Abstract

Goat (GCW) and sheep cheese whey (SCW) are cheese by-products that can be fermented to develop a new product. However, the limited nutrient availability for lactic acid bacteria (LAB) growth and the low stability of whey are challenges. This work evaluated the addition of protease and/or ultrasound-assisted fermentation as tools to improve GCW and SCW fermentation and the final quality of the products. Results showed that the US/protease increased by 23–32% pH decline rate (for SCW only) and modified the separation of cream (≤ 60% for GCW) and whey (≤ 80% for both whey sources, with higher values for GCW) during storage, explained by changes in the microstructure protein, fat globules, and their interactions. Furthermore, the whey source/composition (mainly lower fat content in SCW) affected the destabilization rate and the LAB viability loss (1.5–3.0 log CFU/mL), caused by nutrient depletion and low tolerance at pH ~ 4.0. Finally, exploratory results showed that fermentation under sonication (with/without protease) resulted in 24–218% higher antioxidant activity in vitro than unfermented samples. Therefore, fermentation associated with proteases/sonication can be an interesting strategy to modify GWC and SCW, and the final process chosen depends on the desired changes in whey.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Goat and sheep farming focused on milk production is a growing rural activity in smallholdings, and the milk obtained is used mainly to manufacture artisanal cheese. Whey is a by-product of these processes and is commonly underutilized or discarded, reducing the income of artisanal producers and causing a negative environmental impact (Macedo et al. 2018; Tribst et al. 2020a).

Fermentation of whey to produce dairy beverages or whey drinks is considered a feasible, simple, and inexpensive option for direct use of whey, as it does not require preprocessing, such as concentration or drying (Zotta et al. 2020), which would be incompatible with artisanal size production (Tribst et al. 2020a).

According to Martí-Quijal et al. (2021) and Zotta et al. (2020), fermented whey products have advantages compared to non-fermented products, such as (i) better sensory acceptance due to lactic acid and aroma compounds production, (ii) lower allergenicity due to partial hydrolysis of β-lactoglobulin, (iii) presence of peptides with biological activity due to the proteolytic activity of lactic acid bacteria (LAB) during their growth and potential production of lactobionic acid and exopolysaccharides that have antioxidant properties, and (iv) inhibition of spoilage/pathogens microorganisms growth due to low pH.

However, cheese whey can have nutritional deficiencies, especially protein content, that may hinder/ limit LAB growth (Castro et al. 2013). Consequently, lower acidification rates are expected compared to those observed during milk fermentation (Rama et al. 2019). This effect may be minimized by proteases added to whey before/or during fermentation once protein hydrolysis into short peptide chains and/or essential amino acids favors the growth of LAB (Chourasia et al. 2022). Moreover, hydrolysis can decrease the allergenicity of whey proteins by reducing the β-lactoglobulin content (Chourasia et al. 2022) and improves their nutritional quality by increasing the concentration of peptides with biological activity, such as ACE inhibitory and antioxidant peptides (Magalhães et al. 2022).

Ultrasound (US) is another tool that can be strategically used to improve the fermentation rate (Umego et al. 2021). Ultrasound is defined as sound waves of high frequency, above the threshold of human hearing (> 20 kHz), that can be divided into high intensity-low frequency (20–100 kHz with 10–1000 W/cm2) and low intensity-high frequency (> 1 MHz, < 1 W/cm2). According to Herrera-Ponce et al. (2021), the sonication process alternates high- and low pressures, causing compression and expansion cycles in the medium and forming tiny vacuum bubbles that grow over several cycles and undergo an implosive collapse, releasing energy (cavitation phenomenon). This energy can (i) change the permeability of the cells, (ii) induces structural and physicochemical changes in molecules, and (iii) accelerates chemical reactions (Arruda et al. 2021). Therefore, ultrasound has been used in several food products (dairy, cereals, meat products, fruits, and juices) with different proposes, such as inactivation of spoilage/pathogen microorganisms, enzyme inactivation and activation, changes in food microstructure/texture, extraction and impregnation of compounds of interest, acceleration of reaction rates, among other unit operations (Arruda et al. 2021; Bhargava et al. 2021).

Nevertheless, few studies focused on using the US to improve fermentation in dairy products. Previous results have shown that ultrasound reduces the fermentation time due to the more significant activity of the starter microorganisms (Herrera-Ponce et al. 2021), explained by increased cell permeability and temporary formation of pores on cells subjected to US (Gholamhosseinpour and Hashemi 2018) that improves the mass transfer of substrates into the cells and the removal of by-products from cell metabolism (Herrera-Ponce et al. 2021). Furthermore, acoustic cavitation in US-assisted fermentation acts as a catalyst for various reactions due to the generation of highly reactive radicals, substrate homogenization, chemical dissolution, and breakdown of cell clusters (Umego et al. 2021). In addition to mass transfer improvements, the US-assisted reaction may potentiate enzymatic reactions due to (i) changes in the substrate able to cause great exposure to enzyme attack and (ii) partial unfold of the enzyme, with exposure of active sites entrapped in the hydrophobic core and/or stabilization of the enzyme structure (Magalhães et al. 2022). Despite this, to our knowledge, no previous research has evaluated the impact of US-assisted fermentation of goat (GCW) and sheep (SCW) cheese whey. Therefore, this research aimed to fill this gap by studying GCW and SCW fermentation parameters under the US, with or without proteases and characterizing the obtained products regarding LAB count, physicochemical characteristics, structural stability, and in vitro antioxidant activity.

