Abstract

In this present study, a three-factor Box–Behnken, response surface methodology (RSM) design was employed to optimize the skimmed milk powder (SMP)/whey protein concentrate (WPC) ratio (0.25–0.75%w/v) as a source of milk protein, inulin (1–2%w/v), and honey (4–6%w/v) for production of high-quality goat milk yoghurt (GMY). The resulting ANOVA and response surface equations revealed the significant effect (p < 0.05) of these variables on the various attributes such as total solid (%), pH, titratable acidity [(LA) % by weight], syneresis (%), DPPH (% inhibition), viscosity (m.Pa⋅s), whiteness index (WI), and overall acceptability (OA). The coefficient of determination (R2) for all response variables ranged from 0.88 to 0.99. Lack-of-fit tests resulted in non-significant F-values. The optimal conditions were determined as SMP/WPC at 0.36%w/v, inulin at 1.00%w/v, and honey at 6.00%w/v. The optimum values for total solid, pH, titratable acidity, syneresis, DPPH, viscosity, WI, and OA were 22.03, 4.46, 0.77, 6.34, 25.20, 182.30, 76.29 and 8.37, respectively with desirability value of 0.95.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Consumers’ interest in goat milk has gradually gained momentum in recent years due to nutritional and health benefits such as higher digestibility, lipid metabolism, low allergenicity, alkalinity, higher buffering capacity, and specific therapeutic effects compared to cow milk (Haenlein 2004; Park 2009). Due to goat milk distinct characteristics, its use in dairy products offers a chance to diversify the dairy industry. Globally, goat milk is consumed directly or as dairy products. However, fermented products from goat milk are more popular since they lack goaty flavour due to fermentation by different microbes (Pulina et al. 2018). Processing of dairy products, particularly yoghurt, has increased recently due to the rising trend of healthy eating. Yoghurt has been a popular fermented dairy product worldwide since ancient times because of its nutritional value and health benefits. However, low amount of αS1 casein, smaller casein micelles, low levels of proteins, as well as lower total solids, might negatively affect the texture of goat milk yoghurt (GMY) (Park et al. 2007; Nguyen et al. 2018) as well as customer liking and acceptance (Guichard 2002). Further, different factors, including the yoghurt milk base's composition and processing parameters, impact the quality characteristics. In order to increase the overall solid content and prevent undesired textural defects including weak gel structure and syneresis, skim milk powder (SMP) and other milk protein preparations are frequently added to the milk base (Tamime and Robinson 2007). Several authors have investigated the effect of various forms of protein addition on the quality improvement of yoghurt i.e., GMY with milk protein–based products (Gursel et al. 2016), and GMY with WPC (Zoidou et al. 2019). The addition of prebiotics, which further enhances the overall solid content, texture/rheological, nutritional value, and sensory perception of yoghurt, is one method that manufacturers are attempting to include health-promoting components into the product (Allgeyer et al. 2010). By promoting and preserving the survival of probiotic bacteria, inulin may also be used to alter yoghurt's texture (Mituniewicz-Malek et al. 2014). Honey has grown in popularity as an antioxidant, antimicrobial agent and substitute sweetener in a range of foods in recent years due to its perceived health benefits and ability to boost consumer acceptance of acidic meals like yoghurt (Chick et al. 2001; Varga 2006; Mercan and Akin 2017). According to our knowledge, there is no literature on response surface methodology (RSM)-based optimization of SMP/WPC, inulin, and honey-incorporated goat milk yoghurt. RSM has demonstrated value in experiment design, factor optimization to forecast desired responses, and evaluation of the effects of several factors (Singh et al. 2018). Considering the information mentioned above, the current study was designed to use the RSM statistical tool to optimize the concentration of different ingredients for manufacturing high-quality goat milk yoghurt.

