Abstract

In recent times, there has been a burgeoning interest in harnessing natural plant extracts for the development of innovative biological scaffolds. This article centers on the extraction of Parrotia persica extract and explores its potential suitability for integration into nanofibrous structures. In pursuit of this objective, nanofibers were meticulously crafted using a blend of polyvinyl alcohol (PVA) and the derived Parrotia persica extract (E), employing the electrospinning technique. Different PVA/E ratios (90:10, 80:20, and 50:50) were investigated. The formation of layer-by-layer structures (four layers) was achieved by sequentially electrospinning a layer of PCL nanofibers onto a collector, followed by the deposition of a layer of PVA/E ((80:20) and (50:50)) with the identical thickness. The results revealed that the layered fibers exhibited a strikingly three-dimensional architecture, closely resembling the natural extracellular matrix. Notably, among the samples, the PCL-PVA/E (80:20)-PCL composition demonstrated the most favorable morphology, featuring a contact angle of approximately 40.45° and a diameter measuring 403 nm. Fourier transform infrared spectroscopy (FTIR) analysis conclusively confirmed the presence of Parrotia persica extract, PVA, and PCL within the intricate layers. Furthermore, fibroblast cell culture observations revealed the attachment and spreading of cells on the surface of the PVA/E (80:20)-PCL samples, underscoring their potential for facilitating cellular growth and tissue regeneration.Taking into account their highly desirable hydrophilic properties, the incorporation of Parrotia persica extract with its antibacterial and antioxidant attributes, as well as the presence of PCL endowed with elastic properties akin to those of natural skin, the prepared nanofibrous structures exhibit a promising outlook as viable skin substitutes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, humans are exposed to various threats and injuries that can lead to complex healing processes and even organ failure or death [1]. The healing time of a wound depends on its extent, size, and depth, which classify wounds into superficial, partial thickness, and full-thickness categories [2]. Electrospun nanofibers have emerged as a promising approach for preventing bacterial infections and promoting wound healing [3,4,5]. These nanofibers possess a high surface-to-volume ratio [6], excellent porosity, and mimic the natural extracellular matrix, thereby accelerating the healing process [7, 8]. Electrospinning, a widely used technique for nanofiber production, involves the application of an electrostatic force to a polymer solution, resulting in the formation of nanofibers [6]. The process comprises four stages: the creation of a Taylor cone from polymer solution droplets, the stretching and thinning of the jet, and the deposition of solid fibers onto a collector [9]. By carefully controlling parameters such as voltage, time, and distance between the needle and collector, nanofibers with desired characteristics can be obtained [10,11,12]. Nanofibers can be fabricated from various natural and synthetic polymeric compounds [13]. Use of plant extracts for the treatment of burns and diabetic wounds is a common operation followed over the decades, and it is a significant aspect of health management. Many medicinal plants, as natural derivate and biologically active compounds, have a long history of curative properties in wound healing and medical fields, and there is a growing request for new antimicrobial plant-based drugs. In the field of wound healing, the use of herbal extracts in electrospun nanofiber membranes has demonstrated antibacterial, antiviral, and antifungal properties, making them suitable for wound dressing applications [14]. Numerous plant extracts, including chamomile, curcumin, Moringa, Eucalyptus, Trigonella foenum, Securigera securidaca, Rosemary officinalis, and Palestinian sage fruit extract, have been investigated for their effectiveness in treating wounds, particularly low-thickness wounds and burns. Extracts such as green tea, aloe vera, chamomile, and grape seed have also been successfully incorporated into nanofibers [1, 15]. Parrotia persica extract, derived from the Persian ironwood tree, holds significant promise and potential for various applications within the medical field. Parrotia persica, a medicinal plant belonging to the Hamamelidaceae family [16], has gained attention due to its antibacterial and antioxidant properties. It has been traditionally used for fever and diabetes [17]. Studies have isolated various compounds from Parrotia persica, including flavonoids like kaempferol and quercetin, which accelerate wound healing and tannins, known for their ability to stimulate blood vessel formation and aid in wound repair [18]. Tannins are polyphenolic compounds found in plants that possess antiseptic properties [19]. Furthermore, the bark extract of Parrotia persica has been analyzed, revealing the presence of aromatic acids, aliphatic acids, phenolic compounds, sugars, and sugar derivatives [20]. Given the potential of Parrotia persica extract in wound healing, incorporating it into nanofiber structures becomes a compelling option. For dermatological applications, synthetic polymers like polycaprolactone (PCL) and polyvinyl alcohol (PVA) were selected as suitable platforms for loading the extract. PCL, a biodegradable and cost-effective polymer, offers flexibility, crystallinity, and stiffness, making it an excellent candidate for tissue engineering. However, its hydrophobic nature and limited biological interaction capacity with cells are drawbacks that can be overcome by combining it with other biomaterials [21, 22].

