Abstract

This study was conducted to analyze the drying kinetics of carrot slices in electrohydrodynamic (EHD) dryer at different electrode distances. Higher drying rate was observed up to about 70% (w.b.) moisture content, which has been noted as first falling rate period. The time taken to dry the carrot slices to the safe moisture content of 2.5% (wb) was about 9, 8.5 and 6.8 h at a distance of 7, 5 and 3 cm respectively. Five empirical models, Page Model, Newton model, Henderson and Pabis model, logarithmic model and two term model, were tested for the best fit. The drying rate constant (k) increased in all the empirical models as the distance between the electrode decreased. For 7 cm electrode distance, the Page model fitted best whereas the Logarithmic model was found to be the best fit for 5 and 3 cm electrode distance. There is no significant difference found in shrinkage of dried carrot slices at different electrode distance. Rehydration ratio increased as the distance between electrodes decreased. Moisture diffusivity increased as the distance between the electrode decreased. No significant difference in colour, β-carotene and sensory attributes were found between fresh and EHD dried carrot slices at 3 cm electrode distance. Specific energy consumption was significantly influenced by the electrode distance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Drying is a well-known application of heat under controlled conditions to remove moisture from food by evaporation, resulting in low moisture product. The main goal of drying is to extend the shelf life of food by reducing water activity. It also reduces packaging, storage, handling and transportation cost. Many microorganisms that spoil food and promote unwanted changes in food, cannot grow or function without adequate moisture. However, most of the current drying techniques is energy-intensive and accounts for 12–20% of the energy consumption of the dehydration industry (Kudra and Martynenko 2015; Li et al. 2006). About 85% of the food drying industries uses convective type dryers whose efficiency ranges from 20 to 80% and consumes large amount of energy for heating the air (Martynenko and Kudra 2021). Excessive waste heat is one of major reason for low efficiency of indirect convective dryers. Their operation results in large carbon footprints and high nutrients loss as they generally operate at high temperature.

Hence, new drying techniques are being explored to make the drying energy-efficient, reduce drying temperature and operating cost, minimize waste heat generation and maintain the product's essential characteristics and nutritional profile (Bajgai et al. 2007; Kudra and Martynenko 2015; Singh et al. 2012; Zhang et al. 2015). Also, consumer demand for products with superior sensory and nutritional properties as well as a fresh feel has forced food processors to seek alternative drying and processing techniques. This allows technologies such as freeze-drying, infrared and microwave drying, pulsed field, ultrasonic and superheated steam drying to be applied alone or in combination with traditional drying processes to produce higher-quality dehydrated foods. These novel drying technologies are researched with target to produce high-quality dried products and reduce energy consumption and green house gas (GHG) emission to the environment. Freeze-drying produces products with excellent sensory and hydration properties, but it is expensive to implement on an industrial scale. Using microwaves and radio frequencies has reduced drying times and improved energy efficiency, but scale-up-related issues have caused severe implementation problems (Raghavan et al. 2005).

Electrohydrodynamic (EHD) drying is a new non-thermal drying method which can resolve many issues related to current drying methods such as high energy consumption, nutritional and quality loss at high temperature drying (Zhang et al. 2015; Zhong et al. 2019; Acar et al. 2020; Iranshahi et al. 2023). During EHD drying process, a high voltage electric field is applied at domestic/industrial frequency of 50 or 60 Hz between two electrodes having substantially different radii of curvature (pin/wire and flat plate). The electric discharge from positively charged pointed high voltage electrode creates jets of high energy ions which accelerates towards the flat negative electrode containing material to be dried with speed of 80 to 200 m/s. Along their path, these ion jets transfer their momentum to neutral air molecules by collision causing them to move with speed of 0.1–10 m/s (Bashkir et al. 2020; Paul & Martynenko 2021). The moving ion and air molecules constitutes the corona/ionic wind. This corona wind impinges the wet food material, disturbs the saturated air layer over moist food and enhances the heat and mass transfer rates thus enhancing drying rate. As water molecule orient themselves in direction of applied electric field, entropy is lowered which results in lowering of temperature of product being dried. EHD drying can increase the drying rate by 1.7–4.2 times the conventional drying resulting in reduction of drying time by 15–40% (Kudra and Martynenko 2020).

The development of EHD dryer units has the potential to provide several potent benefits. As EHD drying dry the products at low temperatures and does not require excessive heat, it is considered as non-thermal dehydration technique and suitable for drying heat-sensitive foods (Basiry and Esehaghbeygi 2010; Defraeye and Martynenko 2018; Li et al. 2006; Singh et al. 2012; Vu et al., 2014, Iranshahi et al. 2022). EHD drying improves drying rate, reduces dehydration time and shrinkage (Alemrajabi et al. 2012; Martynenko and Kudra 2015; Yang and Ding 2016; Polat & Izli 2022), maintains uniform texture (Martynenko and Kudra 2016a, b), retains nutrients (Ding et al. 2015; Tirawanichakul et al., 2009) and taste (Martynenko and Kudra 2016a, b; Xiao & Ding 2022) of the dried product. The specific energy requirement in EHD drying of glass beads saturated with water has been reported to be less than latent heat of vaporization (2700 kJ/kg). For the food, where water is present in bound state the energy requirement for phase change of water is expected to be more than that observed in glass beads (Singh et al. 2012). For EHD drying of tomato slices specific energy requirement was reported to be in the 4400–16500 kJ/kg while the oven drying required 3.6 × 106 kJ/kg, which is about 200 times more than the EHD drying (Esehaghbeygi and Basiry 2011). Similarly in EHD of sea cucumber it was found that drying costs only 21.31% of electrical energy required for oven drying (Bai et al. 2013).

