Abstract

In the present study wheat (Triticum aestivum) cultivars were treated with industrial debranning step pre-milling both in a laboratory and a commercial mill to evaluate the benefits of this technology. Different levels of removal of wheat external layers were made (0 to 6%) and the results showed improved color of the flours (0.22 L* value units). Ash contents increased by 8.6% with debranning level, as a result of incorporating high ash aleurone layer in the resulted flour. The α-amylase activity was reduced by 33.8% and 19.8%, for the wheat and flour, respectively. Another benefit was the dropping of 70.6% of the deoxynivalenol (DON) levels. The experimental baking of flours produced with a wheat mix made up 40% Quartzo, 40% Baguette and 20% CD 150 varieties in a commercial mill after debranning resulted in breads with lighter crumb and crust color.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cereals are major sources of nutrients both for human and animal nutrition. They are available in large amounts and diversity and possess important nutritive macromolecules that also have key roles in food technology. Among main cereal crops, wheat outstands due to its versatility when milled to produce flour containing very special proteins that allow gluten network formation when hydrated and properly kneaded (Wringley 2009). Conventional wheat milling has the main objective of separating the parts (endosperm, bran and germ) of the kernel (Kalitsis et al. 2021). Fractions of the ground wheat kernels pass through repeated steps of grinding and sieving to separate the endosperm fractions and by reduction to be converted into a flour (Choy et al. 2015). Significant changes in mill flow diagram, equipment design and construction, instrumentation and automation occurred in the last century (Posner and Hoseney 2015). During the 1990’s an interesting technology from the rice milling (Satake Co., Japan) was suggested by Dexter and Wood (1996) to the wheat processing industry as a treatment of wheat prior to the conventional wheat milling. It is known as debranning and has the objective of removing superficial layers from the wheat kernels (bran) through mechanical abrasion promoted by special fabricated stones and friction between the kernels inside the equipment (Botega et al. 2009), improving the wheat flour production. This alternative process can help increasing the milling loads of conventional wheat mills due to reduction of almost one-third of the necessary stages in a milling flow sheet (Posner and Hibbs 2005), improves the color of the flours (Boatwright 2015), reduces enzymatic activity in the wheat, and in the produced flour (Gys et al. 2004) reduces the contamination with deoxynivalenol (DON) (Antal et al. 2010; Véha et al. 2015; Tibola et al. 2020). Debranning can also lower the microbiological and heavy metal contamination if present on external layers of the grains (Cheli et al. 2010). A significant change in the mill flow for debranned wheat compared with a conventional wheat milling is needed because the bran is removed from the surface of the kernel and expose part of the endosperm (Posner and Hibbs 2005). Even though the debranning system requires additional power, it is usually negligible, because of the significant increase of 30% or above, in the commercial milling unit capacity, per layout of existing equipment.

Therefore, the objective of the present study is to evaluate qualitative changes in performance of Quartzo, Baguette and CD 150 varieties used in Brazil, following treatment with the debranning technology.

Material and methods

Material

Three wheat varieties were used in the study, two Brazilian (CD 150 and Quartzo), and Baguette from Argentina. All wheat samples were debranned with a vertical commercial equipment with 6 MT/h capacity (VTA10AB-L, Satake Latin America Ltd., Joinville, SC, Brazil) (Satake 2013). The different levels of wheat debranning was obtained by adjusting the retention time of the wheat mass into the VTA equipment, which is used for debranning the cereal. It was performed by adjusting the position of the valve of exit flow and subsequent weight out the amount of bran sent to the filter. The percentage of debranned wheat was the result of amount of bran sent to the filter divided by the load mill.

Methods

To obtain an optimal kernel hardness for milling (Posner and Hibbs 2005) the wheat varieties were conditioned as follows according to their hardness level and millers experience: Baguette to 15.9% moisture and tempered for 22 h (PSI hardness 10.5%), CD 150 and Quartzo to 15.6% and tempered for 18 h (PSI hardness 12.3 and 12.5%, respectively).