Polyvinyl alcohol (PVA) is derived from the hydrolysis of vinyl acetate monomer with acetate. It exhibits remarkable biocompatibility, biodegradability, electrospinnability, non-toxicity, suitable bio-adhesion, hydrophilicity, and chemical resistance, making it highly effective in the field of electrospun nanofibers. This polymer possesses ideal mechanical properties that promote cell diffusion, adhesion, and migration. However, one limitation of PVA is its lack of inherent bioactivity. Therefore, it is often blended or spun with natural polymers or other biomaterials to enhance cellular interaction in wound healing applications [1, 22, 23].

In this study, Parrotia persica extract was incorporated into a layered structure composed of polycaprolactone and PVA. This combination offers a suitable simulation of the natural properties of human skin. PCL provides elasticity similar to that of the skin and enhances scaffold strength in aquatic environments. The inclusion of Parrotia persica extract contributes to the structure by providing antioxidant and antibacterial properties, making it beneficial for treating infected wounds. Moreover, loading Parrotia persica extract into PVA, which exhibits hydrogel properties, facilitates its controlled release at the site of repair. Additionally, PVA imparts water-loving characteristics to the prepared structure, promoting improved cellular interactions while effectively absorbing wound secretions and preventing infections, all while maintaining a moist wound environment. The novelty of PVA/PCL loaded with Parrotia persica extract nanofibers for wound healing lies in the synergistic combination of versatile biomaterials and natural bioactive compounds to create an innovative wound dressing solution.

2 Experimental

2.1 Materials

Polycaprolactone (PCL) with a molecular weight of 80 kDa was acquired from Sigma, while polyvinyl alcohol (PVA) with a molecular weight of 72 kDa was obtained from Merck. To obtain the bark extract, freshly cut trees were selected, and the extraction process was initiated.

2.2 Methods

2.2.1 Extraction of Parrotia Persica

In this study, traditional extraction methods were employed to obtain the extract from the Parrotia persica tree. The extraction process involved boiling a layer of freshly peeled bark in water until the water acquired a dark brown color. Subsequently, the mixture was allowed to cool and separate, with the concentrated liquid containing the extract of the Parrotia persica tree.

2.2.2 Preparation of Electrospinning Solutions

The first step involved dissolving PCL with a concentration of 15% by weight/volume in a 90% acetic acid solvent, while PVA was dissolved in water with a concentration of 10 (% w/v). Subsequently, Parrotia persica extract was added to the polymer solutions at varying concentrations of 5%, 10%, 20%, and 50% by weight, based on the dry weight of the polymer. The electrospinning method was then employed to prepare nanofibers from the polymer solutions.

