Abstract

Wheat dough added with baking dried yeast (BDY, 5 g) or baking powder (BP, 5 g) was leavened for 0, 2, 4 and 6 h for producing white bread (BBDY or BBD, respectively). The specific volume of BBDY was higher than for BBP. FTIR analysis revealed that BBP reduced the short-range crystallinity of starch granules, an effect magnified by the leavening time. Hardness and cohesiveness were higher for BBDY than for BBP which had a fragile crust structure. Readily digestible starch content of BBDY decreased (16.1–10.8%), while that of BBD increased at (17.1–31.5%) with leavening time. The opposite trend was found for resistant starch which increased from 71.2 to 79.1% for BBDY, and decreased from 69.3 to 40.2% for BBD. The hydrolysis rate constant for bread made with BP (~ 4 min−1) was about twofold faster than for BBDY.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Leavening is an important step in the bread production process. The leavening step is intended to increase the dough volume by incorporation of carbon dioxide, generating an expansion of the dough structure. In turn, leavening leads to the development of bread with increased porous, sponge-like structure, with enhanced textural properties. For centuries, native yeast S. cerevisiae has been used as leavening agent. Yeast converts sugars to carbon dioxide and alcohol via fermentative processes. In general, fermentation by native yeast is relatively slow, with typical fermentation times of about 8 h. Engineered yeast was designed to reduce the fermentation time, reducing the leavening period to about 0.5–1.0 h (Dequin 2001). DNA technology has allowed the development of new strains of baking yeast (Randez-Gil et al. 1999). Baking powder is a chemical leavening agent that has been in use for at least 100 years (Heidolph 1996). Baking powder is mainly made up by a mixture of sodium bicarbonate, potassium bitartrate and cornstarch. When water is added to a baking recipe, sodium bicarbonate and potassium bitartrate react to form bubbles of carbon dioxide gas according to the following stoichiometry (Brodie and Godber 2000):

The gas cells expand with heat causing the dough to rise when baked. As a matter of fact, chemical leavening agents can leaven dough faster than yeast because they do not require activation periods and specific environmental conditions for gas production (Heidolph 1996).

The effects of the leavening agent and time in the properties of dough and bread have been scarcely studied. For instance, Cepeda et al. (2000) reported that the composition of chemical leavening agents had a determinant effect in the quality of wheat flour tortillas. Gökmen et al. (2008) addressed the effect of leavening agents on the reactions leading to the formation of hydroxymethylfurfural in cookies in the baking process. Alvarez-Ramirez et al. (2019) studied the effect of leavening time on the nonlinear viscoelastic response of yeasted wheat dough. Overall, studies detailing the effects of leavening agents and leavening time on bread properties are required. In fact, studies in this line would provide important insights for the design of production strategies oriented to the fabrication of bread with prescribed nutritional and textural properties.

The task of this work was to assess the effects of the leavening agent (yeast versus baking powder) and leavening time on the textural and in vitro starch digestibility properties of white bread.

Materials and methods

Materials

Wheat flour (WF; moisture 13.1 g/100 g, protein 7.4 g/100 g, dietary fiber 0.5 g/100 g, lipids 0.4 g/100 g, ash 0.8 g/100 g), sugar, baking dry yeast, salt and baking powder were purchased at a local WalMart supermarket. α-amylase (Product 86,250, from Aspergillus oryzae, powder, 1.5 U/mg), amyloglucosidase (AMG, A7095, from Aspergillus niger, 260 U/mL), and pancreatin (P1750, from porcine pancreas, 300U/mL) were provided by Sigma-Aldrich (St. Louis, MO, USA). All other reagents used were analytical grade and purchased from J. T. Baker. Distilled water was used in all experimental runs.