However, EHD drying techniques is still not thoroughly researched nor well adapted due to presence of some grey areas. Not many studies are available on drying different food products under high voltage electric fields. There are many factors that affect the drying behaviour in EHD drying such as type of current (AC or DC), applied voltage, electrode configuration, electrode distance (Kudra and Martynenko 2020; Martynenko and Kudra 2020, 2021).The research on EHD drying is very limited in the food processing sector. Ding et al., (2015) studied the drying behaviour of carrots at varying electric field. However, the effect of varying electrode distance was not studied. It was therefore, decided to investigate the drying kinetics of carrot slices at different electrode distance in EHD dryer. Five analytical models, namely Page model, Newton model, Henderson and Pabis model, Logarithmic Model and Two Term Model were compared to study the best fit model on the drying kinetics of carrot slices.

Materials and methods

Materials

Carrot was procured from a local vegetable market of Anand, Gujarat, India. It was washed, cleaned and the surface moisture was removed by blotting paper. Samples were stored in zip pouches at 4°C in a refrigerator for further use. The initial moisture content (89.74% ± 1.32 (w.b.) of the sample was calculated by hot air oven method (AOAC 1999). Carrot was sliced with the help of adjustable stainless-steel slicer, into 2 ± 0.1 mm thickness with an average size of 45 × 20 mm. The shape of the slice was elliptical with an average value of 45 ± 0.81 mm major and 20 ± 0.45 mm minor axis. No pre-treatment was given to the slices.

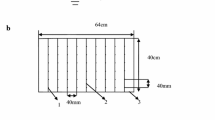

Experimental setup

The experimental setup of electrohydrodynamic dryer with all accessories is shown schematically in Fig. 1. Main components of the experimental setup were a high voltage generator (High Voltage-India, Bangalore), drying chamber, heating chamber, blower, sample holder, anode and cathode electrode and sharp needles. The drying chamber consisted of a wooden box with a coating of matt fire-resistant paint. The inner dimensions of the EHD drying chamber were 30 × 30 × 30 cm. Two hardened SS 316 plates of 1.5 mm thickness were installed as anode and cathode. The sharp pins of 20 mm in length were welded on an anode plate before hardening it. The parameters which were standardised on the basis of trial experiments and available literature before the development of the dryer were: AC or DC voltage, the distance between two electrodes, voltage/cm supplied to electrodes, plate or pin electrodes, type of pin electrodes, number of pin electrodes per square centimetre of the electrode, the distance between pin electrodes, the temperature of the air during drying and air velocity during drying. The developed EHD dryer was operated at variable AC voltage from 0 to 50 kV. Thin, sharp sewing needle electrodes were used at variable distance from 3 to 7 cm. The dryer was operated at ambient temperature with a natural convection. No blower was used during experiments.

Drying experiments

Carrot slices were weighed (40 g) and loaded on the grounded electrode (cathode) of the EHD dryer. Experiments were conducted at an ambient temperature of 30 ± 2 °C with a relative humidity of 33 ± 3%. Drying behaviour of carrot slices in EHD dryer was studied at three different electrode distance (3, 5 and 7 cm) at constant voltages (24 kV) and frequency (50 Hz). The weight of the carrot slices sample was recorded periodically at an interval of 10 min. All the experiments were performed in triplicate. Drying rate and moisture ratio were calculated using the following formula (Shrivastava and Kumbhar, 2011):

where.

DR is drying rate, \({M}_{t}\) is moisture content of carrot slices at time \(t\), \({M}_{t+\Delta t}\) is moisture content of carrot slices at time \(t+\Delta t\), \(\Delta t\) is the difference in time (h), MR is moisture ratio, \(M\) is moisture content at time \(t\) (% db), \({M}_{e}\) is equilibrium moisture content (% db) and \({M}_{0}\) is the initial moisture content (% db).

Empirical models

The main goal of developing a mathematical model of the system is to predict the accuracy and determine which model best defines EHD drying kinetics. Table 1 lists the empirical models used to describe the drying kinetics of the EHD system. These models are purely termed semi-theoretical models and depend on temperature, humidity, air velocity and range of moisture content but not on the geometry of foodstuff, its diffusivity and conductivity. The best-suited models for carrot slices were selected based on the values of statistical parameters at a distance of 3, 5, and 7 cm and under an applied high voltages of 24 kV.