2.2.3 Electrospinning

The electrospinning process was conducted using a Nano Structure Asia electrospinning machine, equipped with a voltage range of 0–40 kV and featuring both positive and negative electrodes. For this study, a fixed drum plate configuration was employed. The PCL solution and the PVA/E solution were separately loaded into two syringes, which were then connected to a single nozzle syringe pump. The electrospinning process was carried out for a total duration of 40 min, with one nozzle being active while the other remained idle. The electrospinning conditions used for nanofiber preparation included a distance of 14 cm between the needle tip and the drum, a flow rate of 1 mL/h, a laboratory temperature of 29.88 ˚C, and a humidity level of 29.88%. A circular drum with a diameter of 5 cm was employed, and a voltage of 15 kV was applied during the process. The first sample was comprised of a PVA/E (90:10) blend, while the second sample featured a PVA/E (80:20) blend, and the third sample consisted of a PVA/E (50:50) blend. To achieve the desired layered nanofiber structure with mechanical stability in aqueous media, the incorporation of PCL polymer was undertaken for an additional layer. PVA/E (80:20) and PVA/E (50:50) were selected for the other components of the final structure. In one of the samples, a composite of PVA/E (20:80) was applied as the uppermost layer, with PCL serving as the second layer, PVA/E (80:20) constituting the third layer, and PCL forming the final layer. Through this arrangement, nanofibers were formed. In a parallel configuration, a PVA/E (50:50) mixture was utilized instead of PVA/E (80:20). Figure 1 shows the process of structure production and final application of them. Concluding the assembly, an additional layer of PCL nanofibers was electrospun onto the PVA/E polymer mixture of the last layer. The resulting structures were meticulously examined and meticulously prepared for subsequent testing and analysis. Upon finalization of the process, the scaffold composed of the electrospun nanofibers was meticulously retrieved from the drum, marking the readiness for further comprehensive analysis and evaluation.

2.2.4 Characterization of Nanofibers

Contact angle measurement analysis was employed to assess the hydrophilicity or hydrophobicity of the samples. This analysis involved the application of a droplet of water onto the surface of the nanofibers, followed by the measurement of the contact angle formed by the droplet. To capture this process, a video equipment model CAG10-9610IL58300, manufactured by Jikan Company CAG-10, was utilized.

The morphology and diameter of electrospun nanofibers were evaluated using scanning electron microscope MIRA III model of TESCAN company, made in Czech Republic.

The TERMO NICOLET device, specifically the AVATAR model manufactured in the USA, was utilized for Fourier transform infrared spectroscopy (FTIR) analysis. The FTIR analysis enabled the examination of the shift in position and intensity of the peaks in the obtained spectra. By comparing these peaks with the pure components, a comprehensive understanding of the changes occurring in the samples could be obtained. The spectral range for analysis was set from 4000 to 600 cm−1 at 4 cm−1 resolution with 20 scans.

For evaluation of scaffold morphology effects on the cell growth, SEM was used to evaluate the morphology, attachment, growth, and spreading of cells on the nanofibers. L929 fibroblast cells were cultured in RMPI1640 supplemented with 10% FBS and 1% penicillin/streptomycin (Sigma-Aldrich) and stored at humidified atmosphere in 37 °C with 5% CO2. The cells’ medium was changed every 2 days. When the cells reached more than 80% of confluency, they were “passaged” and seeded on the plates wrapped with nanofibers for cell behavior assays. Coverslip without nanofiber was used as control. After 72 h of culture, cells were fixed using 3% glutaraldehyde for 20 min and subsequently dehydrated using a series of ethanol solutions (50%, 70%, 95%, and 100%) for 10 min, then air dried. The samples were sputter-coated with gold at a voltage of 15 kV under argon gas, and images were taken by a field emission scanning electron microscopy (FE-SEM) (TESCAN MIRA3-XMU, Czech and FEI Nova NanoSEM 450, USA).

