Abstract

Developing countries demand a sewage treatment plant with low-cost processes that are viable in warm climates. The UASB (upflow anaerobic sludge blanket) associated with the trickling filter (TF) would meet this requirement. However, there is still a need for studies aimed at the use of new support media. Based on this, the use of expanded polystyrene (EPS) as a support media in TF was evaluated in this study. As a result, the TF filled with EPS presented a final effluent with quality similar to reactors filled with crushed stone or patented materials. The density of EPS (6.56 ± 0.30 kg m−3), the void ratio (61.7 ± 2.1%), and the mean surface area (201.9 ± 14.9 m2 m−3) once again demonstrate that EPS has characteristics similar to other alternative or patented materials. Therefore, we found that EPS can be another alternative material to be used in sewage treatment, and also that one could give an appropriate destination to a portion of this material, which is currently still discarded in landfills.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In developing countries, the lack of investment in sanitation has compromised the springs used in the production of drinking water due to the release of untreated or partially treated sewage (Morrissey 2018).

There is a need to seek appropriate solutions for the peculiarities of these countries, which require a sewage treatment plant (STP) with low-cost processes that are viable in warm climates.

Despite these advantages, the UASB reactors have difficulties in producing effluents that can comply with the Brazilian environmental standards. Therefore, the post-treatment step is of great importance as a manner of adapting the treated effluent to the environmental discharge standards. The main objective of the post-treatment is to complement the organic matter removal (Chernicharo and Nascimento 2001).

The combination of anaerobic reactors followed by aerobic ones can be a good alternative, since it has greater simplicity of design, greater operational ease, less sludge production, and less energy consumption compared to the use of the activated sludge system as the main reactor of the process (Magalhães et al. 2019; Tonon et al. 2015).

Within this perspective, the combination of UASB (upflow anaerobic sludge blanket) and trickling filter (TF) has been widely applied and studied in Brazil, India, and Latin America (Chernicharo and Nascimento 2001; Almeida et al. 2011; Bressani-Ribeiro et al. 2018).

The trickling filter (TF) is a low-cost aerobic system that does not need an electric power source that promotes aeration, as in the case of activated sludge (Ali et al. 2017). Some authors suggest a greater simplification of the construction and operation of the system when evaluating changes in the secondary clarifier, or even its removal from the process flowchart (Chernicharo and Nascimento 2001; Almeida et al. 2011).

However, there is still a need for further studies that seek to increase its nitrification efficiency by effluent recirculation (Kanda et al. 2016; Bressani-Ribeiro et al. 2018) and to use new support media with larger specific area and low cost to replace gravel (Bressani-Ribeiro et al. 2018). For this reason, several types of support media have been studied, from pall rings (Metcalf & Eddy, Inc. 2003) to alternative materials such as: corn cob, biochar, granular activated carbon, zeolites, slag, coal cinder, and tire rubber (Ali et al. 2017; Forbis-Stokes et al. 2018; Zhao et al. 2013; Naz et al. 2016).

There is a great diversity of residues that could also fulfill the function of being a support media for the growth of microorganisms in TF. A new alternative would be expanded polystyrene (EPS).

Polystyrene has been widely used as an insulator and in packaging. The most prominent consumer of EPS is Asia; in 2010, Asian countries consumed 2787 kton, 47% of it for packaging (Winterling and Sonntag 2011). It is estimated that, in Brazil alone, over 100 thousand tons of EPS are consumed per year. Of this amount, only 34.5% is recycled (Cempre 2019).

Unfortunately, a large portion of used EPS is discarded in landfills or incinerated in developed countries, and openly burned and thrown in waste dumps in developing countries, barely ever being recycled. This is because EPS are relatively inexpensive, and conventional recycling methods turn them into lower-value materials, such as fuel oil or recycled resin (Chaukura et al. 2016). Even in the USA, a negligible amount of solid waste composed of polystyrene is recycled, of which only 0.9% of the total production goes for recycling (Thakur et al. 2018).

Therefore, it would be very interesting for developing countries to demonstrate that EPS is feasible to be used as support media in trickling filters. This would allow another form of suitable destination for this waste and would also allow the construction of lower cost sewage treatment systems.

Based on this, the use of expanded polystyrene as support media in trickling filters for sewage treatment was evaluated in our study.