Effective water diffusion

During the falling rate period, the internal resistance of moisture transfer is the limiting factor, that governs the dehydration process. The movement of moisture within the product can be explained by overall moisture diffusivity. Fick’s second law of diffusion, used to account the transport of moisture during falling rate period is expressed as:

where; \(M\) is the moisture content (% db), \(t\) is the drying time (s), \(r\) is the spatial dimension and \({D}_{eff}\) is the effective diffusion coefficient (m2/s).

Calculation of effective diffusion coefficient was based on the assumption that the diffusion coefficients was constant for each electrode distance, shrinkage of dried sample was negligible, initial moisture content of the sample was constant and thickness of the slab kept constant during electrohydrodynamic drying. The analytical solution of Eq. (3) can be written as:

where, L is the half the thickness of the slab, n is the positive integer.

For longer drying time, Eq. (4) was simplified and obtained by taking the natural logarithmic on both the side (J. Crank 1979; Arevalo et al. 2004; Caixeta et al. 2002).

Specific energy consumption and electrical cost estimation

Specific energy consumption indicates net amount of energy consumed to evaporate the unit mass of water and expressed as kJ/kg H2O removed. Total energy consumed during EHD drying of carrot slices were measured from a three phase energy meter (Trinity Energy Meter model Entity) whose output was in kWh. Amount of water removed was calculated from the difference of initial and final weight of the sample during EHD drying.

The cost of electricity used in drying was estimated by multiplying the total energy used in the with energy price per unit (INR 10 kWh−1).

Shrinkage and rehydration ratio

For every EHD dried samples, the volume of carrot slices was measured by the liquid displacement method, where toluene was used as a reference liquid (Mohsenin 2020). All experiments performed in triplicate.

where: \({V}_{i}\) is the initial volume of the carrot slice before drying (cm3); \({V}_{o}\) is the final volume of carrot slice after drying (cm3).

Rehydration ratio of dried carrot slices at different electrode distance were calculate by taking 10 g dried carrot slices, which was submersed in 50 ml distilled water for 7 h. The temperature of the distilled water was 35 ± 1°C. Carrot slices were weighed after removing the excess and free water by blotting paper. All experiments were performed in triplicates. Rehydration ratio was calculated by using the equation (Ding et al. 2015):

where; \({m}_{1}\) is the weight of dried carrot slices after rehydration; \({m}_{2}\) is the weight of dried carrot slices before rehydration.

Colour

The International Commission on Illumination (CIE) parameters L*, a*, and b* were measured by Chroma Meter (Konica Minolta, CR-400, Japan). Instrument was calibrated with a standard ceramic white plate (L* = 83.5, a* = 0.1394, b* = 0.3360) prior to colour measurement. The average L*, a*, and b* values were obtained from three replicates readings taken from five different locations in the sample. Chroma (C) value, hue angle (h*), and total color difference (ΔE*) were calculated using the equations (Pathare et al. 2013; Hashinaga et al. 1999):

β-carotene analysis

Β-carotene analysis was carried out by the method adopted by Prakash et al. (2004) with some modifications. The carrot sample (1 g) was grinded with 50 ml of acetone in a mortar. The sample was pulverised with a pestle to facilitate extraction. The acetone extract, petroleum ether (100 ml) and 5 g sodium sulphate (to aid moisture absorption) were taken in a separating funnel and shaken well. The separating funnel was allowed to stand for two layer formation. The upper most layer was taken for further treatment with petroleum ether. The upper most layer was taken and the volume was made up with petroleum ether to 100 ml. The absorbance was measured at 452 nm by using spectrophotometer.

Sensory evaluation

Sensory evaluation of fresh and rehydrated EHD dried carrot slices were carried out to confirm the product acceptability. Ten semi-trained panel members (5 male and 5 female faculty, age between 32 to 48 years) carried out organoleptic evaluation on 9-point hedonic scale (1- dislike extremely and 9-like extremely). The average hedonic score is reported with standard deviation. One way ANOVA (Daniel’s XL Tool Box Version 7.3.4) was carried out by employing Bonferroni-Holm posthoc test.

Statistical analysis

Non-linear regression analyses were performed to select the best equation and model to define the drying curves. In addition to R2, the various statistical parameters such as chi-square (χ2), mean bias error (P) and root mean square error (RMSE) were used to determine the quality of the fit. The best model must have the lower values of χ2. RMSE gives the deviation between the experimental and predicted values and P indicates the relative percent error. The prediction carried out using the model showed that MR values nearest to the trendline prove the model's best fit at different drying characteristics of the product being dried. This analysis was performed in MATLAB software. The following equations calculated these parameters (Darabi et al., 2001; Jena and Das 2007; Kaleta and Górnicki 2010; Menges and Ertekin 2006).

where.

\(M{R}_{\mathit{exp}.,i}\) is experimental moisture ratio found in any measurement, \(M{R}_{pre.,i}\) is predicted moisture ratio for this measurement, \(N\) is the number of observations and \(n\) is number of constants.