3 Results and Discussion

3.1 Morphology of Fibers

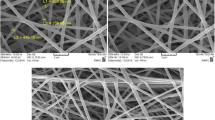

Figure 2 presents scanning electron microscope (SEM) images of the electrospun nanofibers. The average diameters of the PVA/E (90:10), PVA/E (80:20), and PVA/E (50:50) structures are approximately 405, 576, and 895 nm, respectively. The variation in measured diameter can be attributed to changes in the polymer solution concentration, as the properties of the polymer are influenced by flow rate and electrospinning tension, which in turn affect fiber morphology. Consistent with previous studies, an increase in polymer solution concentration typically results in larger fiber diameters [24]. Hence, with a higher concentration of extract, the entanglement of polymer chains increases, positively impacting the measured average diameter. Overall, these nanofibers exhibit a uniform distribution without bead formation. Figure 2d and 2e corresponds to layered structures comprising PCL and PVA/E (80:20) and PVA/E (50:50), respectively. The surface of PCL nanofibers appears smooth and round [25], as observed in previous studies. The presence of PCL in these figures contributes to a wider diameter distribution within the formed structure. In Fig. 2d, the appropriate concentration of extract and PCL results in polymer chains with an average diameter of 403 nm, which are well intertwined and a fiber structure of the PVA/E (50:50) sample with an average diameter of 592 nm.

In this study, PCL polymer, known for its strength, was incorporated to reinforce the nanofiber scaffold [26]. The addition of PCL did not cause a significant difference in diameter compared to samples without PCL. Overall, the obtained images suggest that the layered scaffold of PCL-PVA/E (80:20)-PCL exhibits smaller diameter with proper morphology. In the morphology of PVA/E (50:50)-PCL, several cracks can be seen that may result in lower strength of fabricated structures.

3.2 Contact Angle of Fibers

Wettability of nanofibers, which determines their interaction with a water droplet, is influenced by intermolecular forces. The balance between cohesion and adhesion forces defines the wettability of a material. When the adhesive force between a liquid phase and a solid phase is stronger, the liquid droplet spreads over the solid surface. Conversely, cohesive forces within the liquid phase prevent spreading, resulting in a spherical shape of the water droplet on the surface [27]. The amount of wettability is quantified by the contact angle, which represents the angle formed among the three phases: liquid, solid, and gas [27, 28]. A contact angle close to zero indicates hydrophilicity, while an angle nearing 180° suggests hydrophobicity. An angle of 90° signifies the boundary between hydrophilicity and hydrophobicity [27]. This characteristic holds a significant importance in tissue engineering applications as wettability affects cell adhesion, proliferation, and exudate absorption capacity [25]. Hydrophilicity enhances cell adhesion and proliferation on nanofibers, enabling uniform distribution of loaded cells throughout the scaffold. On the other hand, hydrophobic nanofibers lack effective functional groups and sufficient surface sites for proper cell interaction, hindering cell viability. The contact angle measurement results, depicted in Fig. 3, provide insights into the wettability of the samples. PCL and PVA are two synthetic polymers widely utilized in tissue engineering due to their biodegradability and biocompatibility. PVA, being a hydrophilic biopolymer, exhibits strong adhesion properties and promotes cell proliferation. Conversely, PCL, being hydrophobic, is not suitable as a substrate for cellular growth and migration [1, 25]. Lignocellulose materials are typically hydrophilic due to the abundance of hydrophilic groups that they contain [28]. Parrotia persica extract, rich in polyphenolic and polysaccharide compounds [18], possesses numerous hydrophilic groups, resulting in high hydrophilicity. As the amount of extract in relation to PVA, a water-soluble polymer [29], increases, the contact angle decreases, but this reduction is not significantly. The measured contact angle for the PVA/E (50:50) sample was 23.63°. In layered samples, the presence of hydrophobic PCL, characterized by numerous hydrophobic groups, leads to an increase in the contact angle [26, 30]. The measured contact angles for the layered samples PCL-PVA/E (80:20)-PCL and PCL-PVA/E (50:50)-PCL were approximately 40.45° and 53.42°, respectively. Although a higher contact angle was expected due to the hydrophobic nature of the surface layer of nanofibers, the observed values were lower than anticipated. This can be attributed to the porosity between fibers, allowing water penetration into the completely hydrophilic middle layer. Nevertheless, when compared to samples without PCL, these values indicate increased water repellency in the layered samples.

