Abstract

In this study, the effect of roasting times on bioactive compounds, antioxidant capacity, fatty acids, polyphenol and nutrients of amaranth seed and oils roasted in pan at 120 °C was investigated. Total phenolic and flavonoid results of the seeds of unroasted (control) and roasted-amaranth were recorded between 48.81 (6 min) and 231.35 mg GAE/100 g (15 min) to 64.29 (6 min) and 144.29 mg/100 g (15 min), respectively. Antioxidant activities of unroasted and roasted-amaranth extracts were recorded between 5.50 (control) and 12.78 mmol/kg (15 min). L* values of amaranth seeds ranged from 51.21 to 78.53. Roasting for 3 min and 6 min was increased the L* values of samples, while roasting for 9–12 min caused a decrease in L* values. Gallic acid results of amaranth seeds were identified between 21.94 (control) and 71.06 mg/100 g (15 min). The linoleic acid results of amaranth seed oils were reported between 44.24 (control) and 45.76% (12 min). The highest amounts of elements in roasted and unroasted amaranth seeds were P, K,Ca, Mg and S. In general, it was observed that both macro and micro-elements of amaranth seed samples increased with the application of heat treatment. However, microelement contents differed depending on the roasting time.

Graphical abstract

In this study, the effect of thermal process times on total phenol, flavonoid, antioxidant activity, fatty acids, phenolic and minerals of amaranth seed and oils roasted in pan at 120 °C was investigated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amaranth (Amaranthus cruentus L.) is an unconventional plant belongs to the Amaranthaceae family (Januszewska-Jogwiak and Synowiecki 2008), and resistant to drought and pests (Paredes-Lopez et al. 1989). Grain amaranth, a pseudoceral product, contains proteins, lipids, energy and fiber at high concentrations (Muyonga et al. 2013). Amaranth grains contain more calcium, iron, sodium, potassium, A, E, C, and folic acid (Becker et al. 1981). Phenolic contents of grain amaranth change among species and may be affected by environmental factors such as sunlight, temperature and rain (Escudero et al. 2004). Recently, considerable studies on the phenolic component content of amaranth seeds have been intensified (Repo-Carrasco-Valencia et al. 2010). Amaranth seeds, produced frequently in the form of expanded popping and flakes, are gluten-free and high nutritional value. This property of amaranth seeds is important to consumers suffering from celiac disease (Escudero et al. 2004; Gorinsteir et al. 2007). In last years, the use of amaranth seeds has increased as they are a source of lipids, flakes, exploded seeds, several bread types (Januszewska-Jogwiak and Synowiecki 2008) and are also used as an ingredient for the production of confectionery (Sindhuja et al. 2005). As a result of the heat treatment of grains such as baking, maillard reaction products with antioxidant properties may be formed in the bread crust (Lindenmeier and Hofmann 2004). In recent years, amaranth seeds have been used as an ingredient in the manufacture of lipids, flakes, popped seeds, various types of bread and confectionery (Mlakar et al. 2010). Amaranth seeds, which are gluten-free and often produced in expanded poppy and flake form, are important to consumers suffering from celiac disease (Gorinstein et al. 2007). During roasting, the texture, color, aroma and appearance of the seeds change, and therefore the crispness and taste characteristics of the product obtained compared to the raw seed develop positively (Chandrasekara and Shahidi 2011). The phenolic profile of the seeds changes with the roasting of the seeds, and it has been reported that the antioxidant capacity of the seeds increases (Dewanto et al. 2002; Kim et al. 2011). Roasting causes significant changes in the physical, chemical, structural and sensory properties of seeds. Although the roasting process disrupts the component integrity of the cells, they break the covalent bonds between the phenolic compounds and the cell wall (Kim et al. 2011). Roasting is one of the most common heat treatments applied to seeds to easily obtain oil from oilseeds and to increase yield and nutritional quality (Hama 2017). The goal of this investigation was to investigate the effect of roasting times on bioactive compounds, antioxidant capacity, fatty acids, polyphenol and nutrients of amaranth seed and oils roasted in pan at 120 °C.

Material and methods

Material

Amaranth grains were purchased from a local market in Konya province in Turkey in 2021. The seeds were cleaned from leaves, stems, stones. Roasting processes of amaranth samples were performed at 120 °C for 3, 6, 9, 12, 15 min in pan.

