Abstract

Prodigiosin has attracted great interest for several decades for its proapoptotic anticancer and other activities. However, the low productivity of prodigiosin under submerged fermentation (SmF) limits its commercial application. In this study, S. marcescens Xd-1 was newly isolated from a mouldy tofu sample and was used to produce prodigiosin by solid-state fermentation (SSF) using bagasse as an inertia matrix. The result showed that S. marcescens Xd-1 was adapted to SSF for prodigiosin production and could bear a higher concentration of glycerol. Process parameters were systematically examined to improve the conversion of glycerol to prodigiosin by a response surface methodology. The maximal yield of prodigiosin (40.86 g kg−1 dry solid) was achieved with glycerol 1.17 g g−1 bagasse, soy peptone 0.33 g g−1 bagasse, an initial moisture content of 83.5 %, and 1-mm particles of bagasse by using a response surface methodology (RSM). In addition, the extraction ratio of prodigiosin increased rapidly to 90 % in 30 min by using ultrasonic-assisted reflux extraction. Our results expand the culture method of S. marcescens for prodigiosin production and enhanced the conversion of glycerol to prodigiosin.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Prodigiosin is a multifaceted, secondary metabolite with a tripyrrole structure that is produced by Serratia marcescens, Pseudomonas magnesiorubra, Hahella chejuensis, and other eubacteria (D'Aoust and Gerber 1974; Harris et al. 2004; Huh et al. 2007; Lee et al. 2011). It has attracted great interest for several decades for its proapoptotic anticancer activity (Pérez-Tomás et al. 2003; Regourd et al. 2007). Many researches have shown it has apoptotic activity against more than 60 cancer cell lines with a concentration of 2.1 μM, including lung, colon, kidney, hematopoietic, and breast cancers, and has low cytotoxicity in noncancerous cells (Montaner et al. 2000; Williamson et al. 2007; Perez-Tomas et al. 2010). Prodigiosin has also shown effective antimalarial, antifungal, immunosuppressive activity, and algicidal activity (Pandey et al. 2003, 2007; Patil et al. 2011; Park et al. 2012; Singh and Shekhawat 2012).

The carbon source has played a crucial role in prodigiosin production. As shown in Table 1, many studies have been performed to determine the optimal conditions for prodigiosin production by submerged fermentation (SmF). S. marcescens is the major source of prodigiosin production (Fürstner 2003; Montaner et al. 2000; Pryce and Terry 2000). There are many kinds of carbon sources utilized for prodigiosin production, such as glycerol, brown sugar, mannitol, peanut seed, and so on. In this study, glycerol was used as the carbon source under solid-state fermentation (SSF) condition. Glycerol is the principal byproduct of biodiesel production, which accounts for about 10 % by weight (Chi et al. 2007). It is a promising renewable carbon source that has been used in several types of fermentations by both prokaryotic and eukaryotic strains. Currently, the most promising metabolites are 1,3-propanediol, 2,3-butanediol, ethanol, butanol, citric acid, microbial lipids, and H2 (Silva et al. 2009; Markov et al. 2011; Zhang et al. 2007; Chatzifragkou et al. 2011).

However, there are great differences in the yields of prodigiosin by different strains, and furthermore, prodigiosin produced by S. marcescens is mostly bound to bacterial envelopes and still a small part is released into the broth (Purkayastha et al. 1960; Kobayashi and Ichikawa 1991). So, the separation and purification processes have some bottlenecks that prevent large-scale production of prodigiosin by SmF. For industrialization purposes, a high-output and cost-effective method for prodigiosin production is demanded.

O’Rear (O'Rear et al. 1992) found that prodigiosin-producing S. marcescens will adhere to hydrophobic surfaces, whereas anon-prodigiosin-producing species will not. Therefore, prodigiosin may be involved in the attachment of S. marcescens to hydrophobic surfaces in its natural habitat, which means that S. marcescens might be adapting to the environmental conditions in SSF. We, therefore, isolated a new strain of S. marcescens for the production of prodigiosin. To enhance the efficient conversion of glycerol to prodigiosin, we studied the culture conditions required to produce a higher yield of prodigiosin using bagasse as a carrier in SSF.