Results and discussion

Drying rate

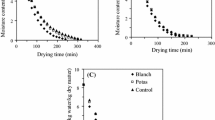

Drying rate graphs plotted against the time for dehydration of carrot slices is shown in Fig. 2. It can be observed from the figure that the constant rate period was absent and drying took place in the falling rate period only. The falling rate period occurred in three different stages. During the first falling rate period, the drying rate decreased rapidly up to about 70% (w.b.) moisture content. In the second falling rate period, the drying rate decreased gradually while in the third falling rate period, it decreased very slowly. This is due to the fact that during first falling rate period, surface and free moisture evaporates very fast whereas in second and third falling rate period, the rate of drying depends on the outside condition of the solids and transfer of moisture takes place through capillary action and mass transfer through diffusion process. Similar findings were also reported by Pirnazari et al. (2016) and Shrivastava and Kumbhar (2011). At different electrode distances in an electrohydrodynamic dryer, it was noted that with a decrease in the distance, the electric field applied to the product increases henceforth, drying time decreases with a decrease in distance. Goodenough et al. (2007), Kudra and Martynenko (2015), Sumariyah et al. (2019) also observed that as distance between the electrode decreased, the drying rate increased. To remove the same moisture content from carrot slices, the time taken was 550, 505 and 410 min at 7, 5 and 3 cm electrode distances respectively. This study reveals that the best drying rate was found at 3 cm electrode distance, whereas Li et al. (2006) reported the maximum drying rate at 3.5 cm electrode distance. There was notable variation in drying rates with time in different electrode distances due to the generation of different electric field strengths at ambient temperature. It was 4.66 kV/cm, 3.4 kV/cm and 3.1 kV/cm for 3, 5, 7 cm electrode distance respectively. It can therefore concluded that the higher the electric field intensity between the electrodes, the lesser the drying time and vice versa.

Empirical modeling of drying behaviour

Moisture ratio graphs for five different empirical models have been plotted along with experimental moisture ratio against time for EHD drying of carrot slices. It can be seen from Figs. 2 and 3 that the drying rate decreased with the moisture ratio. Similar findings were also reported by Ding et al. (2015) and Alem-Rajabif and Lai (2005). Moisture ratio decreased almost constantly and no sudden fall was noticed in moisture ratio with time. The criteria for selecting the best fit model describing the drying kinetics of electrohydrodynamic drying were based on the highest value of R2 and lowest values of RMSE, P and χ2. It can be seen from Table 2 that the Page model fitted best for 7 cm electrode distance with the highest value of R2 being 0.99 and the lowest value of χ2 is 0.003439, RMSE being 0.057604 and P is 0.070857. The Logarithmic model was found to be the best fit for 5 and 3 cm electrode distance with a maximum R2 of 0.99 in both the case. A minimum value of χ20.000512 and 0.003884, RMSE0.02197 and 0.060055, P 0.016216 and 0.001847 was found for 5 and 3 cm electrode distance respectively. Drying constants are given in Table 3. Among all drying constants of all five empirical models, k is the drying rate constant (h−1). The value of k indicates the rate at which water from the product is removed. It can be seen from Table 3 that the value of k increased in all the empirical models as the distance between the electrode is decreased from 7 to 3 cm. The increasing value of k indicates the rapid increase in drying rate.

Experiments conducted on EHD drying of carrot slices revealed that as the electrode distance decreased, moisture diffusivity increased. The average moisture diffusivity coefficient was found to be 4.60 × 10–8, 3.94 × 10–8 and 3.68 × 10–8 m2/s at 3, 5 and 7 cm electrode distance respectively. Due to less distance, the effect of ionic wind is more prominent at 3 cm compare to 5 and 7 cm electrode distance. This might be due to acceleration in disintegration of hydrogen bonds of water molecules at 3 cm electrode distance. This leads to continuous flow of ionic wind, which remove the water faster from the surface of the carrot slices yielding in best drying rate at 3 cm electrode distance.

Specific energy consumption and electrical cost estimation

The specific energy consumption (SEC) consumed during electrohydrodynamic drying varied from 6.82–9.83 × 104 kJ/kg water removed (Table 4). It could be seen that the specific energy consumption during drying (kJ/kg H2O) was significantly influenced by the electrode distance (p < 0.05) and energy consumption increases as the distance between the electrodes increases. The increase in SEC with electrode distance is due to increased drying time at larger electrode distance and subsequently large net energy consumption thereof. Same trend of results were also reported by Sumariyah et al. (2019) in drying of potato slices. Authors observed SEC in range of 10–20 × 107 kJ/kg water removed as the electrode distance increased from 4 to 12 cm. Bai et al. (2013) reported SEC of 4.386 × 103 kJ/kg in case of EHD of sea cucumber. Esehaghbeygi and Basiry (2011) observed SEC of 4.4–16.5 × 103 kJ/kg in case of EHD drying of tomato. Our SEC results lies in between the values reported for potato slices and tomato slices. The high value of SEC in our study is due to low sample holding capacity of the fabricated equipment (40 g). However, the observed SEC in our study are much less than SEC reported for hot air drying (297.29 MJ/kg) (Abbaspour-Gilandeh et al. 2020) and comparable to the combined infrared/hot air drying (30.20–87.51 MJ/kg) (Geng et al. 2022) of carrot. Interestingly Dehghannya et al (2021) reported SEC for intermittent microwave drying of carrot between ~ 300 × 103 to 650 × 103 MJ/kg which quite high as compared to SEC observed in this study.

