Abstract

This work presents the study of the moisture ratio and carotenoid compounds in dried mamey (Pouteria sapota) using non-invasive spectroscopic techniques. The drying behavior of mamey at 64 °C by a homemade solar dryer is analyzed by fitting the experimental data to four different mathematical drying models. In addition, this result is compared with other drying techniques, namely by heat chamber with natural convection at temperatures of 50 °C and 60 °C. The results show that the Lewis model is the one that best fits the experimental moisture ratio curve of mamey. On the other hand, Near-Infrared and Terahertz spectroscopic techniques are used to estimate the moisture ratio, since water absorption is most sensitive at these frequencies. Fourier Transform Infrared-attenuated total reflectance and Raman spectroscopy are performed to detect the carotenoid compounds in dried mamey. This compound has important applications in the food industry and health benefits. To our knowledge, there are few studies on the dehydration of Pouteria sapota as well as its characterization using spectroscopic techniques for the detection of moisture ratio and carotenoid content; therefore, this study can be useful in agriculture and food sectors when detailed information about the cited parameters is needed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The mamey (Pouteria sapota) is a tropical fruit native from southern México and Central America. The production of this fruit in México is around 21,800 tons per year, the harvest loss is between 20 and 30%, and the rest is used for local consumption or exported mainly to Asia and Europe (SIAP 2020). The flowering of this fruit occurs 2–4 times per year, being the main harvest season from March to July (Villegas-Monter 2016). Mamey has a thin shell with a rough texture, its pulp is reddish in color and its taste is sweet. The mamey pulp is characterized by having a water content between 84.9 and 61.5% and by having a high content of carbohydrates, vitamin A, vitamin C, calcium, iron, and phosphorus (Alia-Tejacal et al. 2007; Solís-Fuentes et al. 2015). The peculiar color of mamey is due to its high concentration of carotenoid compounds, which have an antioxidant effect that is essential for the protection of cells and strengthening of the immune system (Gul et al. 2015; Torres-Rodríguez et al. 2011). The carotenoids compound has also been used as a natural dye in solar cell technology (Supriyanto et al. 2018). Carotenoids can be divided into hydrocarbon (named carotenes) and oxygenated carotenoids (commonly known as xanthophylls). The total concentration of carotenoid compounds in mamey may depend on genotype, postharvest handling, ripeness, and production and conservation processes (Alia-Tejacal et al. 2007). These compounds have been characterized using the HPLC–DAD methodology in mamey pulp (Murillo et al. 2013, 2016). It was found that the main compound is the ketocarotenoids with \(\kappa \) rings, both hydroxylated (cryptocapsin, capsanthin, and capsorubin) and not hydroxylated (sapotexanthin), which are pro-vitamin A carotenoids.

Due to the large production of mamey and the fact that its maturation process is very fast, an alternative to reduce the harvest loss while preserving the organoleptic and nutritional properties is the dehydration process (Mujumdar 2006; Onwude et al. 2016). This process consists of removing the water from the food until a solid product with low moisture content (MC) is obtained. An additional advantage is that dehydrated fruit are preserved for long periods of time, and their storage and transport are easier and more cost-effective since the weight and volume are reduced. There are several mathematical models to simulate the drying kinetics as a function of moisture ratio (MR), which relates MC at any drying time to the initial moisture content in food (Ertekin and Firat 2017). For many years, non-invasive spectroscopic techniques have been used to characterize moisture content, chemical composition, and carotenoid determination of fruit, vegetables, oils, and other biological samples (Alander et al. 2013; H-Domínguez et al. 2018; Long et al. 2021; Walsh et al. 2020). Due to the high absorption of water in the near-infrared (NIR) frequency range, NIR spectroscopy can detect moisture content within the wavelength range of 780–2500 nm, where several characteristic water absorption peaks are present around the bands at 970 nm, 1140 nm, and 1430 nm (Lee et al. 2020; Long et al. 2021; Walsh et al. 2020). A novel technique that is also capable of estimating moisture in biological samples is Terahertz (THz) time domain spectroscopy, since water also has strong absorption in the THz region (Gente et al. 2013). This technique allows the retrieval of electric field amplitude and phase in the range of 300 GHz and 10 THz (far infrared); this information is useful to obtain optical parameters such as the complex refractive index, thickness, dielectric function of a material, and even estimates of the moisture content in the sample using a mathematical fit (Hernandez-Serrano et al. 2014). On the other hand, considering the high content of carotenoids in mamey fruit as well as the benefits they provide to health, it is vitally important to verify the presence of this compound during the drying process. The carotenoids concentration on vegetables and fruit has been studied under the influence of drying temperature (Demiray and Tulek 2017; Suvarnakuta et al. 2005). Fourier Transform Infrared-attenuated total reflectance (FTIR-ATR) spectroscopy is used to the identification of the functional groups as well as the chemical structure of materials since it is sensitive to the molecular vibrations in the mid-infrared region of the electromagnetic spectrum between 4000 and 450 cm−1; in particular, it is capable of detecting carotenoids in food (Carvalho et al. 2014; Quijano-Ortega et al. 2020). Another potential alternative technique is Raman spectroscopy which provides chemically specific information by measuring the vibrational energy modes of a sample; therefore, it can identify carotenoids compounds in characteristic bands of C=C (ν), C–C (ν), and CH3 (δ) in fruit and vegetables (Carvalho et al. 2019; de Oliveira et al. 2010).

