Abstract

This study aimed to evaluate the feasibility of using sugar-sweetened beverages (SSB) for citric acid (CA) production and its impact on chemical oxygen demand (COD) of SSB. Five types of SSB were used as a carbon source for CA production by A. niger, and the COD of each SSB was measured before and after the bioprocess. Results showed that all tested SSB were suitable for CA production, with maximum yields ranging from 13.01 to 56.62 g L− 1. The COD was reduced from 53 to 75.64%, indicating that the bioprocess effectively treated SSB wastes. The use of SSB as a substrate for CA production provides an alternative to traditional feedstocks, such as sugarcane and beet molasses. The low-cost and high availability of SSB makes it an attractive option for CA production. Moreover, the study demonstrated the potential of the bioprocess to simultaneously treat and reuse SSB wastes, reducing the environmental impact of the beverage industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Citric acid (CA) is the most widely used acidulant in foods and beverages industries, which are responsible for 70% of its consumption (Wang et al. 2020). Driven mainly by increased consumption of ready-to-drink beverages and processed meals, the worldwide market of CA reached a volume of 2.39 million tons in 2020 and it is expected to reach 2.91 million tons by 2026 (Mordor Intelligence 2020). CA’s different properties, such as flavor enhancer, preservative, acidulant, chelating agent, and its GRAS status justify the increased demand for this organic acid (Behera et al. 2021).

In 2021, the global market for non-alcoholic beverages was valued at US$ 1.23 trillion and it is expected to reach 1.66 trillion in 2026. Soft drinks were the largest segment with a market valued of US$ 820 billion. The United States is the market leader with an estimated revenue of $ 445.20 billion in 2022, followed by China, Japan, Germany, and the United Kingdom (Statista Market Forecast, 2022). Nevertheless, the non-alcoholic beverage industry is an important contributor to liquid waste production, where for each liter of beverage produced, approximately 0.5 L of effluent are generated (Kasmi et al. 2016; Statista Market Forecast, 2022). A significant portion of this waste is composed of discarded products due to some problems in formulation, carbonation, and/or bottling, packaging problems or expiration date, leading to beverage losses (Kasmi et al. 2016). It is estimated that 2 to 5% of the total production of SSB is discarded given the problems aforementioned (Comelli et al. 2015). SSB present high carbohydrate content (up to 12% w/v), high chemical oxygen demand (COD) (usually more than 100,000 mg O2 L− 1) and low pH (less than 4). Owing these pollutant characteristics, SSB discards are generally added to other industrial wastewaters and treated conventionally before disposal to meet regulations (Kasmi et al. 2016; Wickham et al. 2019). Several studies have investigated anaerobic fermentation to reduce COD levels in beverage industry wastewater while producing biogas, biofuels, and biomass as main products (Comelli et al. 2015; El-Kamah et al. 2010; Kasmi et al. 2016; Tawfik and El-Kamah 2012; Wickham et al. 2019). Nonetheless, no research has been found about the removal of COD in wastewater via an aerobic process utilizing A. niger while also producing a bioproduct such as CA.

Maltose, sucrose, glucose, mannose, and fructose can be employed for CA, production in a range of 120 g L− 1 to 180 g L− 1, with conversions of 0,35 to 1,03 g CA g− 1 of substrate and productivities of 0,05 to 2,57 g L− 1 h− 1 (Hossain et al. 1984; Ul-Haq et al. 2002; Mores et al. 2021). However, the growing demand for CA and the market’s interest in the circular economy has pushed the search for low-cost feedstock such as agro-industrial wastes (Dhillon et al. 2011; Amato et al. 2020; Mores et al. 2021), where the most common substrates used to produce the organic acid by submerged fermentation are sugarcane and beet molasses (Mores et al. 2021). Given the SSB characteristics and the need to search for low-cost substrates for CA production, the objectives of this study were: (1) to evaluate the use of different SSB as substrate for CA production by A. niger, and (2) to evaluate the impact of the developed bioprocess on chemical oxygen demand (COD) of SSB.