Material and methods

Materials

The fresh goat milk was obtained from the Jamunapari goat farm of ICAR-Central Institute for Research on Goats (CIRG), Makhdoom (India). The lyophilized starter culture containing Streptococcus thermophilus and Lactobacillus bulgaricus was procured from Chr Hansen (India) Pvt Ltd., Mumbai. Skim milk powder (0.56% w/w fat, 34% w/w protein; Govind milk and milk products®, Maharashtra, India), and honey (Dabur) were procured from local market. Whey protein concentrate was procured from M/s Modern Dairies Ltd., Karnal. The precious gift of Inulin (Orafti®GR) sample was obtained from BENEO India Private Limited, Gurugram, India. All the chemicals (AR grade) were supplied by standard firms like Sigma chemicals (India) Pvt Ltd., Central Drug House and Hi-media.

Preparation of goat milk yoghurt

For the manufacturing of set-type goat milk yoghurt, selected concentrations of SMP/WPC ratio (0.25, 0.5 and 0.75%w/v) were added to the fresh goat milk and mixed thoroughly. The milk was heated in a stainless-steel vat at 90 ± 1 °C for 5 min with occasional stirring. Further, the milk was supplemented with different levels of inulin (0.5, 1.0 and 1.5%w/v) and honey (2.0, 4.0 and 6.0%w/v) followed by cooling to 43 ± 1 °C. The milk was inoculated at a rate of 2% with yoghurt culture followed by incubation at a temperature of 43 ± 1 °C in an incubator until the pH reduced to 4.5–4.7. After fermentation, the yoghurt cups were transferred to a refrigerator and stored at 4 ± 1 °C. The developed product was then analysed for total solid (%), pH, titratable acidity [(LA) % by weight], syneresis (%), DPPH (% inhibition), viscosity (m.Pa.s), whiteness index (WI) and overall acceptability (OA) of developed product. Using response surface technique, the impact of SMP/WPC, inulin, and honey levels on goat milk yoghurt was assessed.

Experimental Design

The Box Behnken Design (BBD) of response surface methodology was used to study the possible combinations of factor levels containing the central point (five replicates) used for the optimization. Using Design -Expert statistical software (Trial version 13, Stat-Ease, Inc., Minneapolis, USA), 17 experiments were designed and the ranges of the independent variables in the design were prescribed into three levels, which were 0.25, 0.5 and 0.75% w/v for SMP/WPC (X1); 0.5, 1.0 and 1.5% w/v for inulin level (X2); and 2.0, 4.0 and 6.0% w/v for honey level (X3). The ranges of independent variables were selected after conducting a series of preliminary trials. The following response variables were measured: total solid (%), pH, titratable acidity [(LA) % by weight], syneresis (%) DPPH (% inhibition), viscosity (m.Pa.s), WI and OA. The experiment results were fitted with quadratic polynomial model for each response according to Eq. 1.

where Y is the response variable, the β0, βi βik and βii are the regression coefficients for intercept, linear, interaction and quadratic effects, respectively. Xi and Xj are the coded independent variables influencing the responses Y. With a 5% significance level, the P value (probability) was used to determine model terms and the fit polynomial model was evaluated by coefficient of determination (R2). The response surface plots were also generated to assess the effect of independent variables on responses of GMY.

Analytical procedure

The total solid (%) of yoghurt samples was evaluated by using a moisture analyser. The pH of yoghurt samples was measured with the help of a digital pH meter (Mettler Toledo®, Ohio, USA). Titratable acidity was evaluated by titration with 0.1N sodium hydroxide solution by following the method of AOAC (2005) and results were expressed as lactic acid (% by weight). Syneresis (%) in the yoghurt samples was carried out using the centrifugal method according to the procedure of Nguyen et al. (2017). Antioxidant activity was estimated by DPPH method according to the procedure described by Brand-Williams et al. (1995). The viscosity of the samples were evaluated using a dynamic rheometer (MCR72, Anton Paar Ltd., Austria) following the method of Nguyen et al. (2017). The colour values of the yoghurt samples were measured by evaluating Hunter lightness (L*), redness (a*) and yellowness (b*) values using Color Tec PCM + (Color Tec Associates, Inc., Clinton, NJ). The whiteness index (WI) was calculated through Eq. 2.