In this work, we study the moisture ratio during the drying process of mamey with a solar dryer at 64 °C. We adjusted the drying curve to four mathematical models, namely Lewis, Page, Herderson-Pabis, and logarithmic models. We also compare this result with others obtained at drying temperatures of 50 °C and 60 °C in a heat chamber with natural convection. Although the spectroscopic techniques mentioned above have been used to assess moisture ratio and carotenoid content in some fruit, there are no studies to evaluate these parameters in the dried mamey. Therefore, the aim of this work is to demonstrate and study the usefulness of these techniques for the specific case of Pouteria sapota. This study can be useful for the agriculture and food sectors that need complete information of the dried mamey.

Materials and methods

Sample preparation and drying procedure

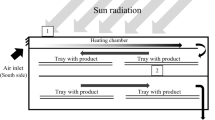

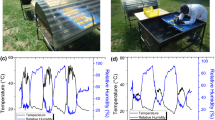

Mature, fresh and healthy mamey was obtained from a local market from Chiapas, México. It was cleaned and then cut into slab shapes using a food slicer. The samples are 50 × 30 mm slices with a thickness of 1.59 ± 0.18 mm and an average weight of 3.20 ± 0.22 g. Nine slices were used for the dehydration process; three slices for each drying temperature. The mass weight of each slice was measured by a digital electronic balance (Pioneer PX, OHAUS) with a 0.01 mg precision before starting the drying process. To dehydrate the mamey slabs, a homemade solar dryer (Iglesias-Díaz et al. 2011) operated at 64 °C was used for 300 min and a heat chamber with natural convection (BLINDER) at 50 °C and 60 °C for 350 min. For each drying temperature, the weight loss of slabs was registered every 30 min until the mass of the sample no longer changed.

The procedure for preparing the samples before their spectroscopic characterization is described below. One sample to analyze the water content through IR spectroscopy was selected. The first measurement of the IR transmission spectrum was for the fresh slice. Afterwards, it was placed inside the dryer at 50 °C and the spectrum measurements were performed after 40 min, 70 min, 130 min and 350 min of dehydration. Each measurement took 5 min. To the rest of techniques, four selected samples were dried at 50 °C during 90 min, 110 min, 300 min and 350 min, respectively, with the aim that each of them present different water content. The samples were then stored in food-grade plastic bags to prevent spoilage. Subsequently, the measurements were made with the THz, FTIR and Raman spectroscopes that were in another laboratory.