Materials and methods

Strain

The strain used in this study, A. niger NRRL 599, was obtained from the ARS Culture Collection (NRRL), National Center for Agricultural Utilization Research, Peoria, IL. The fungus was maintained on potato dextrose agar slants and stored at 4 °C. Fresh spores were extracted using a Tween-80 solution (0.1% v/v) after being cultured for 7 days at 30 °C in Erlenmeyer flasks containing potato dextrose agar. Then, the concentration of spore’s suspension was determined in a Neubauer chamber and aliquots were used for production media inoculation so as to have a spore concentration of 1.81 × 106 spores. mL.

Media and culture conditions

Five sugar-sweetened beverages were tested as a carbon source for CA production: soft drink, energy drink, sport drink, fruit juice and nectar juice. It is important to note that each beverage has its own composition of sugars and other components such as additives, preservatives, acidulants and others. The beverages were not pretreated and they were simply added of (per liter): CH4N2O – 0.8 g, KH2PO4 – 3.0 g, MgSO4 × 7H2O – 0.25 g, FeSO4 × 7H2O – 0.81 mg, ZnSO4 – 3 mg and ethanol 3% (v/v). The pH of the medium was adjusted to 4.5 before sterilization at 121 °C during 15 min. All the products used were past their expiration date.

Fermentation was carried out in 250 mL Erlenmeyer flasks containing 50 mL of fermentation flasks were inoculated with suspension of spores to obtain a medium. The concentration of 3.62 × 107 spores per mL and were incubated in a rotary shaker (Solab, Sao Paulo, Brazil) at 150 rpm and 30 °C for 10 days. One mL sample was withdrawn from each Erlenmeyer flask every 24 h for the analysis of CA, sugars and COD. All experiments were conducted in duplicate.

Biomass concentration

The mycelia was separated by filtration from production medium and washed with distilled water after the end of fermentation. The amount of dry biomass was determined gravimetrically after drying at 105 °C till constant weight.

Analysis of citric acid, sugar content and chemical oxygen demand

CA and sugars (glucose and fructose) concentration were estimated by high-performance liquid chromatography (HPLC). Samples were injected into an Agilent 1260 Infinity 143 Quaternary LC chromatograph coupled to a diode array detector (DAD) and refractive index (RID). A Hiplex-H (300 × 7.7 mm) column (Agilent Technologies, Santa Clara, CA, USA) was employed with an isocratic mobile phase composed of 4.0 mM H2SO4, with a flow rate of 0.5 mL min− 1 for 30 min. The sample, column and RID detector temperatures used throughout the run were 25, 70, and 50 °C, respectively.

Chemical oxygen demand (COD) was determined using the dichromate reduction method (Baird et al. 2017). All analysis were conducted in duplicate.

Statical analysis

The results of CA concentration and COD removal were assessed by analysis of variance (ANOVA), and Tukey’s multiple range test at 5% significance level (p ≤ 0.05) were used to detect differences among mean values. This analysis was performed using Minitab statistical software (Version 20.3, Minitab Inc., State College, PA, USA).

Results and discussion

Substrate analysis

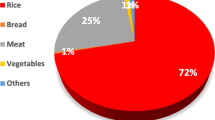

Five types of commercially available SSB were tested as carbon sources. The substrates were analyzed after supplementation. These beverages have a complex and varied composition (Table 1) including acidity regulators, colorants, sweeteners, antioxidants, caffeine, taurine, glucuronolactone, natural and artificial flavorings, vitamins, preservatives, among others. All tested beverages had a pH lower than 4.0.

Analyses of beverages’ composition indicated an initial sugars’ content and COD ranging from 33 to 112 g L− 1 and 115,186 to 189,050 mg of O2 L− 1, respectively. The high reducing sugars’ content of beverages is the main cause of elevated COD (Comelli et al. 2015). However, organic acids such as CA, ascorbic acid, also contributes to it. Among the evaluated beverages, the lowest COD was observed for sport drink, which also presented the lowest concentration of sugars.

For fruit juice, energy drink, nectar juice, sport drink and soft drink, the amount of citric acid were: 4.09 ± 0.17, 6.33 ± 0.31, 4.48 ± 0.69, 4.09 ± 0.17, 1.85 ± 0.10 and 0.56 ± 0.08 g L− 1, respectively. These results confirm the preference and wide use of citric acid as an acidulant by the SSB industry.