Sensory analysis

Sensory analysis of yoghurt samples was carried out by a panel of 20 semi-trained panellists comprised of scientists and scholars. The panellists were not specifically trained, they were previously acclimatised with the sufficient knowledge of sensory evaluation methods and product attributes. The panellists were briefed about the experiment and were requested to rate the coded samples on the sensory evaluation sheet using 9-point hedonic scale (1 = extremely dislike and 9 = extremely like) for overall acceptability. The overall acceptability of product took into account the average scores for colour and appearance, body and texture, flavour and mouth feel. The panellists provided overall acceptability scores for the yoghurt samples based on their collective perception of the samples.

Results and discussion

Model fitting

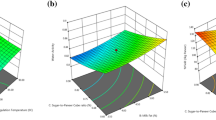

The findings of the experiment investigating the impact of independent variables on goat milk yoghurt production, along with the recorded responses for the 17 treatments, are detailed in Table 1. A statistically adequate models was obtained using the response surface method that effectively elucidates the influence of independent variables on the studied responses. There were linear, quadratic, and interactive effects recorded for each model. The response surface graphs generated from experiment data are shown in Figs. 1, 2 and 3. Experimental data were used to obtain models, which were then analysed for level of significance. An analysis of variance (ANOVA) was conducted to determine the statistical significance of each model term. The results of the regression analysis and ANOVA for each response are shown in Table 2. In all the cases, we observed an insignificant lack of fit (F-values), which confirmed the validity of the models. The coefficient of determination (R2) values for all responses were higher than 0.85. According to Lima et al. (2010), the (R2) should be approximately 80% to indicate that the model fits well.

Total solid

This study investigated the influence of SMP/WPC, inulin, and honey levels on total solid content of GMY using the application of RSM. The R2 value of 0.9164 indicates a strong fit of the model to the data (Table 2). The quadratic equation representing the model that elucidates the correlation between the total solid content of GMY and its independent variables is as follows: Total solid = + 25.50 + 2.82X1-10.26X2 + 0.42X3 + 2.14X12 + 0.34X13 + 0.04X23-8.62X11 + 3.13X22-0.01X33. In this case, honey level (linear), SMP/WPC, and inulin levels (quadratic) were significant model terms and affected the GMY. Notably, honey level displayed the most pronounced linear effect, suggesting its dominant influence on total solid (Table 2). Factors SMP/WPC and inulin level have statistically significant quadratic effects, implying a non-linear relationship with total solid. The model is statistically significant and provides a good fit to the data. Quadratic effects indicate the curvature in the response due to squared values of factors (Fig. 1a–c). Similarly, an increase in total solid value on honey addition has been reported for set type yoghurt by Mercan and Akin (2017); Sert et al. (2011). Differences in the total solid of GMY may be due to higher solid-non-fat and protein levels on SMP/WPC additions in different formulations. The above results followed Gursel et al. (2016) and Costa et al. (2016), who also found changes in the composition of GMY with the incorporation of protein ingredients.

pH

The pH of the GMY varied from 4.31 to 4.49 (average pH of 4.40) (Table 1). The R2 value was 0.9836, this value indicates that approximately 98.36% of the variability in the pH can be explained by the model (Table 2). This suggests a strong relationship between the factors and the pH response. The pH value can be determined using the following equation: pH = + 4.10 + 0.39X1 + 0.18X2-0.00X3 + 0.02X12-0.01X13 + 0.01X23-0.33X11-0.07X22 + 0.00X33. In Table 2, the linear effects represent the changes in pH due to variations in each factor. Factors SMP: WPC and honey levels have significant linear effects on pH. Quadratic effects indicate curvature in the response due to squared values of the factors. All three factors have significant quadratic effects on pH. Response surface plot of pH values are presented in Fig. 1d–f. The coefficient of variation (CV) = 0.23%, indicates the relative variability of the data (Table 2). A low CV suggests that the data points are closely clustered around the mean. There is a possibility that different pH values can be attributed to the metabolic activities of lactic acid bacteria in the presence of additives in milk. Further, pH variation in yoghurt was reported due to buffering action of whey proteins (Akalin et al. 2007). Sert et al. (2011) reported a similar change in pH in set-type yoghurt added with honey. According to Passeephol and Sherkat (2009) inulin powder additions did not affect yoghurt milk pH and TA.