Materials and methods

Isolation of the strain

Bean products and soil samples were inoculated in a 250-mL flask containing 50 mL of Luria-Bertani broth (lysogeny broth; LB). The broth was cultivated at 200 rpm for 2 h at 28 °C; it was then diluted and spread onto an LB agar plate to obtain a single colony. Cultures from the single colony were periodically maintained on LB agar medium containing 10 g L−1 peptone, 5 g L−1 yeast extract, 10 g L−1 NaCl, and 1.5 g L−1 agar after growth on LB agar medium for 24 h at 28 °C. Prodigiosin is a kind of red intracellular pigment. It has a connection between the color of the colony and yield of prodigiosin. To screen for strains with high prodigiosin production, the red colony collected was inoculated into LB broth at 28 °C for 16 h as seed cultures. And then it was inoculated into an SmF medium containing 20 g L−1 glycerol, 5 g L−1 soybean peptone and cultured at 28 °C for 48 h. The yield of prodigiosin was then detected with high-performance liquid chromatography (HPLC). The standard sample of prodigiosin was purchased from Sigma-Aldrich Co.

Effect of inertia matrices on prodigiosin production

In this experiment, bagasse, wheat straw powder, and wood chips were chosen as inertia matrices for investigation of their effects on prodigiosin productivity under SSF. S. marcescens Xd-1 was cultivated on LB liquid medium and was used for seed cultures for 16 h at 28 °C. The inertia matrices were pretreated as described by Pintado (Pintado et al. 1998) for use as an inert carrier for prodigiosin production in SSF. The particle size of inertia matrices were 1 mm. Initially, 2 g of pretreated inertia matrices was added to a 250-mL Erlenmeyer flask before other nutrient content was added. The initial contents of glycerol and soy peptone were 0.75 g g−1 bagasse and 0.6 g g−1 bagasse, respectively. The initial moisture content was 80 %. The contents of the flask were mixed and autoclaved for 20 min at 121 °C. After cooling, each flask was inoculated with 10 % (v/w) seed cultures. Fermentation was carried out at 28 °C for 48 h with mixing every 12 h.

Effect of glycerol concentration on prodigiosin production

Effect of concentrations of glycerol ranging from 0.1 to 1.5 g g−1 bagasse on prodigiosin production by SSF was investigated. The inoculum density was 10 % (v/w) seed cultures and was incubated at 28 °C for 48 h with mixing every 12 h.

Effect of nitrogen sources on prodigiosin production

Six nitrogen sources were used to enhance the conversion of glycerol to prodigiosin by S. marcescens Xd-1; four of these nitrogen sources were organic (casein hydrolysate, yeast extract, tryptone, and soy peptone) and two were inorganic ((NH4)2SO4 and NaNO3). The nitrogen sources were added into the initial solid medium at 0.6 g g−1 bagasse. Then, the effects of different concentrations of soy peptone (0.25, 0.4, 0.5, 0.6, 0.75, and 1.0 g g−1 bagasse) on the prodigiosin yield of S. marcescens Xd-1 in SSF were studied.

Effect of initial moisture content on prodigiosin production

Six different initial moisture levels, i.e., 70 %, 75 %, 80 %, 83 %, 85 %, and 87 % (w/w substrate) were established in the inertia matrix to study the effects of the initial moisture content on prodigiosin production. The initial total moisture content of the substrate was calculated with the following formula:

Effect of particle size on prodigiosin production

Bagasse with different particle sizes (0.1, 1, 2, 3, and 5 mm) was used to study the influence of particle size on the yield of prodigiosin in SSF of S. marcescens Xd-1.

RSM analysis for prodigiosin production

The response surface methodology (RSM; Box–Benhnken design) procedure was employed to screen the cultural conditions and medium compositions for prodigiosin production. Glycerol, soybean peptone, and initial moisture content were optimized as the major factors. Three variables with designed levels (−1, 0, +1) and three replicates are shown in Table 2. The results were analyzed by using Design expert 8.0 program.

Ultrasound-assisted reflux extraction of prodigiosin from S. marcescens Xd-1

In this experiment, the extraction ratio of prodigiosin by ultrasound-assisted reflux extraction was studied. Extraction was carried out at different concentrations of ethanol (70 %, 80 %, and 90 %) with an extraction temperature of 55 °C, a solid–liquid ratio of 1:5 (w/v), and ultrasonic power of 105 W.