Increasing the sample holding and drying capacity will increase the water removed per batch of drying and thus would reduce the SEC. The variation in SEC values can be attributed to first the product variation where water are held in tissue matrix by different forces, second to variation in applied voltage by different researchers and third to different electrode position and configuration in different EHD set up used by them.

The electrical cost of drying per kg of fresh carrot by EHD drying considering INR 10 per unit charge in India for different electrode distance is mentioned in Table 4. Drying cost increased proportional to the increase in net energy consumption. Since the present set up is a bench top model the cost of drying is liable to decrease on scale up. This is because increase in sample holding capacity of EHD dryer will increase the evaporation capacity of dryer without increasing the energy consumption substantially. However, research needs to be carried out to analyse the effect of increasing platform size with larger number of electrodes on the net energy consumption. Abbaspour-Gilandeh et al (2020) reported SEC of 297.29 MJ/kg in hot air drying of carrot slices at 65 °C at air speed of 1 ms−1. Considering their 100 g sample size and final moisture content of 0.2% (db), the total electric consumption turns out to be 7.05 kWh and the cost of drying 1 kg of fresh carrot is INR 705 which is more than 50% the cost estimated for our EHD dryer.

Shrinkage and rehydration ratio

The shrinkage of dried carrot at 3, 5, 7 cm electrode distance at 24 kV supplied voltage were found 67.133, 67.276 and 68.531% respectively. It reveals that there is no significant difference on shrinkage of dried carrot (p > 0.05) at different electrode distance. This might be due to the structural network of the carrot slices and the even distribution of cell water at high corona wind under needle to plate electrode. Similar trends of result were reported by Bai et al. (2012), Esehaghbeygi and Basiry (2011) and Esehaghbeygi et al. (2014). Rehydration ratio of carrot slices was found to be 3.8, 4.1 and 4.8 at electrode distance of 7, 5 and 3 cm respectively. As the distance between the electrode increased, rehydration ratio decreased and vice versa. This might be due to the varied structural changes at different electrode distance. Significant penetration of corona wind caused porous structure created at smallest electrode distance (3 cm) with constant voltage supply while at larger electrode distance such porous structure formation were limited. Therefore best drying rate and rehydration ratio were observed at smallest electrode distance. Statistical analysis indicate that the rehydration ratio was significantly influenced (P < 0.01) by the distance between the electrode. The same trend of results were reported by Yu et al. (2018), Yang and Ding, (2016). Best drying rate and highest rehydration ratio were found at 3 cm electrode distance.

Colour

Comparison of change in color of fresh, EHD dried and rehydrated carrot slice are depicted in Table 5. The hue angle (h*), chroma (C), darkness factor (b*/a*), and L*, a*, b* values characterise and determine the change in color. Fresh carrot slices had a significant (P ≤ 0.05) brighter color due to highest L* value than dried and rehydrated slices at different electrode distance. This bright color was retained in EHD dried and rehydrated carrot slices at 3 cm electrode distance and there is no significant difference (P ≤ 0.05) noted between colour parameters of fresh and EHD dried. There is also no significant difference found in a*, b* values at 3 cm electrode distance as compared to fresh sample, which indicate that the EHD dried and rehydrated sample retained its red color. Redness was reduced and yellowness was increased at 5 and 7 cm electrode distance in both dried and rehydrated samples. As the drying time at 5 & 7 cm electrode distance relatively higher than 3 cm electrode distance, the browning pigment formation increases. Chroma (C) is a parameter to determine the degree of difference hue compared to gray color (Shrivastav et al. 2021). It is observed from Table 5 that the value of C is significantly different at 5 and 7 cm electrode distance in both EHD dried and rehydrated sample as compared to fresh carrot slices whereas at 3 cm electrode distance no significant difference was noticed. This indicates that the intensity of color perceived by human being is good for dried as well as rehydrated samples at 3 cm electrode distance. Total color difference (ΔE) was found to be minimum at 3 cm electrode distance, which indicates that the magnitude of color difference is very less between the dried and fresh sample. This is attributed to less time taken for the sample drying at 3 cm electrode distance compared with 5 & 7 cm electrode distance. As mentioned earlier, lower electrode distance increases high electric field. Consequently, water molecules escape at faster rate and thereby lowering product temperature and entropy by releasing heat to the surrounding (Hashinaga et al 1999). Therefore, it imparts better color retention advantage as a non-thermal process technology. Similar results were also reported by Shrivastav et al. (2021).