Mathematical modeling of the drying kinetics

The moisture content (g water g−1 dry base (d.b.)) at certain drying time in a sample is related to the weight loss of the sample, and it can be calculated by \(MC=\left({w}_{t}-{w}_{d}\right)/{w}_{d}\), where \({w}_{t}\) is the current mass weight (g) at time \(t\) of the sample and \({w}_{d}\) is the mass of the dry sample (Guo et al. 2022). The principal parameter in this work is the moisture ratio value that is calculated using Eq. (1) (Ertekin and Firat 2017),

where \({M}_{t}\) is the moisture content at time \(t\) (g g−1 d.b.) during the drying process, \({M}_{0}\) is the initial moisture content (g g−1 d.b.) of the sample and \({M}_{e}\) is the equilibrium moisture content (g g−1 d.b.) which corresponds to the moisture content becomes a constant in the drying process. The Eq. (1) can be reduced to Eq. (2) since \({M}_{e}\) is small relative in comparison with \({M}_{0}\) and \({M}_{t}\), therefore it can be negligible. Note that MR is a dimensionless value.

Mathematical models are useful to estimate the drying time in order to optimize the drying process. Therefore, four mathematical drying models (Table 1) were used to evaluate the drying kinetics of the samples (Ertekin and Firat 2017; Onwude et al. 2016). Using the MATLAB© (version R-21016b) software a non-linear regression analysis was performed for the adjustment of the mathematical models.

Implementing a statistical analysis was possible to determine which mathematical model is the most appropriate to describe the drying behavior for the mamey. The coefficient of determination (\({R}^{2}\)) value was the principal criteria for choosing the fit model, in addition to the sum square error (\(SSE\)), mean square error (\(MSE\)), and the root mean square error (\(RMSE\)) (Eq. 3):

where \({MR}_{exp}\) and \({MR}_{pre}\) is the experimental and predicted dimensionless moisture ratios, respectively. \(N\) is the observation number.

The model with the highest value of the \({R}^{2}\) coefficient and the lowest \(SSE\), \(MSE\) and \(RMSE\) values is considered as the best model to describe the drying kinetics.

Spectroscopy techniques

The NIR spectrum was measured by a UV–VIS-NIR spectrophotometer (Shimadzu, Model UV-3600) in the 850–1650 nm spectral range with spectral resolution of 1 nm. The equipment was configured in transmittance mode. Two absorbance spectra were registered per sample at two different points and then they were averaged to obtain a single spectrum. Using a THz spectrometer (Picometrix T-Gauge, Model T-Ray 5000), the transmitted electric field \(E(t)\) was measured for a reference signal (\({E(t)}_{r}\)), taken without a sample, and for the sample (\({E\left(t\right)}_{s}\)) in the time domain (Nuss and Orenstein 1998). The data was acquired with a 0.1 ps resolution and 1000 scans/second were taken and averaged. These signals were translated into the frequency domain (\(\omega \)) through the fast Fourier transform, obtaining a spectrum, \({E}_{\omega }\), with spectral range from 0.2 to 1.4 Thz.

The FT-IR spectrophotometer with diamond ATR accessory (Thermo scientific, Nicolet Is50 FT-IR) was configured in the spectral range 540–4000 cm−1 with resolution of 4 cm−1. Raman spectra were measured by a Renishaw InVia microscope Raman spectrometer with an excitation source at 785 nm using a 20X objective (0.4 NA) in the range 800–1650 cm−1.

Results and discussion

Drying kinetics parameters of mamey slab

The initial MC in the fresh mamey was \(70\%\), the rest may be fiber, sugar, and amino acids contained within the pulp (Solís-Fuentes et al. 2015). Figure 1 shows the experimental data of the moisture ratio for mamey slabs dried at 64 °C (square symbol) by solar dryer, and at 50 °C (asterisk symbol) and 60 °C (diamond symbol) by heat chamber as a function of drying time. Note that MR value equal to 1 corresponds to fresh fruit, that means with \(100\%\) of water content. On the other hand, the value of \(MR=0\) indicates that the fruit is totally dehydrated. The inset in Fig. 1a shows pictures of the fruit, the fresh and the dried slabs. The dehydrated sample presents a slight color change with respect to the fresh fruit; this may be due to various reasons such as the presence of sugars, little remaining moisture in the product or the degradation of some volatile compounds (Calín-Sánchez et al 2020). Observe that the constant moisture ratio value is achieved faster with the solar dryer, around 180 min, while for the others it takes up to 300 min. Therefore, using the home-made solar dryer shows advantages as it requires less dehydration time, offers energy savings, does not cause heat damage to the product and is low cost compared to commercial dryers. The drying time can also depend on several factors such as the ripening of the fruit, the thickness of the slabs, the temperature and humidity inside the dryer (Mujumdar 2006; Onwude et al. 2016).

