason, they are less suitable than native lignins for vanillin and syringaldehyde production. This comparison demonstrates the prospects of the “lignin first” concept [10] with the use of lignin oxidation as the first stage of processing of lignocellulosic materials. Agrotechnical wastes from processing herbaceous plants combine the advantages of native and technical lignins: low prices and the possibilities to obtain low-molecular products with high yields.

Flax shives contain 18–28% of lignin that is more than the lignin content in hardwoods and close to that in softwood. Possibilities to obtain valuable chemicals by hydrogenation and pyrolysis of flax shives are under study [11,12,13]. There are only few works on nitrobenzene oxidation of flax shives (Table 1) [14, 15], the reported yield of vanillin of 15–20 wt% based on lignin being lower of that obtained by oxidation of coniferous lignins (23–28%). Again, syringaldehyde is obtained at a significantly lower yield from shives (6–11%) than from native hardwood lignins. Data on the yield of para-hydroxybenzaldehyde while oxidizing flax shives are contradictory and range from 0.4 to 7%. The yields of aldehydes from flax shives may be higher than those observed during oxidation of wheat straw (14%) [14,15,16,17,18].

Any data on catalytic oxidation of flax shives with oxygen are not found in the literature. Only a few data on the influence of the intensity of mass transfer of reagents on the rate and selectivity of catalytic oxidation of lignins are reported [4, 21, 22]. The goal of this work is to study quantitatively the effect of mass transfer intensity on the catalytic oxidation of flax shives with oxygen to aromatic aldehydes and pulp. The obtained results show that the oxidation process under study is diffusion-controlled completely. The influence of mass transfer intensity on the kinetics of oxygen consumption and vanillin formation is successfully described by a simple quantitative model, and on these basics, the possibilities to improve the process were found.

2 Materials and methods

Air-dried powdered (≤ 1 mm) flax shives (Linum usitatissimum, Rosinka type, [23], harvest of 2020, Tver region or Belarus origin) were used for the experiments. Lignin content in the studied materials was measured as the Klason lignin remaining after hydrolyzing the carbohydrate components with 72 vol.% sulfuric acid (standard technique [24]). Cellulose content was measured in the form of Kuerschner cellulose obtained by refluxing a studied sample three times for 1 h with a 1:4 (by volume) mixture of concentrated nitric acid and ethyl alcohol [25]. The dried shives contained 29.5 wt% lignin, 41.4 wt% cellulose, 1.45 wt% extractives, and 1.9 wt% ash. Hemicelluloses as the main components, flax seeds and other impurities were the remaining 25.75 wt% of the sample.

2.1 Prehydrolysis of flax shives powder

A sample of air-dried raw powder was mixed with HCl (23%, 10 ml per gram of the shives) and kept at 20 °C for 1 h. The powder was filtered, washed with distilled water to obtain the neutral reaction, and dried at room temperature, and the mass loss of the flax shives was determined.

2.2 Oxidation of the shives

A reaction mass was prepared by successive addition of required amounts of shives (50 g/l), sodium hydroxide (50 g/l), water (300 ml), and a catalyst (CuSO4 · 5H2O, 37.5 g/l), if otherwise do not note, into a reactor under stirring all the while. The catalyst converted finally in a form of copper oxide (12 g/l) dispersed on the shives surface and in water phase under the process conditions.

Experiments were conducted in a stainless steel autoclave [7, 8] (volume 1 l, internal diameter 95 mm, height 180 mm) at 160 °C and oxygen partial pressure of 0.2 MPa) equipped with a magnetic stirrer (stir bar diameter 10 mm and length 60 mm) at 100–700 rpm during 60 min, if otherwise do not note. The process conditions were chosen according to our data [7, 8]. Heating (in argon) and temperature stabilization took 25–40 min, and then oxygen was introduced. Oxygen was fed into the reactor from a calibrated buffer volume through a valve to maintain the constant pressure in the reactor. Amount of the consumed oxygen was calculated from a change in pressure inside the buffer volume. An error of an experimental points in the curves of the oxygen consumption is determined by an accuracy of manometer used (10 kPa) and estimated as 4.2 mmol. Temperature was maintained automatically with ± 2 °C accuracy. After oxidation, the reactor was cooled down to 90 °C for 20 min, excess pressure was vented to the atmosphere, and the reactor was opened.