β-carotene

Β-carotene (in wet basis) content of fresh and rehydrated EHD dried samples is represented in Table 6. No significant (p < 0.05) difference was observed in fresh and EHD dried sample at 3 cm electrode distance. However, significant reduction in β-carotene content was observed at EHD drying at 5 cm & 7 cm electrode distance relative to fresh carrot sample. The higher β-carotene reduction at higher electrode distance can be attributed to higher drying time and more exposure to corona wind. This might have induced oxidation of β-carotene unsaturated chemical structure (Prakash et al. 2004).

Sensory evaluation

Sensory evaluation of fresh and rehydrated EHD dried carrot slices were carried out and the data pertaining to sensory evaluation is depicted in Table 6. Rehydrated EHD dried carrot slices at 3 cm electrode distance was not significantly different (p > 0.05) than fresh carrot slices. However, EHD dried carrot slices at 5 & 7 cm electrode distance were significantly different (p > 0.05) compare to fresh carrot slices. Sensory evaluation confirmed the EHD dried product quality of carrot slices.

Conclusion

Application of EHD drying is one of the promising technologies nowadays, which dry the products at atmospheric temperature with low energy consumption during drying because there is no latent heat of vaporization required for removal of moisture and no greenhouse gases production. In this paper carrot slices were dried at electrode distance of 7, 5, 3 cm with an applied AC voltage of 24 kV at ambient temperature. Multiple needle electrodes were used and drying rates, moisture ratio were studied. Carrots drying followed three different falling rate periods where the maximum amount of moisture was removed during the first stage of the falling rate period. As the distance between the electrodes decreased, drying rate increased and the best drying rate was observed at 3 cm distance. High electric field between the electrodes reduced the drying time. Statistical data revealed that Page model was the best fit for the drying kinetics at 7 cm electrode distance, whereas the Logarithmic model was best fit for 5 and 3 cm electrode distance. As drying rate increased, the drying rate constant also increased. No significant difference is noted in the percentage of shrinkage at different distance of electrode. Rehydration ratio found highest in the sample dried at minimum electrode distance. Highest moisture diffusivity of 4.60 × 10–8 m2/s was noted at 3 cm electrode distance and the lowest was 3.68 × 10–8 m2/s. Difference of magnitude of color was minimum in between fresh and EHD dried carrot slices. Specific energy consumption in EHD drying for carrot slices was found to be in the range 6.82–9.83 × 104 kJ/kg water removed. EHD dried samples exhibited good β-carotene retention and sensory attributed comparable to fresh sample. EHD drying is a step ahead towards obtaining a high quality dried product with less energy consumption.

Data availability

All the data presented are original and not submitted elsewhere.

References

Abbaspour-Gilandeh Y, Kaveh M, Aziz M (2020) Ultrasonic-microwave and infrared assisted convective drying of carrot: Drying kinetic, quality and energy consumption. Appl Sci 10(18):6309

Acar C, Dincer I, Mujumdar A (2020) A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technol 12:1–27

Alemrajabi AA, Rezaee F, Mirhosseini M, Esehaghbeygi A (2012) Comparative evaluation of the effects of electrohydrodynamic oven and ambient air on carrot cylindrical slices during drying process. Drying Technol 30(1):88–96. https://doi.org/10.1080/07373937.2011.608913

Alem-Rajabif A, Lai FC (2005) EHD-enhanced drying of partially wetted glass beads. Drying Technol 23(3):597–609

AOAC (1999) Association of Official Analytical Chemists Official Methods of Analysis AOAC, Washington, DC

Arevalo P, Ngadi MO, Bazhal MI, Raghavan GSV (2004) Impact of pulsed electric fields on the dehydration and physical properties of apple and potato slices. Drying Technol 22(5):1233–1246

Bai YX, Yang GJ, Hu YC, Qu M (2012) Physical and sensory properties of electrohydrodynamic (EHD) dried scallop muscle. J of Aquatic Food Product Technol 21(3):238–247

Bai Y, Qu M, Luan Z, Li X, Yang Y (2013) Electrohydrodynamic drying of sea cucumber (Stichopus japonicus). LWT-Food Sci and Technol 54(2):570–576

Bajgai TR, Raghavan GSV, Hashinaga F, Ngadi MO (2007) Electrohydrodynamic drying – A concise overview. Drying Technol 7:905–910. https://doi.org/10.1080/07373930600734091

Bashkir I, Defraeye T, Kudra T, Martynenko A (2020) Electrohydrodynamic drying of plant-based foods and food model systems. Food Eng Rev 12(4):473–497

Basiry M, Esehaghbeygi A (2010) Electrohydrodynamic (EHD) drying of rapeseed (Brassica napus L.). J Electrostat 68(4):360–363. https://doi.org/10.1016/j.elstat.2010.05.002