Drying curve of mamey slices at different temperature. a Evolution of moisture ratio (MR) as a function of drying time. Asterisk, diamond and square symbols correspond to the experimental data at 50 °C, 60 °C and 64 °C, respectively. Dots and dashes red line, dotted pink line and continuous blue line are the calculated MR using a mathematical model for 50 °C, 60 °C and 64 °C, respectively. b The drying coefficients and the \({R}^{2}\) value for each model

By fitting four mathematic models (Table 1) to the experimental data it was possible to know the mamey drying behavior under different drying temperatures and moisture information. A statistical analysis allows to determine the goodness of fit of the experimental data. All the models present a very small value of lowest \(SSE\), \(MSE\) and \(RMSE\), below 0.019. \({R}^{2}\) value is very close to 1, which means that all selected models are appropriated to describe the drying behavior for mamey slabs (Fig. 1b). The calculated moisture curves corresponding to the best-fit model to each drying temperature are shown in Fig. 1a. The Lewis, logarithmic and Page models are the best model for the temperature at 50 °C, 60 °C and 64 °C, respectively. The calculated constants shown in Fig. 1b are useful to evaluate the equations of the moisture ratio as a function of time for each drying condition. In this way, it will be possible to predict the behavior of MR at any instant of time. For simplicity and regardless of drying method, the Lewis mathematic model can be convenient for description of the drying characteristic of mamey.

The results of Fig. 1 allow to know the correlation of the drying time with the value of MR in the mamey. Therefore, the analysis of the spectral response of the mamey in the following “Detection of the moisture ratio in mamey” and “NIR spectroscopy” sections will be done based on the value of moisture ratio.

Detection of the moisture ratio in mamey

In the literature, the recommended temperature for fruit dehydration is between 50 and 65 °C. The selected temperature range allows to analyze significant changes in the characterization techniques.

NIR spectroscopy

Figure 2 shows the absorbance spectrum of a mamey sample wit MR of 40%, 25%, 11% and 0% in the range of 850 nm-1650 nm for a drying temperature at 50 °C. The value of MR = 100% (MR = 1) and MR = 0% (MR = 0) represent a total water content and a sample without water (dried), respectively. All spectra show a similar trend in the range tested. The loss of moisture can clearly be seen in the bands around to 1440 nm and 1470 nm centered at 1462 nm (O–H stretch first overtone). The intensity of this peak is maximum for the fresh slab (MR = 100%), which means that there is a high content of water molecules that absorb IR radiation in this range. On the contrary, the spectrum of dried sample shows an attenuated intensity amplitude up to 12% due to the absence of water.

It can also be noted that other weak water absorption peaks are found around 979 nm and 1190 nm that are related to the second and first overtone of the O–H stretching mode, respectively (Lee et al. 2020). When the product is dry (MR = 0%), the absorption peaks in this range of the spectrum almost completely disappear. With these results we have qualitatively demonstrated that the absorption spectroscopy technique in the NIR range is a useful tool to visualize the water content in a product.