Material and methods

Goat (GCW) and sheep cheese whey (SCW)

GCW (1.01% fat, 0.68% protein, and 3.23% lactose) was obtained from a fresh cheese inoculated with starter culture Lacticaseibacillus casei (BGP 93, Sacco Brasil Campinas, Brazil) produced in the laboratory of Federal University of Viçosa (Viçosa, Brazil). SCW (0.18% fat, 0.95% protein, and 4.72% lactose) was obtained from an artisanal cheese inoculated with Lactococcus lactis subsp. Lactis, Lactococcus lactis subsp. cremoris (R-704, Chr. Hansen Indústria e Comércio, Valinhos—SP, Brazil), produced in São Clemente artisanal cheese factory (Ouro Preto, Brazil). Whey was stored at 1ºC up to processing (24 h).

GCW and SCW fermentation process

A volume of 5.4L of each whey was pasteurized at 75 °C/5 min to reach microbial counts lower than 102 UFC/mL (Santos et al. 2023; Tribst and Leite Júnior 2022) and cold to 43 °C. Then, each whey was inoculated with ~ 106 CFU/mL yogurt starter microorganisms (Streptococcus thermophilus and Lactobacillus bulgaricus, Y472e Code, Sacco Brasil—Campinas, Brazil) and divided into two parts of equal volume (2.7 L) and one of these parts was added with 27 mL of protease (solution prepared in water with 1% v/v of Alcalase®, Novozymes Latin America—Araucaria, Brazil). Finally, each sample was again divided into two parts, one of them was traditionally fermented in a thermostatic bath at 43 °C (Solidsteel, Piracicaba, São Paulo), and the other was fermented at the same temperature in an ultrasonic bath (Unique, USC 2800 A model, Indaiatuba, Brazil). The ultrasonic bath had internal dimensions of 30 × 24 × 15 cm and was equipped with five transducers of 25 kHz arranged below the vat. Its nominal potency was 450 W, and its volumetric potency was 23.8 W/L. Each process was carried out in triplicate, and fermentation was carried out in a sterilized borosilicate bottle.

The fermentation was evaluated by measuring the pH decline at 30-min intervals up to reach pH 4.60 ± 0.05. The results were modeled by a modified Gompertz equation adapted by de Brabandere and Baerdemaeker (1999) to describe the pH decline in fermentation (Eq. 1).

where pH0 = initial pH, pH∞ = final pH, μ = maximum pH decline rate (h−1), λ = lag phase time (h), and t = time (h).

After fermentation, the bottles containing the whey samples were refrigerated at 7 °C and evaluated during storage for up to 28 days.

pH, LAB counts, physical stability, microstructure, and in vitro antioxidant activity of the fermented whey

After 1, 14, and 28 days of fermentation, the pH of the GCW and SCW samples was measured in triplicate, and lactic acid bacteria (LAB) counts were determined in duplicate, following the methodology described by Tribst et al. (2020a).

The physical stability of the whey was availed using three sterilized borosilicate tubes filled with 10 mL of each fermented whey and kept at 7 °C. 7 °C. After 1, 3, 7, 14, 21, and 28 days of storage, the whey destabilization was measured using a digital pachymeter considering: (i) the occurrence of cream separation as a dense phase in the top of the tube, (ii) whey separation, as the translucent phase, and (iii) sedimentation, as a dense phase in the bottom of the tube (Tribst et al. 2020a). Illustrative images of the tube samples were taken on all stability assessment days.

In addition, to get insights about the sample’s microstructure, after 1, 14, and 28 days of storage, a drop of each sample was placed on a microscope slide, and images were obtained at 40 × magnification (Anatomic Opton®, TIM-18, Brasil), according to the described Tribst et al. (2020a).

In vitro antioxidant activity was measured in triplicate, after 1 and 28 days of storage, by 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) radical scavenging activity (Magalhães et al. 2022). The stock solution containing ABTS (7 mM) and potassium persulfate (2.45 mM) (1:1 ratio) was prepared and stored (12–16 h) at 4 °C in the dark. Then, the solution was diluted with distilled water to reach an absorbance at 734 nm of 0.700 ± 0.02. Subsequently, 150 μL of the fermented sample (diluted 1:100) was added to 2.85 mL of the diluted ABTS radical solution. After 1 h incubation at room temperature in the dark, the absorbance was read at 734 nm. The ABTS radical scavenging activity was calculated using Eq. (2).

where: Abs 0 min is the absorbance of the sample at time 0, and Abs60min is the absorbance of the sample after 60 min of reaction.