Kinetics of reducing sugar and citric acid production by A. niger using different SSB

CA concentration (Fig. 1a), sugars concentration (Fig. 1b), and chemical oxygen demand (Fig. 1c) were monitored during fermentation. As it is shown in Fig. 1a, the highest CA concentrations of 56.62 and 53.08 g L− 1 were reached after 240 h of fermentation using soft drink and nectar juice, respectively. These results are significantly (p < 0.05) higher than those obtained for other beverages. This can be explained by the fact that these beverages have the highest concentrations of sugars: 105.41 ± 6.36 for soft drink and 93.65 ± 5.60 g L− 1 for nectar juice. It is well known that the initial sugar concentration greater than 10% results in higher CA yields (Behera et al. 2021). A. niger was able to consume a large part of the sugars present in the medium. The fermentation broth of energy drinks exhibited approximately 26 g L− 1 of residual sugars at the end of fermentation. Others had sugar levels below 5 g L− 1 (Fig. 1b).

The yield of CA obtained with the energy drink was significantly lower compared to the soft drink and nectar juice. The presence of B vitamins in the energy drink may have favored biomass formation at the expense of CA accumulation. Sirisansaneeyakul et al. (2000) observed a significant increase in cell dry weight when the culture medium for A. niger was supplementing with a solution of B vitamins. Besides, previous studies indicated the deleterious effect of some vitamins and amino acids in CA biosynthesis (Lal and Srivastava 1982; Lesniak and Podgorski 2000).

It is well established in the literature that limited growth is crucial for CA bioproduction. Previous works indicate high CA production with biomass concentrations in the range of 12 to 24 g L− 1 (Yin et al. 2017; Ozdal and Kurbanoglu 2019). Similarly, in this study, the best CA yields (Table 2) were obtained with soft drink and sports drink, with lower biomass productions: 20.0 and 18.4 g L− 1, respectively. All beverages promoted low biomass growth (Table 2) with concentrations lower than 24 g L− 1, indicating that the medium composition was adequate to limit fungus growth. Furthermore, sport drink and soft drink had the highest substrate-to-product conversions, despite having the lowest final biomass concentrations of 10.5 and 9.3 g L− 1, respectively. This fact shows that even if the composition of SSB (additives, preservatives, and others) may affect growth, it is not a significant point in CA production processes where the limitation of growth leads to better synthesis of the organic acid. So, there is no need to remove these components or to conduct SSB pretreatment before the fermentation step.

CA final concentrations, which were obtained using soft drinks (56.62 g L− 1), nectar juice (53.08 g L− 1) and energy drink (47.05 g L− 1), are similar to previous studies that used conventional substrates and mutant strains of A. niger: 68.8 g L− 1 CA with sugar beet molasses and chicken feather peptone as media (Ozdal and Kurbanoglu 2019), 53 g L− 1 CA with sucrose as substrate (Hossain et al. 1984) and 42 g L− 1 CA with cane molasses (Ikram-Ul et al. 2004).

Those results demonstrate that SSB can be used as a substrate for CA production without requiring pre-treatment. This is an advantage concerning others substrates. Carbon sources such as molasses and date syrup, commonly used for CA bioproduction, require treatments to remove metal ions and other inhibitors (Roukas and Kotzekidou 1997; Mostafa and Alamri 2012). Also, materials composed of complex sugars, such as corn and agro-industrial waste, need to be transformed to release fermentable sugars (Zhou et al. 2017).

The CA yield factors (Yp/s), in g g− 1, were: 0.54, 0.49, 0.78, and 0.52 for soft drink, energy drink, sport drink, and nectar juice, respectively. These production yields are higher than those obtained in different works that used sucrose (0.48 g g− 1), glucose (0.35 g g− 1), and sugarcane molasses (0.45 g g− 1) for CA production by parental strains of A. niger (Hossain et al. 1984; Ul-Haq et al. 2002).

On the other hand, fermentation using fruit juice as substrate showed much lower performance when compared to other beverages. Fruit juices have complex rheological behavior and high viscosity because they are heterogeneous suspensions formed by large insoluble particles and fragments of cellular tissues (Dahdouh et al. 2016). This may have affected the production of CA due to the difficult homogenization of the culture medium and, consequently, by altering mass and oxygen transfer and the formation of pellets.