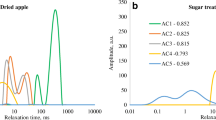

THz spectroscopy

The THz wave radiation is safe for analyzing organic samples, since it is a non-ionizing radiation that does not damage tissues and biomolecules in food. Therefore, the THz spectroscopy technique is a powerful non-destructive technology for monitoring food quality. Based on the fact that water molecules have a strong absorption of THz radiation, it is possible to apply this technique in the qualitative determination of the moisture ratio in a mamey slab. This method has the limitation that a THz signal can be completely absorbed by samples with high water content or with a thickness greater than 1 mm (Arteaga et al 2021). Figure 3a shows the THz time-domain spectra emerged from the dried mamey at 50 °C with MR values of 25%, 17%, 7% and 0%. The measured air signal is the reference wave, without any sample, which is useful to compare the change in the THz signal due to the water content in the mamey slab. Observe that the amplitude of the electric field, \(E\left(t\right)\), and the time delay change as a function of the MR in the sample. These variations may be attributed to the physical and optical characteristics of the sample, such as the thickness, the absorption coefficient and refractive index (Gente et al. 2013; Hernandez-Serrano et al. 2014). Figure 3b illustrates the frequency-domain spectra of the transmitted THz signal amplitude for dried samples in the range from 0.2 to 1.4 THz. As expected, the amplitude of the fast Fourier transform of the \(E\left(t\right)\) increases gradually as the moisture ratio decreases in the sample. Note that the amplitude of dried slab (MR = 0%) is reduced to 76% of its amplitude compared to the wet sample of MR = 25%.

These results show that THz spectroscopy has great potential for the study of moisture content in the dehydration processes of various agricultural products, as well as its utility as a method for the classification or characterization of samples. This technique has advantages as compared to the other methods since it could be possible to obtain a calibration curve and from it estimate the moisture ratio.

Detection of the carotenoid compounds in mamey

FTIR-ATR spectroscopy

Agricultural products can be composed of water, sugars, carbohydrates, organic acids, and several vitamins. Therefore, the FTIR-AT technique is a useful tool to identify the functional groups of the molecules contained in an organic sample. Figure 4 shows the FTIR transmittance spectra of the mamey samples with MR of 25%, 7% and 0%. As has been reported in the literature, one of the main carotenoid compounds in mamey is ketocarotenoids, such as the capsanthin, capsorubin and cryptocapsin, which are xanthophylls containing 6-oxo-κ end-group in their molecules (Murillo et al 2016; Chacón-Ordoñez et al. 2017). In the spectra can be identify the vibration modes around 1550–1720 cm−1 that correspond to the double bond C=C (1541 cm−1) and C=O(ν) stretching (1635 cm−1) vibrations related to the capsanthin and capsorubin carotenes (Lóránd et al. 2002). These compounds are a characteristic carotenoid of the mamey pulp that causes its red pigmentation. Observe that the difference in the intensity of the transmittance peak corresponding to this compound is negligible, so it can consider that the dehydration process does not modify the carotenoid compounds in the sample.

Additional functional group information can be subtracted from the FTIR-ATR spectra. For instance, a strong absorption band can be observed belonging to the saturated hydrocarbon groups (2917 cm−1), corresponding to a methyl group (C–H3), and 2849 cm−1 corresponding to a methylene group (C–H2). In the IR region, from 1542 to 965 cm−1, several IR bands can be observed corresponding to the vibration of the C–O, C–C, C–H and C–N bonds. The intense absorption bands from 965 to 1200 cm−1 (C–O and C–C groups) indicate the presence of carbohydrates. The identification of these function groups in dry mamey confirms that the dehydration process maintains the presence of carotenoid compounds and preserves a high carbohydrate content.

On the other hand, this technique is also able to detect the water content. The strong absorption occurs in bands around of the 3649–3292 cm−1 that is related with the stretching vibrations of O–H. The central peak oscillates in the wavenumber region around 3270 cm−1, where the maxima absorbance peak belongs to the sample with 25% MR. This is consistent with the result shown in the IR absorbance spectrum shown in Fig. 2.

Raman spectroscopy

To our knowledge, a determination of carotenoid compounds in mamey has not been carried out through Raman spectroscopy. Since it has been reported that the mamey pulp is contained mostly by ketocarotenoids, this Raman analysis is focused on the identification of these compounds that their characteristic peaks can be seen between 1006 and 1518 cm−1 at 785 nm excitation.