Statistical evaluation

The impacts of processing conditions (traditional and US-assisted fermentation carried out with/without protease) on the GCW and SCW fermentation parameters and pH, LAB count, stability parameters, and in vitro antioxidant activity were evaluated by using the analysis of variance (ANOVA) and the Tukey test at a 95% confidence level. The same tests were used to compare the product throughout its shelf life.

Results and discussion

Fermentation profile of goat and sheep cheese whey

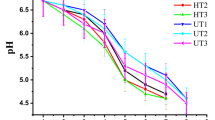

The pH decline curves were obtained for each sample during fermentation (Supplementary File—Figure S1). Fermentation time was mainly influenced by the whey source, being 25% slower in SCW. In addition, US-assisted fermentation slightly delayed the total fermentation time in GCW, and adding protease improved the fermentation time in SCW. The obtained data had a good adjustment to the modified Gompertz model (R2 > 0.95), showing that the pH decline of the samples could be used to indirectly assess bacterial growth through the parameters of Eq. 1 (de Brabandere and Baerdemaeker 1999; Tribst et al. 2018, 2020b), as shown in Table 1.

The parameter λ represents the lag phase of the pH decline, i.e., the time spent on LAB adaptation plus the time spent to produce the minimum concentration of acid capable of overcoming the buffering capacity of each whey leading to the first pH drop, whereas the parameter µ represents the maximum rate of pH decline (de Brabandere and Baerdemaeker 1999; Tribst et al. 2018, 2020b). The results of λ and µ showed that US-assisted fermentation and the addition of protease resulted in parameters similar to those observed for traditional fermentation of GCW (p > 0.05). On the other hand, for SCW, it was observed that although both interventions negatively impacted the lag phase, delaying it by 41–70% (p < 0.05), they led to significantly higher rates of pH decline (23–32%) when compared to traditional fermentation (Table 1). Considering the GWC fermentation time (up to 1 h faster than the SCW fermentation—Supplementary File—Figure S1), we hypothesize that the yogurt starter cultures did not have growth difficulties in GCW, making the interventions tested unnecessary. On the contrary, the longer fermentation of SCW suggests that the culture had some growth barriers (such as low nutrient availability, mainly fat—"Goat (GCW) and sheep cheese whey (SCW)" in section, justifying the observed impact of the US-assisted processing and protease. However, to validate this hypothesis, additional parameters, including availability/depletion of nutrients and counts of LAB (Abesinghe et al. 2019), should be evaluated during fermentation in future studies.

In symbiotic fermentation using yogurt culture, S. thermophilus is the microorganism with the quickest growth at the beginning of the process, due to its ability to grow at high pH (Tribst et al. 2018). Thus, the increase in the lag phase time caused by protease and the US in SCW suggests that these interventions harmed this microorganism's adaptation phase (parameter λ—Table 1). On the other hand, the results of the maximum pH decline rate (parameter µ—Table 1), which occurs between 5.7 and 5.0 due to the symbiotic growth of S. thermophilus and L. bulgaricus (de Brabandere and Baerdemaeker 1999), suggest a positive influence of US-assisted fermentation and the addition of protease.

The protease effect can be explained by the partial hydrolysis of proteins into peptides and/or amino acids after 60–90 min of reaction, improving the availability of essential amino acids (Magalhães et al. 2022) for S. thermophilus, which is produced exclusively by L. bulgaricus in traditional fermentation (Nasri et al. 2022). The effects of US can be explained mainly by its ability to increase cell permeability (Gholamhosseinpour and Hashemi 2018), improving: (i) mass transfer of substrates to cells, including the metabolites produced by S. thermophilus that are important for L. bulgaricus growth and vice-versa (Nasri et al. 2022), (ii) the removal of by-products from cell metabolism (Herrera-Ponce et al. 2021), and (iii) the excretion of enzymes that hydrolyze nutrients necessary for bacteria growth, such as β-galactosidase (Ewe et al. 2012). On the other hand, the absence of improvement when protease and US were combined, compared to the individual interventions, showed that the effects of US and protease were not additive and that the expected positive impact of US on enzyme performance (Magalhães et al. 2022) was insufficient to alter the growth of the microorganism and, consequently, the pH decline. However, it is important to note that this preliminary hypothesis was based solely on pH decline and the well-understood symbiotic behavior of starter growth during fermentation (Tamime and Robinson 2007). Therefore, to confirm this, differential counts of both microorganisms during fermentation should be performed.

pH and LAB count of fermented goat and sheep cheese whey

During the storage of the samples, a continuous reduction in the pH occurred, regardless of the whey source, fermentation under sonication, and addition of protease (Table 2). These results suggested that LAB remained to produce lactic acid even during storage at 7 °C (Wei et al. 2017), causing post-acidification, as related by other authors (Tribst et al. 2020a). The comparison between the different samples showed that the only consistent observation was the higher pH of the sample added with protease and fermented without the US (p < 0.05), possibly due to basic peptides formed from the hydrolysis of protein (Jia et al. 2022).