3.3 FTIR Analysis

The FTIR analysis outcomes are illustrated in Fig. 4, delineating the infrared spectral peaks that facilitate the structural analysis of the fibrous materials comprising PCL, PVA, and the extract. Figure 4-A showcases the extract's spectrum. Notably, the absorption within the 3600–3200 cm−1 range signifies the OH group's stretching vibration. Furthermore, the absorption at 2922 cm-1 denotes the stretching vibration of CH groups, while the peak at 1717 cm−1 corresponds to the C=O (ketone) group’s stretching vibration. The presence of C=C groups is evidenced by the absorption peak at 1609 cm−1, and the aromatic ring within the extract's structure becomes apparent at 1541 cm−1. Additionally, the bending vibration of CH groups manifests at 1448 cm−1. Moving on to Fig. 4-B, distinctive peaks indicative of the PVA polymer are discernible. Notably, the characteristic peak at 3447 cm−1 corresponds to the OH group's stretching vibration within PVA and the associated extract. The peak at 2938 cm-1 is aligned with CH stretching vibrations, whereas the peak at 1652 cm-1 is attributed to C=O stretching vibrations. Further, the characteristic peak at 1442 cm-1 corresponds to the bending vibration of CH groups. The peaks at 1144 cm−1 and 1097 cm−1 are definitive of CO stretching vibrations, affirming the presence of PVA [31]. Distinctive peaks attributed to the Parrotia persica extract are also evident. For instance, the peak at 1732 cm−1 corresponds to the C=O stretching vibration, while the peak at 1650 cm-1 aligns with the stretching vibration of C=C. The peak at 1320 cm−1 pertains to the bending vibration of CO, and the peak at 1260 cm−1 corresponds to the stretching vibration of C–O. Moreover, the peaks at 950 cm−1 and 700 cm−1 are associated with the bending vibration of C=C. Furthermore, Fig. 4 underscores the characteristic peaks characteristic of PCL within the layered structure, thus confirming its presence in the electrospun nanofiber scaffolds. Notably, for the PCL polymer, the peaks at 2915 cm−1 and 2879 cm−1 correspond to the CH2 stretching vibrations. The peak at 1239 cm−1 aligns with C–O–C stretching vibrations, while the peak at 1047 cm−1 signifies C–O stretching vibrations. Additionally, the peak at 1099 cm−1 relates to carboxyl group vibrations. Importantly, the characteristic peak at 1725 cm−1 represents C=O stretching vibrations in both PCL and the extract [32].

3.4 Cell Culture Studies

Many plant extracts, including those from Parrotia persica, have been investigated for their potential interactions with fibroblast cells. These interactions can include promoting cell proliferation, migration, and collagen synthesis, which are essential processes for wound healing and tissue regeneration. Additionally, the extract's antioxidant and anti-inflammatory properties may contribute to creating a conducive environment for fibroblast activity. Figure 5 shows SEM images of fibroblast cells on control sample that contains coverslip and four layered PVA/E (80:20)-PCL sample after passing 3 days. Fibroblasts grown on a coverslip are observable in Fig. 5A. As it is clear from the related pictures, the fibroblast cells are uniformly spread on the surface of scaffold and completely cover it, so that on cell growth in three dimensions can be seen in it (Fig. 5B).

