Abstract

To make fresh fruits, vegetables and other food substances safe and edible for a longer period of time than usual, their shelf life is increased. Therefore, their shelf life enhancement has garnered significant attention from scientists across the globe. Nanotechnology has played a vital role in this field of research for decades. In this study, a simple green synthesis technique was used to synthesize highly efficient ZnO nano-rods based nanostructures. The properties of bio-synthesized ZnO samples were examined using various characterization techniques including Scanning Electron Microscopy (SEM), Energy Dispersive X-ray spectroscopy (EDX), X-ray diffraction (XRD) and UV–visible spectroscopy. To study the effect of ZnO NPs on the shelf life of tomatoes the100 ppm solution of ZnO NPs and ZnO NPs along with Chitosan due to its potential anti-microbial properties have been sprayed on tomatoes. The physiological weight loss (PWL) and physical appearance and overall acceptability using 5-point scale are employed for consideration of variations in shelf life. It was seen that ZnO NPs have unequivocally preserved the tomatoes for a longer period and extended their shelf-life as compared to control and ZnO NPs along with Chitosan. Furthermore, ZnO NPs have shown no toxic effects on tomatoes. In this work, it has been investigated that high concentration of leaf extract gives smaller sized ZnO NPs and larger antimicrobial activity. This research is highly suitable for researchers for choice of suitable synthesis method as well as for the food industry for the improvements in shelf time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanotechnology and nanoscience are new boondocks of this century (Afsheen 2020) and food nanotechnology is a developing innovation (Ravichandran 2009). In the present era, the applications of nanotechnology in food production and packaging are being increased by every passing day (Arciniegas-Grijalba et al. 2017). Due to size minimization, there has been an enlargement in surface area of NPs (Bajpai et al. 2018; Singh 2018) that tends to several kinds of modifications in characteristics along with a potential effect on raw vegetables and fruits conservation (Miranda-Linares et al. 2018). In recent few years, nanotechnology have many promising applications in food sector such as nanopackaging materials (Duncan 2011), active packaging of food (Galstyan et al. 2018; Alsoufi and Aziz 2017). Limited shelf life of raw fruits is because of their several intrinsic factors including microbial contamination, environmental circumstances, mechanical damage as well as physiological disorders (Iqbal et al. 2021a), the stretch of postharvest treatment (Kusumaningrum et al. 2015) and biochemical changes that causes change in ethylene emission, respiration rate, and enzymatic activity of processed fruits and vegetables (Artes and Allende 2005). Shelf life of fresh produce can be enhanced by controlling various parameters (Sridhar et al. 2021) including temperature (Bekele 2018), relative humidity (Arah et al. 2015b), ethylene (Nayik and Muzaffar 2014), respiration rate and senescence (Aked 2002), pre-harvest and post-harvest factors (Ramjan and Ansari 2018; Ijaz et al. 2020a). The post-harvest losses in tomatoes are due to over-ripening, decay, immaturity and mechanical damage attributed to unsuitable harvesting periods (Meena et al. 2020), ill-suited harvesting containers and lack of preservation facilities, inappropriate packaging materials(Nagaraj et al. 2020) and poor field sanitation (Arah et al. 2015a).

Tomatoes have been among the most consumed fruits as fresh or processed food products containing several bioactive compounds including vitamin C, carotenoids and phenolic compounds (Hernández-Fuentes et al. 2017; Ray et al. 2016). Malva Parviflora also known as cheeseweed, cheeseweed mallow and small whorl mallow that has been utilized as oxidizing and reducing agent (Abdel-Ghani et al. 2013). Recently, it has been discovered that Malva parviflora contains anti-fungal proteins and the anti-fungal genes could be transferred to improve resistance of otherwise pathogen sensitive (Abd El-Rahim Mashaly 2012). Recently, it has been found that Chitosan has found frequent applications in the food industry (Sucharitha et al. 2018). Of its astonishing antimicrobial activity against numerous microbes (Ghaouth et al. 1992). It is among the most valuable polymers for pharmaceutical and biomedical applications because of its biocompatibility, biodegradability (Leak et al. 1179) as well as antimicrobial, anti-tumor (Alvarenga 2011) and non-toxic nature that make it applicable to be used as an additive in food sector (Sandeep et al. 2013). Green synthesized Zinc Oxide NPs (Tahir et al. 2020) has been acknowledged for its antibacterial and antimicrobial characteristics (Siddiqi et al. 2018). Devatha et al. have investigated that Green synthesis technique gives both environmental and economic advantages (Ijaz et al. 2020b) being a substitute of both physical and chemical methods because this technique does not require toxic chemicals, high temperature, pressure and energy (Devatha and Thalla 2018). Green synthesis is also known as bionanofactories (Iqbal et al. 2021b) because of the biogenic synthesis of nanoparticles in it (Noah 2019). Plant-mediated green synthesis of ZnO NPs using Malva Parviflora leaves provides phytochemical such as phenols, ascorbic acids, carboxylic acids, aldehydes, terpenoids, flavons, ketones and amides that acts as capping and reducing agents and capable to reduce metal salts into metal NPs (Singh et al. 2018; Ijaz et al. 2020c). These biogenic NPs have numerous applications in the area of nanomedicine (Iqbal et al. 2020) and bio-imaging and may possibly be applicable in manufacturing of printable electronic devices and antimicrobial textiles (Rosa et al. 2013; Ijaz and Zafar 2021).

The above Table 1 represents that current work shown as significant results as previous literature. However, it also shows that ZnO NPs are more appropriate than Ag NPs for shelf life enhancement of tomatoes and composites with chitosan showing even better results.

In this study, zinc oxide nanoparticles (ZnO NPs) have been synthesized successfully by simple single-step Green’s method using leaf extract of cheeseweed mallow plant and to spray these NPs on fresh tomatoes in order to enhance their shelf life. To confirm these biogenic NPs, various analytical techniques have been involved including SEM, EDX, XRD and UV–vis. To calculate the effect of ZnO NPs on the shelf time of tomatoes was investigated by various parameters including physiological weight loss, physical appearance and overall appropriateness under room temperature.