For LAB counts (Table 2), GCW samples had ~ 107 CFU/mL, and SCW had a population 1 log smaller, suggesting that the longer fermentation of SCW occurred due to culture inhibition at the end of acidification (Nasri et al. 2022). After 14 days, LAB counts remained equal in fermented GCW, while a further decrease (p < 0.05) of at least 1.26 log CFU/mL was observed for SCW samples. On the other hand, at the end of storage, the GCW showed reductions in LAB counts similar to those observed in SCW after 14 days. For SCW, the only sample that showed a difference between 14 and 28 days was the one added with protease, with an increase in the LAB count (~ 1.5 log CFU/mL). This growth should be attributed to the release of peptides and amino acids during storage by residual protease activity (Shori et al. 2022). The presence of these peptides may overcome the limitation of nutrients in fermented SWC, favoring the residual growth of LAB starter cultures even under adverse conditions, such as low pH and temperature. On the other hand, the lack of LAB growth in the protease-added and sonicated sample suggests that the extensive exposure time to the US may have inactivated the added enzyme (Magalhães et al. 2022), preventing this beneficial hydrolysis during storage. Furthermore, for the other samples, minor and unspecific differences were observed between samples produced using the same whey, suggesting that whey composition/characteristics were more important for the survival of LAB during storage than the interventions studied during fermentation.

In addition, although post-acidification is considered an important cause of viability loss of yogurt microorganisms (Undugod and Nilmini 2019), the comparison of the results in Table 2 suggest that the reductions in LAB counts were not exclusively due to pH reduction since GCW and SCW samples had similar pH at days 1 and 14, but counts in SCW were approximately 1 and 2.5 log CFU/mL lower, respectively. These results indicated that, although LAB culture was stressed by nutrient restriction and cumulation of inhibitory substances (Rama et al. 2019) in the storage of both whey sources, the characteristics of SCW (including composition, salt balance, or presence of antimicrobials) were more harmful to yogurt starters culture, reinforcing the hypothesis about the benefits of residual protease activity during the storage for this sample. Moreover, the overall evaluation of these results highlighted that storage at 7 ºC was insufficient to maintain the LAB viability for 28 days, emphasizing the need to increase the LAB count at the end of fermentation and/or store the fermented whey at a lower temperature to reduce the microorganism’s metabolism during storage (Tribst et al. 2020a).

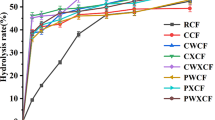

Physical stability and microstructure of fermented goat and sheep cheese whey

The evaluation of the physical stability of fermented GCW (Fig. 1) and SCW (Fig. 2) showed that the samples destabilized during storage in different ways. Their micrographs obtained after 1, 14, and 28 days of storage help to explain the observed phenomena (Fig. 3).

Whey destabilization during the shelf life at 7 °C of goat cheese whey (GCW) fermented through traditional and ultrasound (US) assisted processes, added or not by protease. Illustrative images (A), Whey separation (B), Cream separation (C), and Sedimentation (D) of GCW during storage (D). Fermentation process: T: Traditional; T + P: Traditional + Protease; US: US-assisted; US + P: US-assisted + Protease. A-D Capital letters indicate significant differences evaluated by the Tukey test (p < 0.05) among the processes at each day. a−c Lower case superscripts indicate significant differences evaluated by the Tukey test (p < 0.05) for the same sample at different days

Whey destabilization during the shelf life at 7 °C of sheep cheese whey (SCW) fermented through traditional and ultrasound (US) assisted processes, added or not by protease. Illustrative images of SCW during storage (A); Whey separation (B). Fermentation process: T: Traditional; T + P: Traditional + Protease; US: US-assisted; US + P: US-assisted + Protease. A-D Capital letters indicate significant differences evaluated by the Tukey test (p < 0.05) among the processes at each day. a−c Lower case superscripts indicate significant differences evaluated by the Tukey test (p < 0.05) for the same sample at different days. In these samples, creaming and sedimentation phenomena were not observed

Microscopic observation (40 × of magnification) of goat (GCW) and sheep cheese whey (SCW) fermented through traditional and ultrasound (US) assisted processes, added or not by protease. Blue arrows identify the protein agglomerates formed in the samples and the red square shows the most organized structure observed among the samples. Fermentation process: T: Traditional; T + P: Traditional + Protease; US: US-assisted; US + P: US-assisted + Protease

For GCW, an intense destabilization was observed after 3 days (Fig. 1A), with cream separation (Fig. 1C), whey separation (Fig. 1B), and sedimentation (Fig. 1D). These levels of destabilization remained almost unchanged for up to 28 days, which can be explained by the absence of a strong protein network that could contract during storage leading to additional water release (Laiho et al. 2017) and by the minimal hydrophobic protein attraction under refrigeration, maintaining protein aggregation only through weaker interactions (Liyanaarachchi and Vasiljevic 2018).