The rates of oxygen consumption were estimated on the kinetic curves in the time interval 5–15 min. Errors were estimated as the standard deviation, confidence intervals at the 68% confidence level calculated by the method of least squares. They are given in the corresponding figures. A double arithmetic mean standard deviation at the 95.5% confidence level was calculated according to Eq. (1):

where sm is arithmetic mean standard deviation, s is the standard deviation, and NEP is the number of experimental points. Most part of the experiments on oxidation were made twice, ones to register the oxygen consumption, and ones for sampling to analyze vanillin and syringaldehyde. Samples of the reaction mass of 13–15 ml volume were taken from the reactor through the special valve during the oxidation process and after the experiment. To analyze the reaction products, the solution was acidified with HCl to pH 3–4, and triply extracted with chloroform. Vanillin concentration was determined by GLC (Chromos Engineering GH1000 chromatograph, column 30 m × 0.32 mm, stationary phase 25% trifluoropropyl polysiloxane), column temperature 180 °C, and anthracene was used as internal standard.

3 Results and discussion

3.1 Oxidation of the original flax shives

Milled flax shives (≤ 1 mm) were oxidized with oxygen in an alkaline medium at 160 °C and partial oxygen pressure of 0.2 MPa over copper oxide as the catalyst (a solution of copper sulfate was loaded into the reactor). Monotone curves of oxygen consumption were observed earlier in the processes of wood and lignosulfonates oxidation [4, 7, 8, 21, 26]. Oxidation of original flax shives proceeds different way under similar conditions: the stepwise time dependences of oxygen consumption were obtained and poorly reproduced (Fig. 1). These problems become more pronounced as the mass transfer decreases in intensity (stirring speed, the volume ratio of gas to liquid in the reactor). The step-like curves of the oxygen consumption are not evidently related to the errors of pressure measuring in the reactor and buffer tank that were used to calculate the volume of oxygen consumed. The volume of oxygen consumed decreases when the volume of the liquid phase increases, i.e., when the mass of the shives in the reactor increases.

The results obtained show that there are at least two types of diffusion limitation of the oxygen consumption by the liquid phase components in the reaction system under consideration. The first barrier can be localized at the liquid–gas interface in the form of gas-tight films. It forms and destroys accidentally, and its origin is discussed in Section 3.2. The second effect of diffusion limitation is caused by the viscosity of the liquid phase; this is the reason for a decrease in the oxygen consumption with increasing volume of the reaction mass. The first barrier is mainly overcome under conditions of maximum mass transfer intensity at the highest stirring speed and the minimal volume of the liquid phase in the reactor (Fig. 1b).

Similar trends (reduction of the oxidation rate—sometimes down to complete halt—due to the increasing lignin concentration) were observed in catalytic oxidation of straw soda cooking liquor, lignosulfonates [16, 26], and brown rotted pine wood [4]. The complete stoppage of the process was accounted for by the lignin condensation to form a gas-tight polymeric film on the liquid–gas interface that impedes the access of oxygen to the reaction mass [4].

3.2 Oxidation of prehydrolyzed flax shives

In the system under consideration, the chemical nature of the diffusion barrier at the gas–liquid interface may relate to flax mucilage but not lignin derivatives. Whole flax seeds and their pieces were found in the initial and milled samples of shives from Tver region (Tver shives). The flax mucilage concentrated in flax seeds contains 50 to 80% carbohydrates and 4 to 20% proteins [27, 28]. The flax mucilage forms colloidal solutions, and sol–gel transitions may occur near the gas–liquid interface as a result of water evaporation or oxidation with oxygen to form a weak but gas-tight film.

The ether bonds of polysaccharides are known to be hydrolyzed in an acidic medium and quite stable in alkali solutions [29]. For this reason, we used acid prehydrolysis of flax shives to remove soluble hydrolysis products in order to avoid the diffusion limitations which generate the stepwise time dependences of oxygen consumption. Earlier, we used similar acid prehydrolysis of wood for hydrolyzing hemicellulose and lignin to decrease alkali consumption and to increase vanillin yield [8].

Table 2 shows the component composition of flax shives samples from Tver and Belarus, original and prehydrolyzed. As a result of prehydrolysis, flax shives lose 10% of their mass, mainly due to the dissolution of hemicelluloses. The ash content of the flax shives is noticeably reduced, while the contents of lignin and cellulose increase. Variation of the hydrochloric acid concentration (23–28%) changes the degree of hydrolysis insignificant.