Materials and methods

Chemical/reagents

Zinc acetate [Zn(CH3CO2)2·2H2O], sodium hydroxide NaOH and deionized water were obtained from Nano laboratory of Physics department from University of Gujrat (Hafiz Hayat Campus), Pakistan. The chemicals were used without purifying. The chitosan was purchased from Tiens Islamabad, Pakistan. Fresh leaves of Malva Parviflora plants were used to produce leaf extract and fresh tomatoes were used as targeted test subjects.

Preparation of Malva Parviflora leaf extract

Malva Parviflora plant, commonly known as Cheeseweed mallow, was collected from the garden of the university. Then these fresh leaves were washed with deionized water and have been cut into tiny pieces, 10 g of cut leaves has been soaked in 200 mL of deionized water. The solution has been heated for 20 min on a magnetic stirrer. The leaf extract has been cooled to room temperature. Then, the leaf extract has been filtered into a flask by using a Whatsman number-1 filter paper and stored for synthesis purposes.

Green synthesis of ZnO NPs

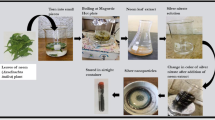

0.02M zinc acetate [Zn(CH3CO2)2·2H2O] was added and dissolved into 50 mL of deionized water and stirred for half an hour at normal room temperature. Then, leaf extract was added drop by drop into the solution until a light yellow color of solution appeared. The concentration of leaf extract used here was 4 mL. The solution was kept on stirring for 3 h by using a magnetic stirrer. 0.04 M NaOH was added and dissolved into 50 mL of distilled water and stirred for 20 min. Then, solution of NaOH was added drop by drop in solution of Zinc acetate and leaf extract until pH of the solution reached to 12. Then, the solution was kept on stirring for one hour. After that, the white precipitates are formed in the bottom of beaker. The solution has been washed by using distilled water over and over again and pH was continuously checked until it reached 7. Then, the precipitates of ZnO NPs were collected and dried at 80 °C for 6 consecutive hours in an oven. Then dried precipitates were crushed and were grinded into dust form. The white colored ZnO NPs were obtained and preserved in an airtight container. Same procedure was repeated twice by replacing 0.04 M NaOH with 0.05 M and 0.1 M NaOH in 50 mL distilled water, respectively. In both processes, the leaf extract was half concentrated because, instead of 10 g of leaves, 5 g of leaves was added into 200 mL of distilled water. In second attempt, 10 mL of leaf extract was used while in the third attempt, 12 mL of leaf extract was used. So, three samples of ZnO NPs were prepared and named sample 1, sample 2 and sample 3, respectively. The concentration of leaf extract used in synthesis processes was lowest in case of sample 1 and highest in case of sample 3. The precipitates of ZnO NPs of sample 3 were obtained quicker as compared to other two samples on the base of beaker because of lesser dilute solution of NaOH. The stepwise evaluation of the green synthesis process of sample 1 of ZnO NPs is represented in Fig. 1.

Figure 1 demonstrates a flow chart giving a better understanding of the procedure that leads to green synthesis of biogenic ZnO NPs. Besides the flow chart, the green synthesis method has also been illustrated stepwise in Fig. 2

.

Figure 2 clearly provides the basic visual understanding of the experiment of green synthesis of ZnO NPs. The first picture displays leaves of cheeseweed plant which have been used to produce leaf extract. Similarly the whole synthesis process is illustrated briefly that shows the synthesis process of ZnO NPs as discussed earlier.

Plant extract plays the major role in synthesizing ZnO NPs by reducing the zinc acetate dehydrate to zinc hydroxide. Zn(OH)2 is reduced to ZnO in the presence of sodium hydroxide (NaOH) solution . The NaOH is used to adjust pH value up to 12 and reaction is summarized in equations below:

The synthesis process involves two steps. First step is the bioreduction of zinc acetate dehydrate to zinc hydroxide and second step is production of ZnO NPs precipitates in the presence of aqueous solution of pH stabilizing agent NaOH. The flavonoids present in plant extract are responsible for bioreduction of zinc acetate and they behave as ligands stabilizing the ions to the nano scale.

Results and Discussions

The ZnO NPs have been produced through the green synthesis process by using leaf extract of Malva parviflora plant. Their characterization has confirmed that biogenic ZnO NPs have been synthesized successfully. Their optical properties have been studied through UV–visible spectroscopy. The SEM, XRD and EDX have been utilized to study the surface morphology, structure and chemical compositions of synthesized NPs, respectively. The aqueous solution of ZnO NPs has been sprayed on tomatoes and kept under observation for 2 weeks to examine their effects on shelf life of tomatoes. The same procedure has been repeated with aqueous solution of ZnO NPs plus chitosan. Different parameters have been studied regarding shelf life such as weight loss, color, firmness and physical appearances.