Interestingly, the fermentation conditions, i.e., protease addition and US, impacted the way that GCW destabilized. In the traditional fermented sample, destabilization resulted in a proportional creaming and sedimentation (~ 10%), with a layer of whey between them. This separation profile indicates that the low protein content of GCW associated with its destabilization—caused by pasteurization followed by acidification that proximate it to the isoelectric point—leads to the instability of the suspension (Tribst et al. 2020a). Consequently, fat globules separated from the system and migrated to the top of the tube due to their low density (Gallier et al. 2020), while the whey protein agglomerates (Fig. 3, after 14 days of storage) sedimented, and whey translucent material containing soluble nutrients was formed between them.

Smaller sediments were formed for the sample added with protease than those observed in traditional fermentation. This is explained by the partial hydrolysis of proteins, resulting in less agglomeration (Fig. 3) and greater solubility (Bustamante et al. 2021) compared to the control. On the other hand, the larger cream suggests that part of these hydrolysates interacted with the fat globules (Capela et al. 2022), forming a thick and dense layer at the top of the tube (p < 0.05). The sample fermented in the US had the opposite behavior, without cream separation and with dense sedimentation (p < 0.05). Considering that US can reduce fat globule size (Capela et al. 2022), alter protein structures (Zhao et al. 2014), and favor interactions between these compounds (Zhao et al. 2014), the main hypothesis to explain the phenomenon is the formation of protein-fat complex, with the protein governing the physical behavior of the structure, leading to dense sedimentation. This hypothesis is corroborated by the micrographs of US-fermented samples (Fig. 3). Conversely, the sample added with protease and fermented under the US showed the thickest cream (p < 0.05), suggesting that the partially hydrolyzed protein interacted with small fat globules forming a light (Fig. 1A and C) and more continuous structure (Fig. 3), with better water holding capacity than other samples, resulting in less whey separation.

In contrast to GCW, destabilization of SCW resulted only in whey separation at the top of the tube after 14 days of storage (Fig. 2), followed by a continuous separation up to 28 days, with higher values (~ 50%) for protease-added samples and lower separation for sample fermented under US (p < 0.05). On the other hand, Fig. 3 showed that the microstructures of SCW protein processed under different conditions were similar to those observed for GCW. Therefore, the differences observed in the destabilization of goat and sheep cheese whey can be attributed to the differences in whey composition since SCW had almost no fat (0.18 vs. 1.01% in GCW), preventing cream separation and a high concentration of protein (0.95 vs. 0.68% in GCW), slightly favoring water holding capacity (Sánchez et al. 2020). Finally, regarding the greater whey separation in SCW added with proteases, maybe the reduction of protein agglomerates due to partial hydrolysis resulted in smaller structures with better accommodation, reducing the amount of water between them. The overall assessment of the samples physical stability emphasized the importance of developing strategies to ensure whey stabilization by adding stabilizers (Arab et al. 2022) associated with skimming or fat size reduction (Tribst et al. 2020b).

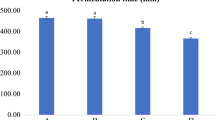

In vitro antioxidant activity of fermented goat and sheep cheese whey

After fermentation, all samples showed higher in vitro antioxidant activities of the ABTS radical compared to their respective unfermented whey (Fig. 4), with higher values for SCW. In addition, for SCW samples, an increase in antioxidant activity was observed during storage (p < 0.05). In contrast, for GCW, a reduction in antioxidant activity was observed for all samples (p < 0.05) during storage, except for the sample produced under the US and added with protease.