Dough preparation

Wheat dough was prepared based on baking dry yeast (DBDY) and baking powder (DBP) as leavening agents. The preparation of the wheat dough was done as reported by Alvarez-Ramirez et al. (2018). Briefly, wheat flour (100 g), water (60 g), sugar (3 g), salt (1.5 g), and 5 g of dry yeast (for DBDY) or 5 g of baking powder (for DBP), were mixed (Laboratory Spiral Mixer, SP-800-J, Detmold, Germany) at low speed conditions (10 min), followed by high speed conditions (5 min). Water was incorporated at the start of the low-speed phase, and 1.5 g salt was incorporated at the start of the high-speed phase. The dough was allowed to rest (10 min), divided into 300 g portions and placed in silicone containers for fermentation in a leavening chamber (0, 2, 4 and 6 h at 28 °C, 85% relative humidity. For convenience, the resulting dough was tagged as either DBDY.x and DBP,x, and bread as BBDY.x and BBP,x, where the subindex “x” denotes the leavening time.

Dough viscoelasticity

Oscillatory strain measurements were conducted in a Physica MCR 300 rheometer (Physica Meβtechnik GmbH, Stuttgart, Germany) following the procedure of Alvarez-Ramirez et al. (2018). A cone-plate geometry was used, with the rotating cone having 50 mm diameter and the cone having angle 2° angle. The gap was set at 0.05 mm. Amplitude sweeps were obtained for 0.01–100% (1.0 rad s−1). The storage modulus (\(G^{\prime}\)) and the loss modulus (\(G^{\prime\prime}\)) were recorded and analyzed with the rheometer software (US200/32 V2.50).

Bread making

The leavened dough was distributed in stainless steel containers (size 25 × 10 × 10 cm) which were loaded into an automatically controlled static convection oven (Rational AG, Landsberg, Germany) under conditions 210 °C, and 20% relative humidity, for 25 min. Afterwards, the bread loaves were allowed to cool down to room temperature (approx. 20 °C).

Bread specific volume

The bread obtained after cooling was weighed (20 °C) and the corresponding volume was obtained via rapeseed displacement AACC method 10–05.01 (2010).

Moisture content

The moisture content was estimated by means of the AACC-method 44–15.02 (2010). Experimental measurements were conducted within the first 10 min after completing the making of the bread.

Texture

The texture of the breads was characterized by means of a Brookfield CT3-4500 texturometer (AMETEK Brookfield, Middleborough, MA, USA) endowed with a TA25/1000 aluminum cylinder probe with size 50.8 mm diameter and 20 mm length. The analysis was conducted in triplicate 3 h after completing the baking process.

Amylose content

The apparent amylose content was determined by the procedure reported by Hoover and Ratnayake (2002). Absorbance measurements were conducted in a Spectronic Genesys 2 UV–vis spectrophotometer (Thermo Fisher Scientific, Houston, TX, USA).

ATR-FTIR spectroscopy

Bread samples were also analyzed by ATR-FTIR spectroscopy by following the procedure described by van Soest et al. (1995). Measurements were obtained from a Perkin Elmer spectrophotometer (Spectrum 100, Perkin Elmer, Waltham, MA, USA) endowed with a crystal diamond universal ATR sampling accessory. A numerical deconvolution procedure with Gaussian functions (half-width of 15 cm−1, resolution enhancement 1.5) was carried out to obtain individual contributions for distinctive bands.

In vitro starch digestibility

The total starch (TS) content of bread samples was estimated by means of the standard AACC-method 76.13.01 (2010). On the other hand, the resistant starch (RS) content was obtained via the standard AACC method 32–40 (2010). To this end, kits from Megazyme International Ireland Ltd. (Bray Business Park, Bray, Co., Wicklow, Ireland) were used. In vitro starch digestion was carried out by following the methodology of Englyst et al. (1992). The estimated rapidly digestible starch (RDS) and the slowly digestible starch (SDS) fractions were adjusted relative to the available starch content. The expected glyemic index (GI) was computed according to the expression

where \(H_{90}\) is the hydrolysis index after 90 min.

Statistical analyses

The results were reported as the mean and standard deviation of triplicate experimental runs. The statistical analysis was made by means of ANOVA and Tukey’s tests for (statistical significance p ≤ 0.05) with software SPSS Statistics 19.0).