Morphological analysis of ZnO NPs

The surface morphology of synthesized samples of ZnO NPs is observed with SEM-JSM-5910. SEM or scanning electron microscope measures the particle size and characteristics, magnifies the image up to 200,000 times and it is sensitive down to 1 nm (Heera and Shanmugam 2015). It supplies information regarding surface morphology, topology, crystallography and composition (Akhtar et al. 2018). The 3 samples of ZnO NPs were analyzed at 15 kV and at various magnifications and scale bar lengths. Sample 1 is analyzed at (a) 2500 × with 10 µm, (b) 5000 × with 5 µm, (c) 10,000 × with 1 µm and (d) 30,000 × with 0.5 µm as shown in Fig. 3a–d. The SEM provides 2D image and it has shown that particles in sample 1 have hexagonal and irregular shapes which are in good agreement with literature (Alamdari et al. 2020). The particle sizes were determined by using ImageJ software which shows that the sizes of ZnO NPs from sample 1 are within range of 18–55 nm (Yashni et al. 2019). The mean size was determined by drawing histogram on Origin 8.5 and it was 32 nm. Sample 2 is analyzed at (a) 2500 × with 10 µm, (b) 5000 × with 5 µm, (c) 10,000 × with 1 µm and (d) 30,000 × with 0.5 µm as shown in Fig. 3e–h. Here, particles have spherical and irregular shapes which corresponds with previous literature (Naseer et al. 2020). Their size was also determined by using ImageJ software and the sizes were within the range of 12–45 nm (Jamdagni et al. 2018). The mean particle size was determined by drawing a histogram on Origin 8.5 and it was 43 nm. Sample 3 is also analyzed at (a) 2500 × with 10 µm, (b) 5000 × with 5 µm, (c) 10,000 × with 1 µm and (d) 30,000 × with 0.5 µm as shown in Fig. 3i–l. In the 2D image of sample 3 provided by SEM, the particles are nanorods and irregular nanochips in shape and are clustered together which corresponds to previous literature (Yang 2010; Saputra and Yulizar 2017). The range of sizes of particles in the sample was 15–53 nm. The mean particle thickness was found to be 18 nm.

The SEM results of sample 1, sample 2 and sample 3 of ZnO NPs, respectively have shown that the size and shape of synthesized NPs depend upon the concentration of leaf extract used in synthesis process.

Elemental analysis of ZnO NPs

To study the stoichiometry of ZnO NPs, the quantitative analysis of samples was done through EDX analysis at room temperature. The EDX was recorded in the energy region 18keV. The graph shows three strong and sharp peaks related to zinc below 10keV that verifies the elemental distribution of ZnO NPs (Aldalbahi et al. 2020). The results of EDX analysis of 3 different samples of ZnO NPs are shown in Fig. 4. The strong peaks in these figures confirm that Zn and O are the major elements in nanostructure (El-Belely et al. 2021). Figure 4a also shows that the weight percentage of Zn and O in sample 1 is 85.99% and 13.2%, respectively. However, the 0.81% weight percentage of Ti shows the presence of a very tiny amount of impurity. The atomic weight of Zn, O and Ti is 60.985, 38.23% and 0.79%.

Similarly in Fig. 4b, the results of sample 2 show that it consists of 88.35 of Zn and 10.86 of O elements. However, 0.79% Ti was also present which shows the sample is not 100% pure. The atomic weight of Zn, O and Ti is 66.03, 33.17% and 0.8%, respectively. The Fig. 4c shows the weight percentage of Zn and O in sample 3 is 86.58% and 11.59% but the presence of 0.93% and 0.9% weight percentage of Ti and Cu, respectively shows that the sample 3 is 1.83% impure.

The impurity, present in all three samples, is due to the substrate over which they were held (Jayanta 1999). The other reason is that NPs are highly reactive and unstable. However, the sample 1, sample 2 and sample 3 are 99.19%, 99.21% and 98. 17%, respectively are pure.

Structural analysis of ZnO NPs

X-ray diffraction or XRD technique has been used to study the crystal structure of samples of ZnO NPs, under the conditions of Bragg’s Law (Bunaciu et al. 2015). For three samples of ZnO NPs, the XRD graphs have been plotted and studied by using Origin 8.5 software. Figure 5 presents the sharp diffraction peaks for sample 1 of ZnO NPs have been identified at 31.8°, 34.3°, 36.25°, 47.6°, 56.6°, 62.9°, 68.1° and 69.15°. The sharp and strong peaks are corresponding to crystal planes (100), (002), (101), (102), (110), (103), (112) and (201,) respectively and are matched with JCPDS card No. 36-1451 (Dutta and Ganguly 2012). They are also matched with previous reported literature (Talam et al. 2012). The XRD pattern shows that the sample has highly crystalline nature and hexagonal wurtzite structure. The diameter of synthesized NPs of ZnO is calculated by the following formula (Tokumoto et al. 2003):

where, λ is wavelength of X-rays which is 1.5406 Å, β is broadening of diffraction line calculated by full width half maximum (FWHM) of peak with maximum intensity and D is the diameter of synthesized NPs of ZnO which is also referred as average crystallite size. The FWHM is calculated from Origin 8.5 software and then it was converted into radian units. The calculated average size of sample 1 of ZnO NPs from Eq. (1) is 36 nm which is in good agreement with previous literature (Raj and Lawerence 2018).

The XRD pattern of sample 2 shows sharp diffraction peaks at 31.79°, 34.32°, 36.13°, 47.47°, 56.44°, 62.87°, 68.02° and 69° corresponding to crystal planes (100), (002), (101), (102), (110), (103), (112) and (201) respectively. This pattern is also matched with JCPDS card No. 36-1451 and it reveals the hexagonal wurtzite structure of ZnO NPs. The average size of ZnO NPs (sample 2) calculated from Eq. (1) is 27 nm which lies within the range estimated by SEM. These results are also matched with previous literature just as sample 1.

Similarly, the XRD pattern of ZnO NPs of sample 3 shows diffraction peaks at 31.81°, 34.34°, 36.14°, 47.61°, 56.55°, 62.8°, 68.02° and 69.06° corresponding to the crystal planes (100), (002), (101), (102), (110), (103), (112) and (201) respectively. Just like sample 1 and sample 2, this pattern also matches with JCPDS card No. 36-1451 and it shows that the ZnO NPs have hexagonal wurtzite structure. The average size of ZnO NPs of sample 3 calculated from Eq. (1) is 24 nm which lies within the range estimated by SEM. These results are also in good agreement with previous literature just as sample 1 and sample 2. Comparing the sizes of ZnO NPs with the amount of leaf extract used in synthesis process, it can be seen that the larger the concentration of leaf extract used, smaller will be the particle size (Demissie 2020).