In vitro antioxidant activity (ABTS assay) of goat (GCW) and sheep cheese whey (SCW) fermented through traditional and ultrasound (US) assisted processes, added or not by protease. A−DCapital letters indicate significant differences evaluated by the Tukey test (p < 0.05) among the processes for each whey source at each day. a−cLower case superscripts indicate significant differences evaluated by the Tukey test (p < 0.05) for the same sample at different days. Fermentation process: T: Traditional; T + P: Traditional + Protease; US: US-assisted; US + P: US-assisted + Protease. Orange (–) and purple (–) dashed line represents the antioxidant activity (%) of unfermented GCW (26.36 ± 1.28) and SCW (24.44 ± 0.95), respectively. *: indicate significant differences evaluated by the Tukey test (p < 0.05) of each sample in relation to the respective unfermented whey

Fermented whey's in vitro antioxidant activity may be explained by the composition of whey proteins, mainly β-lactoglobulin, which has a large amount of sulfur-containing amino acids, principally cysteine (Ma et al. 2018). As observed for the SCW, the presence of lactic acid cultures and protease contributed to an increase in the scavenging ABTS radicals during storage due to increased protein hydrolysis, allowing the release of amino acid residues in the polypeptide chain, which is related to improvements in antioxidant properties (Magalhães et al. 2022). However, an opposite behavior was observed for GCW, with an antioxidant activity reduction during storage for most of the samples. Comparing the results of physical stability (Figs. 2 and 3) and antioxidant activity (Fig. 4), it is highlighted that all samples with sedimentation (GCW traditionally fermented and added with protease or sonicated separately) had a reduction in the antioxidant activity after storage, which suggests that denser protein aggregates formed in these samples hindered their antioxidant activity (Arranz et al. 2019). Despite this, it is to note that these results must only be considered indicative/exploratory. Further investigations, including in vivo assays of antioxidant activity, are mandatory to affirm the biological benefits of fermented whey.

Conclusion

US-assisted fermentation and the addition of proteases could be interesting interventions to improve the pH decline rate in SCW fermentation, which was more challenging to ferment than GCW, probably due to limited nutrients. Moreover, these interventions directly affected how samples were destabilized during storage, due to the reduction in the fat globule size caused by US and proteolysis caused by protease, although none of them were able to avoid phase separation during whey storage. In contrast, interventions were insufficient to guarantee higher levels of LAB viability during storage, avoid post-acidification, and improve the in vitro antioxidant activity of the samples. Future studies should access the impact of these interventions, associated with the addition of stabilizers and nutritional supplementation/storage at low temperatures, on the structure of the product and sensory characteristics/acceptance of the developed fermented whey. In addition, considering that the US can lead to the inactivation of spoilage microorganisms, further studies should evaluate the impact of sonication on undesirable native microorganisms in whey.

Availability of data and material

The raw data of these experiments were available at: Tribst, Alline Artigiani Lima; Bruno Ricardo de Castro Leite Júnior; Fábio Ribeiro dos Santos, 2022, "Fermentation (traditional and US-assisted), of sheep and goat cheese whey added by protease", https://doi.org/10.25824/redu/RBIQSW, Repositório de Dados de Pesquisa da Unicamp, V1.

Code availability

Not applicable.

References

Abesinghe AMNL, Islam N, Vidanarachchi JK, Prakash S, Silva KFST, Karim MA (2019) Effects of ultrasound on the fermentation profile of fermented milk products incorporated with lactic acid bacteria. Int Dairy J 90:1–14. https://doi.org/10.1016/j.idairyj.2018.10.006

Arab M, Yousefi M, Khanniri E, Azari M, Ghasemzadeh-Mohammadi V, Mollakhalili-Meybodi N (2022) A comprehensive review on yogurt syneresis: effect of processing conditions and added additives. J Food Sci Technol. https://doi.org/10.1007/s13197-022-05403-6

Arranz E, Corrochano AR, Shanahan C, Villalva M, Jaime L, Santoyo S, Callanan MJ, Murphy L, Giblin L (2019) Antioxidant activity and characterization of whey protein-based beverages: Effect of shelf life and gastrointestinal transit on bioactivity. Innov Food Sci Emerg Technol 57:e102209. https://doi.org/10.1016/j.ifset.2019.102209

Arruda TR, Vieira P, Silva BM, Freitas TD, do Amaral AJB, Vieira ENR, Leite Júnior BRC (2021) What are the prospects for ultrasound technology in food processing? An update on the main effects on different food matrices, drawbacks, and applications. J Food Process Eng 44:e13872. https://doi.org/10.1111/jfpe.13872

Bhargava N, Mor RS, Kumar K, Sharanagat VS (2021) Advances in application of ultrasound in food processing: a review. Ultrason Sonochem 70:e105293. https://doi.org/10.1016/j.ultsonch.2020.105293

Bustamante SZ, González JG, Sforza S, Tedeschi T (2021) Bioactivity and peptide profile of whey protein hydrolysates obtained from Colombian double-cream cheese production and their products after gastrointestinal digestion. Food Sci Technol 145:e111334. https://doi.org/10.1016/j.lwt.2021.111334

Capela AP, Tribst AAL, Augusto PED, Leite Júnior BRC (2022) Use of physical processes to maximize goat milk cream hydrolysis: Impact on structure and enzymatic hydrolysis. Food Res Int 156:e111343. https://doi.org/10.1016/j.foodres.2022.111343