All the data below are obtained with flax shives from Tver region except specially noted results. Table 3 compares catalytic oxidation of the original and prehydrolyzed shives for the reaction masses of identical compositions. The oxygen consumption by prehydrolyzed shives was as high as ten times of that during oxidation of the original non-hydrolyzed shives at high reaction mass loads (400 ml). This ratio of the oxygen amount consumed by the prehydrolyzed and original shives decreases from 10.8 to 1.5 when the reaction mass decreases in volume. Hence, the diffusion limitation of oxygen mass transfer in the reaction mass volume weakens upon removal of the easily hydrolyzable mucilage and carbohydrates from the flax shives. Data on the dynamics of oxygen consumption during oxidation of the original and prehydrolyzed shives (Fig. 2) also show that the steps are observed in the curves of oxygen consumption in oxidation of the original shives but practically not in the curves of oxidation in the prehydrolyzed feedstock. Hence, prehydrolysis and mucilage destruction prevent the formation of gas-tight films on the gas–liquid interface during oxidation and thus eliminates this barrier for oxygen mass transfer. Comparing the curves of oxygen consumption with original flax (Fig. 2a, b) reviles unusual dependence; the smaller the reactant volume is, the higher the oxygen consumption. This may be accounted for the non-Newtonian behavior of the reactant suspension and will be discussed below (Section 3.4).

Dynamics of oxygen consumption during the oxidation of the original and prehydrolyzed flax shives at different loads of the reaction mass—400 ml (a) and 300 ml (b). See Fig. 1 for the process conditions

Prehydrolysis of shives also leads to an increase in the vanillin yield during the oxidation process (by 20–40%), although the effect is less significant than an increase in the oxygen consumption. The vanillin yield from the prehydrolyzed flax shives varies slightly (by 8–9%) with a decrease in the loading of the reaction mass into the autoclave. The results obtained show that the diffusion limitation in the oxidation process suppresses the oxygen consumption much stronger than the vanillin yield. On one hand, such difference is caused by the fact that the oxygen is mainly consumed in the side processes of oxidation (oxygen consumption per formed vanillin is 18–156 mol/mol, (Table 3) but not for the vanillin formation. On the other hand, it has been recently shown that during catalytic oxidation of lignins with oxygen, the hydroperoxides are formed in the solution, and their concentration exceeds significantly the concentration of dissolved oxygen [30, 31]. These hydroperoxides, along with molecular oxygen, can oxidize lignin to vanillin and thus reduce the effect of O2 mass transfer on the vanillin yield in the process. The difference between the diffusion limitation of the oxygen consumption and vanillin formation has not been discussed before; it can be used to reduce the oxygen and, possibly, alkali consumption in the processes of lignin oxidation to aromatic aldehydes.

3.3 Influence of the stirring speed on the rate of oxygen consumption

Figure 3 illustrates the effect of the stirring speed and reaction mass volume on the kinetics of oxygen consumption during oxidation of prehydrolyzed flax shives. The rate of oxygen consumption increases with the stirring speed (Fig. 3a) in agreement with the classical view on the kinetics of diffusion-controlled reactions. The relation between the stirring speed of the magnetic stirrer (N) and the initial rate of oxygen consumption (\({{W}_{O}}_{2}\)) is quantitatively revealed in logarithmic coordinates (Fig. 5) and described satisfactorily by the linear equation

Impact of the stirring speed (a) on the kinetics of oxygen consumption during oxidation of prehydrolyzed flax shives; logarithmic dependence (b) of the initial rate of oxygen consumption on the stirring speed. See Fig. 1 for the process conditions

With the line slope a2 = 1.88 ± 0.17, where s = 0.17 is a standard deviation. The corresponding double arithmetic mean standard deviation of the slope 2sm = 0.13 for the confidence level 0.955, and this deviation may be estimated as satisfied value for the process in four-phase reaction system. With sufficient accuracy, this means that the rate of oxygen consumption is proportional to the square of the stirrer speed. The simplest model of the influence of stirring speed on the mass transfer intensity in a gas–liquid system states that the latter is proportional to the stirring power density in the bulk of the liquid phase [32]. The kinetic energy of the moving liquid phase is proportional to the square of its velocity, and the latter is proportional to the speed of stirring [33]. Thus, the close-to-linear dependence of the oxygen consumption on the square of the stirrer speed corresponds to the mass transfer model determined by the stirring power density in the liquid phase volume:

where \({{W}_{O}}_{2}\) is oxygen consumption rate, ai is proportionality coefficients, P0 and N are the power and stirring speed of the stirrer, respectively.