Titratable acidity (TA)

A yoghurt's titratable acidity is essential when analysing its consumer acceptability. The linear model for acidity can be obtained by the following equation: TA = + 0.67 + 0.01β1 + 0.01β2 + 0.02β3. The linear effects represent the changes in TA due to variations in each individual factor. The analysis of variance showed that honey has a significant (p < 0.05) linear effect on titratable acidity. The TA of GMY in the present study varied from 0.70 to 0.79 with independent variables (Table 1). The CV indicates the relative variability of the data. A moderate CV = 1.22% suggests a moderate dispersion of data points around the mean (Table 2). The pattern of variation of TA as an effect of honey level can be observed from Fig. 1g, h. As we increase the honey level, there might be an upward trend in TA. This is because the significant positive coefficient indicates that increasing the honey level leads to higher TA. The trend might be relatively steep due to the high coefficient (102.33*). This suggests that even small changes in honey level could result in noticeable changes in titratable acidity. The International Dairy Federation has recommended yoghurt should have a minimum acidity of 0.70%, and most of the formulations assessed has achieved this level in the present study (Obi et al. 2010). Further, a study by Akalin et al. (2007) found that, the fructooligosaccharides present in honey stimulate bifidobacteria, whereas the honey level increased the titratable acidity of the product. The results in this study contradict those reported by Varga (2006), who found that honey did not significantly affect acidity.

Syneresis

A syneresis occurs when the gel network becomes unstable and impairs its ability to trap all the serum phase (Costa et al. 2016). The following equation can obtain the quadratic model for syneresis: Syneresis = + 9.42 + 5.67β1 + 3.73β2-0.78β3 + 0.20β12 + 0.11β13-0.05β23-5.67β11-1.28β22-0.06β33. Syneresis (%) varied from 6.09 to 11.67 among a range of formulations studied (Table 1). The syneresis in the GMY was demonstrated by the high R2 value (0.9892) as shown in Table 2. The linear effects represent the changes in syneresis due to variations in each factor. Honey has a significant (p < 0.05) linear effect on syneresis, whereas the effect of SMP/WPC level on syneresis was significant (p < 0.05) in quadratic terms. This suggests that the SMP/WPC level and syneresis relationship follow a curved pattern, possibly with an optimal point where syneresis is minimized or maximized (Table 2, Fig. 1i, j, k). In fermented milk gels, syneresis can be reduced by increasing total solid and protein contents, apparently due to higher water-holding sites (Costa et al. 2016; Hussain et al. 2016). Previous studies have also reported that the water holding capacity of yoghurt is significantly improved by adding caseins or whey proteins in the form of caseinates to milk (Akalin et al. 2012). The reduced syneresis may also come from honey, which is high in water-binding capacity due to its fructose content (Sert et al. 2011). A study by Srisuvor et al. (2013) found no significant differences in syneresis between samples of yoghurt made from reconstituted milk and that supplemented with 1, 2 or 3% inulin.

DPPH

The DPPH scavenging activity of the GMY formulations ranged from 20.68% to 25.17% (Table 1). The R2 indicates that the model can explain approximately 96.63% of the variability in DPPH (Table 2). This suggests a strong relationship between the factors and the DPPH response. DPPH can be obtained by following equation: DPPH = + 23.79 + 1.26β1-4.75β2 + 0.03β3 + 0.68β12-0.15β13-0.03β23-1.18β11 + 1.55β22 + 0.12β33. The linear terms of honey level were observed to have a significant effect (p < 0.05) on DPPH scavenging activity of GMY. Quadratic effects indicate curvature in the response due to squared values of the factors. Independent variables such as inulin and honey have significant (p < 0.05) quadratic effects, suggesting non-linear relationships with DPPH activity. A lack of fit value of 1.41 suggests that there might be some unexplained variability between the model and the observed data (Table 2). Response surface plots (Fig. 1l–n) show the effect of independent variables on DPPH of the GMY. As the honey level increases or decreases, a distinct change in DPPH activity would be observed. The coefficient value will likely govern the steepness of this change. Similar reports of higher DPPH with increase in honey level were also reported by Mercan and Akin (2017) during the preparation of set-type yoghurt. It is generally believed that yoghurt's antioxidant capacity is primarily attributed to small bioactive peptides (protein hydrolysates) released during fermentation.