4 Conclusion

Parrotia persica, commonly known as Persian ironwood, is renowned for its diverse bioactive constituents, which encompass phenolic compounds, flavonoids, tannins, and other secondary metabolites. These components bestow upon it potential therapeutic attributes, including noteworthy antioxidant and anti-inflammatory effects. In this groundbreaking endeavor, we achieved successful incorporation of Parrotia Persica plant extract into a meticulously engineered nanofibrous scaffold, resulting in a scaffold with highly favorable surface properties. This feat was accomplished by seamlessly blending varying concentrations of the extract with PVA structures. To ensure robustness and stability in aqueous environments, a layer of PCL was strategically applied atop the PVA/extract layers using the precision of the electrospinning technique. The layer-by-layer electrospinning process yielded nanofibers characterized by a continuous network and an impeccably uniform structure, devoid of any undesirable bead formation. Notably, the overall morphology of the PCL-PVA/E (80:20)-PCL structure showcased highly desirable properties, demonstrating a significant breakthrough. Infrared spectroscopy analysis provided robust confirmation of chemical bonding within the nanofiber scaffold, effectively validating the successful integration of PCL, PVA, and the extract within the intricacies of the layer-by-layer structure. The characteristic peaks observed in the spectra provided concrete evidence of the presence of these essential constituents. Contact angle analysis revealed the excellent water affinity of PVA and the extract, rendering them exceptionally suitable for the intricate layer-by-layer structure. The uniform distribution of cells on the scaffold surface affirmed excellent biocompatibility and distinctly favorable cellular interactions. Of particular significance, the PVA/E (80:20)-PCL scaffold showcased remarkable three-dimensional cell growth, signifying its exceptional potential for stimulating cell proliferation and facilitating tissue regeneration. This exciting discovery underscores the pivotal role played by the combination of hydrophilic and hydrophobic components within the scaffold, giving rise to its distinctive properties and promising prospective applications. The confluence of appropriate morphology, hydrophilicity, and exceptionally positive cellular interactions positions these nanofibers as highly promising candidates for advanced wound dressings and the creation of innovative tissue engineering scaffolds. To validate the full clinical potential and benefits of these revolutionary nanofiber materials in promoting wound healing and tissue regeneration, further rigorous investigations and essential in vivo studies are undoubtedly warranted. This exciting endeavor holds immense promise for advancing the frontier of medical science.

References

Kamoun, E.A.; Loutfy, S.A.; Hussein, Y.; Kenawy, E.S.: Recent advances in PVA-polysaccharide based hydrogels and electrospun nanofibers in biomedical applications: a review. Int. J. Biol. Macromol. 187, 755–768 (2021). https://doi.org/10.1016/j.ijbiomac.2021.08.002

Alven, S.; Buyana, B.; Feketshane, Z.; Aderibigbe, B.A.: Electrospun nanofibers/nanofibrous scaffolds loaded with silver nanoparticles as effective antibacterial wound dressing materials. Pharmaceutics. 13(7), 964 (2021). https://doi.org/10.3390/pharmaceutics13070964

Ranjbar-Mohammadi, M.; Arab-Bafrani, Z.; Karimi, F.; Javid, N.: Designing hybrid nanofibers based on keratin-poly (vinyl alcohol) and poly (Ɛ-caprolactone) for application as wound dressing. J. Ind. Text. 51, 1729S-1949S (2021). https://doi.org/10.1177/1528083721988978

Ranjbar-Mohammadi, M.; Abbasian, M.; Mousavi, E.; Arab-Bafrani, Z.: Multi-cellular tumor spheroids formation of colorectal cancer cells on Gelatin/PLCL and Collagen/PLCL nanofibrous scaffolds. Eur. Polym. J. 115, 115–124 (2019)

Ranjbar-Mohammadi, M.; Shakoori, P.; Arab-Bafrani, Z.: Design and characterization of keratin/PVA-PLA nanofibers containing hybrids of nanofibrillated chitosan/ZnO nanoparticles. Int. J. Biol. Macromol. 187, 554–565 (2021)

Vargas-Campos, L.; de Dios Figueroa-Cárdenas, J.; Tochihuitl-Vázquez, D.; Ramírez-Bon, R.; Yáñez-Limón, J.M.; Pérez-Robles, J.F.: Study of the dextrose equivalent of maltodextrins in electrospinning using an ethanol/water mixture as the electrospinning solvent. Food Hydrocoll. 139, 108498 (2023). https://doi.org/10.1016/j.foodhyd.2023.108498

Hadipour-Goudarzi, E.; Hemmatinejad, N.; Shokrgozar, M.A.: Fabrication and DOE Optimization of Electrospun Chitosan/Gelatin/PVA Nanofibers for Skin Tissue Engineering. Macromol. Mater. Eng. 308, 2200562 (2023)

Zhao, Y.; Liu, Y.; Tian, C.; Liu, Z.; Wu, K.; Zhang, C.; Han, X.: Construction of antibacterial photothermal PCL/AgNPs/BP nanofibers for infected wound healing. Mater. Des. 226, 111670 (2023)