UV–visible analysis and Tauc plot

The synthesized ZnO NPs have been confirmed through their characterization. The UV–visible spectrometer has been used to study the optical properties of ZnO NPs. UV–visible spectroscopy has been conducted to measure the wavelength and the bandgap and to study the optical properties which confirmed that synthesized NPs were zinc oxide nanoparticles. The valence electrons are excited to free electron band called conduction band when they absorb energy and this phenomenon is called absorption. The absorption of valence electrons is analyzed by UV visible spectrum obtained from UV–visible spectrometer. The dilute solution of ZnO NPs has been prepared and analyzed by UV–Vis spectrometer. The UV spectrometer plots a graph between wavelength and absorbance. The peak value on graph determines the absorption wavelength of ZnO NPs. The graphs for all samples have been plotted on Origin 8.5 software within wavelength range 280–520 nm. The value of bandgap of ZnO NPs has been determined by deduction of Tauc Plot. It presents the connection between the optical absorption coefficient (α) and energy of photon (hυ) as shown in Eq. (2) below:

here, A is the effective mass of given material regarding conduction and valence bands, Eg is the bandgap and n represents the transition type of that material. For n = 0.5, transition is direct but for n = 1 and n = 1.5, transition is indirect and forbidden, respectively. The given spectrum tells absorption peak for sample 1 at 366 nm (3.39 eV) and the presence of only one peak indicates that only ZnO NPs have been synthesized. The peak specifies that most of synthesized particles are at nanoscale (Estrada-Urbina et al. 2018). The value of absorption decreases as the wavelength increases and it can be seen that it is 2.5 at 400 nm and 2.425 at 500 nm. The Tauc plot determines the value of bandgap which is 3.39 eV which has been illustrated in figure. Thus, the synthesized NPs in sample 1 are ZnO NPs.

The dilute solution of sample 2 was analyzed using the same spectroscopy. The UV visible characterization of sample 2 also evaluates the Tauc plot for bandgap analysis. The absorption peak has been obtained at 369nm (3.36 eV) for sample 2 and one peak represents that only ZnO NPs have been synthesized and most of synthesized particles are at nanoscale. The absorption peak is obtained at 1.8 and absorption decreases as the wavelength increases. Absorption is 1.675 at 400 nm and it is 1.575 at 500 nm. The Tauc plot determines the value of bandgap which is 3.36 eV as it can be seen in Tauc plot, the blue arrow cuts the x-axis at 3.36 eV determining the bandgap of ZnO NPs. The absorption peak has been obtained at 370 nm (3.35 eV) for sample 3 and one peak represents that only ZnO NPs have been synthesized and most of synthesized particles are at nanoscale. The absorption peak is obtained at 1.898 and absorption decreases as the wavelength increases. Absorption is 1.837 at 400 nm and it is 1.708 at 500 nm. The Tauc plot determines the value of bandgap which is 3.35 eV as it can be seen in Tauc plot, the magenta arrow cuts the x-axis at 3.35 eV determining the bandgap of ZnO NPs. So, all the samples prepared from the green synthesis technique are ZnO NPs. The graphical representations of UV Analysis of all synthesized samples of ZnO NPs have confirmed that these NPs are successfully synthesized from green synthesis method. The bandgaps for all the synthesized samples of ZnO NPs are acceptable. The wavelengths 366 nm, 369 nm and 370 nm and corresponding bandgaps 3.38 eV, 3.36 eV and 3.35 eV respectively also confirmed that synthesis of ZnO NPs was successful. Figure 6 represents the UV visible absorption spectra of all samples of ZnO NPs synthesized from green synthesis method. The red, blue and magenta colors represent the UV–visible analysis of sample 1, sample 2 and sample 3 respectively. The graph is plotted within the same range of wavelengths that is 280–520 nm. It clearly demonstrates that all the samples of synthesized ZnO NPs have shown approximately same behavior on plot but at different values of absorption. This is due to the different concentrations of leaf extract used in synthesis process. Since absorbance is the negative common logarithm of ratio of incident and transmitted radiation powers, larger the value of absorbance is, smaller will be transmittance.

So, sample 1 with red spectrum shows the high absorption and small transmittance while the sample 2 with blue spectrum and sample 3 with magenta spectrum represents comparatively smaller absorbance and larger transmittance. The reason is that the leaf extract has concentration (w/v) during synthesis process of sample 1 but comparatively low concentration (w/v) during the synthesis process of sample 2 and sample 3 (Ahmed et al. 2016). The difference between absorption values between sample 2 and sample 3 is due to a reason that leaf extract was added during their synthesis up to 10 mL and 12 mL, respectively. That is why sample 1 shows much higher absorption as compared to the other synthesized samples. The other reason is because of the difference of dilute solutions since it is hard to prepare dilute solutions of exactly same concentration. The absorption range for first sample is within range 2.4–2.6 a.u and the absorption range for second and third samples are below 2.1 a.u. For sample 2, the absorption range is within range 1.5–2.0 a.u. For sample 3, it is within range 1.7–2.1 a.u.

Preparation of ZnO NPs solution for spray

100 ppm ZnO solution has been prepared by dissolving 20 mg of ZnO NPs (sample 1) into 200 mL of deionized water. The solution has been stirred at room temperature for exact 10 minutes and then it is stored for spray purposes. The same procedure was repeated for other two samples. 100 ppm ZnO solutions were again prepared from three samples of ZnO NPs using the same method. Also 15 mg of chitosan was added to newly prepared ZnO NPs solutions. Because of non-toxicity and anti-microbial property of chitosan and its applications in food sector, it was used to see whether it would improve the functionality of ZnO NPs or not. So, there are total six ZnO NPs solutions, three including chitosan and three excluding chitosan.