Aspergillus niger can utilize sugars, such as maltose, galactose, and fructose, but glucose and sucrose produce the best results for CA production (Amato et al. 2020). These are the main sugars of these beverages, such as sucrose and/or high fructose corn syrup, which are usually used to sweeten SSB. In addition, these carbohydrates, maltodextrin is commonly added to energy drinks and sports drinks. This can explain the increase in the amount of reducing sugars in the 48 h of fermentation when these beverages were used as substrate. Probably the fungus secreted enzymes capable of degrading maltodextrin into glucose and fructose (Bagheri et al. 2014).

Kinetics of COD for different SSB used as substrate for CA production by A. niger

As well as the sugars, the COD showed a decreasing profile (Fig. 1c) throughout CA fermentation. The analysis of the fermentation broths at the end of process indicated a COD removal (Table 2) higher than 53.80% and could reach up to 75.64%.

The COD reduction is directly related to the consumption of sugars medium during fermentation. However, CA presents a theoretical COD of 0.75 g of O2 g− 1. This explains the significantly lower COD removal for soft drink and nectar juice, which are beverages that promoted higher CA concentration at the end of fermentation. Likewise, these results indicate that the COD removal of the discards can be even higher after CA recovery. Alam et al. (2007), for example, obtained higher removal of COD (80%), but lower CA production by A. niger (5.2 g L− 1) using sed palm oil mill effluent (POME) as the main substrate.

In this work a COD removal rates up to 597 mg of O2 L− 1 h− 1 was obtained. These results are higher than those reported in several previous studies that used conventional anaerobic processes for the treatment of similar wastes. Sheldon and Erdogan (2016) reported a maximum removal rate of 458 mg of O2 L− 1 h− 1 when soft drink industry wastewater (COD between 2242 and 11,717 mg L− 1) was treated with an anaerobic expanded granular sludge bed (EGSB) reactor. Similarly, soft drink and fruit processing waste with loadings of 312.5 mg of O2 L− 1 h− 1 were treated using anaerobic fluidized bed reactors with a COD removal of 78% (Stronach et al. 1987). A COD removal of 61 and 67,4% with an organic loading rate of 362.5 and 245.8 mg of of O2 L− 1 h− 1 were obtained during the treatment of high strength wastewater from the fruit juice industry using a two-stage up-flow anaerobic sponge reactor and two anaerobic hybrids reactors, respectively (El-Kamah et al. 2010; Tawfik and El-Kamah 2012).

The use of SSB waste for CA production dispenses the need for chemical or physical pretreatment for organic load reduction since the characteristics of the substrate are favorable for the process. Thus, the consumption of reagents and the number of steps can be reduced during wastewater treatment. Furthermore, aerobic treatments have advantages such as to minimize the problems of longer retention time, production of undesirable odors, slow startup, and difficulties to operate that are observed in conventional anaerobic processes.

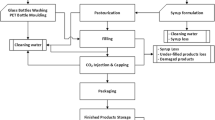

Mas balance of CA production processes using SSB

The mass balance of the proposed process with the use of soft drink, energy drinks, or nectar juice as carbon sources is presented in Fig. 2. In this case, only glucose was considered as the carbon source, and urea as nitrogen source. However, probably, the fungus also utilized others sources of carbon and nitrogen that are present in SSB compositions. During fermentation, A. niger uses carbon, nitrogen, and oxygen to produce CA, carbon dioxide, water and biomass. For example, when utilizing soft drink, for each 1000 kg of CA produced, 1821 kg of glucose, 14.28 kg of urea and 755,7 kg of oxygen are necessary. In addition, carbon dioxide (793 kg), water (617 kg) and biomass (187.86 kg) are also generated. The production of other organic acids was not detected.

Conclusions

This study demonstrated the potential use of sugar-sweetened beverages (SSBs) waste as a substrate for A. niger CA synthesis. The fungus was capable of producing CA in every SSB medium tested, with the highest concentration observed when soft drink (56.62 g L− 1) and nectar juice media as substrates (53.08 g L− 1) were used. Furthermore, chemical oxygen demand (COD) was greater than 53% for all tested SSBs, with fruit juice (75.64%) and energy drink (75.51%) showing the highest COD rate removal. These results suggest that despite the complexity and characteristics of SSBs, A. niger can be used to promote the valorization of this kind of waste through CA production. Future studies may focus on the optimization and scale-up of CA fermentation and investigate the use of SSBs for the production of other bioproducts in a biorefinery approach.