Behere, I.; Ingavle, G.: In vitro and in vivo advancement of multifunctional electrospun nanofiber scaffolds in wound healing applications: Innovative nanofiber designs, stem cell approaches, and future perspectives. J. Biomed. Mater. Res. Part A. 110(2), 443–461 (2021). https://doi.org/10.1002/jbm.a.37290

Quoc Pham, L.; Uspenskaya, M.V.; Olekhnovich, R.O.; Olvera Bernal, R.A.: A review on electrospun pvc nanofibers: Fabrication, properties, and application. Fibers. 9, 12 (2021)

Li, T.; Sun, M.; Wu, S.: State-of-the-art review of electrospun gelatin-based nanofiber dressings for wound healing applications. Nanomaterials 12, 784 (2022)

Rahmati, M.; Mills, D.K.; Urbanska, A.M.; Saeb, M.R.; Venugopal, J.R.; Ramakrishna, S.; Mozafari, M.: Electrospinning for tissue engineering applications. Prog. Mater. Sci. 117, 100721 (2021)

Thamer, B.M.; Al-Sabri, A.E.; Almansob, A.; El-Newehy, M.H.: Fabrication of Biohybrid Nanofibers by the Green Electrospinning Technique and Their Antibacterial Activity. ACS Omega 7, 7311–7319 (2022). https://doi.org/10.1021/acsomega.1c07141

Mani, M.P.; Faudzi, A.A.M.; Ramakrishna, S.; Ismail, A.F.; Jaganathan, S.K.; Tucker, N.; Rathanasamy, R.: Sustainable electrospun materials with enhanced blood compatibility for wound healing applications–a mini review. Curr. Opin. Biomed. Eng. 27, 100457 (2023)

Ranjbar-Mohammadi, M.; Nouri, M.: Production and in vitro analysis of catechin incorporated electrospun gelatin/poly (lactic acid) microfibers for wound dressing applications. J. Ind. Text. 51, 7529S-7544S (2022)

Ali, H.; Ullah, K.; Siddiqui, H.; Iqbal, S.; Goren, N.; Ayatollahi, S.A.; Choudhary, M.I.: Chemical constituents from Parrotia persica-Structural derivatization and their potential prolyl endopeptidase inhibition activity. Bioorg. Chem. 96, 103526 (2020)

Dehghan, H.; Sarrafi, Y.; Salehi, P.: Antioxidant and antidiabetic activities of 11 herbal plants from Hyrcania region. Iran. J. food drug Anal. 24, 179–188 (2016)

Moghadam, S.E.; Ebrahimi, S.N.; Salehi, P.; Moridi Farimani, M.; Hamburger, M.; Jabbarzadeh, E.: Wound healing potential of chlorogenic acid and Myricetin-3-O-β-Rhamnoside isolated from Parrotia persica. Molecules 22, 1501 (2017)

Azadbakht, M.; Akbari, J.; Pasandi, S.: Formulation of herbal antiperspirant from parotia persica (DC.) CA Mey. (Hamamelis persica) and preliminary clinical study. J. Med. Plants. 3, 35–42 (2004)

Lakani, S.A.; Hedjazi, S.; Abdulkhani, A.: Chemical analysis and antioxidant activities of bark extracts from four endemic species of Hyrcanian forests in Iran. Holzforschung 73, 287–294 (2019)

Boraei, S.B.A.; Nourmohammadi, J.; Bakhshandeh, B.; Dehghan, M.M.; Gholami, H.; Gonzalez, Z.; Sanchez-Herencia, A.J.; Ferrari, B.: Capability of core-sheath polyvinyl alcohol–polycaprolactone emulsion electrospun nanofibrous scaffolds in releasing strontium ranelate for bone regeneration. Biomed. Mater. 16, 25009 (2021)

Mahalingam, S.; Bayram, C.; Gultekinoglu, M.; Ulubayram, K.; Homer-Vanniasinkam, S.; Edirisinghe, M.: Co-Axial Gyro-Spinning of PCL/PVA/HA Core-Sheath Fibrous Scaffolds for Bone Tissue Engineering. Macromol. Biosci. 21, 2100177 (2021)