Spraying ZnO NPs solutions on tomatoes

After the preparation of ZnO NPs solutions, they were sprayed on tomatoes by using 200mL spray bottles. The disposable gloves were worn on hands and solutions were poured in spray bottles. The ZnO NPs were sprayed and distributed on all over the sample tomatoes. They were sprayed on fingers of gloves too so that we touch tomatoes without affecting the distribution of NPs. The same procedure was repeated by using solutions which were containing chitosan. Then, the weight of each tomato was measured by using digital balance. A few tomatoes, which weren’t sprayed on, were also used as controlled sample and their weight was also calculated separately. After that all sample tomatoes were stored separately for observations. The ZnO solution was sprayed on some tomatoes and ZnO plus chitosan solution was also sprayed on some other tomatoes.

The controlled and sprayed tomatoes were kept under observation for 2 weeks and their weight loss and physical appearance was checked on planned schedules. The measurements have been taken on day 1, day 8 and day 15 as presented in Fig. 7.

Physiological weight loss (PWL) analysis

Physiological weight loss of all samples tomatoes have been calculated on Day 8 and Day 15 respectively.

To calculate weight loss, the following formula is used (Haile and Safawo 2018):

The initial weight of all tomatoes was measured on day 1. The current weight of tomatoes was measured on 4th, 8th, 11th and 15th day, respectively. But for clear results, measurements of just day 8 and day 15 are taken for calculations. For PWL on day 15, the initial weight is the weight measured on day 8. For overall physiological weight loss, the initial weight is the weight measured on day 1 and current weight is weight measured on day 15. The average weight loss is actually average of physiological weight losses of all sample tomatoes of a certain category. A table is formulated for better interpretation and the PWL of tomatoes of controlled, sprayed with ZnO NPs and sprayed with ZnO NPs plus Chitosan categories can also be compared from the table. Weight loss of all tomatoes under observation has been calculated from Eq. (3). The exact weight loss was calculated on 4th, 8th, 11th and 15th day, respectively. However the relative weight loss (%) was calculated on day 8 and day 15 since the prominent changes were shown after every week. The post-harvest losses in tomatoes are due to over-ripening, decay, immaturity and mechanical damage attributed to unsuitable harvesting periods, ill-suited harvesting containers and lack of preservation facilities, inappropriate packaging materials and poor field sanitation (Arah et al. 2015a). The weight loss of controlled and sprayed tomatoes is mention in Table 2.

From Table 2, it is shown that weight loss of controlled samples in first week is above 5%. While the samples sprayed with ZnO NPs have weight loss less than 4%. The sample sprayed with ZnO NPs plus chitosan have even better results, their weight loss is less than 2% in first week. In short, the tomatoes which were sprayed with ZnO NPs lost less weight than the controlled ones and the tomatoes(Raliya, et al. 2015), sprayed with ZnO NPs plus chitosan, barely lost their weight.

After calculating weight loss after 2 weeks (day 15), the weight loss increases exponentially. It means that as the time passes the rate of decay of tomatoes also increases. The weight loss of controlled tomatoes is above 13%, ZnO sprayed tomatoes lost their weight maximum up to nine percent and composite solution of ZnO plus chitosan sprayed tomatoes lost their weight maximum nearly up to four percent. There is exception that a controlled tomato lost its weight much faster than the others. It lost nearly one third of its weight in 2 weeks (due to internal parameters). Later, the experiment was repeated for controlled tomatoes by calculating the weight loss of some other tomatoes for 2 weeks. The results cleared that the physical weight loss of controlled tomatoes is usually less than 20%. The overall weight loss is the relative weight which each tomato lost in 2 weeks. The average weight loss is the average of weight losses of all samples. Table 2 also shows that the average weight loss of tomatoes which aren’t sprayed is above 13%, nearly 20%. The average weight loss of ZnO NPs sprayed tomatoes is above 5 but less than 10%. The average weight loss of ZnO NPs plus chitosan is less than 5%. The graphical representation of physiological weight loss of tomatoes is demonstrated in Fig. 8. These results show that the ZnO NPs solution has prominent effects on reducing the physical weight loss of tomatoes. This weight loss is approximately half of the weight loss of controlled tomatoes. The ZnO NPs plus chitosan solution has shown even better results, proving the reduction of microbial activities and anti-microbial property of chitosan as studied by Sharifan and co-workers (2021). The tomatoes lost weight less than 5% in 2 weeks.

Physical appearance and overall acceptability

There are three categories of tomatoes which are under observation. The first category is called controlled in which no NPs were sprayed on tomatoes. The controlled tomatoes are just ordinary tomatoes which are stored for analysis and comparison. The second category is the tomatoes in which 100 ppm solution of ZnO NPs was sprayed over them. The third category is in which ZnO NPs plus chitosan Solution was sprayed on tomatoes. After the observation of two weeks, the result of these three categories is described below:

Controlled

The controlled sample tomatoes have been observed for 2 weeks and their physical appearance was checked regularly on planned schedules. Figure 9a shows their physical condition on day 1, day 8 and day 15, respectively from left to right. It can be seen that their physical appearances had been started changing in first week. On day 8, tomatoes have shown darker red color, slightly shriveling and loss of shininess. They were poorly useable and they were softer than first day. On day 15, the tomatoes were highly shriveled, complete loss of shininess and totally unusable. The first sample was completely rotten compared to second one. This is because of the pre-harvest factors or harvest factors. Later few tomatoes were also kept in observation for two weeks and the calculations were readjusted. On day 15, the controlled tomatoes were completely unusable since their physical properties were deteriorated.