The experiments were conducted in two stages. One of them in laboratory scale (AACC 2000, method 38-12 A) with Baguette variety and another with wheat mix of CD 150 variety (20%), Quartzo variety (40%) and 40% Baguette variety in a commercial mill.

Laboratory tests

Following the tempering time, the Baguette variety was industrially debranned to the following levels: 0, 2, 4, and 6% (in weight). Done that, two kilograms of each debranned wheat was milled in a laboratory mill (CD1 model mill, Chopin, Villeneuve-la-Garenne Cedex, France) (AACC 2000, method 38-12 A). Flour samples obtained from laboratory mill were used for the physicochemical analyses. The produced flours were analyzed for moisture (Brabender HAV, Brabender, Duisburg, Germany) (AACC 2000, method 54-21), enzymatic activity with the Perten 1500 Falling Number equipment (Perten, Stockholm, Sweden) (AACC 2000, method 26-10 A), and for ash contents (AACC 2001, method 08-12). Flour color was determined using a chromameter measuring equipment (Minolta Konica CR300s, Minolta, Tokyo, Japan) (AACC 2000, method 22-08) only for L* value due to its importance for the bakery flour specification. The rheological analyses included the wet gluten content (Glutomatic equipment, Perten, Stockholm, Sweden) (AACC 2000, method 44-15), farinography (Brabender Farinograph Typ 810,114, Brabender, Duisburg, Germany) (AACC 2000, method 54-30) and alveography (Chopin NG alveo consistograph, Chopin, Villeneuve-la-Garenne Cedex, France) (AACC 2000, method 56-81 B).

Industrial tests

In this experiment stage a wheat mix of the three mentioned varieties was, previously blended, and hereafter debranned. The industrial diagram used in this stage have the following technical specification: Nominal capacity of 250 MT/day, specific roll length of 9.73 mm/100 kg/24 h, specific sifter area of 0.042 m2/100 kg/24 h and purifier surface of 0.56 mm/100 kg/24 h. The wheat mix was debranned only to 2 and 6% (in weight) due to limitations of the industrial process. The flour obtained from industrial process was used for an experimental baking test, rheological and physicochemical tests as well.

Analysis

The wheat samples were analyzed for hardness according to the PSI methodology (Yamazaki and Donelson, 1983), ash contents (AACC 2000, method 08-12), enzymatic activity with the Perten 1500 Falling Number equipment (Perten, Stockholm, Sweden) (AACC 2000, method 56-81B), and DON measurement with the Neogen Elisa Kit (AOAC 2019). Scanning electron microscopy/field emission gun (MIRA 3, Tescan, Czech Republic) was used with 15 kV electron beam voltage and the samples fixed with double-faced carbon ribbons and metalized.

Experimental baking

The baking tests were performed using two kilograms of flour obtained by the industrial facility, adding 40 g of refined sugar, 32 g of refined iodide salt, 20 g of flour improver (ascorbic acid and azodicarbonamide) and 7 g of fresh biological yeast. The ingredients were transferred to the dough kneader machine (FAMAG Brazil, model AM.12, São Paulo, SP, Brazil) and mixed for 30 s. Water addition was made slowly (56% of water) at 1125 rpm for three minutes, changing to 2200 rpm until the gluten network become completely developed (total time of seven minutes). The formed dough was divided into 650 g balls that rested for 10 min covered by a plastic film. After this period the balls were molded (Perfecta nº 6 bread molding machine, Curitiba, PR, Brazil). The molded doughs fermented at 30 °C until desired development with the height surpassing by 4 cm above the upper rim of the bread pan. Breads were baked in an oven at 200 °C for 30 min. After 4 h of baking the specific bread volume test was conduct according to AACC 2001, method 10-05.

Statistical analysis

All the analyses were performed in triplicate and the analysis of variance (ANOVA) and the Tukey test (p < 0.05) were used for the statistical analysis. The Pearson correlation coefficient was also used to check if significant correlations were present between color (L* value), ash contents, enzymatic activity, and the external layer removal percentages. The Minitab 18 software (Minitab Co., State College, USA) was used in this study.