Moreover, the transfer of stirring energy in a gas–liquid system is less efficient than in the liquid phase [33]:

where P and P0 are the power transmitted by the stirrer to the gas–liquid and liquid media, respectively. Combining Eqs. (3) and (4) gives an equation of relationship between the oxygen consumption rate and the stirrer speed in a three-phase system:

in which the exponent coincides very precisely with the experimentally determined coefficient of Eq. (2) a2 = 1.88 ± 0.17 for the confidence level of 0.955.

3.4 Influence of the reaction mass volume in the reactor on the rate of oxygen consumption

The influence of the volume of the reaction mass (Fig. 4) on the dynamics of oxygen consumption by the prehydrolyzed shives reveals different regularities: the absolute initial rate remains practically not changed in the range of liquid phase volumes of 200–350 ml. Hence, the initial rate of oxygen consumption per unit volume, i.e., the rate of the oxidation reaction in the liquid phase, decreases proportional to the reaction mass volume. Independence of the absolute rate from the volume of the liquid phase and the mass of the loaded shives corresponds quantitatively to Eqs. (3) and (6):

were P0/V is stirring power density. The rate of oxygen consumption is determined by the power of the stirrer and does not depend on the volume of the reaction mass under a constant rotation speed and other conditions.

The further increase in the volume of the liquid phase from 350 to 400 ml results in a sharp decrease in the rate and volume of oxygen consumed. This effect may be accounted for by the non-Newtonian behavior of the oxidized suspension: at low stirring power densities and rates of shear strain, a region with increased viscosity and disproportionately low mass transfer intensity is formed far from the stirrer. Such increase in viscosity is not due to a change in the physicochemical properties of the medium but due to a decrease in the shear rate, the non-Newtonian dependence of the viscosity on the stirring speed [34]. A decrease in the volume of oxygen consumed with increasing reaction mass is observed in the whole range of volumes using the original, non-hydrolyzed shives (Table 3, Fig. 1). Consequently, the high viscosity of the reaction mass with mucilage of non-hydrolyzed shives may lead to a non-Newtonian behavior of the system in the entire range of liquid phase volumes under study (Figs. 1 and 2, Table 3).

Inspection of the results obtained (Figs. 1, 2, 3, and 4, Table 3) shows that the flax shives oxidation is the diffusion-controlled process, i.e., the rate of oxygen mass transfer in the reaction mass limits completely the chemical process of oxidation. In the general case including oxidation of non-hydrolyzed flax shives, mass transfer can be limited at one of three stages: (1) oxygen transfer through the gas–liquid interface when mucilage slows the rate down to zero; (2) oxygen transfer through the bulk of the Newtonian liquid phase; and (3) oxygen transfer through the bulk of the non-Newtonian suspension (liquid–solid reaction mass). In the absence of first and third factors, the dependences of the oxygen consumption rate on the stirring speed and on the volume of the reaction mass in the reactor are successfully described by a simple model connecting the mass transfer intensity and the stirring power density in the two-phase gas–liquid system [32, 33].

3.5 Comparative results on oxidation of seed-free flax shives

The results obtained can be compared to oxidation of Belarusian shives free of flax seeds (Table 2) and, therefore, of mucilage. As expected, oxygen consumption during oxidation of the Belarussian shives proceeds without any complications: the oxygen consumption curves, as in the case of the prehydrolyzed shives from Tver (Fig. 3a), are monotonous and reach saturation in 60 min (Fig. 4). Prehydrolysis of the Belarussian flax shives does not change dynamics of oxygen consumption in the further oxidation process (Fig. 5) and vanillin yield (Table 4), because these shives do not contain flax seeds and mucilage. The curves of oxygen consumption of prehydrolyzed Tver and Belarusian shives are practically coinciding under identical conditions (Fig. 5, Table 4).