Sprayed with ZnO NPs

The tomatoes sprayed with ZnO NPs were also kept under observation for same interval of time and were checked on same dates and time. Figure 9b shows the physical appearances of those tomatoes on day 1, day 8 and day 15, respectively from top to bottom. The results of 2 weeks of observations are described. On day 8, the color of all tomatoes was slightly darker but only one tomato was shriveled and lost shininess and smoothness. One tomato has shown slightly signs of mold while the other didn’t show any sign of mold, shriveling or any change. Overall, two third of the total number of tomatoes were usable. On day 15, one tomato was completely shriveled and softened, one was slightly shriveled and softened and one did not show sign of shriveling or further softness. But that tomato was affected by mold and it was partially unusable. The two third tomatoes were poorly useable in which only half were useable. But these are quite better results than those of controlled tomatoes. Hence, the ZnO NPs have extended the durability of their usability. In figure, tomato in first column was sprayed with sample 3, tomato in second column was sprayed with sample 2 and tomato in third column was sprayed with sample 1 of ZnO NPs. Here, sample 3 has shown comparatively better results than sample 1 and sample 2.

Sprayed with ZnO NPs and Chitosan

The tomatoes sprayed with ZnO NPs plus chitosan solution have shown comparatively better results. These tomatoes were also kept stored for 2 weeks and were being checked on same schedule. The Fig. 9c shows the physical appearances of those tomatoes on day 1, day 8 and day 15. On day 8, the tomatoes were slightly dark red and were slightly smoothened and softened. There was also no sign of shriveling or mold on tomatoes. Hence, all tomatoes were still in excellent shape to be used. On day 15, one tomato did not change its appearance and was slightly softened. The other tomatoes were shriveled but one was fair useable and the other was poor useable. Overall, the tomatoes were good and useable after 2 weeks which clearly showed that their shelf life had been prolonged. The first column of tomatoes shows results of sample 3, second column shows results of sample 2 and third column shows results of sample 1. For clear results, this test was repeated and second attempt has clearly shown that sample 3 has demonstrated better effects on tomatoes as compared to sample 1 and sample 2. From these results of “Sprayed with ZnO NPs” and “Sprayed with ZnO NPs and Chitosan”, it is concluded that larger the concentration of leaf extract used in synthesis process, better will be the anti-microbial activity of synthesized ZnO NPs.

Acceptability

The physical appearance includes level or degree of visible mold growth, color, firmness, smoothness, shininess and shriveling of fruits. The acceptability level of tomatoes was determined on a scale after observing their physical appearances and visible parameters. A 1–5 rating was used to evaluate tomatoes quality (Haile and Safawo 2018).

-

1 is value for unusable

-

2 is value for useable

-

3 is value for fair usable

-

4 is value for good usable

-

5 is value for excellent

Table 3 clearly shows difference between usability levels of tomatoes of all three categories on day 1, day 8 and day 15. After receiving the results from physiological weight loss, physical appearances and level of acceptability, these results are concluded. These results specify that whether the shelf life of tomatoes has been prolonged by using ZnO NPs or not. Table 3 shows the level of acceptability for control tomatoes, tomatoes sprayed with ZnO NPs and tomatoes sprayed with ZnO NPs plus chitosan. After the observation of physical appearance of tomatoes which includes their visible mold growth, smoothness, shriveling and shininess, the results were concluded whether they were useable or not. From the figures, the acceptability levels of tomatoes were determined. The results for acceptability level were made on the basis of collected data from 5 co-respondents.

So, from the results obtained from physiological weight loss and physical appearance, it was confirmed that ZnO NPs have preserved the tomatoes for a longer period and extended their shelf-life. The ZnO NPs have shown even better results with chitosan and they nearly doubled the shelf life of tomatoes as reported by Saekow et al. in 2019 (Saekow et al. 2019). Furthermore, ZnO NPs have shown no toxic effects on tomatoes. It has also been seen that sample 3 have shown best results among all three samples which concludes that larger the concentration of leaf extract used in synthesis process, smaller will be the size of ZnO NPs and larger will be their anti-microbial activity.

Conclusion

As technology is becoming increasingly advanced with the passage of every single day, nanotechnology can be used in the food sector to meet customer’s demands regarding quality and preservation of food for a longer period of time. Food preservation is an issue the world is facing today which scientists need to overcome to avoid food spoilage because some raw foods and food products are fresh for a short period of time and start ripening because of fungal and bacterial activity inside food material. Therefore, it is necessary to discuss and improve morphology of NPs such as ZnO NPs in such a way that they can be used to prolong the shelf life effectively of those foods which have short post-harvest life and are being wasted at large scale because of their deterioration. In this work, a novel green synthesis approach has been used to prepare ZnO NPs successfully using leaf extract of Malva Parviflora plant and zinc acetate [Zn(CH3CO2)2·2H2O] as precursor material. This experiment has been conducted thrice and all three prepared samples of ZnO NPs have been characterized and rapid synthesis of white powder ZnO NPs has been confirmed by using Scanning Electron Microscopy (SEM), Energy Dispersive analysis of X-ray (EDX), X-ray powder Diffraction (XRD) and UV–visible spectroscopy. In contrast to sample 1 and 2, 24 nm ZnO nanorods and irregular nanochips of sample 3 exhibited a superior anti-microbial efficiency in case of tomatoes as compare to control and ZnO NPs along with 5 mg of chitosan polymer sprayed tomatoes have been monitored for two weeks. The results have been derived on the basis of alteration in their physiological weight loss (PWL) and several parameters of physical appearance such as color, smoothness, shininess, shriveling and also mold growth. The ZnO NPs have shown promising results, especially when it was mixed with chitosan. There has been less physiological weight loss (PWL) and smaller variation in physical appearances of sprayed tomatoes as compared to the controlled tomatoes. These results have concluded that ZnO NPs have preserved the food quality for a longer period and prolonged the shelf-life of tomatoes. Furthermore, it is also concluded that larger the concentration of leaf extract, smaller will be the size of synthesized biogenic ZnO NPs, better will be their anti-microbial activity which results in larger shelf-life of tomatoes. It is suggested to use a dilute solution of NaOH to obtain ZnO NPs precipitates quickly.