Bruce DM (1985) Exposed-layer barley drying: Three models fitted to new data up to 150°C. J Agric Eng Res 32(4):337–348. https://doi.org/10.1016/0021-8634(85)90098-8

Caixeta AT, Moreira R, Castell-Perez ME (2002) Impingement drying of potato chips. J Food Process Eng 25(1):63–90

Crank J (1979) The mathematics of diffusion. Oxford University Press

Darabi J, Ohadi MM, DeVoe D (2001) An electrohydrodynamic polarization micropump for electronic cooling. J Microelectromech Syst 10(1):98–106. https://doi.org/10.1109/84.911097

Defraeye T, Martynenko A (2018) Future perspectives for electrohydrodynamic drying of biomaterials. Drying Technol 36(1):1–10

Dehghannya J, Seyed-Tabatabaei SR, KhakbazHeshmati M, Ghanbarzadeh B (2021) Influence of three stage ultrasound—intermittent microwave—hot air drying of carrot on physical properties and energy consumption. Heat Mass Transf 57(12):1893–1907

Ding C, Lu J, Song Z (2015) Electrohydrodynamic drying of carrot slices. PLoS ONE 10(4):e0124077. https://doi.org/10.1371/journal.pone.0124077

Esehaghbeygi A, Basiry M (2011) Electrohydrodynamic (EHD) drying of tomato slices (Lycopersicon esculentum). J Food Eng 104(4):628–631

Esehaghbeygi A, Pirnazari K, Sadeghi M (2014) Quality assessment of electrohydrodynamic and microwave dehydrated banana slices. LWT-Food Sci Technol 55(2):565–571. https://doi.org/10.1016/j.lwt.2013.10.010

Geng Z, Torki M, Kaveh M, Beigi M, Yang X (2022) Characteristics and multi-objective optimization of carrot dehydration in a hybrid infrared/hot air dryer. LWT 172:114229

Goodenough TIJ, Goodenough PW, Goodenough SM (2007) The efficiency of corona wind drying and its application to the food industry. J Food Engg 80(4):1233–1238. https://doi.org/10.1016/j.jfoodeng.2006.09.016

Hashinaga F, Bajgai TR, Isobe S, Barthakur NN (1999) Electrohydrodynamic (EHD) drying of apple slices. Drying Technol 17(3):479–495

Henderson SM, Pabis S (1961) Grain drying theory I. temperature effects on drying coefficient. J Agric Eng Res 6:169–174

Iranshahi K, Onwude DI, Rubinetti D, Martynenko A, & Defraeye T (2022) Scalable electrohydrodynamic drying configuration for dehydrating biological materials at industrial scale.

Iranshahi K, Rubinetti D, Onwude DI, Psarianos M, Schlüter OK, Defraeye T (2023) Electrohydrodynamic drying versus conventional drying methods: a comparison of key performance indicators. Energy Convers Manage 279:116661

Jena S, Das H (2007) Modelling for vacuum drying characteristics of coconut presscake. J Food Eng 79(1):92–99. https://doi.org/10.1016/j.jfoodeng.2006.01.032

Kaleta A, Górnicki K (2010) Some remarks on evaluation of drying models of red beet particles. Energy Convers Manag 51(12):2967–2978. https://doi.org/10.1016/j.enconman.2010.06.040

Kudra T, Martynenko A (2015) Energy aspects in electrohydrodynamic (EHD) drying. Drying Technol 33:1534–1540. https://doi.org/10.1080/07373937.2015.1009540

Kudra T, Martynenko A (2020) Electrohydrodynamic drying: theory and experimental validation. Drying Technol 38(1–2):168–175

Lai FC, Sharma RK (2005) EHD-enhanced drying with multiple needle electrode. J Electrostat 63(3–4):223–237

Li FD, Li LT, Sun JF, Tatsumi E (2006) Effect of electrohydrodynamic (EHD) technique on drying process and appearance of okara cake. J Food Eng 77:275–280. https://doi.org/10.1016/j.jfoodeng.2005.06.028

Martynenko A, Kudra T (2016a) Electrohydrodynamic (EHD) drying of grape pomace. Japan J Food Eng 17(4):123–129. https://doi.org/10.11301/jsfe.17.123

Martynenko A, Kudra T (2016b) Electrohydrodynamic (EHD) drying of grape pomace. Japan J of Food Engg 17(4):123–129

Martynenko A, Kudra T (2020) Electrohydrodynamic dryer: effect of emitters’ density and gap between discharge and collecting electrodes. Drying Technol 38(1–2):158–167

Martynenko A, Kudra T (2021) Alternating versus direct current in electrohydrodynamic drying. Drying Technol 16:1–4. https://doi.org/10.1080/07373937.2021.1942899

Menges HO, Ertekin, C (2006) Mathematical modeling of thin layer drying of Golden apples. J Food Eng 77(1):119–125. https://doi.org/10.1016/j.jfoodeng.2005.06.049

Mohsenin NN (2020) Physical properties of plant and animal materials: v. 1: physical characteristics and mechanical properties. Routledge.