Thus, the mucilage of flax seeds in the shives slows dramatically the consumption of oxygen during the oxidation process, while the removal and destruction of mucilage by the acid prehydrolysis permits to eliminate almost completely this problem.

After oxidation, the cellulose content in the solid residue is 77–78% of its content in the original non-hydrolyzed shives independently of the sample nature but 57–66% of the content in the prehydrolyzed shives (Table 4). A similar effect of prehydrolysis on the cellulose yield was shown earlier [8] for oxidation of pine wood to vanillin.

3.6 Influence of stirring speed on the vanillin accumulation

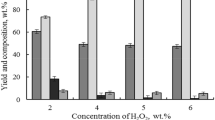

Figure 6 illustrates the influence of stirring speed on the dynamics of vanillin accumulation during oxidation of the prehydrolyzed flax shives. There are extreme curves of vanillin accumulation with the maximum vanillin yield varied between 8 and 10 wt% referred to the lignin shives. Vanillin content decreases after reaching maximum values due to its further oxidation [4, 8].

Influence of the stirring speed on the dynamics of vanillin accumulation (a); logarithmic dependence of vanillin formation rate (estimated as 1/tmax, reverse time to attain the maximum vanillin concentration) (b). See Fig. 1 for the process conditions

Time of reaching the maximum vanillin concentration is shifted from 20 to 90–200 or more minutes as the stirring speed decreases from 700 to 200 min−1. A similar, though less pronounced, influence of the stirring speed on the time of reaching the maximum vanillin yield was reported elsewhere [21]. The previously observed extreme dependence of the yield of vanillin and other monomeric oxidation products on the stirring speed at a constant duration of the process [22] may be accounted for by this shift (Fig. 6a) of the maximum yield of vanillin in time. A weak extreme dependence between maximum vanillin yield and stirring speed may exist (Fig. 6), but it is negligible compared to the influence of the stirring speed on the time of reaching the maximum vanillin concentration. More difference between mass transfer intensity of prehydrolyzed and original Tver shives causes almost double, but not proportional, increasing the vanillin yield under the conditions used (Table 3).

It was shown above that the kinetics of oxygen consumption is adequately described by Eqs. (2) and (5) based on the relationship between the intensity of mass transfer and the stirring power. If taken the reverse time of attaining the maximum vanillin concentration (1/tmax) as a characteristic of the rate of vanillin formation, it is possible to plot the logarithmic dependence between 1/tmax and the stirring speed similar to Fig. 3b (Fig. 6b). This dependence is linear and has slope tgφ = 1.86 ± 0.06:

This tangent coincides with the tangent in Eq. (2) for the rate of oxygen consumption within the experimental accuracy. The corresponding double arithmetic mean deviation of the tangent (7) 2sm = 0.06 is less compared to the deviation for oxygen consumption dependences (2). Possible explanation of this difference is discussed in Section 3.2.

The coincidence of the tangents of experimental dependences (2) and (7) with the tangent in Eq. (5), which follows from the known simplest laws of mass transfer, shows that, despite the complexity of the studied chemical process, both the rate of oxygen consumption and the curves of vanillin accumulation correspond to the model of mass transfer intensity (3)–(5) determined by the stirring power density in the volume of the liquid phase [32, 33]. As a result, the rates of oxygen consumption have a linear relationship with vanillin accumulation (estimated as 1/tmax) (Fig. 7). This relationship can be used to estimate the time of attaining the maximum vanillin concentration using less time-consuming experimental dependences of the oxygen consumption rate on the stirrer speed.

Note again that mass transfer intensity affects only slightly the vanillin yield but strongly the oxygen consumption during the process. As a result, the oxygen consumption per vanillin formed increases sharply (up to three times) with the intensity of mass transfer (Fig. 8). This dependence, as well as the effect of prehydrolysis on the oxidation process established earlier [8], can be used to reduce the consumption of oxygen and, possibly, alkali in the processes of lignin oxidation to aromatic aldehydes at a moderate intensity of mass transfer. Moderate intensity of mass transfer permits also to increase a pulp yield in the process [22].