References

Abdel-Ghani AE, Hassan HM, El-Shazly AM (2013) Phytochemical and biological study of Malva parviflora L. grown in Egypt. Zagazig J Pharm Sci 22(1):17–25

Abd-El-Rahim-Mashaly I (2012) Autecology and economic potentialities of Malva parviflora L. at El Dakahlia, Nile Delta. J Environ Sci 42:661–683

Afsheen S et al (2020) Synthesis and characterization of metal sulphide nanoparticles to investigate the effect of nanoparticles on germination of soybean and wheat seeds. Mater Chem Phys 252:123216

Ahmed S et al (2016) Green synthesis of silver nanoparticles using Azadirachta indica aqueous leaf extract. J Radiat Res Appl Sci 9(1):1–7

Aked J (2002) Maintaining the post-harvest quality of fruits and vegetables. Fruit and vegetable processing. Elsevier, pp 119–149

Akhtar K et al (2018) Scanning electron microscopy: principle and applications in nanomaterials characterization. Handbook of materials characterization. Springer, pp 113–145

Alamdari S et al (2020) Preparation and characterization of zinc oxide nanoparticles using leaf extract of Sambucus ebulus. Appl Sci 10(10):3620

Aldalbahi A et al (2020) Greener synthesis of zinc oxide nanoparticles: characterization and multifaceted applications. Molecules 25(18):4198

Alsoufi M, Aziz R (2017) Extending shelf life of fruits by using some microorganisms biological products. Int J Mol Biol Open Access 2(5):00032

Arah IK et al (2015a) An overview of post-harvest losses in tomato production in Africa: causes and possible prevention strategies. J Biol Agric Healthc 5(16):78–88

Arah IK et al (2015b) Preharvest and postharvest factors affecting the quality and shelf life of harvested tomatoes: a mini review. Int J Agron 2015:1–6

Arciniegas-Grijalba P et al (2017) ZnO nanoparticles (ZnO-NPs) and their antifungal activity against coffee fungus Erythricium salmonicolor. Appl Nanosci 7(5):225–241

Artes F, Allende A (2005) Minimal fresh processing of vegetables, fruits and juices. Emerging technologies for food processing. Elsevier, pp 677–716

Bajpai VK et al (2018) Prospects of using nanotechnology for food preservation, safety, and security. J Food Drug Anal 26(4):1201–1214

Bekele D (2018) Review on factors affecting postharvest quality of fruits. J Plant Sci Res 5(2):106900

Bunaciu AA, UdriŞTioiu EG, Aboul-Enein HY (2015) X-ray diffraction: instrumentation and applications. Crit Rev Anal Chem 45(4):289–299

de Alvarenga ES (2011) Characterization and properties of chitosan. Biotechnol Biopolym 91:48–53

de la Rosa G et al (2013) Effects of ZnO nanoparticles in alfalfa, tomato, and cucumber at the germination stage: root development and X-ray absorption spectroscopy studies. Pure Appl Chem 85(12):2161–2174

Demissie MG et al (2020) Synthesis of zinc oxide nanoparticles using leaf extract of Lippia adoensis (koseret) and evaluation of its antibacterial activity. J Chem 2020:1–9

Devatha CP, Thalla AK (2018) Green synthesis of nanomaterials. Synthesis of inorganic nanomaterials. Elsevier, pp 169–184

Duncan TV (2011) Applications of nanotechnology in food packaging and food safety: barrier materials, antimicrobials and sensors. J Colloid Interface Sci 363(1):1–24

Dutta S, Ganguly BN (2012) Characterization of ZnO nanoparticles grown in presence of Folic acid template. J Nanobiotechnol 10(1):1–10

El Ghaouth A et al (1992) Chitosan coating to extend the storage life of tomatoes. HortScience 27(9):1016–1018

El-Belely EF et al (2021) Green synthesis of zinc oxide nanoparticles (ZnO-NPs) using Arthrospira platensis (Class: Cyanophyceae) and evaluation of their biomedical activities. Nanomaterials 11(1):95

Estrada-Urbina J et al (2018) Nanoscale zinc oxide particles for improving the physiological and sanitary quality of a Mexican landrace of red maize. Nanomaterials 8(4):247

Galstyan V et al (2018) Metal oxide nanostructures in food applications: quality control and packaging. Chemosensors 6(2):16

Haile A, Safawo T (2018) Shelf life and quality of tomato (Lycopersicon esculentum Mill) fruits as affected by different packaging materials. Afr J Food Sci 12(2):21–27

Heera P, Shanmugam S (2015) Nanoparticle characterization and application: an overview. Int J Curr Microbiol App Sci 4(8):379–386

Hernández-Fuentes AD et al (2017) Postharvest behavior of bioactive compounds in tomato fruits treated with Cu nanoparticles and NaCl stress. Appl Sci 7(10):980

Ijaz M, Zafar M (2021) Titanium dioxide nanostructures as efficient photocatalyst: progress, challenges and perspective. Int J Energy Res 45(3):3569–3589

Ijaz M et al (2020a) A review on Ag-nanostructures for enhancement in shelf time of fruits. J Inorg Organomet Polym Mater 30(5):1475–1482

Ijaz M, Zafar M, Iqbal T (2020b) Green synthesis of silver nanoparticles by using various extracts: a review. Inorg Nano-Metal Chem 51(5):744–755

Ijaz M et al (2020c) A review on antibacterial properties of biologically synthesized zinc oxide nanostructures. J Inorg Organomet Polym Mater 30:2815–2826

Iqbal T et al (2020) Simple synthesis of Ag-doped CdS nanostructure material with excellent properties. Appl Nanosci 10(1):23–28

Iqbal T et al (2021a) Chromium incorporated copper vanadate nano-materials for hydrogen evolution by water splitting. Appl Nanosci 11(5):1661–1671