Analysis of prodigiosin

Solid cultures of S. marcescens Xd-1 (5 g) were extracted with 50 mL of ethanol by refluxing in a 45-°C water bath for 1 h. After filtration, the ethanol solution was maintained at 4 °C in preparation for the next experiment.

The concentration of prodigiosin was analyzed with HPLC. An Amethyst C18 column (4.6 × 150 mm i.d.; Sepax Co., Newark, DE, USA) was used for analysis. The mobile phase was composed of 1 % AcOH/H2O-CH3CN (0 min, 25:75; 15 min, 90:10; 15.5 min, 25:75; 21 min, 25:75). The flow rate was 0.6 mL min−1, the injection volume was 20 μL, and the UV detection wavelength was set at 535 nm. The operating temperature was maintained at 37 °C.

Detection of pH

Solid cultures of S. marcescens Xd-1 (5 g) were put in 50 mL of distilled water for 15 min at room temperature. Then, the extraction liquid was gathered by filtration and pH was measured by pH meter.

Statistical analysis

All of the experiments were carried out in triplicate. Analysis of variance (ANOVA) and regression analysis were conducted, and contour plots were drawn using the Design-Expert 8.0 software package. The results are expressed as the mean ± standard deviation (SD)

Results and discussion

Screen strains for prodigiosin production

As shown in Table 3, six strains with red colonies were selected for prodigiosin detection. The strain Xd-1 had the highest yield of prodigiosin, which reached 1.14 g L−1. The 16S rDNA nucleotide sequence of strain Xd-1 was amplified with the following primers: 27 F: 5'-AGA GTT TGA TCC TGG CTC AG-3', 1492R: 5'-GGT TAC CTT GTT ACG ACT T-3'. The fragments from polymerase chain reactions were sequenced and identified as S. marcescens based on the 16S rDNA sequence. The prodigiosin product was purified from the fermentation broth and identified with liquid chromatography–mass spectrometry and HPLC.

Effect of inertia matrices on conversion of glycerol to prodigiosin

As shown in Fig. 1, bagasse was the best inertia matrix for fermentation (with a prodigiosin yield of 20.13 g kg−1 dry solid), followed by wood powder. The prodigiosin yield was lowest (only 10.6 g kg−1 dry solid) when wheat straw powder was used as the inertia matrix. Because wheat straw powder had a closer fiber structure, it had a lower glycerol-absorbing capacity than that of bagasse. The distribution of glycerol was uneven, and most of it had gathered in the bottom of the substrate; therefore, the biosynthesis of prodigiosin was restricted.

Effect of glycerol concentration on prodigiosin production

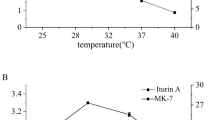

The glycerol concentration has an important effect on growth and product synthesis during fermentation processes. In SSF, the yield of prodigiosin was enhanced as the concentration of glycerol was increased from 0.1 to 1.5 g g−1 bagasse, beyond which a decrease in the prodigiosin yield was observed (Fig. 2a). The maximum yield of prodigiosin (24.14 g kg−1 dry solid) was recorded in 1.0 g g−1 bagasse glycerol.

Effects of fermentation conditions on prodigiosin production. (A) The glycerol concentration has an important effect on prodigiosin product. S. marcescens Xd-1 could bear a high concentration of glycerol (1 g g−1 bagasse) in solid-state fermentation. (B) Six nitrogen sources were used to enhance the conversion of glycerol to prodigiosin by S. marcescens Xd-1. 1 Casein hydrolysate; 2 yeast extract; 3 tryptone; 4 soy peptone; 5 (NH4)2SO4; 6 NaNO3. (C) Effect of soy peptone contents on prodigiosin production and final medium pH. (D) Effect of initial moisture content on prodigiosin production. The yield of prodigiosin markedly increased as the initial moisture content rose from 70 % to 83 %