Material and methods

For the study, a system composed of UASB reactor and trickling filter (TF) was set up. Both were built in PVC pipe with 100 mm in diameter (Fig. 1). The total volume of the UASB was 17.2 L, with a hydraulic holding time of 10 h. The reactor was inoculated with sewage sludge from the UASB reactor at ETE Barão Geraldo, Campinas (Brazil).

The TF was built in PVC with a useful height of 1.50 m, with a hydraulic loading rate (HLR) of 5.6 m3 m−2 day as a sizing parameter. At the base of the reactor, a grid was placed as an underdrain system; just above it, a 0.05 m layer of crushed stone, and, finally, the support media.

The reactors were fed using sewage from the collection network of the University of Campinas (Unicamp) campus. The TF received the influent by gravity, directly from the outlet of the UASB reactor. Both reactors were operated for 1 year and fed with an influent flow rate of 1.75 L h−1. (II) The empty bed contact time of the trickling filter was 30 min. No secondary clarifier was used after the TF.

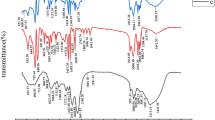

Wastewater samples were collected at the following points (Fig. 1): raw wastewater, UASB reactor effluent and TF effluent. The analyses of the influent and effluent of the reactors were carried out once a week for one year. The following analyses were carried out to monitor the reactors: pH, total alkalinity, dissolved oxygen (DO), turbidity, COD (Chemical Oxygen Demand), and BOD (Biochemical Oxygen Demand). In all cases, the guidelines of APHA et al. (2012) were followed.

Packing material

The EPS used to fill the TF is shown in Fig. 2. The media was a S-shape, that is the common shape for EPS used for protecting fragile materials inside boxes in Brazil. For example, electronic equipment is placed in cardboard boxes and then the S-shape EPS is placed inside to fill in the empty spaces, preventing damage to the equipment. Therefore, there is the generation of large amounts of this material as waste after a single use.

To characterize this expanded polystyrene (EPS), mean mass and mean volume of each unit, void ratio, and surface area were determined. To determine the mean mass, a 1.0 L beaker was filled with the packing material. Then, the total mass of packing material placed in the beaker was determined and the number of units used in packing was counted. Knowing the total mass and the amount of packing material used, it was possible to determine the mean mass of each unit.

To calculate the mean volume and the void ratio of the packing material, a 2.0 L beaker was used. Initially, it was filled up to the 2.0 L limit mark with the EPS units. Soon after, water was added until reaching the height corresponding to that same volume of 2.0 L. The volume of water used in this procedure was considered to be the void ratio of the packing material. The missing volume to complete 2.0 L was considered to be the total volume of the packing material and, knowing the number of units used, it was possible to determine the mean volume of each unit.

To obtain the surface area (SA) it was considered that the S-shape was composed of a toroidal shape with a square section cut in half (Fig. 3). In calculating this SA there is the need to determine the height (H), width (W), ray (R) and perimeter of the square (P). With these values, it was possible to determine the surface area using Eq. 1 and 2 (Harris and Stocker 1998).

Each of these determinations was made in quintuplicate.

Results and discussion

During the treatment evaluation, we observed that the UASB (Table 1) presented pH and alkalinity close to the typical range of behavior of this reactor (Chernicharo 1997). Likewise, the biomass concentration found (30 g L−1 in terms of total solids) was similar to the values reported for UASB reactors used in full scale (Chernicharo 1997).

There was a decrease of only 62% in COD (Table 1). This decrease is slightly below the values found in the literature and obtained in UASB reactors operated at full scale. There are several full-scale plants already in operation in Colombia, Brazil, Indonesia, India and Egypt and COD removals above 70% have been observed by several authors (Cecconet et al. 2022; Lew et al. 2003; Kalogo and Verstraete 2000; Chernicharo and Cardoso 1999; Souza and Foresti 1996).

In the analysis carried out for this study on a laboratory scale, it was not possible to categorically define the factors that caused this lower-than-expected efficiency. A possible hypothesis would be the non-removal of sludge throughout the study. Failure to discard sludge may have caused it to be dragged along with the effluent, compromising its quality. Another possibility could be related to the low COD value found for raw sewage (530 ± 82 mg L−1), which was related to the fact that this wastewater originates from a university campus.