Methods

Determination of moisture results

The moisture contents of amaranth seeds were recorded at 105 °C using an oven till fixed weight (AOAC 1990).

Determination of oil amount

After the seeds were powdered, 10 g for each sample was weighed into a Soxhlet cartridge and the cartrige was closed with cotton. After adding 250 ml of petroleum ether to the balloon in the Soxhlet system, oil extraction was carried out at 50 °C for 5 h. At the end of this period, the flask containing micella was placed in the rotary evaporator and the petroleum ether was completely removed at 50 °C. The oil residue was calculated (%) (AOAC 1990).

L*, a* and b* values

The system stated by Rizzo et al. (2014) was applied to measure color values of amaranth seeds roasted in pan at different times.

Extraction procedure

After the solution consisting of 10 ml of acidic methanol/water (50:50 v/v) mixture was added to 0.5 g of ground amaranth powder weighed into the folkom tube, the mixture was mixed manually and shaken in a water bath for 1 h. Then the solution was centrifuged at 6000 rpm/10 min and the supernatant was removed. The resulting extract was filtered (Abderrahim et al. 2015).

Determination of total phenolic

The total phenolic contents of amaranth seed extracts were reported by using Folin-Ciocalteu chemical according to system defined by Yoo et al. (2004). The absorbance was read at 750 nm. Findings were recognisedas mg GAE/100 g (dw).

Total flavonoid content

The study carried out by Hogan et al. (2009) was applied for total flavonoid amounts of amaranth seed extracts. The absorbance of each sample was recorded at 510 nm. The findings werestated as mg quercetin/100 g (fw).

DPPH radical scavenging activity

The antioxidant capacity results of extracts were tested by using 1.1-diphenyl-2-picrylhydrazyl (DPPH) (Lee et al. 1998). Antioxidant capacity (%) results of extracts were determined by using following relation:

Determination of phenolic compounds

Chromatographic separation of phenolic compounds were carried out by High Power Liquid Chromatography (Shimadzu) equipped with a PDA detector and an Inertsil ODS-3 column. The injection volume was 20 µl.

Fatty acid composition

Fatty acids of amaranth seed oil esterified according to ISO-5509 (1978) was detected by gas chromatography (Shimadzu) montaged with flame ionization detector and capillary column for method GC-2010) was used.

Determination of mineral

After 5 mL of 65% HNO3 and 2 mL of 35% H2O2 were added to 0.5 g of amaranth seed powder, which was dried in an oven at 70 °C to fixed weight, the mixture was burned in a closed microwave. After the sample volume was completed to 20 ml with distilled water, the mineral results of each sample were recorded by ICP-AES.

Statistical analyses

After averaging the results of the triplicate analysis, they were subjected to analysis of variance. Significant changes between control, germination, blanching and roasting types results were stated using Duncan's Multiple Range Test (p < 0.05).