As shown in Table 1, as compared to other carbon sources, the yield of prodigiosin was lower by using glycerol in SmF. One reason could be a lower concentration of glycerol in the fermentation broth and higher glycerol content could trigger catabolite repression. Tao JL et al. studied a two-step feeding strategy in a 5-L bioreactor in which production of prodigiosin was 583 mg L−1 and the glycerol concentration in the medium being was always about 5 g L−1, about 0.5 % (w/w; Tao et al. 2005). While, S. marcescens Xd-1 could bear a high concentration of glycerol [1.0 g g−1 bagasse glycerol, about 7 % (w/w)] under SSF conditions. Zhang BB et al. showed that the phenomenon of glycerol concentration gradient existed in SSF, which could well-explain the resistance effect to high concentration of glycerol in SSF (Zhang et al. 2015). Based on these results, the cultivation of S. marcescens Xd-1 using the agricultural byproduct bagasse as an inert carrier was suitable for efficient conversion of high concentrations of glycerol into prodigiosin. Further study of mechanisms by which SSF could bear higher concentrations of glycerol is required.\

Influence of nitrogen sources on prodigiosin production

The results revealed that S. marcescens Xd-1 produced the maximum level of prodigiosin (24.46 g kg−1 dry solid) in the presence of soy peptone (Fig. 2b). Pigmentation was delayed in media supplied with inorganic nitrogen sources ((NH4)2SO4 and NaNO3), and the growth of S. marcescens Xd-1 was poorer. Yeast extract and tryptone could be used to promote the proliferation of S. marcescens Xd-1, but the biosynthesis of prodigiosin was lower than with soy peptone. The types of nitrogen sources are very important for prodigiosin production of S.marcescens Xd-1. Research has shown that S. marcescens has a very weak ability to produce prodigiosin when inorganic nitrogen sources were used in the medium (Hejazi and Falkiner 1997; Rokem and Weitzman 1987; Hardjito et al. 2002). These results suggest that the choice of nitrogen source is species-specific for different fermentation systems and plays a crucial role in cell growth, production, and secretion of prodigiosin (Bennett and Bentley 2000; Kurbanoglu et al. 2015).

Influence of concentration of soy peptone on prodigiosin production

As shown in Fig. 2c, the maximum yield of prodigiosin (33.63 g kg−1 dry solid) was obtained with the addition of 0.4 g g−1 bagasse of soy peptone to the medium. A further increase in soy peptone content resulted in a clear decrease in the prodigiosin yield. These results might be directly attributable to the proportion variance of the carbon and nitrogen sources. Higher concentrations of soy peptone contributed to increased growth of S. marcescens Xd-1; however, further increases in soy peptone proved disadvantageous for the synthesis of prodigiosin by diverting more carbon into cell growth.

The effect of pH has been reported to play an important role in prodigiosin production due to its involvement in carbon source uptake and essential amino acid synthesis (Mohammed et al. 2012). Interestingly, the pH of the solid medium increased as the soy peptone concentration increased. The pH was about 4.1 when the concentration of soy peptone was less than 0.4 g g−1 bagasse, and the substrate was dark red. As the soy peptone concentration exceeded 0.6 g g−1 bagasse, the pH of the solid medium increased rapidly, reaching 8.0 or even more, but the substrate was purplish red or light red. Williams et al. showed that lower environmental pH values inhibited prodigiosin synthesis in SmF (Williamson et al. 2005). However, the results contrasted to those in SSF. The differences in the biomass were tested by the colony-counting method. The results showed that the biomass content of the solid medium increased significantly with the increase in soy peptone (1.5 × 107 to 7.2 × 108 colony-forming units per gram of bagasse as the concentration of soy peptone increased from 0.25 to 1.0 g g−1 bagasse). Results for the effect of peptone on biomass and prodigiosin production are in agreement with the observation of Wen TS et al. (Su et al. 2011).

Influence of initial moisture content on prodigiosin production

The maximum yield of prodigiosin (39.54 g kg−1 dry solid) was attained when the initial moisture content was 83 % (Fig. 2d). The yield of prodigiosin markedly increased as the initial moisture content rose from 70 % to 83 %. However, a further increase in the initial moisture content led to a notable decrease in prodigiosin production. The initial moisture content could play an important role in SSF, especially for bacterial fermentation. The low initial moisture content reduced the water activity of the substrate too far for cell growth and metabolite production. In contrast, higher initial moisture content resulted in a decrease in the porosity of the bagasse, thereby decreasing the diffusion of gas exchange (Corona et al. 2005; Singhania et al. 2009).