Viscosity

The viscosity of yoghurt is one of the most important parameters that describe its texture. Yoghurt can be described as a non-Newtonian fluid with shear-thinning characteristics (Afonso and Maia 1999). The following equation can express the viscosity of GMY: Viscosity = + 131.95–52.20β1-24.07β2 + 11.06β3 + 25.20β12-3.59β13-1.46β23 + 19.37β11 + 6.45β22 + 0.70β33. The F-value of quadratic model for viscosity was significant (p < 0.05). Viscosity of GMY varied from 121.88 to 181.47 m.Pa.s depending on the varying levels of SMP/WPC, inulin and honey (Table 1). The R2 indicates that the model can explain approximately 94.92% of the viscosity variability (Table 2). This suggests a strong relationship between the factors and the viscosity response. As shown in Table 2, the individual effect of honey level significantly affected the viscosity of GMY (p < 0.05). As the honey level changes along the axis, a corresponding viscosity value change was observed. The steepness of the change will likely be determined by the coefficient value of 126.67 wherein increasing the honey level leads to higher viscosity (Table 2). This suggests that even slight changes in honey level could lead to notable variations in viscosity. A trend line shows how viscosity changes as the honey level varies (Fig. 2a-c). By adding honey, the yoghurt's solids content increased and its consistency improved, leading to a direct connection between the amount of honey added and its viscosity (Machado et al. 2017). The previous study also showed that adding pine honey to yoghurt enhanced viscosity (Mercan and Akin 2017). However, SMP/WPC and inulin level showed a little increase in the viscosity of GMY at the studied range. Akin to the present study, Costa et al. (2016) reported a similar increase in the viscosity of yoghurt after the addition of inulin and whey protein. This behaviour can also be explained by the milk base composition which plays a role in casein aggregation and gel structure formation (Damin et al. 2009).

Whiteness Index (WI)

The coefficient of determination (R2) indicates that the model can explain approximately 97.84% of the variability in WI (Table 2). This suggests a strong relationship between the factors and the WI response. The linear effects represent the changes in WI due to variations in each factor. Since the linear effects of factors SMP: WPC and honey are significant (p < 0.05) with coefficients of 20.86*, and 263.32*, respectively, a clear and noticeable pattern for each factor can be observed (Table 2). The quadratic equation of the model that explained the relationship between the WI of GMY and the independent variable is shown in the equation: WI = + 91.86–2.76β1-10.29β2-2.25β3 + 1.19β12 + 0.11β13 + 0.20β23 + 2.76β11 + 2.89β22 + 0.11β33. It is evident from Table 2, inulin and honey level had a significant (p < 0.05) effect in quadratic terms. Quadratic effects indicate curvature in the response due to squared values of the factors. In the 3D plot, this might translate to a more pronounced curvature along the axis (Fig. 2d, e, f). The curvature might be more pronounced since the coefficient is relatively large viz., 18.73 and *7.39* for inulin and honey, respectively. A similar result was reported by Sert et al. (2011) for set type yoghurt added with honey where lightness (L*) value decreased, redness (a*) and yellowness (b*) values increased. The increase of milk protein content in dairy foods elevates the total protein acidic groups, resulting in better protein coagulation which further affects the ratio reflected: absorbed light, leading to a reduced perception of lightness (da Silva Teba et al. 2017).