Raman spectra of dried mamey with MR of 17%, 7% and 0% are shown in Fig. 5. It is possible to detect the peaks of carotenoids with the \(\kappa \) end groups, such as capsorubin around 1006 (bending, C–CH3 (δ)) cm−1, and capsanthin in 1154 (stretching, C–C (ν)) and 1518 (stretching, C=C (ν)) cm−1 (Murillo et al 2013). Note that the intensity of the main peaks increases and the broadening of their width changes at lower moisture ratio. A similar behavior was observed for sweet potatoes under heat treatment (Sebben et al. 2018). Therefore, this indicates that the presence of carotenoid compounds in fruit may decrease as a function of moisture ratio, temperature and drying time (Carvalho et al. 2019). This effect can probably be related to the thermal degradation of the carotenoids and the isomerization process during drying. For this reason, it is important to monitor the presence of carotenoids in a dried fruit to avoid losses of this compound and thus ensure the quality of the final product.

Although there are methodologies to quantify the concentration of carotenoids in a fruit pulp by means Raman spectroscopy combined with chemometrics (Carvalho et al. 2019; Wang et al. 2021), this work focuses on performing a qualitative analysis of the presence of carotenoid compounds in mamey through this optical technique.

Conclusion

Four drying kinetic models have been evaluated to describe the drying curve of a mamey (Pouteria sapota) slab. The Lewis model is the most efficient and presents the smallest approximation error, which will be useful to predict the moisture ratio of mamey at any time under specific drying conditions. NIR and THz spectroscopies are useful to qualitatively analyze the moisture ratio in a mamey slice, but the last technique can additionally provide more information about the optical parameters of the sample, such as its refractive index, thickness, and dielectric coefficients. On the other hand, the preservation of carotenoids and carbohydrates in dried mamey is verified by FTIR and Raman spectroscopy, even in a sample with low moisture content. Hence, this study demonstrates that these non-invasive optical spectroscopy techniques can determine the moisture ratio and the presence of carotenoid compounds in mamey. This confirms the usefulness of these methods for rapid quality control measurements in food.

Abbreviations

- MR:

-

Moisture ratio

- NIR:

-

Near-infrared

- THz:

-

Terahertz

- FTIR-ATR:

-

Fourier transform infrared-attenuated total reflectance

References

Alander JT, Bochko V, Martinkauppi B, Saranwong S, Mantere T (2013) A review of optical nondestructive visual and near-infrared methods for food quality and safety. Int J Spectrosc 2013:1–36. https://doi.org/10.1155/2013/341402

Alia-Tejacal I, Villanueva-Arce R, Pelayo-Zaldívar C, Colinas-León MT, López-Martínez V, Bautista-Baños S (2007) Postharvest physiology and technology of sapote mamey fruit (Pouteria sapota (Jacq.) HE Moore & Stearn). Postharvest Biol Technol 45:285–297. https://doi.org/10.1016/j.postharvbio.2006.12.024

Arteaga H, León-Roque N, Oblitas J (2021) The frequency range in THz spectroscopy and its relationship to the water content in food: a first approach. Sci Agropecu 12(4):625–634. https://doi.org/10.17268/sci.agropecu.2021.066

Calín-Sánchez Á, Lipan L, Cano-Lamadrid M, Kharaghani A, Masztalerz K, Carbonell-Barrachin ÁA, Figiel A (2020) Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods 9(9):1261. https://doi.org/10.3390/foods9091261

Carvalho DG, Sebben JA, de Moura NF, Trierweiler JO, da Silveira EJ (2019) Raman spectroscopy for monitoring carotenoids in processed Bunchosia glandulifera pulps. Food Chem 294:565–571. https://doi.org/10.1016/j.foodchem.2019.04.120

Carvalho LMJD, Smiderle LDASM, Carvalho JLVD, Cardoso FDSN, Koblitz MGB (2014) Assessment of carotenoids in pumpkins after different home cooking conditions. Food Sci Technol 34:365–370. https://doi.org/10.1590/fst.2014.0058

Chacón-Ordóñez T, Schweiggert RM, Bosy-Westphal A, Jiménez VM, Carle R, Esquivel P (2017) Carotenoids and carotenoid esters of orange-and yellow-fleshed mamey sapote (Pouteria sapota (Jacq.) HE Moore & Stearn) fruit and their post-prandial absorption in humans. Food Chem 221:673–682. https://doi.org/10.1016/j.foodchem.2016.11.120