Influence of particle size on prodigiosin production

As shown in Table 4, the maximum prodigiosin yield (40.11 g kg−1 dry solid) was obtained for the bagasse with a 1-mm particle size. An increase or decrease in the particle size led to a reduction in the prodigiosin yield. In the SSF process, the availability of surface area plays a critical role in microbial attachment, mass transfer of various nutrients and inertia matrices, and subsequent microbial growth and metabolite production. The availability of surface area, in turn, depends on the particle size of the substrate or support matrix (Prakasham et al. 2006). In general, smaller substrate particles provide a larger surface area for microbial attachment and metabolite production. However, substrate particles that are too small may lead to substrate agglomeration in most cases, which may interfere with microbial respiration and mass transfer, especially for air and heat transfer. Oxygen is necessary in the production of prodigiosin and S. marcescens cannot synthesis prodigiosin in anaerobic conditions (Heinemann et al. 1970). In contrast, larger particles provide better respiration efficiency (due to their increased interparticle space) but provide limited surface for microbial attachment. Thus, an appropriate particle size is required for a particular process in SSF (Ellaiah et al. 2004; Sangeetha et al. 2004).

The response surface analysis for prodigiosin production

As shown in Table 5, further optimization of culture conditions was carried out by the Box–Benhnken design (BBD). Fifteen trails were performed to determine the culture conditions for prodigiosin production in solid state fermentation by S. marcescens Xd-1. To investigate the simultaneous influences of the variables, regression analysis was performed to fit the response function to the experimental data (Table 6). The fit value of the model, or R2 (determination coefficient), was calculated as 0.9537, indicating that 95.37 % of the variance in the response of prodigiosin production could be explained by the second-order polynomial prediction equation given below. The ANOVA results prove this model to be appropriate. Y = 40.24 + 2.10X 1 − 1.80X 2 − 0.33X 3 − 1.29X 1 X 2 + 2.66X 1 X 3 + 0.19X 2 X 3 − 2.69X 1 2 − 1.85X 2 2 − 2.82X 3 2where Y is the prodigiosin yield (predicted response), and X 1, X 2, and X 3 are the coded values of the test variables glycerol, soybean meal, and initial moisture content, respectively.

By solving the model regression equation, the maximum production of prodigiosin and the optimum values of the variables can be acquired. The maximum prodigiosin production of 41.57 g kg−1 dry solid was attained under the condition of 1.17 g g−1 bagasse glycerol, 0.33 g g−1 bagasse soy peptone, and an initial moisture content of 83.5 %. As shown in Fig. 3, the garnet color of the SSF product of S. marcescens Xd-1 was distributed uniformly on the bagasse.

To confirm these results, verified experiments under optimized conditions were carried out. The maximum production of prodigiosin produced experimentally was 40.68 g kg−1 dry solid, which was in close agreement with the predicted yield. According to the p value of each model term, the constants X 1, X 2, X 1 X 3, X 1 2, X 2 2, X 3 2 were found to be significant (p < 0.05). The corresponding contour plot of glycerol and initial moisture content was obtained from the calculated response surface plot, and is shown in Fig. 4.

Extraction of prodigiosin from solid-state fermentation production of S. marcescens Xd-1

As shown in Fig. 5, the extraction ratio of prodigiosin increased rapidly as the concentration of ethanol increased from 70 % to 90 %. The highest extraction ratio was 95.1 % when ethanol reached 90 %. A higher concentration of ethanol can be used to shorten the extraction time. During the initial 30 min, the extraction rate of prodigiosin was considerably increased, but rose little thereafter. Consequently, the optimum extraction time was 30 min in 90 % ethanol.

Downstream engineering in many fermentation processes is responsible for up to 60–70 % of the overall cost (Keller et al. 2001). Prodigiosin is mainly an intracellular product, and a small amount was secreted outside the cell. In SmF, some research on the recovery and separation of prodigiosin from a liquid has included ultrafiltration, organic solvent extraction, and macroporous polymeric resin adsorption processes (Kim et al. 1999; Wang et al. 2004; Juang et al. 2012; Juang and Yeh 2014). However, it is difficult to recover prodigiosin from both cells and broth. In SSF, it’s simple and efficient to extract and recover prodigiosin with ethanol. In addition, there was almost no waste during the extraction process. Because the bagasse is an inertia matrix, it retained its fluffy appearance and adsorption property after the prodigiosin was extracted by ultrasound, so it could be reused.