Impact of the stirring speed on the oxygen consumption referred to the vanillin obtained during oxidation of prehydrolyzed flax shives. See Fig. 7 for the process duration

3.7 Comparison of the vanillin yields during oxidation of the flax shives with oxygen and nitrobenzene

It is well known that the selectivity to intermediate products including vanillin can be increased in transferring the oxidation process from the diffusion-controlled to kinetic regimes [4, 32]. Such a change in the selectivity cannot be determined experimentally in the used reactor. It is generally accepted that oxidation of lignins with nitrobenzene gives vanillin yields corresponding to the theoretical selectivity limit. We used these results as estimation of the maximum possible selectivity of the flax shives oxidation with oxygen in the kinetic regime.

Table 5 shows vanillin yields in oxidation of Belarusian flax shives with nitrobenzene (15.1 wt% per lignin) and molecular oxygen (12.5%). These results and the similar results of oxidation of prehydrolyzed Tver flax shives show that the transfer from the maximally selective process to the diffusion-limited oxidation with oxygen leads to a relative decrease in the vanillin yield by 17–30%. In our opinion, these are unexpectedly low differences; they indicate a very large ratio of the rates of formation and oxidation of vanillin.

The results obtained for nitrobenzene oxidation of shives are slightly different from the literature data [14, 15]. This may be due to the specific features of different samples of flax shives. The obtained ratio of vanillin:syringaldehyde 3.4:3.7 is close to the literature data [14].

4 Conclusions

Catalytic oxidation of flax shives with oxygen permits to process this waste into vanillin, syringaldehyde, and pulp. The latter can be converted to glucose, ethanol, levulinic acid, and other valuable products using enzymatic, microbiological, and chemical methods.

Effective oxidation of flax shives with oxygen in an alkaline media needs studying and overcoming the problems of diffusion limitation of oxygen transfer through the gas–liquid interface. They are identified as stepwise dependences of the oxygen consumption on time including long (up to 20 min) periods of zero consumption rate. This obstacle is mainly caused by flax mucilage forming colloidal solutions (sols), and it may lead to the formation of gels on the gas–liquid interface and prevent the interphase transfer of molecular oxygen. Possible mechanisms of the sol–gel transition are the physical concentration of mucilage at the gas–liquid interface as a result of water evaporation, or the oxidative condensation of mucilage on the interface. This obstacle was overcome via acid prehydrolysis of flax shives and partial removal of easily hydrolyzable carbohydrates and mucilage.

The obtained results show that the oxidation process under study is diffusion-controlled, i.e., the rate of mass transfer of oxygen in the reaction mass limits completely oxidation of flax shives components. Three kinds of limitations are observed: (1) oxygen transfer through the gas–liquid interface when mucilage slows the rate down to zero; (2) oxygen transfer through the bulk of the Newtonian liquid phase; and (3) oxygen transfer through the bulk of the non-Newtonian suspension (liquid–solid reaction mass).

In the absence of first and third factors, the dependences of the oxygen consumption rate on the stirring speed and on the volume of reaction mass in the reactor are successfully described by the classical model connected the intensity of mass transfer and the stirring power density in the two-phase gas–liquid system [32, 33]: the rates of oxygen consumption and vanillin formation on the stirrer speed are linear in logarithmic coordinates with the coinciding slopes (tgφ = 1.88 ± 0.17 and 1.86 ± 0.06 correspondingly). This is the first and productive attempt to describe quantitatively mass-transfer regularities in the processes of lignins oxidation.

The found regularities show that the oxygen consumption per vanillin formed increases sharply (up to three times) with the intensity of mass transfer. This dependence can be used to reduce the consumption of oxygen and, possibly, alkali in the processes of lignin oxidation to aromatic aldehydes at a moderate intensity of mass transfer.

Despite the diffusion-controlled regime of the process under consideration, the maximum yields of vanillin per lignin in the oxidation processes of shives with nitrobenzene (15–16%) and oxygen (11–12.5%) differ by 17–30 relative percent. In our opinion, these are unexpectedly low differences. The observed decrease in the yields of vanillin (and syringaldehyde) in the processes of oxidation upon substitution of oxygen for nitrobenzene can be interpreted as an estimation of decrease in the selectivity of the oxidation by oxygen when going from the kinetic to diffusion modes.

Moreover, the vanillin yields that are closer or even equal to the yield in the oxidation with nitrobenzene were recently obtained using the same reactor [7, 8] and, hence, under the diffusion-controlled conditions. Comparison of the processes of catalytic oxidation of lignins with oxygen obtained in the present study and elsewhere [7, 8] indicates that the maximal theoretical vanillin yields can be attained under diffusion-controlled conditions.