Overall acceptability (OA)

The sensory acceptability of yoghurt is considered one of the most important characteristics that determine its ultimate use. The OA varied from 7.78 to 8.48 for all the formulations (Table 1). The following quadratic equation of the model that explains the relationship between the OA of GMY and the independent variable: OA = + 6.46 + 1.83β1 + 0.39β2 + 0.53β3 + 0.60β12-0.04β13-0.02β23-2.71β11-0.25β22 + 0.05β33. The linear effects represent the changes in OA due to variations in each factor. The honey level had a significant (p < 0.05) positive effect on OA of GMY at the linear level with a coefficient of 59.10* (Table 2). Increasing honey levels substantially increases OA values, whereas factors SMP/WPC and honey level have significant quadratic effects (p < 0.05) on OA. The high coefficient value of 23.13* indicates a substantial quadratic effect of factor SMP/WPC. This could lead to a pronounced curve along the axis on the OA response surface. A large positive coefficient of 30.47* indicates a significant quadratic effect of honey. As honey increases or decreases, it significantly influences the non-linear variation in OA (Fig. 3a, b, c). The coefficient of variation CV = 0.89% indicates the relative variability of the data (Table 2). A relatively low CV suggests that the data points are not widely dispersed around the mean. Yoghurt acceptability is closely related to its composition which enhances flavour, texture, and appearance. Improved score ratings were also reported by Mercan and Akin (2017) in set-type yoghurt incorporated with honey. It is evident from the finding of Mazzaglia et al. (2020) that the addition of inulin does not affect the sensory qualities of goat milk yoghurt.

Optimization

In order to optimize the level of independent variables for the development of novel goat milk yoghurt, various constraints were identified. Table 3 shows the optimization experiment related to the independent variables (factors) and dependent variables (responses). The aim is to find the optimal conditions for the independent variables (SMP/WPC, inulin level, honey level) to achieve the desired outcomes for the dependent variables. The analyses show that the goat milk yoghurts have total solid ranged from 18.04 to 22.33, pH from 4.31 to 4.49, TA from 0.70 to 0.79, syneresis from 6.09 to 11.67, DPPH from 20.68 to 25.17, viscosity from 121.88 to 181.47, WI from 75.45 to 80.93 and overall acceptability varied from 7.78 to 8.48. During optimization, the responses i.e. total solid (%), pH, titratable acidity [(LA) % by weight], and whiteness index, were kept in range while the other responses like syneresis (%), DPPH (% inhibition), viscosity (m.Pa.s.), and overall acceptability were maximized. However, all factors have been assigned equal importance. To confirm the obtained optimum formulation, two replications of yoghurt samples with the optimized formulation were prepared and the validation test was performed. The changes in predicted and observed value were not significant. It was found that optimal conditions for goat milk yoghurt production were achieved at a 0.36%w/v of SMP/WPC, 1.00%w/v of inulin level, and 6.00%w/v of honey content with a desirability of 0.95.

Conclusion

This study successfully utilized a three-factor Box-Behnken design coupled with response surface methodology to optimize the formulation of high-quality goat milk yoghurt by considering the concentrations of SMP/WPC, inulin, and honey. The outcomes of the study showcased the substantial influence of these variables on several key attributes of GMY, including total solid, pH, titratable acidity, syneresis, DPPH, viscosity, whiteness index, and overall acceptability. Honey played a significant role in improving the overall quality of yoghurt and both SMP/WPC and honey have improved the overall acceptability of yoghurt. However, no significant effect of inulin was observed at linear and interaction level. The desirability value of 0.95 highlighted the attainment of the optimization process in achieving the desired product characteristics. Therefore, the present study provides valuable insights into the formulation optimization of goat milk yoghurt using a systematic approach. The results contribute to the enrichment of GMY production processes, ultimately producing a novel product with well-balanced rheological attributes and high overall acceptability.

Data availability

The Data and material that support the findings of this study are available from the corresponding author (TPS), upon reasonable request.

Code availability

‘Not applicable’.

Abbreviations

- GMY:

-

Goat milk yoghurt

- SMP:

-

Skimmed milk powder

- WPC:

-

Whey protein concentrate

- BBD:

-

Box Behnken design

- RSM:

-

Response surface methodology

- TA:

-

Titratable acidity

- LA:

-

Lactic acid

- OA:

-

Overall acceptability

- WI:

-

Whiteness index

- L* :

-

Lightness

- a * :

-

Redness

- b * :

-

Yellowness

- ANOVA:

-

Analysis of variance

- CV:

-

Coefficient of variation

- R2 :

-

Coefficient of determination

- AOAC:

-

Association of Official Analytical Chemists

References

Afonso IM, Maia JM (1999) Rheological monitoring of structure evolution and development in stirred yoghurt. J Food Eng 42:183–190. https://doi.org/10.1016/S0260-8774(99)00118-1

Akalin AS, Gonc S, Unal G, Fenderya S (2007) Effects of fructoooligo-saccharide and whey protein concentrate on the viability of starter culture in reduced-fat probiotic yoghurt during storage. J Food Sci 72:222–227. https://doi.org/10.1111/j.1750-3841.2007.00436.x

Akalin AS, Unal G, Dinkci NAYIL, Hayaloglu AA (2012) Microstructural, textural, and sensory characteristics of probiotic yogurts fortified with sodium calcium caseinate or whey protein concentrate. J Dairy Sci 95(7):3617–3628

Allgeyer LC, Miller MJ, Lee SY (2010) Sensory and microbiological quality of yoghurt drinks with prebiotics and probiotics. J Dairy Sci 93(10):4471–4479

AOAC (2005) Official Methods of Analysis. Association of Official Analytical Chemists, Washington, DC

Brand-Williams W, Cuvelier ME, Berset CLWT (1995) Use of a free radical method to evaluate antioxidant activity. LWT-Food Science Technol 28(1):25–30

Chick H, Shin HS, Ustunol Z (2001) Growth and acid production by lactic acid bacteria and bifidobacteria grown in skim milk containing honey. J Food Sci 66:478–481

Costa MP, Frasao BS, Rodrigues BL, Silva AC, Conte-Junior CA (2016) Effect of different fat replacers on the physicochemical and instrumental analysis of low-fat cupuassu goat milk yogurts. J Dairy Res 83(4):493–496

da Silva TC, da Silva EMM, Chávez DWH, de Cárvalho CWP, Ascheri JLR (2017) Effects of whey protein concentrate, feed moisture and temperature on the physicochemical characteristics of a rice-based extruded flour. Food Chem 228:287–296. https://doi.org/10.1016/j.foodchem.2017.01.145

Damin MR, Alcântara MR, Nunes AP, Oliveira MN (2009) Effects of milk supplementation with skim milk powder, whey protein concentrate and sodium caseinate on acidification kinetics, rheological properties and structure of non-fat stirred yoghurt. LWT-Food Sci Technol 42:1744–1750

Guichard E (2002) Interactions between flavour compounds and food ingredients and their influence on flavor perception. Food Rev Int 18:49–70

Gursel A, Gursoy A, Anli EAK, Budak SO, Aydemir S, Durlu-Ozkaya F (2016) Role of milk protein–based products in some quality attributes of goat milk yoghurt. J Dairy Sci 99(4):2694–2703

Haenlein GFW (2004) Goat milk in human nutrition. Small Ruminant Res 51(2):155–163. https://doi.org/10.1016/j.smallrumres.2003.08.010

Hussain SA, Patil GR, Yadav V, Singh RRB, Singh AK (2016) Ingredient formulation effects on physico-chemical, sensory, textural properties and probiotic count of Aloe vera probiotic dahi. LWT-Food Sci Technol 65:371–380

Lima CJ, Coelho L, Contiero J (2010) The use of response surface methodology in optimization of lactic acid production: Focus on medium supplementation, temperature, and pH control. Food Technol Biotech 48:175–181

Machado TADG, de Oliveira MEG, Campos MIF, de Assis POA, de Souza EL, Madruga MS, do Egypto RDCR (2017) Impact of honey on quality characteristics of goat yogurt containing probiotic Lactobacillus acidophilus. LWT-Food Sci Technol 80:221–229

Mazzaglia A, Legarova V, Giaquinta R, Lanza CM, Restuccia C (2020) The influence of almond flour, inulin and whey protein on the sensory and microbiological quality of goat milk yogurt. LWT-Food Sci Technol 124:109138

Mercan E, Akın N (2017) Effect of different levels of pine honey addition on physicochemical, microbiological and sensory properties of set-type yoghurt. Int J Dairy Technol 70(2):245–252