Iqbal T et al (2021b) Synthesis and characterization of Ag–TiO2 nano-composites to study their effect on seed germination. Appl Nanosci 11:1–15

Jamdagni P, Khatri P, Rana J (2018) Green synthesis of zinc oxide nanoparticles using flower extract of Nyctanthes arbor-tristis and their antifungal activity. J King Saud Univ Sci 30(2):168–175

Jayanta K (1999) Synthesis and characterization of ZnO nano-particles. Department of Physics, National Institute of Technology, Rourkela, 769008, Orissa, Indi

Kusumaningrum D et al (2015) A review of technologies to prolong the shelf life of fresh tropical fruits in Southeast Asia. Journal of Biosyst Eng 40(4):345–358

Leak C et al (2015) Effects of chitosan coating on quality and shelf life of tomato during CoolBot cold storage. In: III Southeast Asia Symposium on Quality Management in Postharvest Systems 1179

Meena M et al (2020) Cu-chitosan nano-net improves keeping quality of tomato by modulating physio-biochemical responses. Sci Rep 10(1):1–11

Miranda-Linares V et al (2018) Solid lipid nanoparticles based edible coating for saladette tomato preservation. In: International Society for Horticultural Science ISHS, Leuven

Nagaraj E et al (2020) The biosynthesis of a graphene oxide-based zinc oxide nanocomposite using Dalbergia latifolia leaf extract and its biological applications. New J Chem 44(5):2166–2179

Naseer M et al (2020) Green route to synthesize zinc oxide nanoparticles using leaf extracts of Cassia fistula and Melia azadarach and their antibacterial potential. Sci Rep 10(1):1–10

Nayik GA, Muzaffar K (2014) Developments in packaging of fresh fruits-shelf life perspective: a review. Am J Food Sci Nutr Res 1(5):34–39

Noah N (2019) Green synthesis: characterization and application of silver and gold nanoparticles. Green synthesis, characterization and applications of nanoparticles. Elsevier, pp 111–135

Raj A, Lawerence R (2018) Green synthesis and characterization of ZNO nanoparticles from leafs extracts of Rosa indica and its antibacterial activity. Nutrition 11:1339–1348

Raliya R et al (2015) Mechanistic evaluation of translocation and physiological impact of titanium dioxide and zinc oxide nanoparticles on the tomato (Solanum lycopersicum L) plant. Metallomics 7(12):1584–1594

Ramjan M, Ansari MT (2018) Factors affecting of fruits, vegetables and its quality. J Med Plants 6(6):16–18

Ravichandran R (2009) Nanoparticles in drug delivery: potential green nanobiomedicine applications. Int J Green Nanotechnol Biomed 1(2):B108–B130

Ray S et al. (2016) Different quality characteristics of tomato (Solanum lycopersicum) as a fortifying ingredient in food products: a review. Technical Sciences/University of Warmia and Mazury in Olsztyn, 19(3):199–213

Saekow M et al (2019) Effect of carboxymethyl cellulose coating containing ZnO-nanoparticles for prolonging shelf life of persimmon and tomato fruit. J Food Sci Agric Technol (JFAT) 5:41–48

Sandeep A et al (2013) A brief overview on chitosan applications. Indo Am J Pharm Res 3(12):1564–4574

Saputra I, Yulizar Y (2017) Biosynthesis and characterization of ZnO nanoparticles using the aqueous leaf extract of Imperata cylindrica L. IOP Conf Ser Mater Sci Eng 188:012004

Sharifan H et al (2021) Postharvest spraying of zinc oxide nanoparticles enhances shelf life qualities and zinc concentration of tomato fruits. Crop Pasture Sci

Siddiqi KS, Ur-Rahman A, Husen A (2018) Properties of zinc oxide nanoparticles and their activity against microbes. Nanoscale Res Lett 13(1):1–13

Singh P (2018) Nanotechnology in food preservation. Food Sci 9:435–441

Singh J et al (2018) ‘Green’ synthesis of metals and their oxide nanoparticles: applications for environmental remediation. J Nanobiotechnol 16(1):84

Sridhar A et al (2021) Food preservation techniques and nanotechnology for increased shelf life of fruits, vegetables, beverages and spices: a review. Environ Chem Lett 19(2):1715–1735

Sucharitha K, Beulah A, Ravikiran K (2018) Effect of chitosan coating on storage stability of tomatoes (Lycopersicon esculentum Mill). Int Food Res J 25(1):93–99

Tahir M et al (2020) Hierarchical WO3@ BiVO4 nanostructures for improved green energy production. Appl Nanosci 10(4):1183–1190

Talam S, Karumuri SR, Gunnam N (2012) Synthesis, characterization, and spectroscopic properties of ZnO nanoparticles. Int Sch Res Not 2012:1–6

Tokumoto M et al (2003) Preparation of ZnO nanoparticles: structural study of the molecular precursor. J Sol-Gel Sci Technol 26(1–3):547–551

Yang LL (2010) Synthesis and characterization of ZnO nanostructures. Linköping University Electronic Press

Yashni G et al (2019) Green synthesis of ZnO nanoparticles by Coriandrum sativum leaf extract: structural and optical properties. Desalin Water Treat 167:245–257

Acknowledgements

The author (Imen Kebaili) extends her appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through Research Groups Program under Grant Number (R.G.P.2/179/42).

Author information

Authors and Affiliations

Contributions

TI: funding acquisition, conceptualization, supervision. AR: writing—original draft. MZ: formal analysis, data curation. SA: validation, project administration. IK: funding acquisition, conceptualization. HA: manuscript writing, project administration.

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Iqbal, T., Raza, A., Zafar, M. et al. Plant-mediated green synthesis of zinc oxide nanoparticles for novel application to enhance the shelf life of tomatoes. Appl Nanosci 12, 179–191 (2022). https://doi.org/10.1007/s13204-021-02238-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-021-02238-z