Results and discussion

The chemical and bioactive compounds of amaranth seeds roasted in pan

The moisture results, bioactive compounds and antioxidant capacity results of amaranth seeds roasted in pan at 120 °C are given in Table 1. Findings obtained showed some changes depending on roasting times. While the moisture results of unroasted- and roasted-amaranth seeds vary between 2.94 (15 min) and 6.24% (control-unroasted), the oil results of unroasted and roasted seeds were measured between 4.75% (15 min) and 6.35% (9 min). Also, bioactice compounds (total phenolic and total flavonoid) of unroasted (control) and roasted-amaranth seeds were determined between 48.81 (6 min) and 231.35 mgGAE/100 g (15 min) to 64.29 (6 min) and 144.29 mg/100 g (15 min), respectively. Significant changes were established among the bioctive properties of unroasted and roasted amaranth seeds according as roasting time (p < 0.05). Alvarez-Jubete et al. (2010) described that amaranth seed contained 16.5% protein. Ogrodowska et al. (2014) determined 16.1% protein, 9.66% moisture and 8.30% fat in amaranth seeds. Rathod et al. (2017) determined 5.23 and 7.07% oil in Suvarna and Durga varieties of A.caudatus seeds. Alvarez-Jubete et al. (2010) determined 21.2 mg GAE/100 g (dw) total phenol and 28.4 mg TE/100 g radical scavenging activity value in amaranth seeds. Ogrodowska et al. (2012) recognized 272.6–615.3 mg/kg total phenol and 11064–15327 µmol/kg antioxidant activity (DPPH) in seeds of Amaranthus cruentus. Also, antioxidant activities of unroasted and roasted-amaranth seeds were measured between 5.50 (control) and 12.78 mmol/kg (15 min). While the moisture results of the amaranth seeds increased up to 9 min, and a partial decrease in the oil result occurred in the following periods. The reason for this decrease may be due to the oil leaking out of the seed after long roasting and contaminating the roasting pan. In addition, an increase was determined in the total phenol and flavonoid and antioxidant capacity results of roasted seeds according to control (unroasted). However, in the 3rd and 6th minutes of roasting, a partial decrease and then an increase was recorded in both components (total phenol and flavonoid) compared to control. The total phenol, flavonoid and antioxidant capacity results of roasted amaranth seeds showed a linear connection. The increase in these properties with roasting time may be due to a relative increase in moisture content in the seed and maillard reaction products with heating. L* results of amaranth seeds ranged from 51.21 to 78.53. Roasting for 3 min and 6 min was increased the L* results of samples, while roasting for 9–12 min caused a decrease in L* values. The increase in L* results for begining of roasting is probably due to the glazed appearance (Moss and Otten 1989). On the other hand, the decrease after roasting for 9 min is resulted from dehydration of the carbohydrate molecules (Moss and Otten 1989). The a* and b* values were determined as 2.90–7.19 and 19.80–24.25, respectively. The highest a* (7.19) and b* (24.25) values were detected in sample roasted for 12 min. Roasting process caused a decrease for 3 and 6 min, and an increase after 9 min in comparison with control sample. There is a lack of study about color values of amaranth seeds. While L* result decreased from 83.01 to 72.77, a* and b* results of seeds increased from − 0.27 to 2.49 and from 15.49 to 25.25, respectively (Wani et al. 2016).

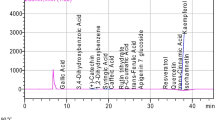

The phenolic profiles of unroasted and roasted amaranth seed extracts

The phenolic constituents of unroasted and roasted amaranth seed extracts are seed in Table 2. Gallic acid and catechin were the main compounds with the most quantitative values in roasted and roasted amaranth seeds (Fig. 1). While gallic acid results of seeds vary between 21.94 (control) and 71.06 mg/100 g (15 min), 3,4-dihydroxybenzoic acid results of amaranth seed extracts were identified between 1.00 (3 min) and 11.12 mg/100 g (15 min). Catechin and p-coumaric acid results of unroasted and roasted amaranth seeds were recorded between 3.21 (6 min) and 28.69 mg/100 g (15 min) to 1.74 (3 min) and 2.95 mg/100 g (15 min), respectively. Quercetin results of amaranth extracts were recorded between 0.39 (9 min) and 4.31 mg/100 g (control). The highest ferulic acid and kaempferol were determined in unroasted seeds. Also, the highest syringic acid (1.11) and caffeic acid (3.28 mg/100 g) were found in amaranth seeds roasted in the 9th and 15th minutes, respectively. Significant changes were determined among quantitative values of phenolic profiles of unroasted and roasted amaranth seeds depending on roasting time (p < 0.05). But, there is no significant differences between the resveratrol results of amaranth seeds roasted in the 9th and 12th minutes. In addition, cinnamic acid values of amaranth seeds that were unroasted and roasted for 6 to 9 min were found to be statistically insignificant. Alvarez-Jubete et al. (2010) determined that amaranth seed contained 13.6 µmol/100 g (dw) protocatechuic acid. Repo-Carrasco-Valencia et al. (2010) determined 0.9 caffeic acid, 6.9 ferulic acid, 0.89 p-coumaric acid, 3.0 p-OH-benzoic acid, 5.4 vanillic acid, 0.15 sinapic acid, 5.0 mg/100 g protocatechuic acid in amaranth seed. Ogrodowska et al. (2012) determined 3.08–5.51 caffeic acid, 54.30–83.81 ferulic acid, 8.33–11.48 p-coumaric acid, 88.68 p-hydroxybenzoic acid, and 109.69–158.43 mg/kg vanillic acid in seeds of Amaranthus cruentus. While gallic, 3,4-dihydroxybenzoic acid, catechin, caffeic, rutin, p-coumaric acid and cinnamic acid contents of roasted amaranth seed extracts increased depending on the roasting time, ferulic acid and kaempferol contents of amaranth seed extracts decreased. While syringic acid results of samples increased up to 9th minutes of roasting, it decreased partially in the following periods. It has been observed that the majority of phenolic components in amaranth seeds are resistant to heat treatment. In addition, the increase in the amount of phenolic components depending on the roasting time may likely be due to the thermal breakdown of the cell walls containing the bound phenolic constituents in the seed, resulting in the formation of phenolic compounds. The possible reason of the increase of phenolic amount of foods may be due to the release of bound phenolics by heat (Dewanto et al. 2002). Results regarding phenolic constituents exhibited some changes compared to data of previous literatures. These differences can be probable due to cultural conditions, environmental factors, seed maturity and thermal process time.