Results and discussion

Dough viscoelasticity

Doughs DBP.x (Fig. 1a) and DBDY,x (Fig. 1b) exhibited a predominant solid viscoelastic behavior as \(G^{\prime\prime}\) > \(G^{\prime}\) over the whole strain amplitude range studied. Both, \(G^{\prime}\) and \(G^{\prime\prime}\) displayed a monotonous decreasing pattern with respect to the applied strain amplitude independently of the leavening agent used. The decrease in \(G^{\prime}\) and \(G^{\prime\prime}\) was more pronounced the longer was the leavening time. These results indicate that dough malleability improved as larger strains were applied, and this behavior can be associated to the formation of gas cells in the dough bulk, that gave rise to an intricate dough porous network with reduced capability for resisting mechanical deformation. Higher amounts of gas were produced the longer was the leavening time, and the lesser the dough resistance to withstand mechanical external forces. Also, the incorporation of ionic species carried by the baking powder can induce alterations in gluten elasticity. For instance, it has been reported that sodium chloride has the ability of increasing non-covalent interactions and β-sheet structures in gluten proteins, leading to a less elastic dough network (Tuhumury et al. 2014). Figure 1c shows that the decreasing pattern of \(G^{\prime}\) and \(G^{\prime\prime}\) with leavening time depended on the leavening agent. The differences between the viscoelastic moduli magnitudes for DBDY were smaller than for DBP at all leavening times. At relatively short leavening times (~ 2.5–3 h) the viscoelastic moduli values were higher for DBP than for DBDY, but at longer leavening times (~ 3–4 h) a crossover of the viscoelastic moduli took place. As stated above, the decreasing viscoelastic moduli trend with leavening time can be explained as due to the formation of gas cells, but the crossover between the viscoelastic moduli can be explained by the changes arising in the dough components interactions (Tuhumury et al. 2014).

Storage (\(G^{^{\prime}}\), closed symbols) and loss (\(G^{^{\prime\prime}}\), open symbols) moduli of dough made with a baking powder (BPx), and b baking dried yeast (BDYx), where x = leavening agent time c Variation of \(G^{^{\prime}}\) and \(G^{^{\prime\prime}}\) with the leavening time. The values correspond to at 1% strain deformation

Specific volume

Images of the bread loaves cooled down to room temperature are presented in Figure S1. The upper row images correspond to breads made with baking powder, while the lower row images exhibit the breads made with baking dried yeast. The BBDY produced loafs with higher volume. Leavening time was positively correlated with the specific volume of both BBDY and BBP (Fig. 2a). As already stated above, baking powder had a lower capability for generating gas, and thus, the development a dough network interspaced with gas cells was lesser than for BBDY. Interestingly, the specific volume of BBDY with leavening time did not increase monotonously, showing a maximum value after about 4 h of leavening time, while for BBP, the specific volume increase was rather small, tending to flatten out after 2 h. In the case of BBDY, it seems that there is a critical leavening time of ~ 4 h when the amount of gas produced exceeds the elastic limit of the dough, which is not capable of retaining further gas. In such case, bread will display coarse and fragile crumb with a fallen center.

Moisture content

Figure 2b shows the variation of the moisture content of bread with respect to the leavening time. The moisture content of BBP was non-significantly higher than for BBDY at all leavening times. The lower specific volume of BBP indicated a more compact structure, which was accompanied by reduced water loss in the baking process. In general, the moisture content decreased with the leavening time, an effect that can be explained from the expanded dough structure induced by gas cell formation. That is, the expanded structure of leavened dough facilitated the mobility of water molecules in the gasified structure.

Hardness and cohesiveness

Hardness can be linked to the consolidation of the bread crust. Figure 2c shows that the hardness of BBP increased for leavening times up to 4 h. However, hardness decreased from 15.2 (4 h) to 12.3 N (6 h). A significantly lower hardness (~ 60–75%) was exhibited by BBDY than for BBD at all leavening times. During the first 2 h of leavening time hardness of BBDY decreased, but at longer leavening times hardness increased steadily. The increase of hardness with leavening time might be attributed to the expanded dough structure, which allowed a better convective transport in the dough bulk.