Conclusion

Prodigiosin is a multifaceted, secondary metabolite with a tripyrrole structure that has attracted great interest because of its apoptotic activity against a group of cancer cell lines and its low cytotoxicity in noncancerous cells. The yield of prodigiosin is inhibited in SmF, and the separation and purification processes still have some bottle necks that prevent large-scale production. In this paper, S. marcescens Xd-1 was adapted to SSF for prodigiosin production by using bagasse as an inert carrier and could bear a higher concentration of glycerol. The maximal yield of prodigiosin (40.86 g kg−1 dry solid) was achieved with 1.17 g g−1 bagasse, glycerol, 0.33 g g−1 bagasse soy peptone, an initial moisture content of 83.5 %, and 1-mm particles of bagasse by using a response surface methodology. In addition, the extraction of prodigiosin from SSF was more convenient than that from SmF. These results expand the culture method of S. marcescens for prodigiosin production and demonstrate a superior means of producing useful activity metabolites using an agricultural byproduct as an inertia matrix under SSF.

References

Araújo HWCD, Fukushima K, Takaki GMC (2010) Prodigiosin production by serratia marcescens ucp 1549 using renewable-resources as a low cost substrate. Molecules 15(10):6931–6940

Aruldass CA, Venil CK, Zakaria ZA et al (2014) Brown sugar as a low-cost medium for the production of prodigiosin by locally isolated serratia marcescens utm1. Int Biodeterior Biodegrad 95:19–24

Bennett JW, Bentley R (2000) Seeing red: the story of prodigiosin. Adv Appl Microbiol 47:1–32

Chatzifragkou A, Makri A, Belka A et al (2011) Biotechnological conversions of biodiesel derived waste glycerol by yeast and fungal species. Energy 36(2):1097–1108

Chi ZY, Pyle D, Wen ZY et al (2007) A laboratory study of producing docosahexaenoic acid from biodiesel-waste glycerol by microalgal fermentation. Process Biochem 42:1537–1545

Corona A, Saez D, Agosin E (2005) Effect of water activity on gibberellic acid production by Gibberella fujikuroi under solid-state fermentation conditions. Process Biochem 40(8):2655–2658

D'Aoust JY, Gerber NN (1974) Isolation and purification of prodigiosin from Vibrio psychroerythrus. J Bacteriol 118(2):756–757

Ellaiah P, Srinivasulu B, Adinarayana K (2004) Optimization studies on neomycin production by a mutant strain of Streptomyces marinensis in solid state fermentation. Process Biochem 39(2):529–534

Fürstner A (2003) Chemistry and biology of roseophilin and the prodigiosin alkaloids: a survey of the last 2500 years. Angew Chem 42(21):3582–3603

Hardjito L, Huq A, Colwell RR (2002) The influence of environmental conditions on the production of pigment by Serratia marcescens. Biotechnol Bioprocess Eng 7:100–104

Harris AKP, Williamson NR, Slater H et al (2004) The Serratia gene cluster encoding biosynthesis of the red antibiotic, prodigiosin, shows species- and strain-dependent genome context variation. Microbiology 150:3547–3560

Heinemann B, Howard AJ, Palocz HJ (1970) Influence of dissolved oxygen levels on production of l-asparaginase and prodigiosin by S. marcescens. Appl Microbiol 19:800–804

Hejazi A, Falkiner FR (1997) Serratia marcescens. J Med Microbiol 46(11):652–654

Huh JE, Yim JH, Lee HK et al (2007) Prodigiosin isolated from hahella chejuensis suppresses lipopolysaccharide-induced NO production by inhibiting p38 mapk, jnk and nf-kappab activation in murine peritoneal macrophages. Int Immunopharmacol 7(13):1825–1833

Jong SL, Yong-Sook K, Sooyeon P et al (2011) Exceptional production of both prodigiosin and cycloprodigiosin as major metabolic constituents by a novel marine bacterium, zooshikella rubidus s1-1. Appl Environ Microbiol 77(14):4967–4973