However, such behavior did not impair the study of the later stage composed by the trickling filter (TF). The effluent quality of the UASB reactor was within the range obtained by other authors on a laboratory scale, pilot (Oliveira et al. 2019; Silva et al. 2015) and real (Chernicharo 1997).

After the passage of the anaerobic effluent through the TF, there was a significant increase in the concentration of dissolved oxygen (DO) in the final effluent. The influent DO concentration was close to zero, a characteristic of anaerobic effluent, and increased to 5.7 ± 1.8 mg L−1 after the TF. Naz et al. (2015) obtained similar results when operating laboratory scale biological trickling filter filled with different packing materials. Effluent DO values rose to 7.18 ± 0.28, 6.94 ± 0.06, 6.85 ± 0.5 and 6.18 ± 1.1 mg L−1 in stone, plastic, polystyrene and plastic media TF, respectively (Naz et al. 2015). These high values of DO were due to the contact of wastewater with biofilm on media. Vieira et al. (2013) obtained similar values (5.6 ± 0.6 mg L−1) when using a larger TF (3.2 m in diameter).

This behavior shows that EPS enabled an excellent contact between the influent and the gas phase that occupied the TF, favoring its natural aeration capacity.

Khalifa et al. (2020) observed an increase in aeration capacity in a wetland after the addition of polystyrene foam. The authors attributed this improvement to the EPS porosity, which allowed high aeration, comparable to systems with artificial aeration.

The turbidity of the final effluent reached 18 ± 19 UT. Therefore, the TF increased its quality by reducing the values by an additional 57% compared to the UASB effluent. When we measure the overall efficiency of the system (UASB + TF), the value jumps to 70%. Both results are compatible with the results found in the operation of the same system at full scale with the use of patented packing materials (Tonetti et al. 2019). At this point, it is important to highlight that such efficiency was obtained without the presence of a secondary clarifier.

Regarding the removal of organic matter, the TF managed to decrease the COD values by another 50% compared to the UASB effluent. The overall efficiency reached 81%. The overall efficiency was compromised by the low performance presented by the UASB reactor in this study. However, when we evaluate the final effluent in terms of BOD, efficiency is compatible with that of the literature (Almeida et al. 2011; Bressani-Ribeiro et al. 2018), reaching 91%. At this point, it is important to highlight that such efficiency was obtained without the presence of a secondary clarifier.

Even with the low performance of UASB, the final effluent presented values lower than the discharge standards used in developing countries, such as Brazil, El Salvador, Guatemala, Honduras, and Nicaragua (Oakley et al. 2000). Such countries mention the values of 180 mg COD L−1 and 60 mg BOD L−1 as a limit. It would also be below the COD limit of 125 mg O2 L−1 established by the European guideline for discharge into water bodies (91/271/EEC). In all cases, this service occurred in 100% of the analyses performed for the final effluent.

According to Stefanakis et al. (2019), efficiency could be increased if there was a recirculation of the TF effluent in the reactor itself, increasing the contact time between effluent and biofilm.

Therefore, we can see that EPS proved to be another alternative material that could be used in sewage treatment. The quality of the final effluent has always been within the limits of several global laws and compatible with materials used in sewage treatment plants at a full scale that use patented materials (Tonetti et al. 2019), and also compatible with studies that used alternative materials (Almeida et al. 2011).

As a future step, one must verify the occurrence of nitrification with this support media. In addition, it is essential to analyze the influence of the EPS geometry on the reactor efficiency and how the EPS behaves for a prolonged period of use.

Support media characteristics

The mean mass of each EPS unit was 76.4 ± 3.3 mg. The mean volume was 11.7 ± 0.2 mL. Therefore, the density was 6.56 ± 0.30 kg m−3 (Table 2). These values were much lower than those obtained for crushed stone (1442 kg m−3) and pall rings (27 kg m−3) (Daigger and Boltz 2011). As a consequence, it can be expected that the use of EPS in the construction of TF will not require very robust structures to support the weight of the material. Therefore, the filter support of the reactor should only fulfill the function of separating the bed of the packing material from the bottom that drains the effluent.

Even in this regard, a more simplified system could be obtained, eliminating the support and the bottom of the reactor, responsible for draining the effluent. This system could be replaced by a bottom with a slope converging to perforated tubes, which would direct it out of the TF. This tube would be in contact with the packing material composed of EPS. Logically, the tube should be produced with a material that would support the small weight of the EPS column that would be on it.