The fatty acid profiles of unroasted and roasted-amaranth seed oils

The fatty acids of unroasted (control) and roasted-amaranth seed oils are shown in Table 3. The results of fatty acids showed some differences depending on roasting times. While palmitic acid results of oils are recorded between 17.80% (unroasted-control) and 19.61% (15 min), stearic acid results of amaranth oils were monitored between 3.21% (control) and 3.32% (12 min). Also, oleic acid amounts of unroasted and roasted amaranth seed oils were recorded between 24.58% (15 min) and 26.87% (control) while the linoleic acid results of amaranth seed oils are reported between 44.24% (control) and 45.76% (12 min). Also, linolenic acid results of unroasted and roasted amaranth seed oils were established between 0.88% (3 min) and 1.61% (9 min). Another important fatty acid found in amaranth seed oil is erucic acid, the amount of this acid varied between 4.42% (12 min) and 4.80% (control). Since the amount of erucic acid in the oil remains within tolerable (max 5%) limits, it is thought that it does not pose a significant risk. Fatty acid components of amaranth seed oils, which were roasted and unroasted for certain periods, fluctuated depending on the roasting time. When compared with the control, the amount of fatty acid decreased in some roasting times, while it increased in others. The reason for this difference may be due to the fact that the oil is affected by ait oxygen and temperature in an irregular manner depending on time. Significant changes were found among fatty acid results of unroasted and roasted amaranth seed oils depending on roasting time (p < 0.05). Jahaniaval et al. (2000) determined 20.4% palmitic, 3.9% stearic, 0.3% behenic, 32.1% oleic, 38.2% linoleic, 0.7% linolenic acids in Amaranthus cruentus seed oil. Ogrodowska et al. (2014) determined 23.45% palmitic, 4.16% stearic, 24.66% oleic, 47.05% linoleic and 0.69% linolenic acids in amaranth seed oil. Rathod et al. (2017) determined 0.36 and 0.36% myristic, 21.36 and 19.31% palmitic, 5.92 and 14.74% stearic, 33.13 and 30.55% oleic, 34.24 and 30.16% linoleic, 1.23 and 1.16% linolenic, 1.59 and 1.72% arachidic and 0.78 and 0.78% behenic in “Suvarna” and “Dunga” varieties of amaranth (A. caudatus) seed oils. Some changes were found in fatty acid contents of oil samples according to previous literature results. These differences can be probable due to genetic, agronomic conditions, ripening, especially temperature, and biosynthesis of oil in plant tissue. It is thought that oven and microwave roasting is more beneficial compared to the linoleic acid content of amaranth seed oils.