Hussein, M.A.M.; Gunduz, O.; Sahin, A.; Grinholc, M.; El-Sherbiny, I.M.; Megahed, M.: Dual spinneret electrospun polyurethane/PVA-gelatin nanofibrous scaffolds containing cinnamon essential oil and nanoceria for chronic diabetic wound healing: Preparation, physicochemical characterization and in-vitro evaluation. Molecules 27, 2146 (2022)

Fathurochman, F.; Wuriantika, M.I.; Santjojo, D.J.D.H.; Nurhuda, M.: Mechanical, degradation rate, and antibacterial properties of a collagen-chitosan/PVA composite nanofiber. Mater. Res. Express. 10, 25401 (2023)

Alyamani, A.A.; Al-Musawi, M.H.; Albukhaty, S.; Sulaiman, G.M.; Ibrahim, K.M.; Ahmed, E.M.; Jabir, M.S.; Al-Karagoly, H.; Aljahmany, A.A.; Mohammed, M.K.A.: Electrospun Polycaprolactone/Chitosan Nanofibers Containing Cordia myxa Fruit Extract as Potential Biocompatible Antibacterial Wound Dressings. Molecules 28, 2501 (2023)

Talouki, P.Y.; Tackallou, S.H.; Shojaei, S.; Benisi, S.Z.; Goodarzi, V.: The role of three-dimensional scaffolds based on polyglycerol sebacate/polycaprolactone/gelatin in the presence of Nanohydroxyapatite in promoting chondrogenic differentiation of human adipose-derived mesenchymal stem cells. Biol. Proced. Online. 25, 9 (2023)

Kabir, H.; Garg, N.: Machine learning enabled orthogonal camera goniometry for accurate and robust contact angle measurements. Sci. Rep. 13, 1497 (2023)

Wei, J.; Xu, Y.; Bao, M.; Yu, Y.; Yu, W.: Effect of Resin Content on the Surface Wettability of Engineering Bamboo Scrimbers. Coatings 13, 203 (2023)

Abd El-Mohdy, H.L.; Aly, H.M.: Characterization, properties and antimicrobial activity of radiation induced phosphorus-containing PVA hydrogels. Arab. J. Sci. Eng. 48, 341–351 (2023)

Shadman-Manesh, V.; Gholipour-Kanani, A.; Najmoddin, N.; Rabbani, S.: Preclinical evaluation of the polycaprolactone-polyethylene glycol electrospun nanofibers containing egg-yolk oil for acceleration of full thickness burns healing. Sci. Rep. 13, 919 (2023)

Luthfianti, H.R.; Waresindo, W.X.; Edikresnha, D.; Chahyadi, A.; Suciati, T.; Noor, F.A.; Khairurrijal, K.: Physicochemical Characteristics and Antibacterial Activities of Freeze-Thawed Polyvinyl Alcohol/Andrographolide Hydrogels. ACS Omega 8, 2915–2930 (2023)

Lotfi, Z.; Khakbiz, M.; Davari, N.; Bonakdar, S.; Mohammadi, J.; Shokrgozar, M.A.; Derhambakhsh, S.: Fabrication and multiscale modeling of polycaprolactone/amniotic membrane electrospun nanofiber scaffolds for wound healing. Artif. Organs (2023). https://doi.org/10.1111/aor.14518

Funding

The authors declare that no external funding was received for the research, preparation, or publication of this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no competing interests that could be perceived as prejudicing the impartiality of this research. There are no financial, personal, or professional relationships that may have influenced the study design, data collection, analysis, interpretation of results, or the preparation of this manuscript.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ranjbar-Mohammadi, M., Shiralipour, M. Production of Multilayer Nanofibers Through Polyvinyl Alcohol/Parrotia Persica Extract and Polycaprolactone Combination. Arab J Sci Eng 49, 8311–8319 (2024). https://doi.org/10.1007/s13369-024-08866-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-024-08866-1