Juang RS, Yeh CL (2014) Adsorptive recovery and purification of prodigiosin from methanol/water solutions of serratia marcescens fermentation broth. Biotechnol Bioprocess Eng 19(1):159–168

Juang RS, Chen HL, Lin YC (2012) Ultrafiltration of coagulation-pretreated Serratia marcescens fermentation broth: Flux characteristics and prodigiosin recovery. Sep Sci Technol 47:1849–1856

Keller K, Friedmann T, Boxman X (2001) The bioseparations need for tomorrow. Trends Biotechnol 19:438–441

Kim CH, Kim SW, Hong SI (1999) An integrated fermentation-separation process for the production of red prodigiosin by Serratia sp. KH-95. Proc Biochem 35:485–490

Kim SJ, Hong KL, Lee YK et al (2008) Mutant selection of hahella chejuensis kctc 2396 and statistical optimization of medium components for prodigiosin yield-up. J Microbiol 46(2):183–188

Kobayashi N, Ichikawa Y (1991) Separation of the prodigiosin‐localizing crude vesicles which retain the activity of protease and nuclease in serratia marcescens. Microbiol Immunol 35(8):607–614

Kurbanoglu EB, Ozdal M, Ozdal OG et al (2015) Enhanced production of prodigiosin by serratia marcescens mo-1 using ram horn peptone. Braz J Microbiol 46(2):631–637

Lee JS, Kim YS, Park S et al (2011) Exceptional production of both prodigiosin and cycloprodigiosin as major metabolic constituents by a novel marine bacterium, zooshikella rubidus s1-1. Appl Environ Microbiol 77(14):4967–4973

Markov SA, Averitt J, Waldron B (2011) Bioreactor for glycerol conversion into H2 by bacterium Enterobacter aerogenes. Int J Hydrog Energy 36:262–266

Mohammed HB, Naseer J, Aruna K (2012) Study on optimization of prodigiosin production by Serratia marcescens msk1 isolated from air. Int J Adv Biotechnol Res 2:671–680

Montaner B, Navarro S, Piqué M et al (2000) Prodigiosin from the supernatant of Serratia marcescens induces apoptosis in haematopoietic cancer cell lines. Brit J Pharmacol 131(3):585–593

O'Rear J, Alberti L, Harshey RM (1992) Mutations that impair swarming motility in Serratia marcescens 274 include but are not limited to those affecting chemotaxis or flagellar function. J Bacteriol 174(19):6125–6137

Pandey R, Chander R, Sainis KB et al (2003) A novel prodigiosin-like immunosuppressant from an alkalophilic Micrococcus sp. Int Immunopharmacol 3(2):159–167

Pandey R, Chander R, Sainis KB (2007) Prodigiosins: a novel family of immunosuppressants with anti-cancer activity. Indian J Biochem Biophys 44(5):295–302

Parani K, Saha BK (2008) Optimization of prodigiosin production from a strain of serratia marcescens sr1 and screening for antifungal activity. J Biol Control 22(1):73–79

Park H, Lee SG, Tai KK et al (2012) Selection of extraction solvent and temperature effect on stability of the algicidal agent prodigiosin. Biotechnol Bioprocess Eng 17(6):1232–1237

Patil CD, Patil SV, Salunke BK et al (2011) Prodigiosin produced by Serratia marcescens NMCC46 as a mosquito larvicidal agent against Aedes aegypti and Anopheles stephensi. Parasitol Res 109(4):1179–1187

Pérez-Tomás R, Montaner B, Llagostera E et al (2003) The prodigiosins, proapoptotic drugs with anticancer properties. Biochem Pharmacol 66(8):1447–1452

Perez-Tomas R, Vinas M et al (2010) New Insights on the Antitumoral Properties of Prodiginines. Curr Med Chem 17(21):2222–2231

Pintado J, Lonsane BK, Gaime-Perraud I et al (1998) On-line monitoring of citric acid production in solid-state culture by respirometry. Process Biochem 33(5):513–518

Prakasham RS, Subba RC, Sarma PN et al (2006) Green gram husk–an inexpensive substrate for alkaline protease production by Bacillus sp. in solid-state fermentation. Bioresour Technol 97(13):1449–1454