Results and discussion

Enzymatic activity (α-amylase) corresponds with previous studies (Liu et al. 1986; Hareland 1986), showing that the degree of removal of the external layers was related with decreasing of enzymatic activity (Falling Number) both in wheat grains and their flours (Table 1). When considering the Pearson correlation coefficients for the external layers’ removal percentage with the Falling Number of wheat and of the flour produced in experimental milling high values were found (r = 0.969, p < 0.0001 and r = 0.959, p < 0.0001, respectively).

Differences in enzymatic activities were widely reported for wheat kernel parts (Kruger and Tipple 1980; Every et al. 2002; Brier et al. 2015; Sakhare et al. 2015), with higher values in the aleurone, testa, pericarp, embryo, and scutellum. Removal of external layers that are more prone to higher α-amylase concentrations, showed significant reduction, by debranning and determination of Falling Number (FN). The FN of the control wheat compared to its flour (without debranning step), showed an increase by 37 s. In general, the reduction in FN with the conventional commercial milling process can be attributed to the design of the flow sheet and adjustment in separation of the bran and germ from the flour. The more severe the debranning, and deeper removal of external layers caused the FN increase, by 45, 60, 94, and 103 s, for 2, 4, and 6% bran removal, respectively (Kruger and Tipple 1980; Hareland 1986; Liu et al. 1986; Every et al. 2002; Sakhare et al. 2015).

Analysis of DON content in the wheat kernels, at different debranning levels is shown in Table 1. As a result of increasing levels of debranning, and more bran fractions are taken out, lower levels of DON were found for the Baguette variety (Table 2). These results are in line with a study in which the debranning technology reduced Fusarium and its natural mycotoxin contamination and also in samples artificially contaminated (Cheli et al. 2013; Véha et al. 2015; Savi et al. 2016). Our study showed that 2–4% outer kernel layers removal promoted around 50% reduction in DON level when compared with the control wheat (0%). With 6% removal of external layers the reduction of DON reached around 70%.

Ash content of produced flour in mills is still used as a measure of the extraction level (Oliver et al. 1993; Kim and Flores 1999) and quality in the commerce. Table 1 shows the values of color (L*) and ash contents for flour produced from debranned wheat.

Removal of external layers from wheat kernels improved the L* value contributing to the production of a “Premium” quality flour (Boatwright et al. 2015). The whiter flours also have higher ash contents, what is unexpected when thinking about conventional wheat milling (Mousia et al. 2004). With the use of debranning technology adapted to a conventional mill, however, the ash content cannot be considered anymore as indicative of extraction level or of the quality of the flours.

One of the explanations for this new behavior of wheat kernels after debranning has to do with the incorporation of the aleurone layer into the flour when debranning is included in the wheat milling (Dexter and Wood 1996). The aleurone layer has a bright/light color but has high contents of ash. Results are in line with a previous study (Atwell et al. 2007) that also produced lighter flours with higher ash contents due to aleurone layer incorporation. Accordingly, the ash content of flour should not be used as an indicator of extraction.

Analyzing the Pearson correlations found between ash content and color (L*) the value was r = 0.857 (p < 0.0001) and it describes a strong correlation with these two-quality parameter for the Baguette variety. It is related with the presence of aleurone layer into the flour according to evidence described by Boatwright et al (2015) and the use of this technology as a support to produce whiter flour but higher in ash content.

Scanning Electron Microscopy/ Field Emission Gun (FEG).

The images at 20 × magnification clearly show the morphological changes promoted by the mechanical abrasion. In the Fig. 1a, without debranning, it is possible to view the hairs of brush on upper side of the grains. In the Fig. 1b, with 2% removal of external layers a small remnant of brush is still visible. In the Fig. 1c, with 4% removal of the external layers very few hairs are visible; in the Fig. 1d, on the other hand, with 6% removal of the external layers, there is no visible hair anymore. The images show the sequential removal of external components of the kernel surface including parts of the epidermis.