Data availability

Not applicable.

Code availability

Not applicable.

References

Alam MZ, Jamal P, Nadzir MM (2007) Bioconversion of palm oil mill effluent for citric acid production: statistical optimization of fermentation media and time by central composite design. World J Microbiol Biotechnol 2007 24:7. https://doi.org/10.1007/S11274-007-9590-5

Amato A, Becci A, Beolchini F (2020) Citric acid bioproduction: the technological innovation change. Crit Rev Biotechnol 40:1–14. https://doi.org/10.1080/07388551.2019.1709799

Bagheri A, Khodarahmi R, Mostafaie A (2014) Purification and biochemical characterisation of glucoamylase from a newly isolated Aspergillus niger: relation to starch processing. Food Chem 161:270–278. https://doi.org/10.1016/J.FOODCHEM.2014.03.095

Baird RB, Eaton AD, Rice EW, Bridgewater L (2017) Standard methods for the examination of water and wastewater. American Public Health Association, Washington, DC

Behera BC, Mishra R, Mohapatra S (2021) Microbial citric acid: production, properties, application, and future perspectives. Food Front 2:62–76. https://doi.org/10.1002/fft2.66

Comelli RN, Seluy LG, Grossmann IE, Isla MA (2015) Treatment of High-Strength Wastewater from the Sugar-Sweetened Beverage Industry by an alcoholic fermentation process. Ind Eng Chem Res 54:7687–7693. https://doi.org/10.1021/acs.iecr.5b00591

Dahdouh L, Wisniewski C, Ricci J et al (2016) Rheological study of orange juices for a better knowledge of their suspended solids interactions at low and high concentration. J Food Eng 174:15–20. https://doi.org/10.1016/j.jfoodeng.2015.11.008

Dhillon GS, Brar SK, Verma M, Tyagi RD (2011) Recent advances in citric acid bio-production and recovery. Food Bioproc Tech 4:505–529. https://doi.org/10.1007/s11947-010-0399-0

El-Kamah H, Tawfik A, Mahmoud M, Abdel-Halim H (2010) Treatment of high strength wastewater from fruit juice industry using integrated anaerobic/aerobic system. Desalination 253:158–163. https://doi.org/10.1016/J.DESAL.2009.11.013

Hossain M, Brooks JD, Maddox IS (1984) The effect of the sugar source on citric acid production by Aspergillus niger. Appl Microbiol Biotechnol 19:393–397. https://doi.org/10.1007/BF00454376

Ikram-Ul H, Ali S, Qadeer MA, Iqbal J (2004) Citric acid production by selected mutants of Aspergillus niger from cane molasses. Bioresour Technol 93(2):125–130. https://doi.org/10.1016/j.biortech.2003.10.018

Kasmi M, Chatti A, Hamdi M, Trabelsi I (2016) Eco-friendly process for soft drink industries wastewater reuse as growth medium for Saccharomyces cerevisiae production. Clean Technol Environ Policy 18:2265–2278. https://doi.org/10.1007/s10098-016-1144-9

Lal DN, Srivastava AS (1982) Effect of vitamins on Microbial Production of Citric Acid by Aspergillus niger. Zentralbl Mikrobiol 137:381–385. https://doi.org/10.1016/S0232-4393(82)80016-4

Lesniak W, Podgorski W (2000) Effect of amino acids and vitamins on citric acid biosynthesis. Prog Biotechnol 17:251–256. https://doi.org/10.1016/S0921-0423(00)80076-3

Mordor I CITRIC ACID MARKET - GROWTH, TRENDS, COVID-19 IMPACT FORECASTS (2020) (2021–2026). https://www.mordorintelligence.com/industry-reports/citric-acid-market. Accessed on 22nd June, 2021

Mores S, Vandenberghe LP, de Magalhães Júnior S AI, et al (2021) Citric acid bioproduction and downstream processing: Status, opportunities, and challenges. Bioresour Technol 320:124426. https://doi.org/10.1016/j.biortech.2020.124426