Pryce LH, Terry FW (2000) Spectrophotometric assay of gene expression: Serratia marcescens pigmentation. Bioscene 26:3–13

Purkayastha M, Williams RP et al (1960) Association of pigment with the cell envelope of Serratia marcescens (Chromobacterium prodigiosum). Nature 187(4734):349–350

Regourd J, Ali AA, Thompson A et al (2007) Synthesis and anti-cancer activity of C-ring-functionalized prodigiosin analogues. J Med Chem 50(7):1528–1536

Rokem JS, Weitzman P (1987) Prodigiosin formation by Serratia marcescens in a chemostat. Enzyme Microb Technol 9:153–155

Sangeetha PT, Ramesh MN, Prapulla SG et al (2004) Production of fructosyl transferase by Aspergillus oryzae CFR 202 in solid-state fermentation using agricultural by-products. Appl Microbiol Biotechnol 65(5):530–537

Shahitha S, Poornima K (2012) Enhanced production of prodigiosin production in serratia marcescens. J Appl Pharm Sci 2(8):138–140

Silva GPD, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27(1):30–39

Singh P, Shekhawat N (2012) Chemometric descriptors in the rationale of antimalarial activity of natural and synthetic prodiginines. J Curr Chem Pharm Sci 2:244–260

Singhania RR, Patel AK, Soccol CR et al (2009) Recent advances in solid-state fermentation. Biochem Eng J 44(1):13–18

Song C, Sanada M, Johdo O et al (2000) High production of prodigiosin by Serratia marcescens grown on ethanol. Biotechnol Lett 22(22):1761–1765

Su WT, Tsou TY, Liu HL (2011) Response surface optimization of microbial prodigiosin production from Serratia marcescens. J Taiwan Inst Chem Eng 42(2):217–222

Suryawanshi RK, Patil CD, Borase HP et al (2014) Studies on production and biological potential of prodigiosin by serratia marcescens. Appl Biochem Biotechnol 173(5):1–13

Tao JL, Wang XD, Shen YL et al (2005) Strategy for the improvement of prodigiosin production by a serratia marcescens mutant through fed-batch fermentation. World J Microbiol Biotechnol 21(6–7):969–972

Wang XD, Tao JL, Wei DZ et al (2004) Development of an adsorption procedure for the direct separation and purification of prodigiosin from culture broth. Biotechnol Appl Biochem 40(3):277–280

Wang SL, Wang CY, Yen YH et al (2012) Enhanced production of insecticidal prodigiosin from Serratia marcescens TKU011 in media containing squid pen. Process Biochem 47(11):1684–1690

Williamson NR, Simonsen HT, Ahmed RA et al (2005) Biosynthesis of the red antibiotic, prodigiosin, in Serratia: identification of a novel 2-methyl-3-n-amylpyrrole (MAP) assembly pathway, definition of the terminal condensing enzyme, and implications for undecylprodigiosin biosynthesis in Streptomyces. Mol Microbiol 56:971–989

Williamson NR, Fineran PC, Leeper FJ et al (2007) The biosynthesis and regulation of bacterial prodiginines. Nat Rev Microbiol 4(12):887–899

Zang CZ, Yeh CW, Chang WF et al (2014) Identification and enhanced production of prodigiosin isoform pigment from serratia marcescens n10612. J Taiwan Inst Chem Eng 45(4):1133–1139

Zhang GL, Ma BB, Xu XL et al (2007) Fast conversion of glycerol to 1, 3-propanediol by a new strain of Klebsiella pneumonia. Biochem Eng J 37:256–260

Zhang BB, Lu LP, Xu GR (2015) Why solid-state fermentation is more advantageous over submerged fermentation for converting high concentration of glycerol into Monacolin K by Monascus purpureus 9901: A mechanistic study. J Biotechnol 206:60–65

Acknowledgments

This research work was financially supported by the Hujiang Foundation of China (D15012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, Y., Wang, G., Lin, X. et al. Solid-state fermentation with Serratia marcescens Xd-1 enhanced production of prodigiosin by using bagasse as an inertia matrix. Ann Microbiol 66, 1239–1247 (2016). https://doi.org/10.1007/s13213-016-1208-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-016-1208-4