The images at 500 × magnification show details of the structures of the wheat pericarp. In the Fig. 1f the original surface without any abrasion is visible whilst in the Fig. 1g and h some alterations on the surface are showed. Finally, in the Fig. 1I some starch granules entrapped in the protein network are apparent due to the deep abrasion and also some debris from the pericarp are still there.

Experimental baking

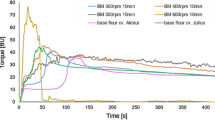

Table 2 shows results of selected analysis that correspond to Fig. 2 of the breads produced by experimental baking.

The experimental baking results show that higher removal of external layers brought benefits to the final product related with the color of the flour used for the bakery test, as well as with the higher falling number. Both results are in line with previously measured values from this study. Other consistent results were the ash content which increased as long as more abrasive was the process. The moisture values of the flours were 14.55% and 13.87%, for flours from 2 and 6% abrasion, respectively. The lower value for the higher abrasion degree may be associated with the more intensive abrasion that heated a little bit the grains.

Bread volume decreased by the use of debranning technology and the rheology also demonstrated some degree of changes for Farinograph and Alveograph comparing both tests. The reduction of bread volume is correlated to the changes in the rheology. The flour with higher level of debranning became weaker compared with lower level of abrasion. The development time was reduced considerably and the stability was also reduced for the removals 2 and 6%, respectively. The development time is crucial for the gluten formation and the fact that the procedure to bread making was the same for both indicates that the dough with 6% of debranning was stressed during kneading process and reduced the strength of the dough. The Alveograph results, as described in the Table 2, show that the flour became more extensive and less elastic. Comparing L values and P values it is confirmed that the flour became less mechanical resistant as increased the level of abrasion. The changes in the rheology suggest that the procedure of bread making needs to be adjusted according to the flour characteristics in order to avoid excessive mechanical effort to the dough and consequently impact in the bread volume.

The change in the rheology observed in the flour used for bread is very likely due to the fact the industrial mill was adjusted with the same general adjustment for both tests. This condition affects much more the wheat with less bran than with less intensive debranning and therefore with more bran. It is explained by the successive mechanical effort into the roller mill. Moreover, for the wheat with less bran and under more intensive mechanical process, part of the bran was fragmented to the flour’s granulation an it might has affected the interaction between this component and the protein network and thus interfering in the dough rheology. New studies are necessary to clarify these points and they must include wider sampling with more wheat varieties and with different mill adjustments.

In addition, probably the bakers will realize that the flour produced by this technology will need some degree of changes in the bakery process due to the modification of development time and stability. Therefore, this information must be clearly analyzed in advance before the flour utilization.

The experimental baking results confirmed that using the debranning technology the flour became lighter/whiter (> L*) with the higher removal of external layers and the breads produced also had lighter crumb and crust when comparing the two levels of abrasion (2 and 6% removal). In the Brazilian market, lighter/whiter flours and bread crumbs are valued and the debranning technology can be very useful from commercial point of view.

Conclusion

It was concluded that debranning installed in a conventional wheat milling produces several changes in the physical behavior of kernels as well as physicochemical and rheological changes in the produced flours. As a summary, the use of debranning technology previously to the mill is useful for the milling industry. Flour obtained with this technology can help the industry to use in a such level wheat with lower FN and deliver flour according to customer specification, and whiter flour as well. Changes in the flour rheology require special attention in the final use by the bakers.

Data availability

Experimental data used during the current study is available from the corresponding author on reasonable request.