The element results of unroasted (control) and roasted amaranth seeds

The element contents of unroasted (control) and roasted amaranth seeds are explained in Table 4. The highest amounts of elements in roasted and unroasted amaranth seeds were P, K, Ca, Mg and S., and followed by Na, Fe, Mn and Cu in descending order. While P results of amaranth seeds are monitored between 3263.41 (control) and 4543.65 mg/kg (15 min), K amounts of seed samples changed between 2963.63 (control) and 4024.65 mg/kg (15 min). Also, Ca results of seeds were reported between 2894.93 (12 min) and 3532.80 mg/kg (3 min) while Mg contents of amaranth seeds are recorded between 2013.64 (control) and 2705.51 mg/kg (15 min). S results of seeds were recorded between 1809.96 (control) and 2266.00 mg/kg (15 min). As a microelements, while Fe amounts of seed samples roasted at different roasting times are found between 74.67 (control) and 98.95 mg/kg (15 min), Mn results of amount seeds were reported between 20.50 (control) and 25.67 mg/kg (15 min). Cu amounts of amaranth seeds were found between 11.70 (control) and 14.67 mg/kg (3 min) while Zn amounts of seeds vary between 23.26 (12 min) and 26.17 mg/kg (15 min). In general, the macroelement contents of amaranth seeds increased in parallel with the roasting time. However, microelement contents differed depending on the roasting time. In general, it was observed that both macro and micro-elements of amaranth seed samples increased with the application of heat treatment. The probable cause of this increase is thought to be due to a relative increase in the moisture content of the material. Statistically significant changes were observed among quantitative values of mineral results of unroasted and roasted amaranth seeds as according roasting time (p < 0.05). The protein results of unroasted and roasted amaranth seeds were reported between 11.85 (9 min) and 14.63% (15 min). The protein contents of amaranth seeds fluctuated depending on the roasting time. The probable reason for these changes may be due to the very low levels of water in the seeds during roasting. Because, it is estimated that steam resulting from moisture has nore power to denature protein than dry hot air. Amaranth proteins have well-balanced amino acid composition, high bioavailability and good functional properties (Venskutonis and Kraujalis 2013). Nascimento et al. (2014) reported 0.51 Cu, 1.51 Mn, 9.62 Fe, 5.55 Zn, 231 Mg, 165 Ca, 527 P and 530 mg/100 g K in amaranth (A.caudatus) seeds. Kachiguma et al. (2015) reported that the amaranth grain had calcium (78.3 to 1004.6 mg/100 g (dw)), iron (3.61 to 22.51), magnesium (44.31 to 97.38), potassium (267.8 to 473.6) and zinc (0.53 to 1.20). Grace et al. (2017) determined 66 Fe, 11.34 Zn, 78.7 Ca, 37.1 Mn, 2845 Mg and 400 mg/100 g K in amaranth seed. Our results are in partly agreement with several authors that reported amaranth as rich source of minerals (Nascimento et al. 2014; Kachiguma et al. 2015). All of the proposes applied to amaranth seeds resulted in a partial reduction of the overall mineral content. Therefore, it is thought that it is more beneficial to use seeds in control group form in terms of mineral content. Results regarding minerals exhibited some changes compared to results of previous literatures. These differences observed can be probable due to plant species, agronomic factors, harvest time and climatic factors.

Principal component analysis (PCA)

Principal component analysis was carried out to assess the effect of roasting process at different times on phenolic compounds of amaranth. PCA modeling exhibited about 41.974% of explained variance for PC1; 26.283% of variance for PC2; 19.282% of variance for PC3; 8.162% of variance for PC4 and 4.300% of variance for PC5, which are given in Table 1. 3,4-dihydroxybenzoic acid (0.959), catechin (0.948), caffeic acid (0.948), and gallic acid (0.900) had high positive correlation with PC1. In addition, PC2 was recorded with ferulic acid (0.951) and quercetin (0.936). Control sample was located in the negative area of PC1 and positive area of PC2, and also contained higher amounts of quercetin, kaempferol and ferulic acid in comparison with other samples (Fig. 2). The highest gallic acid, 3,4-dihydroxybenzoic acid and catechin contents were monitored in the sample roasted for 15 min.

Conclusion

An increase was determined in the total phenol, flavonoid and antioxidant capacity results of roasted seeds compared to control (unroasted) group. However, in the 3rd and 6th minutes of roasting, a partial decrease and then an increase was established in both components (total phenol and flavonoid) compared to control. The total phenol, flavonoid and antioxidant capacity results of roasted amaranth seeds showed a linear connection. The increase in these properties with roasting time may be due to a relative increase in moisture content in the seed and maillard reaction products with heating. Roasting for 3 min and 6 min was increased the L* values of samples, while roasting for 9–12 min caused a decrease in L* values. Gallic, catechin, caffeic, rutin, p-coumaric acid and cinnamic acid contents of roasted amaranth seed extracts increased depending on the roasting time. While gallic, 3,4-dihydroxybenzoic acid, catechin, caffeic, rutin, p-coumaric acid and cinnamic acid contents of roasted amaranth seed extracts increased depending on the roasting time, ferulic acid and kaempferol contents of amaranth seed extracts decreased. While syringic acid results of samples increased up to 9th minutes of roasting, it decreased partially in the following periods. It has been observed that the majority of phenolic components in amaranth seeds are resistant to heat treatment. Fatty acid components of amaranth seed oils, which were roasted and unroasted for certain periods, fluctuated depending on the roasting time. When compared with the control, the result of fatty acid decreased in some roasting times, while it increased in others. The highest amounts of elements in roasted and unroasted amaranth seeds were P, K, Ca, Mg and S., and followed by Na, Fe, Mn and Cu in descending order. In general, the macroelement contents of amaranth seeds increased in parallel with the roasting time. However, microelement contents differed depending on the roasting time. In general, it was observed that both macro and micro-elements of amaranth seed samples increased with the application of heat treatment. However, microelement contents differed depending on the roasting time.