Mituniewicz-Małek A, Ziarno M, Dmytrów I (2014) Incorporation of inulin and transglutaminase in fermented goat milk containing probiotic bacteria. J Dairy Sci 97(6):3332–3338

Nguyen PTM, Kravchuk O, Bhandari B, Prakash S (2017) Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrocolloids 72:90–104. https://doi.org/10.1016/j.foodhyd.2017.05.035

Nguyen HTH, Afsar S, Day L (2018) Differences in the microstructure and rheological properties of low-fat yoghurts from goat, sheep and cow milk. Food Res Int 108:423–429. https://doi.org/10.1016/j.foodres.2018.03.040

Obi T, Henshaw F, Atanda O (2010) Quality evaluation of plain-stirred probiotic yoghurt produced from skim and whole milk powder during refrigerated storage. Electron J Environ Agric Food Chem 9:1203–1213

Park YW (2009) Bioactive components in goat milk. In: Park YW (ed) Bioactive components in milk and dairy products, 1st edn. Wiley- Blackwell, Hoboken, NJ, USA, pp 43–81

Park YW, Juárez M, Ramos M, Haenlein GFW (2007) Physico-chemical characteristics of goat and sheep milk. Small Ruminant Res 68:88–113. https://doi.org/10.1016/j.smallrumres.2006.09.013

Paseephol T, Sherkat F (2009) Probiotic stability of yoghurts containing Jerusalem artichoke inulins during refrigerated storage. J Functional Foods 1(3):311–318

Pulina G, Milàn MJ, Lavìn MP, Theodoridis A, Morin E, Capote J, Caja G (2018) Invited review: Current production trends, farm structures, and economics of the dairy sheep and goat sectors. J Dairy Sci 101:6715–6729

Sert D, Akin N, Dertli E (2011) Effects of sunflower honey on the physisochemical, microbial and sensory characteristics in set type yoghurt during refrigerated storage. Int J Dairy Technol 64(1):99–107. https://doi.org/10.1111/j.1471-0307.2010.00635.x

Singh TP, Chauhan G, Agrawal RK, Mendiratta SK (2018) Response surface modeling and optimization of tomato puree–casein bio-composite films. Iranian Polym J 27:861–879. https://doi.org/10.1007/s13726-018-0660-3

Srisuvor N, Chinprahast N, Prakitchaiwattana C, Subhimaros S (2013) Effects of inulin and polydextrose on physicochemical and sensory properties of low–fat set yoghurt with probiotic–cultured banana purée. LWT Food Sci Technol 51:30–36

Tamime AY, Robinson RK (2007) Background to manufacturing practice, Tamime and Robinson’s yoghurt science and technology, 3rd edn. Woodhead Publishing Ltd, Cambridge, pp 13–161

Varga L (2006) Effect of acacia (Robinia pseudo acacia L.) honey on the characteristic microflora of yoghurt during refrigerated storage Short communication. International J Food Microbiol 108(2):272–275. https://doi.org/10.1016/j.ijfoodmicro.2005.11.014

Zoidou E, Theodorou S, Moschopoulou E, Sakkas L, Theodorou G, Chatzigeorgiou A, Moatsou G (2019) Set-style yoghurts made from goat milk bases fortified with whey protein concentrates. J Dairy Res 86(3):361–367

Acknowledgements

A special thanks to the Director, ICAR-CIRG, Mathura, India, for providing us with the necessary facilities to accomplish this research work. The authors are also thankful to the laboratory staff for their support and help.

Funding

None.

Author information

Authors and Affiliations

Contributions

TPS: conceptualization, methodology, investigation, writing-original Draft. AKV: data analysis, reviewing and editing. VR: Supervision. MKC: Supervision. SA: data analysis, reviewing and editing. BR: Supervision.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no competing interests to report.

Ethics approval

‘Not applicable’.

Consent to participate

Not applicable’.

Consent for publication

‘Not applicable’.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, T.P., Verma, A.K., Rajkumar, V. et al. Investigating the impact of milk protein, inulin, and honey on quality attributes of goat milk yoghurt. J Food Sci Technol 61, 1598–1608 (2024). https://doi.org/10.1007/s13197-024-05932-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-024-05932-2