Demiray E, Tulek Y (2017) Degradation kinetics of β-carotene in carrot slices during convective drying. Int J Food Prop 20:151–156. https://doi.org/10.1080/10942912.2016.1147460

Ertekin C, Firat MZ (2017) A comprehensive review of thin-layer drying models used in agricultural products. Crit Rev Food Sci Nutr 57:701–717. https://doi.org/10.1080/10408398.2014.910493

Gente R, Born N, Voß N, Sannemann W, Léon J, Koch M, Castro-Camus E (2013) Determination of leaf water content from terahertz time-domain spectroscopic data. J Infrared Millim Terahertz Waves 34:316–323. https://doi.org/10.1007/s10762-013-9972-8

Gul K, Tak A, Singh AK, Singh P, Yousuf B, Wani AA (2015) Chemistry, encapsulation, and health benefits of β-carotene—a review. Cogent Food Agric 1:1018696. https://doi.org/10.1080/23311932.2015.1018696

Guo HL, Chen Y, Xu W, Xu MT, Sun Y, Wang XC, Wang XY, Luo J, Zhang H, Xiong YK (2022) Assessment of drying kinetics, textural and aroma attributes of mentha haplocalyx leaves during the hot air thin-layer drying process. Foods 11:784. https://doi.org/10.3390/foods11060784

H-Domínguez E, Cruz-Lopez E, Reyes-Nava J A, Conde J, Briones E, Vilchis H (2018) First principles for evaluation of the moisture content in mango slice by tera-hertz pulses. In: 15th International conference on electrical engineering, computing science and automatic control (CCE), pp 1–4. https://doi.org/10.1109/ICEEE.2018.8533906.

Hernandez-Serrano AI, Corzo-Garcia SC, Garcia-Sanchez E, Alfaro M, Castro-Camus E (2014) Quality control of leather by terahertz time-domain spectroscopy. Appl Opt 53:7872–7876. https://doi.org/10.1364/AO.53.007872

Iglesias-Díaz R, Pantoja-Enriquez J, Moreira-Acosta J, Farrera-Vázquez N, Íbañez-Duharte G (2011) Diseño de un secador solar con circulación forzada. Lacandonia 5:79–88

Lee D, Lohumi S, Cho BK, Lee SH, Jung H (2020) Determination of drying patterns of radish slabs under different drying methods using hyperspectral imaging coupled with multivariate analysis. Foods 9:484. https://doi.org/10.3390/foods9040484

Long J, Yang J, Peng J, Pan L, Tu K (2021) Detection of moisture and carotenoid content in carrot slices during hot air drying based on multispectral imaging equipment with selected wavelengths. Int J Food Eng 17:727–735. https://doi.org/10.1515/ijfe-2021-0127

Lóránd T, Deli J, Molnár P, Tóth G (2002) FT-IR study of some carotenoids. Helv Chim Acta 85:1691–1697. https://doi.org/10.1002/1522-2675(200206)85:6%3c1691::AID-HLCA1691%3e3.0.CO;2-G

Mujumdar AS (2006) Handbook of industrial drying, 3rd edn. CRC Press, Boca Raton. https://doi.org/10.1201/9781420017618

Murillo E, Giuffrida D, Menchaca D, Dugo P, Torre G, Meléndez-Martinez AJ, Mondello L (2013) Native carotenoids composition of some tropical fruits. Food Chem 140(4):825–836. https://doi.org/10.1016/j.foodchem.2012.11.014

Murillo E, Turcsi E, Szabó I, Mosquera Y, Agocs A, Nagy V, Gulyás-Fekete G, Deli J (2016) Carotenoid composition of the fruit of red mamey (Pouteria sapota). J Agric Food Chem 64:7148–7155. https://doi.org/10.1021/acs.jafc.6b03146

Nuss MC, Orenstein J (1998) Terahertz time-domain spectroscopy. In: Grüner G (ed) Millimeter and Submillimeter Wave Spectroscopy of Solids. Springer, Berlin, pp 7–50. https://doi.org/10.1007/BFb0103419

de Oliveira VE, Castro HV, Edwards HG, de Oliveira LFC (2010) Carotenes and carotenoids in natural biological samples: a Raman spectroscopic analysis. J Raman Spectrosc 41:642–650. https://doi.org/10.1002/jrs.2493