Data and materials availability

The data have been reviewed depending on the literature.

Code availability

There is no special software and code application.

References

Abderrahim F, Huanatico E, Segura R, Arribas S, Gonzalez MC, Condezo-Hoyos L (2015) Physical features, phenolic compounds, betalains and total antioxidant capacity of coloured quinoa seeds (Chenopodium quinoa Willd) from Peruvian Altiplano. Food Chem 183:83–90

Alvarez-Jubete L, Wijngaard H, Arendt EK, Gallagher E (2010) Polyphenol composition and in vitro antioxidant activity of amaranth, quinoa buckwheat and wheat as affected by sprouting and baking. Food Chem 119(2):770–778

AOAC (1990) Official methods of analysis, 15th edn. Association of official analytical chemists, Washington, DC

Becker R, Wheeler EL, Lorenz K, Stafford AE, Grosjean OK, Betschart AA, Saunders RM (1981) A compositional study of amaranth grain. J Food Sci 46(4):1175–1180

Chandrasekara N, Shahidi F (2011) Effect of roasting on phenolic content and antioxidant activities of whole cashew nuts, kernels, and testa. J Agric Food Chem 59(9):5006–5014

Dewanto V, Wu X, Adom KK, Liu RH (2002) Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J Agric Food Chem 50(10):3010–3014

Escudero NL, de Arellano ML, Luco JM, Giménez MS, Mucciarelli SI (2004) Comparison of the chemical composition and nutritional value of Amaranthus cruentus flour and its protein concentrate. Plant Foods Hum Nutr 59(1):15–21

Gorinstein S, Medina Vargas OJ, Jaramillo NO, Salas IA, Ayala ALM, Patricia Arancibia-Avila P, Toledo F, Katrich E, Trakhtenberg S (2007) The total polyphenols and the antioxidant potentials of some selected cereals and pseudocereals. Eur Food Res Technol 225:321–328

Grace ÊT, Olooto FM, Ogundele DT, Williams FE (2017) Nutritional characterization of grain amaranth grown in Nigeria for food security and healthy living. Agrosearch 17:1–10

Hama JR (2017) Comparison of fatty acid profile changes between unroasted and roasted brown sesame (Sesamum indicum L.) seeds oil. Int J Food Proper 20:957–967

Hogan S, Zhang L, Li J, Zoecklein B, Zhou K (2009) Antioxidant properties and bioactive components of Norton (Vitis aestivalis) and Cabernet Franc (Vitis vinifera) wine grapes. LWT - Food Sci Technol 42:1269–1274

ISO-International Organization for Standardization (1978) Animal and vegetable fats and oils preperation of methyl esters of fatty acids, ISO. Geneve, Method ISO 5509:1–6

Jahaniaval F, Kakuda Y, Marcone MF (2000) Fatty acid and triacylglycerol compositions of seed oils of five Amaranthus accessions and their comparison to other oils. J Am Oil Chem Soc 77:847–852

Januszewska-Jozwiak K, Synowiecki J (2008) Characteristics and suitability of amaranth components in Food Biotechnology. Biotechnol 3:89–102

Kachiguma NA, Mwase W, Maliro M, Damaliphetsa A (2015) Chemical and mineral composition of amaranth (Amaranthus L.) species collected from central Malawi. J Food Res 4:92–102

Kim HG, Kim GW, Oh H, Yoo SY, Kim YO, Oh MS (2011) Influence of roasting on the antioxidant activity of small black soybean (Glycine max L. Merrill). LWT-Food Sci Technol 44(4):992–998

Lee SK, Mbwambo ZH, Chung HS, Luyengi L, Games EJC, Mehta RG (1998) Evaluation of the antioxidant potential of natural products. Comb Chem High Throughput Screen 1:35–46