Mostafa YS, Alamri SA (2012) Optimization of date syrup for enhancement of the production of citric acid using immobilized cells of Aspergillus niger. Saudi J Biol Sci 19:241–246. https://doi.org/10.1016/j.sjbs.2012.01.004

Ozdal M, Kurbanoglu EB (2019) Citric acid production by Aspergillus niger from Agro-Industrial By-Products: molasses and chicken feather peptone. Waste Biomass Valorization 10:631–640. https://doi.org/10.1007/s12649-018-0240-y

Roukas T, Kotzekidou P (1997) Pretreatment of date syrup to increase citric acid production. Enzyme Microb Technol 21:273–276. https://doi.org/10.1016/S0141-0229(97)00041-0

Sheldon MS, Erdogan IG (2016) Multi-stage EGSB/MBR treatment of soft drink industry wastewater. Chem Eng J 285:368–377. https://doi.org/10.1016/J.CEJ.2015.10.021

Sirisansaneeyakul S, Jitbanjongkit S, Prasomsart N, Luangpituksa P (2000) Production of β-Fructofuranosidase from Aspergillus niger ATCC 20611. Agric Nat Resour 34:378–386

Statista Market Forecast (2022) Consumer markets: non-alcoholic drinks. https://www.statista.com/outlook/cmo/non-alcoholic-drinks/worldwide. Accessed on 20th June, 2022

Stronach SM, Rudd T, Lester JN (1987) Start-up of anaerobic bioreactors on high strength industrial wastes. Biomass 13:173–197. https://doi.org/10.1016/0144-4565(87)90026-6

Tawfik A, El-Kamah H (2012) Treatment of fruit-juice industry wastewater in a two-stage anaerobic hybrid (AH) reactor system followed by a sequencing batch reactor (SBR). Environ Technol 33:429–436. https://doi.org/10.1080/09593330.2011.579178

Ul-Haq I, Ali S, Qadeer MA, Iqbal J (2002) Citric acid fermentation by mutant strain of Aspergillus niger GCMC-7using molasses based medium. Electron J Biotechnol. https://doi.org/10.2225/vol5-issue2-fulltext-5

Wang J, Cui Z, Li Y et al (2020) Techno-economic analysis and environmental impact assessment of citric acid production through different recovery methods. J Clean Prod 249:119315. https://doi.org/10.1016/j.jclepro.2019.119315

Wickham R, Xie S, Galway B et al (2019) Pilot-scale operation experience of anaerobic co-digestion for possible full scale implementation. Int Biodeterior Biodegradation 142:137–142. https://doi.org/10.1016/j.ibiod.2019.05.020

Yin X, Shin H, Li J et al (2017) Comparative genomics and transcriptome analysis of Aspergillus niger and metabolic engineering for citrate production. Sci Rep 7:41040. https://doi.org/10.1038/srep41040

Zhou PP, Meng J, Bao J (2017) Fermentative production of high titer citric acid from corn stover feedstock after dry dilute acid pretreatment and biodetoxification. Bioresour Technol 224:563–572. https://doi.org/10.1016/j.biortech.2016.11.046

Acknowledgements

This work was supported by Brazilian National Council for Scientific and Technological Development (CNPq), Brazil, and Coordination of Improvement of Higher Education Personnel (CAPES), Brazil.

Author information

Authors and Affiliations

Contributions

SM: Conceptualization and investigation, Experiments, Writing—original draft preparation, final review & editing; LPdeSV: Supervision, Resources; Writing—review and editing; WJM-B: Writing—review and editing; CR: Analytical Procedures; Writing—review and editing; CRS: Resources; Writing—final review & editing, Head of Bioprocess Engineering and Biotechnology Laboratory.

Corresponding author

Ethics declarations

Conflict of interest

Authors state that there is no conflict of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mores, S., de Souza Vandenberghe, L.P., Martinez-Burgos, W.J. et al. Simultaneous reuse and treatment of sugar-sweetened beverage wastes for citric acid production. J Food Sci Technol 60, 2401–2407 (2023). https://doi.org/10.1007/s13197-023-05761-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05761-9