The void ratio reached 61.7 ± 2.1%. This value was compatible with the materials typically used, such as crushed stone (60%), and was lower than pall rings (95%) (Daigger and Boltz 2011; Lemji and Eckstadt 2013). However, at this point we must consider the cost of the materials. Shahid et al. (2019) used polystyrene when treating polluted waters in a wetland and justified the choice due to anti-weathering characteristics, inherent strength, temperature, weight tolerance, and, more importantly, low cost. Pall rings are costly and patented, while EPS is a solid waste that has its final disposition pointed out as a problem in cities in developing countries.

Another positive aspect for the use of EPS as packing material in TF would be that its low density and high void index make it possible to increase the height of the reactor, allowing the reduction of the area of the STP (Daigger and Boltz 2011).

The determining factor for the occurrence of nitrification is the organic load applied to the TF (Metcalf & Eddy, Inc. 2003), thus, a greater height for the reactor can contribute to the development of heterotrophic bacteria in its upper part, where the removal of organic matter would occur. Autotrophic nitrifying bacteria could develop at the bottom, ensuring conditions for nitrification.

The mean surface area was 201.9 ± 14.9 m2 m−3. This value was higher than other alternative materials, even patented materials (Table 2). Therefore, EPS will provide conditions for a high adhesion of microorganisms.

One of the challenges for implementing EPS reverse logistics is reducing transport costs (Oliveira et al. 2019). Therefore, reuse and recycling must be local, avoiding this material to be transported over long distances.

As an example, we can think of a city of 20 thousand inhabitants with a mean influent flow of 3000 m3 day−1. Following the guidelines for the design of the TF pointed out by Chernicharo (1997), and adopting a hydraulic loading rate of 15 m3 m−2 day−1 and a volumetric organic load of 0.60 kg DBO m3 day−1, the TF needed to treat the sewage should have a surface area of 200 m2 and height of 2.50 m. Soon, there would be a need for 500 m3 of packing material.

If we consider the use of EPS in this situation, about 191.5 m3 of material (61.7% void ratio) would be necessary, or the equivalent of 1256 kg (density was 6.56 ± 0.30 kg m−3).

In Brazil, where there is a population of 209 million inhabitants, it is estimated that more than 100 thousand tons of EPS are consumed per year (Cempre 2019). Therefore, this country consumes an average of 0.48 kg of EPS per inhabitant per year. Thus, considering that the city of 20 thousand inhabitants used in the dimensioning of the TF is typical, its population would generate about 9600 kg of EPS per year as waste. However, in Brazil, only 34.5% of the material used is recycled (Cempre 2019). That is, considering this factor, in the city in question there would be recycling of approximately 3312 kg of EPS per year.

Not all of this recycled material would be compatible with its use in a TF reactor. An important portion of this waste corresponds to inappropriate materials due to its small thickness, such as food packaging. Therefore, in this study, only EPS from equipment packaging was considered adequate, which corresponds to 29% of the total amount (Oliveira et al. 2019). In this case, the materials are usually larger and more robust, having dimensions more suitable for use as TF packing material.

Thus, of the total amount recycled in the city in question (3312 kg of EPS per year), we would possibly have 960 kg of EPS per year of material coming from equipment packaging. Since the TF in that city would require 1256 kg of packing material, it would take the city about 16 months to fill the reactor.

It is important to highlight that this waste is not to be directly used in the reactor. The authors of this article believe that the recycled waste must initially undergo a process in which the EPS is crushed into smaller and more uniform sizes, suitable for use in the reactor.

Conclusion

The trickling filter (TF) filled with EPS and used in the treatment of domestic sewage presented a final effluent with a quality similar to reactors filled with crushed stone or patented materials, and always below the limits of several global laws.

The density of EPS (6.56 ± 0.30 kg m−3), the void ratio (61.7 ± 2.1%), and the mean surface area (201.9 ± 14.9 m2 m−3) once again demonstrated that EPS has characteristics similar to other alternative or patented materials, and indicate that its use in the construction of TF will not require very robust structures to support its weight.

Therefore, EPS may be another alternative material to be used in sewage treatment; in addition, part of this material, which is currently still discarded in landfills, could be given an appropriate destination.