Lindenmeier M, Hofmann T (2004) Influence of baking conditions and precursor supplementation on the amounts of the antioxidant pronyl-L-lysine in bakery products. J Agric Food Chem 52:350–354

Mlakar SG, Turinek M, Jakop M, Bavec M, Bavec F (2010) Grain amaranth as an alternative and perspective crop in temperate climate. J Geograp 5(1):135–145

Moss JR, Otten L (1989) A Relationship between colour development and moisture content during roasting of peanuts. Canadian Inst Food Sci Technol J 22:34–39

Muyonga JH, Andabati B, Ssepuuya G (2013) Effect of heat processing on selected grain amaranth physicochemical Properties. Food Sci Nutr 2(1):9–16

Nascimento AC, Mota C, Coelho I, Gueifão S, Santos M, Matos AS, Gimenez A, Lobo M, Samman N, Castanheira I (2014) Characterisation of nutrient profile of quinoa (Chenopodium quinoa), amaranth (Amaranthus caudatus), and purple corn (Zea mays L.) consumed in the North of Argentina: proximates, minerals and trace elements. Food Chem 148:420–426

Ogrodowska D, Czaplicki S, Zadernowski R, Mattila P, Hellström J, Naczk M (2012) Phenolic acids in seeds and products obtained from amaranthus cruentus. J Food Nutr Res 51(2):96–101

Ogrodowska D, Zadernowski R, Czaplicki S, Derewiaka D, Wronowska B (2014) Amaranth seeds and products-the source of bioactive compounds. Polish J Food Nutr Sci 64(3):165–170

Paredes-López O, Schevenin ML, Hernández-López D, Cárabez-Trejo A (1989) Amaranth starch-isolation and partial characterization. Starch-Stärke 41(6):205–207

Rathod KJ, Jadeja BA, Jadav JK, Golakiya BA (2017) Physico-chemical characterization and fatty acid profiling of seed oils of grain Amaranthus cultivars of India -a nutritional perspective. Int J Pure Appl Biosci 5(4):1424–1432

Repo-Carrasco-Valencia R, Hellström JK, Pihlava JM, Mattila PH (2010) Flavonoids and other phenolic compounds in andean indigenous grains: Quinoa (Chenopodium quinoa), Kañiwa (Chenopodium pallidicaule) and Kiwicha (Amaranthus caudatus). Food Chem 120(1):128–133

Rizzo V, Torri L, Licciardello F, Piergiovanni L, Muratore G (2014) Quality changes of extra virgin olive oil packaged in coloured polyethylene terephthalate bottles stored under different lighting conditions. Packaging Technol Sci 27:437–448

Sindhuja A, Sudha ML, Rahim A (2005) Effect of incorporation of amaranth flour on the quality of cookies. Eur Food Res Technol 221:597–601

Venskutonis PR, Kraujalis P (2013) Nutritional components of amaranth seeds and vegetables: a review on composition, properties, and uses. Comprehensive Rev Food Sci Food Safety 12(4):381–412

Wani IA, Gani A, Tariq A, Sharma P, Masoodi FA, Wani HM (2016) Effect of roasting on physicochemical functional and antioxidantproperties of arrowhead (Sagittaria sagittifolia L.) flour. Food Chem 197:345–352

Yoo KM, Lee KW, Park JB, Lee HJ, Hwang IK (2004) Variation in major antioxidants and total antioxidant activity of Yuzu (Citrusjunos SiebexTanaka) during maturation and between cultivars. J Agric Food Chem 52:5907–5913

Acknowledgements

The authors extend their appreciation to Researchers Supporting Project number (RSP2023R83), King Saud University, Riyadh, Saudi Arabia.

Funding

No funding.

Author information

Authors and Affiliations

Contributions

This is not the case as there is only one author.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

No ethic situation.

Consent to participate

Single author.

Consent for publication

This is not the case.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al Juhaimi, F., Ahmed, I.A.M., Özcan, M.M. et al. Effect of roasting times on bioactive compounds, fatty acids, polyphenol and nutrients of amaranth (Amaranthus cruentus L.) seed roasted in pan, and principal component analysis. J Food Sci Technol 61, 129–138 (2024). https://doi.org/10.1007/s13197-023-05828-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05828-7