Castro WF, Cruz AG, Rodrigues D, Ghiselli G, Oliveira CAF, Faria JAF, Godoy HT (2013) Short communication: Effects of different whey concentrations on physicochemical characteristics and viable counts of starter bacteria in dairy beverage supplemented with probiotics. J Dairy Sci 96:96–100. https://doi.org/10.3168/jds.2012-5576

Chourasia R, Phukon LC, Abedin MM, Padhi S, Singh SP, Rai AK (2022) Whey valorization by microbial and enzymatic bioprocesses for the production of nutraceuticals and value-added products. Bio Technol Rep. https://doi.org/10.1016/j.biteb.2022.101144

De Brabandere AG, De Baerdemaeker JG (1999) Effects of process conditions on the pH development during yogurt fermentation. J Food Eng 41:221–227. https://doi.org/10.1016/s0260-8774(99)00096-5

Ewe JA, Abdullah WNW, Bhat R, Karim A, Liong MT (2012) Enhanced growth of lactobacilli and bioconversion of isoflavones in biotin-supplemented soymilk upon ultrasound-treatment. Ultrason Sonochem 19:160–173. https://doi.org/10.1016/j.ultsonch.2011.06.013

Gallier S, Tolenaars L, Prosse C (2020) Whole goat milk as a source of fat and milk fat globule membrane in infant formula. Nutrients 12:3486. https://doi.org/10.3390/nu12113486

Gholamhosseinpour A, Hashemi SMB (2018) Ultrasound pretreatment of fermented milk containing probiotic Lactobacillus plantarum AF1: carbohydrate metabolism and antioxidant activity. J Food Process Eng 42:e12930. https://doi.org/10.1111/jfpe.12930

Herrera-Ponce AL, Salmeron-Ochoa I, Rodriguez-Figueroa JC, Santellano-Estrada E, Garcia-Galicia IA, Alarcon-Rojo AD (2021) High-intensity ultrasound as pre-treatment in the development of fermented whey and oat beverages: effect on the fermentation, antioxidant activity and consumer acceptance. J Food Sci Technol 59:796–804. https://doi.org/10.1007/s13197-021-05074-9

Jia W, Du A, Fan Z, Shi L (2022) Novel insight into the transformation of peptides and potential benefits in brown fermented goat milk by mesoporous magnetic dispersive solid phase extraction-based peptidomics. J Food Chem 389:e133110. https://doi.org/10.1016/j.foodchem.2022.133110

Laiho S, Williams RPW, Poelman A, Appelqvist I, Logan A (2017) Effect of whey protein phase volume on the tribology, rheology and sensory properties of fat-free stirred yoghurts. J Food Hyd 67:166–177. https://doi.org/10.1016/j.foodhyd.2017.01.017

Liyanaarachchi WS, Vasiljevic T (2018) Caseins and their interactions that modify heat aggregation of whey proteins in commercial dairy mixtures. Int Dairy J 83:43–51. https://doi.org/10.1016/j.idairyj.2018.03.006

Ma S, Wang C, Guo M (2018) Changes in structure and antioxidant activity of β-lactoglobulin by ultrasound and enzymatic treatment. Ultrason Sonochem 43:227–236. https://doi.org/10.1016/j.ultsonch.2018.01.017

Macedo A, Monteiro J, Duarte E (2018) A Contribution for the valorisation of sheep and goat cheese whey through nanofiltration. Membranes 8:114. https://doi.org/10.3390/membranes8040114

Magalhães IS, Guimarães ADB, Tribst AAL, Oliveira EBd, Leite Júnior BRC (2022) Ultrasound-assisted enzymatic hydrolysis of goat milk casein: effects on hydrolysis kinetics and on the solubility and antioxidant activity of hydrolysates. Food Res Int 157:e111310. https://doi.org/10.1016/j.foodres.2022.111310

Martí-Quijal FJ, Khubber S, Remize F, Tomasevic I, Roselló-Soto E, Barba FJ (2021) Obtaining antioxidants and natural preservatives from food by-products through fermentation: a review. Fermentation 7:106. https://doi.org/10.3390/fermentation7030106

Nasri R, Abdelhedi O, Nasri M, Jridi M (2022) Fermented protein hydrolysates: biological activities and applications. Curr Opin Food Sci 43:120–127. https://doi.org/10.1016/j.cofs.2021.11.006

Rama GR, Kuhn D, Beux S, Maciel MJ, Volken de Souza CF (2019) Potential applications of dairy whey for the production of lactic acid bacteria cultures. Int Dairy J 98:25–37. https://doi.org/10.1016/j.idairyj.2019.06.012

Sánchez L, Pérez MD, Parrón JA (2020) HPP in dairy products: impact on quality and applications. In: Barba F, Tonello-Samson C, Puértolas E, Lavilla M (eds) Present and future of high pressure processing, 1st edn. Elsevier, Amsterdam, pp 245–272