References

Varfolomeev SD, Moiseev II, Myasoedov BF (2009) Energy carriers from renewable sources: chemical aspects. Her Russ Acad Sci 79:334–344. https://doi.org/10.1134/S1019331609040030

Porfirov P (2014) Development of the flax complex in Russia. Int Agric J 6:30–34

Lin’ AA, Mikhailov VM, Polyakov AV (2016) Flax grower and flax growing - between the past and the future. Agr Rus 12:32–35

Tarabanko VE, Tarabanko N (2017) Catalytic oxidation of lignins into the aromatic aldehydes: general process trends and development prospects. Int J Mol Sci 18:2421. https://doi.org/10.3390/ijms18112421

Vu TT, Lim YI, Song D et al (2021) Economic analysis of vanillin production from Kraft lignin using alkaline oxidation and regeneration. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-01212-z

Erofeev YV, Afanas’eva VL, Glushkov RV, (1990) Synthetic routes to 3,4,5 - trimethoxybenzaldehyde. Pharm Chem J 24:501–510

Tarabanko VE, Kaygorodov KL, Skiba EA, Tarabanko N, Chelbina YV, Baybakova OV, Kuznetsov BN, Djakovitch L (2017) Processing pine wood into vanillin and glucose by sequential catalytic oxidation and enzymatic hydrolysis. J Wood Chem Technol 37:43–51. https://doi.org/10.1080/02773813.2016.1235583

Tarabanko VE, Kaygorodov KL, Vigul DO, Tarabanko N, Chelbina YV, Smirnova MA (2020) Influence of acid prehydrolysis on the process of wood oxidation into vanillin and pulp. J Wood Chem Technol 40:421–433. https://doi.org/10.1080/02773813.2020.1835984

Ponnusamy VK, Nguyen DD, Dharmaraja J, Shobana S, Banu JR, Saratale RG, Chang SW, Kumar GA (2019) Review on lignin structure, pretreatments, fermentation reactions and biorefinery potential. Bioresour Technol 271:462–472. https://doi.org/10.1016/j.biortech.2018.09.070

Renders T, Van den Bosch S, Koelewijn SF, Schutyser W, Sels BF (2017) Lignin-first biomass fractionation: the advent of active stabilisation strategies. Energy Environ Sci 10:1551–1557. https://doi.org/10.1039/C7EE01298E

Sulman EM, Lugovoy YV, Chalov KV, Kosivtsov YY, Stepacheva AA, Shimanskaya EI (2016) Flax shivethermocatalytic processing. https://doi.org/10.1063/1.4968068

Molchanov V, Fomicheva N, Smirnova Y, Sidorov A, Matveeva V (2020) Development of technology for the processing of organic waste and renewable plant materials with the production of biologically active substances for agricultural purposes. https://doi.org/10.1088/1755-1315/624/1/012117

Kazachenko AS, Tarabanko VE, Miroshnikova AV, Sychev VV, Skripnikov AM, Malyar YN, Mikhlin YL, Baryshnikov SV, Taran OP (2021) Reductive catalytic fractionation of flax shive over Ru/C catalysts. Catalysts 11:42. https://doi.org/10.3390/catal11010042

Ross K, Mazza G (2010) Characteristics of lignin from flax shives as affected by extraction conditions. Int J Mol Sci 11:4035–4050. https://doi.org/10.3390/ijms11104035

Karpunin II (1978) Nitrobenzene oxidation of flax shives lignin. Rus J Appl Chem 51:2387–2389

Tarabanko VE, Koropachinskaya NV, Kudryashev AV, Kuznetsov BN, Polyakov SV, Zolotukhin VN, Pervyshina EP (1998) Study of processing wheat straw into aromatic aldehydes and levulinic acid. Khimiya Rastitel’nogo Syr’ya 3:59–64

Billa E, Tollier MT, Monties B (1996) Characterisation of the monomeric composition of in situ wheat straw lignins by alkaline nitrobenzene oxidation: effect of temperature and reaction time. J Sci Food Agric 72:250–256