References

APHA/AWWA/WEF (2012) Standard methods for the examination of water and wastewater. 22ª ed. American Public Health Association (AWWA), Water Environment Federation (WEF), Washington

Ali I, Khan ZM, Peng C, Nazz I, Niaz Y, Sultan M (2017) Identification and elucidation of the designing and operational issues of trickling filter systems for wastewater treatment. Pol J Environ Stud 26(6):2431–2444

Almeida PGS, Oliveira SC, de Chernicharo CA, L. (2011) Operação de filtros biológicos percoladores pós reatores UASB sem a etapa de decantação secundária. Eng Sanit Ambiental 16(3):271–280

Bressani-Ribeiro T, Almeida PGS, Volcke EIP, Chernicharo CAL (2018) Trickling filters following anaerobic sewage treatment: state of the art and perspectives. Environ Sci Water Res Technol 4(11):1721–1738

CEMPRE e Compromisso Empresarial para a Reciclagem (2019) Preço Dos Materiais Reciclaveis. http://cempre.org.br/cempre-informa/id/115/preco-dos-materiaisreciclaveis. Accessed on September 10, 2020

Cecconet D, Callegari A, Capodaglio AG (2022) UASB performance and perspectives in urban wastewater treatment at sub-mesophilic operating temperature. Water 14:115. https://doi.org/10.3390/w14010115

Chaukura N, Gwenzi W, Bunhu T, Ruziwa DT, Pumure I (2016) Potential uses and value-added products derived from waste polystyrene in developing countries: a review. Resour Conserv Recycl 107:157–165

Chernicharo CAL, Cardoso MR (1999) Development and evaluation of a partitioned upflow anaerobic sludge blanket (UASB) reactor for the treatment of domestic sewage from small villages. Water Sci Technol 40(8):107–113. https://doi.org/10.1016/S0273-1223(99)00615-0

Chernicharo CAL, Nascimento MCP (2001) Feasibility of a pilot-scale UASB/trickling filter system for domestic sewage treatment. Water Sci Technol 44(4):221–228

Chernicharo CAL (1997) Princípios do tratamento biológico de águas residuárias: Reatores Anaeróbios. 1. ed. UFMG, Belo Horizonte

Daigger GT, Boltz JP (2011) Trickling filter and trickling filter-suspended growth process design and operation: a state-of-art review. Water Environ Res 83(5):388–404. https://doi.org/10.2175/106143010X12681059117210

da Silva JCP, Tonetti AL, Leonel LP, Costa A (2015) Denitrification on upflow-anaerobic filter filled with coconut shells (Cocos nucifera). Ecol Eng 82:474–479

de Oliveira CT, Luna MMM, Campos LMS (2019) Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics toward circular economy. J Clean Prod 235:562–573

Forbis-Stokes AA, Rocha-Melogno L, Deshusses MA (2018) Nitrifying trickling filters and denitrifying bioreactors for nitrogen management of high-strength anaerobic digestion effluent. Chemosphere 204:119–129

Harris JW, Stocker H (1998) Torus. §4.10.5 in Handbook of mathematics and computational science. Springer, New York, p 113

Henley EJ, Seader JD (2005) Separation process principles, 2nd edn. Wiley, New York, p 700

Kalogo Y, Verstraete W (2000) Technical feasibility of the treatment of domestic wastewater by a CEPS-UASB system. Environ Technol 21:55–65. https://doi.org/10.1080/09593332108618138

Kanda R, Kishimoto N, Hinobayashi J, Hashimoto T (2016) Effects of recirculation rate of nitrified liquor and temperature on biological nitrification-denitrification process using trickling filter. Water Environ J 30:190–196

Khalifa ME, El-Reasha YGA, Ahmed MI, Rizk FW (2020) Effect of media variation on the removal efficiency of pollutants from domestic wastewater in constructed wetland systems. Ecol Eng 143:105668

Lemji HH, Eckstadt H (2013) A pilot scale trickling filter with pebble gravel as media and its performance to remove chemical oxygen demand from synthetic brewery wastewater. J Zhenjiang Univ Sci B 14(10):924–933. https://doi.org/10.1631/jzus.B1300057

Lew B, Belavski M, Admon S, Tarre S, Green M (2003) Temperature effect on UASB reactor operation for domestic wastewater treatment in temperate climate regions. Water Sci Technol 2003(48):25–30. https://doi.org/10.2166/wst.2003.0151