Santos FR, Leite Júnior BRC, Tribst AAL (2023) Kinetic parameters of microbial thermal death in goat cheese whey and growth of surviving microorganisms under refrigeration. J Food Process Eng 46:e14191. https://doi.org/10.1111/jfpe.14191

Shori AB, Aljohani GS, Al-zahrani AJ, Al-sulbi OS, Baba AS (2022) Viability of probiotics and antioxidant activity of cashew milk-based yogurt fermented with selected strains of probiotic Lactobacillus spp. Food Sci Technol 153:e112482. https://doi.org/10.1016/j.lwt.2021.112482

Tamime AY, Robinson RK (2007) Tamime and Robinson’s yoghurt: science and technology. Woodhead Publishing Limited, Sawston

Tribst AAL, Leite Júnior BRC (2022) Heat treatment design for the valorization of sheep cheese whey in artisanal production. Res Soc Devel 11:e20911931776–e20911931776. https://doi.org/10.33448/rsd-v11i9.31776

Tribst AAL, Ribeiro LR, Leite Junior BRC, de Oliveira MM, Cristianini M (2018) Fermentation profile and characteristics of yoghurt manufactured from frozen sheep milk. Int Dairy J 78:36–45. https://doi.org/10.1016/j.idairyj.2017.10.005

Tribst AAL, Falcade LTP, Carvalho NS, Leite Júnior BRdC, Oliveira MMd (2020a) Manufacture of a fermented dairy product using whey from sheep’s milk cheese: an alternative to using the main by-product of sheep’s milk cheese production in small farms. Int Dairy J 111:e104833. https://doi.org/10.1016/j.idairyj.2020.104833

Tribst AAL, Falcade LTP, Carvalho NS, Leite Junior BRC, Oliveira MM (2020b) Using stirring and homogenization to improve the fermentation profile and physicochemical characteristics of set yogurt from fresh, refrigerated and frozen/thawed sheep milk. Food Sci Technol 130:e109557. https://doi.org/10.1016/j.lwt.2020.109557

Umego EC, He R, Huang G, Dai C, Ma H (2021) Ultrasound-assisted fermentation: mechanisms, technologies, and challenges. J Food Process Preserv 45:e15559. https://doi.org/10.1111/jfpp.15559

Wei Z, Zhang W, Wang Y, Wang J (2017) Monitoring the fermentation, post-ripeness and storage processes of set yogurt using voltammetric electronic tongue. J Food Eng 203(41–52):10. https://doi.org/10.1016/j.jfoodeng.2017.01.022

Zhao L, Zhang S, Uluko H, Liu L, Lu J, Xue H, Kong F, Lv J (2014) Effect of ultrasound pretreatment on rennet-induced coagulation properties of goat’s milk. Food Chem 165:167–174. https://doi.org/10.1016/j.foodchem.2014.05.081

Zotta T, Solieri L, Iacumin L, Picozzi C, Gullo M (2020) Valorization of cheese whey using microbial fermentations. Appl Microbiol Biotechnol 104:2749–2764. https://doi.org/10.1007/s00253-020-10408-2

Acknowledgements

The authors would like to thank the São Clemente smallholding for the milk donation.

Funding

The authors are thankful to the financial support from Brazilians Agencies: This work was supported by the São Paulo Research Foundation (FAPESP, project no. 2020/10930-9) and by the National Council for Scientific and Technological Development with the productivity grants of B. R. C. Leite Júnior (306514/2020-6) and A. A. L. Tribst (305050/2020-6) and CAPES (code 001) for the master's scholarship granted to F.R. dos Santos.

Author information

Authors and Affiliations

Contributions

FRS was responsible for investigation, methodology, writing review and editing the MS; BRCLJ was responsible for conceptualization, funding acquisition, project administration, software, supervision, writing—review and editing the MS and AALT was responsible for conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, project administration, validation, writing—original draft, writing—review and editing the MS.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no Conflicts of interest/Competing interests.

Ethical approval

Not applicable.

Consent to participate

All authors have read and approved the MS; and, that all are aware of its submission to JFST.

Consent for publication

I declare that (i) the work described has not been published before (except in the form of an abstract, a published lecture or academic thesis), (ii) it is not under consideration for publication elsewhere, (iii) its submission to JFST publication has been approved by all authors as well as the responsible authorities—tacitly or explicitly—at the institute where the work has been carried out, (iv) if accepted, it will not be published elsewhere in the same form, in English or in any other language, including electronically without the written consent of the copyright holder, and (v) JFST will not be held legally responsible should there be any claims for compensation or dispute on authorship.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

dos Santos, F.R., Leite Junior, B.R.d.C. & Tribst, A.A.L. Impact of ultrasound and protease addition on the fermentation profile and final characteristics of fermented goat and sheep cheese whey. J Food Sci Technol 60, 2444–2453 (2023). https://doi.org/10.1007/s13197-023-05767-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05767-3