Abbreviations

- DON:

-

Deoxynivalenol (µg/g)

- FN:

-

Falling number (s)

- L*:

-

Luminosity

- L :

-

Extensibility (from alveography)

- P :

-

Resistance/maximum pressure during inflation (from alveography)

- PSI:

-

Particle size index

- MT/h:

-

Metric tons per hour

- W :

-

Area under the curve (from alveography

References

AACC International. Method 08–12, Ash in Farina and Semolina; Method 14–22, Color of Pasta—Reflectance Colorimeter Method; Method 22–08, Measurement of alpha-Amylase Activity with Falling Number; Method 56–81B, Experimental Milling: Introduction, Equipment, Sample Preparation, and Tempering; Method 38–12 A, Wet Gluten, Dry Gluten, Water-Binding Capacity, and Gluten Index; Method 44–15, Moisture—Air-Oven Methods; Method 54–21, Farinograph Method for Flour; Method 54–30, Alveograph Method for Soft and Hard Wheat Flour; Method 56–81 B. Approved Methods of Analysis, 10th ed. St. Paul, 2000. Measurement of Volume by Rapeseed Displacement, Method 10–05, 11th ed. St. Paul, 2001.

Antal V, Szabó BP, Guimes E (2010) PeriTec technology to reduce fusarium toxin. Analele Universităţii Din Oradea, Fascicula: Protecţia Mediului 15:217–221

Association of Official Agricultural Chemists—AOAC. (2019) International Official Methods, 21th edition. Validation Procedures for Quantitative Food Allergen ELISA Methods: Community Guindance and Best Practices, Rockville

Atwell B, Reding VW, Earling J, Kanter M, Snow K (2007) Aleurone processing, nutrition, product development, and marketing—whole grains and health, vol 1. Blackwell Publishing, New York

Boatwright M, Posner E, Lopes R, Wetzel DL (2015) Profiling endosperm purity of commercial mill streams preceded by Debranning using quantitative chemical imaging. CFW 60:211–216. https://doi.org/10.1094/cfw-60-5-0211

Bottega G, Caramanico R, Lucisano M, Mariotti M, Franzetti L, Pagani MA (2009) The Debranning of common wheat (Triticum aestivum L.) with innovative abrasive rolls. J Food Eng 94:75–82. https://doi.org/10.1016/j.jfoodeng.2009.03.002

Brier N, Hemdane S, Dornez E, Gomand S, Delcour J, Courtin C (2015) Structure, chemical composition and enzymatic activities of pearlings and bran obtained from pearled wheat (Triticum aestivum L.) by roller milling. J Cereal Sci 62:66–72. https://doi.org/10.1016/j.jcs.2014.12.009

Cheli F, Campagnoli A, Ventura V, Brera C, Berdini C, Palmaccio E, Dell’orto V (2010) Effects of industrial processing on the distributions of deoxynivalenol, cadmium and lead in durum wheat milling fractions. LWT 43:1050–1057. https://doi.org/10.1016/j.lwt.2010.01.024

Cheli F, Pinotti L, Rossi L, Dell’orto V (2013) Effect of milling procedures on mycotoxin distribution in wheat fractions: A review. LWT 54:307–314. https://doi.org/10.1016/j.lwt.2013.05.040

Choy A, Walter K, Panozzo F (2015) Investigation of wheat milling yield based on grain hardness parameter. Cereal Chem 92(6):544–550. https://doi.org/10.1094/CCHEM-04-14-0072-R

Dexter J, Wood P (1996) Recent applications of Debranning of wheat before milling. Trends Food Sci Technol 7:35–41. https://doi.org/10.1016/0924-2244(96)81326-4

Every D, Simmons L, Al-Hakkak J, Hawkins S, Ross M (2002) Amylase, falling number, polysaccharide, protein and ash relationships in wheat millstreams. Euphytica 126:135–142. https://doi.org/10.1023/A:1019699000975

Gys W, Gebruers K, Sørensen J, Courtin C, Delcour J (2004) Debranning of wheat prior to milling reduces xylanase but not xylanase inhibitor activities in wholemeal and flour. J Cereal Sci 39:363–369. https://doi.org/10.1016/j.jcs.2004.01.002

Hareland GA (1986) Effect of pearling on falling number and alpha-amylase activity of preharvest sprouted spring wheat. Cereal Chem 80:232–237. https://doi.org/10.1094/CCHEM.2003.80.2.232