Magalhães TM, Duarte NC, Neves TA, Bueno DAC, Delforno TP, Oliveira VM, Tonetti AL (2019) The challenge of making wastewater treatment plants composed by anaerobic reactors capable of removing nitrogen. Water Air Soil Pollut 30:24. https://doi.org/10.1007/s11270-019-4300-0

Metcalf & Eddy, Inc. (2003) Wastewater engineering: treatment and reuse. McGraw-Hill, Boston

Morrissey A (2018) Treatment and recycling of domestic and industrial wastewater. In: Encyclopedia of renewable and sustainable materials. pp 908–918. ISBN 978-0-12-813196-1

Naz I, Hodgson D, Smith A, Marchesi J, Ahmed S, Avignone-Rossad C, Saroj DP (2016) Effect of the chemical composition of filter media on the microbial community in wastewater biofilms at different temperatures. RSC Adv 6:104345

Naz I, Saroj DP, Naeem Ali SM, Ahmed S (2015) Assessment of biological trickling filter systems with various packing materials for improved wastewater treatment. Environ Technol 36(4):424–434. https://doi.org/10.1080/09593330.2014.951400

Oakley SM, Pocasangre A, Flores C, Monge J, Estrada M (2000) Waste stabilization pond use in Central America: The experiences of El Salvador, Guatemala, Honduras and Nicaragua. Water Sci Technol 42(10–11):51–58. https://doi.org/10.2166/wst.2000.0607

Shahid MJ, Arslan M, Siddique M, Ali S, Tahseen R, Afzal M (2019) Potentialities of floating wetlands for the treatment of polluted water of river Ravi, Pakistan. Ecol Eng 133:167–176

Souza JT, Foresti E (1996) Domestic sewage treatment in an upflow anaerobic sludge blanket sequencing batch reactor system. Water Sci Technol 33(3):73–84. https://doi.org/10.1016/0273-1223(96)00323-X

Stefanakis AI, Bardiau M, Trajano D, Couceiro F, Williams JB, Taylor H (2019) Presence of bacteria and bacteriophages in full-scale trickling filters and an aerated constructed wetlands. Sci Total Environ 659:1135–1145. https://doi.org/10.1016/j.scitotenv.2018.12.415

Thakur S, Verma A, Sharma B, Chaudhary J, Tamulevicius S, V. K. (2018) Recent developments in recycling of polystyrene based plastics. Curr Opin Green Sustain Chem 13:32–38

Tonetti AL, Duarte NC, Santos MRR, dos; Siqueira, G. H. (2019) Environmentally friendly interlocking concrete paver blocks produced with treated wastewater. Water Supply 19(7):2028–2035

Tonon D, Tonetti AL, Coraucci-Filho B, Bueno DAC (2015) Wastewater treatment by anaerobic filter and sand filter: hydraulic loading for removing organic matter, phosphorus, pathogens and nitrogen in tropical countries. Ecol Eng 82:583–589

Vieira PC, von Sperling M, Nogueira LCM, Assis BFS (2013) Performance evaluation of a novel open trickling filter for the post-treatment of anaerobic effluents from small communities. Water Sci Technol 67:12. https://doi.org/10.2166/wst.2013.195

Winterling H, Sonntag N (2011) Rigid polystyrene foam (EPS, XPS). Kunststoffe Int 101(10):18–21

Zhao Q, Zhong H, Wang K, Wei L, Liu J, Liu Y (2013) Removal and transformation of organic matters in domestic wastewater during lab-scale chemically enhanced primary treatment and a trickling filter treatment. J Environ Sci 25(1):59–68

Acknowledgements

The authors thank CNPq (National Council for Scientific and Technological Development, process number 311275/2015-0) and FAPESP (São Paulo Research Foundation, process number 2017/07490-4) for financing this study. The authors would also like to acknowledge the service of the Espaço da Escrita – Dean of Research – UNICAMP for helping translate the original manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The manuscript is an original work with its own merit, has not been previously published in whole or in part, and is not being considered for publication elsewhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Paixão Filho, J.L., Portela, D.G., da Silva, C.I. et al. Use of expanded polystyrene (EPS) as a support media for trickling filters applied to wastewater treatment. Appl Water Sci 13, 66 (2023). https://doi.org/10.1007/s13201-023-01869-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-023-01869-7