Onwude DI, Hashim N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci Food Saf 15:599–618. https://doi.org/10.1111/1541-4337.12196

Quijano-Ortega N, Fuenmayor CA, Zuluaga-Dominguez C, Diaz-Moreno C, Ortiz-Grisales S, García-Mahecha M, Grassi S (2020) FTIR-ATR spectroscopy combined with multivariate regression modeling as a preliminary approach for carotenoids determination in Cucurbita spp. Appl Sci 10:3722. https://doi.org/10.3390/app10113722

Sebben JA, da Silveira EJ, Ranzan L, de Moura NF, Trierweiler LF, Trierweiler JO (2018) Development of a quantitative approach using Raman spectroscopy for carotenoids determination in processed sweet potato. Food Chem 245:1224–1231. https://doi.org/10.1016/j.foodchem.2017.11.086

Servicio de información Agroalimentaria y Pesquera (2020) Anuario estadístico de la producción agrícola. https://www.gob.mx/siap/acciones-y-programas/produccion-agricola-33119 Accessed on May 08, 2022.

Solís-Fuentes JA, Ayala-Tirado RC, Fernández-Suárez AD, Durán-de-Bazúa MC (2015) Mamey sapote seed oil (Pouteria sapota). Potential, composition, fractionation and thermal behavior. Grasas Aceites 66:e056–e056. https://doi.org/10.3989/gya.0691141

Supriyanto A, Nurosyid F, Ahliha AH (2018) Carotenoid pigment as sensitizers for applications of dye-sensitized solar cell (DSSC). IOP Conf Ser Mater Sci Eng 432:012060. https://doi.org/10.1088/1757-899X/432/1/012060

Suvarnakuta P, Devahastin S, Mujumdar AS (2005) Drying kinetics and β-carotene degradation in carrot undergoing different drying processes. J Food Sci 70:s520–s526. https://doi.org/10.1111/j.1365-2621.2005.tb11528.x

Torres-Rodríguez A, Salinas-Moreno Y, Valle-Guadarrama S, Alia-Tejacal I (2011) Soluble phenols and antioxidant activity in mamey sapote (Pouteria sapota) fruits in postharvest. Food Res Int 44:1956–1961. https://doi.org/10.1016/j.foodres.2011.04.045

Villegas-Monter A (2016) Zapote mamey [Pouteria sapota (Jacq.) Moore and Stearn], diversidad y usos. Agro Product 9:47–54

Walsh KB, Blasco J, Zude-Sasse M, Sun X (2020) Visible-NIR ‘point’ spectroscopy in postharvest fruit and vegetable assessment: the science behind three decades of commercial use. Postharvest Biol Technol 168:111246. https://doi.org/10.1016/j.postharvbio.2020.111246

Wang X, Zhang X, Hong H, Guan C, Zhao C (2021) Non-destructive quantitative analysis of carotene content in carrots using Raman spectroscopy. Eur Food Res Technol 247(9):2299–2307. https://doi.org/10.1007/s00217-021-03788-w

Acknowledgements

We would like to thank Dr. Francisco Pola-Albores for the FTIR-ATR spectroscopy measurements. We also would like to thank Dra. Mónica Monserrat Martínez-García and M. C. Edgar Santiago Reyes-Reyes for their support in the measurements of Raman and THz spectra, respectively. G. L. M. thanks to National Council for Science and Technology (CONACYT) for the postdoctoral fellowship.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

GLM: Conceptualization, Methodology, Formal analysis, Writing-Original draft preparation. MFLP: Methodology. PL and RC: Resources, Writing—Review and Editing. HV: Conceptualization, supervision, Writing—Review and Editing, Supervision, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

López-Morales, G., López-Páez, M.F., López, P. et al. Detection of moisture ratio and carotenoid compounds in mamey (Pouteria sapota) fruit during dehydration process using spectroscopic techniques. J Food Sci Technol 60, 1952–1959 (2023). https://doi.org/10.1007/s13197-023-05728-w

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05728-w