Kalitsis J, Minansy B, Quail K, McBratney A (2021) Application of response surface methodology for optimization of wheat flour milling process. Cereal Chem 98:1215–1226. https://doi.org/10.1002/cche.10474

Kim Y, Flores R (1999) Determination of bran contamination in wheat flours using ash content, color, and bran speck counts. Cereal Chem 76:957–961. https://doi.org/10.1094/CCHEM.1999.76.6.957

Kruger J, Tipples K (1980), Relationships between falling number, amylograph viscosity and α–amylase activity in Canadian wheat. Cereal Res Commun 8: 97–105. http://www.jstor.org/stable/23780402

Liu R, Liang Z, Posner E, Ponte J Jr (1986) A technique to improve functionality of flour from sprouted wheat. CFW 31:471–476

Mousia Z, Edherly S, Pandiella SS, Webb C (2004) Effect of wheat pearling on flour quality. Food Res Int 37:449–459. https://doi.org/10.1016/j.foodres.2004.02.012

Oliver J, Blakeney A, Allen H (1993) The color of flour streams as related to ash and pigment contents. J Cereal Sci 17:169–182. https://doi.org/10.1006/jcrs.1993.1017

Posner ES, Hoseney RC (2015) A century of advances in milling and baking. CFW 60:148–153. https://doi.org/10.1094/CFW-60-3-0148

Posner ES, Hibbs AN (2005) Wheat flour milling, vol 2. AACC, Saint Paul

Sakhare SD, Inamdar AA, Indrani D, Kiran MM, Rao GV (2015) Physicochemical and microstructure analysis of flour mill streams and milled products. J Food Sci Tech 52:407–414. https://doi.org/10.1007/s13197-013-1029-4

Satake (2013) Peritec System. Institutional Flyer , Joinville, Santa Catarina, Brazil

Savi GD, Piacentini KC, Tibola CS, Santos K, Maria GS, Scussel VM (2016) Deoxynivalenol in the wheat milling process and wheat-based products and daily intake estimates for the Southern Brazilian population. Food Control 62:231–236. https://doi.org/10.1016/j.foodcont.2015.10.029

Tibola CS, Fontes MR, Miranda MZ, Devos RJB, Dias ARG, Bock E, Zavareze ER (2020) Deoxynivalenol content, phenolic compunds, and antioxidant activity of wheat flour after debranning process. Pesq Agropec Bras 55:1–8. https://doi.org/10.1590/S1678-3921.pab2020.v55.01851

Véha A, Szabó P, Bartók T, Gyimes E (2015) Milling technological experiments to reduce Fusarium toxin contamination in wheat. Acta Univ Sapientiae, Aliment 8:55–62

Wrigley CW (2009) Wheat: a unique grain for world. In: Khalil K, Shewry PR (eds) Wheat chemistry and technology, vol 4. AACC, Saint Paul, pp 1–17

Yamazaki WT, Donelson JR (1983) Kernel hardness of some U.S wheats. Cereal Chem 60(5):344–355

Acknowledgements

Authors would like to thank CNPq and FINEP (Brazil) for financial support and to UEPG/PROPESP/C-LABMU (Brazil) for supporting laboratory facilities.

Author information

Authors and Affiliations

Contributions

RBL was responsible for concepting, data collection, discussion of results and preparing the manuscript; ESP was engaged in the discussion of the results, revision of the document and supervision; AA was engaged in discussion of the results and reviewing the final version; IMD was engaged in funding, concepting experiments, discussion of results, assistance in writing the initial version and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethics approval

The results presented in this MS are original and have not been submitted or published elsewhere.

Consent to participate

All the authors are aware of this submission to JFST and have read and approved the present version of the MS. The concerned authorities are aware of this submission as well.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barroso Lopes, R., Salman Posner, E., Alberti, A. et al. Pre milling debranning of wheat with a commercial system to improve flour quality. J Food Sci Technol 59, 3881–3887 (2022). https://doi.org/10.1007/s13197-022-05411-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05411-6