Onwude DI, Iranshahi K, Rubinetti D, Martynenko A, Defraeye T (2021) Scaling-up electrohydrodynamic drying for energy-efficient food drying via physics-based simulations. J of Cleaner Prod 329:129690

Özdemir M, Onur Devres Y (1999) The thin layer drying characteristics of hazelnuts during roasting. J Food Eng 42(4):225–233. https://doi.org/10.1016/S0260-8774(99)00126-0

Page GE (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. Purdue University.

Pathare PB, Opara UL, Al-Said FAJ (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol 6(1):36–60

Paul A, Martynenko A (2021) Electrohydrodynamic drying: effects on food quality. Dry Tech 39(11):1745–1761

Pirnazari K, Esehaghbeygi A, Sadeghi M (2016) Modeling the electrohydrodynamic (EHD) drying of banana Slices. Int J Food Engg 12(1):17–26. https://doi.org/10.1515/ijfe-2015-0005

Polat A, Izli N (2022) Determination of drying kinetics and quality parameters for drying apricot cubes with electrohydrodynamic, hot air and combined electrohydrodynamic-hot air drying methods. Dry Tech 40(3):527–542

Prakash S, Jha SK, Datta N (2004) Performance evaluation of blanched carrots dried by three different driers. J Food Eng 62(3):305–313

Raghavan GSV, Rennie TJ, Sunjka PS, Orsat V, Phaphuangwittayakul W, Terdtoon P (2005) Overview of new techniques for drying biological materials with emphasis on energy aspects. Brazil J Chem Eng 22:195–201. https://doi.org/10.1590/S0104-66322005000200005

Shrivastav S, Ganorkar PM, Prajapati KM, Patel DB (2021) Drying kinetics, heat quantities, and physiochemical characteristics of strawberry puree by Refractance Window drying system. J Food Process Eng 44(9):e13776

Shrivastav S, Kumbhar BK (2011) Drying kinetics and ANN modeling of paneer at low pressure superheated steam. J Food Sci Technol 48(5):577–583. https://doi.org/10.1007/s13197-010-0167-1

Singh A, Orsat V, Raghavan GSV (2012) A comprehensive review on electrohydrodynamic drying and high-voltage electric field in the context of food and bioprocessing. Dry Technol 30:1812–1820. https://doi.org/10.1080/07373937.2012.708912

Sumariyah SHP, Muhammad N (2019) Drying of electrohydrodynamic (Ehd) on potato slices (Solanum tuberosum) with electrode distance variation. J Nat Sci Res. https://doi.org/10.7176/JNSR/9-24-04

Tirawanichakul S, Prachayawarakorn S, Varanyanond W, Soponronnarit S (2009) Drying strategies for fluidized-bed drying of paddy. Int J Food Eng 5(2). https://doi.org/10.2202/1556-3758.1401

Vu AT (2014) Application of EHD-enhanced drying technology: a sustainable approach for Vietnam’s agricultural product processing in the future. J Vietnamese Environ 6(3):256–263. https://doi.org/10.13141/jve.vol6.no3.pp256-263

Xiao A, Ding C (2022) Effect of electrohydrodynamic (EHD) on drying kinetics and quality characteristics of shiitake mushroom. Foods 11(9):1303

Yagcioglu A, Degirmencioglu A, Cagatay F (1999) Drying characteristics of laurel leaves under different conditions. In 7th Int Congress on Agricultural Mechanization and Energy pp 565–569

Yang M, Ding C (2016) Electrohydrodynamic (EHD) drying of the Chinese wolfberry fruits. Springer plus 5(1):909. https://doi.org/10.1186/s40064-016-2546-1

Yu H, Bai A, Yang X, Wang Y (2018) Electrohydrodynamic drying of potato and process optimization. J Food Process Preserv 42(2):e13492. https://doi.org/10.1111/jfpp.13492

Zhang M, Chen H, Mujumdar AS, Zhong Q, Sun J (2015) Recent developments in high-quality drying with energy-saving characteristic for fresh foods. Drying Technol 33(13):1590–1600. https://doi.org/10.1080/07373937.2015.1012267

Zhong C, Martynenko A, Wells P, Adamiak K (2019) Numerical investigation of the multi-pin electrohydrodynamic dryer: Effect of cross-flow air stream. Drying Technol 37(13):1665–1677

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

SS: Conceptualization, Validation, Supervision, Project administration, Writing-original draft. MS: Experiment, Methodology, Review of literature. PMG: Analysis, Writing, Reviewing and Editing. KK: Validation, Writing, Reviewing and Editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they doesn’t have conflict of interest.

Ethical approval

The authors confirms to follow all the ethical principles of research and publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srivastav, S., Shah, M., Ganorkar, P.M. et al. Modelling of electrohydrodynamic drying kinetics for carrot at varying electrode distance. J Food Sci Technol 61, 139–149 (2024). https://doi.org/10.1007/s13197-023-05829-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05829-6