Sun R, Lawther JM, Banks WB (1995) The effect of alkaline nitrobenzene oxidation conditions on the yield and components of phenolic monomers in wheat straw lignin and compared to cupric (II) oxidation. Ind Crop and Prod 4:241–254

Leopold B, Malmstrom IL (1952) Studies on lignin. IV. Investigation on nitrobenzene oxidation products of lignin from different woods by paper partition chromatography. Acta Chem Scand 6:38–54

Tarabanko VE, Koropachinskaya NV, Chernyak MY (2003) Catalytic oxidation of birch wood (Betula Pendula Roth.) with oxygen in syringaldehyde and vanillin. Khimiya Rastitel’nogo Syr’ya 2:9–14

Pacek AW, Ding P, Garrett M, Sheldrake G, Nienow AW (2013) Catalytic conversion of sodium lignosulfonate to vanillin: engineering aspects. Part 1. Effects of Processing Conditions on Vanillin Yield and Selectivity. Ind Eng Chem Res 52:8361–8372. https://doi.org/10.1021/ie4007744

Zhu YT, Liao YH, Wei L, Liu J, Song XB, Chen LG, Wang CG, Sels BF, Ma LL (2020) Complementing Vanillin and Cellulose Production by Oxidation of Lignocellulose with Stirring Control. ACS Sustain Chem Eng 8:2361–2374. https://doi.org/10.1021/acssuschemeng.9b04837

Pat. No 2648, code 9811598. https://gossortrf.ru. Russian Flax Research Institute (2005), Registered in 2005–04–13

TAPPI Chemical Properties Committee of the Process and Product Quality Division (2002) Acid-insoluble lignin in wood and pulp. TAPPI Standard Test Method 222 om-02

Saeman JF, Moore WE, Mitchell RL, Millett MA (1954) Techniques for the determination of pulp constituents by quantitative paper chromatography. Tappi J 37:336–343

Tarabanko VE, Fomova NA, Kuznetsov BN, Kudryashev AV, Ivanchenko NM (1995) On the mechanism of vanillin formation in catalytic oxidation of lignin with oxygen. React Kinet Catal Lett 55:161–170

Kaewmanee T, Bagnasco L, Benjakul S, Lanteri S, Morelli CF, Speranza G, Cosulich ME (2014) Characterisation of mucilages extracted from seven Italian cultivars of flax. Food Chem 148:60–69. https://doi.org/10.1016/j.foodchem.2013.10.022

Mazza G, Biliaderis CG (1989) Functional properties of flax seed mucilage. J Food Sci 54:1302–1305

Scheller HV, Ulvskov P (2010) Hemicelluloses. Annu Rev Plant Biol 61:263–289. https://doi.org/10.1146/annurev-arplant-042809-112315

Kaigorodov KL, Tarabanko VE, Chernyak MY, Chelbina YV, Tarabanko NV, Smirnova MA (2018) Kinetics of low-temperature oxidation of enzymatic lignin from pine wood (Pinus silvestris) in an aqueous alkaline medium. Russ J Bioorg Chem 44:731–736. https://doi.org/10.1134/S106816201807004X

Kaigorodov KL, Tarabanko VE, Chernyak MY, Chelbina YV, Tarabanko NV, Smirnova MA (2017) Kinetics of low-temperature oxidation of enzymatic lignin from pine wood (Pinus silvestris) in an aqueous alkaline medium. Khimiya Rastitel’nogo Syr’ya 3:63–70

Perry JH (1963) Chemical Engineers’ handbook, (4th Ed.). McGRAW-Hill Book Company, New-York-Toronto-London-Sydney, p. 93

Joshi JB, Pandit AB, Sharma MM (1982) Mechanically agitated gas-liquid reactors. Chem Eng Sci 37:813–844

Mezger TG (2006) The rheology handbook: for users of rotational and oscillatory rheometers (2., rev.ed.). Vincentz Network, Hannover

Funding

This research was supported by the Russian Science Foundation, grant No 20–63-47109.

The equipment of Krasnoyarsk Regional Research Equipment Centre of SB RAS was used in the experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tarabanko, V.E., Vigul, D.O., Kaygorodov, K.L. et al. Influence of mass transfer and acid prehydrolysis on the process of flax shives catalytic oxidation into vanillin and pulp. Biomass Conv. Bioref. 14, 489–499 (2024). https://doi.org/10.1007/s13399-022-02366-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02366-8