Cohesiveness is related to the whole bread structure. For short leavening times, up to 2 h, the cohesiveness of BBD was higher (0.7–0.75) than that for BBDY (0.63–67) (Fig. 2d). Cohesiveness can be related to the compactness of bread. Images of breads (Fig. 2) showed that the compactness of BBD was higher than for BBDY. However, the cohesiveness of BBDY increased monotonously, and became significantly higher (0.75) than that of BBP (0.67) after 6 h of leavening time. The results in Fig. 2 once more tend to indicate that not only leavening time affects the textural characteristics of the bread, but that the nature of the leavening agent and associated compounds (i.e. ionic species in baking powder, proteins and polysaccharides in baking yeast) also play an important role (Tuhumury et al. 2014; Arendt et al. 2007), among other factors.

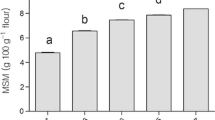

Amylose content and titratable acidity

The leavening action by baking powder is via neutralization mechanisms, leading to the generation of carbon dioxide. In principle, acids and bases are stoichiometrically balanced, such that hydrolysis of starch chains is unlikely. As expected, Fig. 3a shows that the apparent amylose content of BBP remained practically unchanged with leavening time. In contrast, baking yeast displays amylolytic activity (Vernon-Carter et al. 2018). This suggests that yeast might disrupt starch chains during the leavening process. Figure 3a shows that the apparent amylose content of BBDY decreased with leavening time. In fact, the amylose content of BBDY decreased from about 33 g/100 g total starch for unleavened bread, to about 26 g/100 g total starch after 6 h of leavening time. Besides, the amylose content decrease was monotonous, which suggests that the high leavening expansion of dough by the engineered commercial yeast was made at the expenses of sugars obtained from starch chain amylolysis. Figure 3b presents the variation of total reducing sugars with the leavening time. Interestingly, BBP showed an increased total reducing sugars with the leavening time, maybe caused by incipient hydrolysis of starch chains by weak acids in the baking powder. In contrast, BBDY presented a continuous decrease of total reducing sugars with leavening time, an effect ascribed to the metabolic yeast activity. Figure 3c presents the titratable acidity as function of the leavening time. The titratable acidity of BBP remained practically unchanged with leavening time, displaying values of about 0.32 mmol H+/100 g. In contrast, the titratable acidity of BBDY increased from about 0.60 mmol H+/100 g for unleavened bread to about 1.35 mmol H+/100 g after 6 h leavening time. This increase can be attributed to catalytic activity of S. cerevisiae during the fermentation of glucose present in the amylose and amylopectin chains of wheat flour to produced organic acids (Sauer et al. 2008).

FTIR

Figure 4a presents the FTIR spectra BBP and BBDY for the different leavening times. The wide band in the range 3700–3000 cm−1 is commonly linked to vibrations of OH groups and reflects hydration of the bread components (Warren et al. 2016)..The peaks at about 2925 cm−1 and 1745 cm−1 are related to free lipids and starch-lipid complexes (Flores-Morales et al. 2012; Chen et al. 2017). Here, methyl group (–CH3) in 2995–2886 cm−1, methylene group (–CH2) in 2886–2783 cm−1 and ester group in 1793–1693 cm−1 are attributed to functional groups of fatty acids. The vibrational response of protein groups in the amide regions were located at 1700–1600 for Amide I and 1600–1500 cm−1 for Amide II. Finally, the fingerprint band 1100–950 cm−1 is linked to C–O–C stretching and CO (–COH) stretching of starch chains (van Soest et al. 1995). Of particular interest for the present study is the molecular organization of starch as affected by leavening time and leavening agents. Specifically, the peak located at about 995 cm−1 is related to hydrated crystalline structures, the peak at about 1022 cm−1 to amorphous starch domains, whilst the peak at about 1047 cm−1 to ordered formations. In this way, the intensity ratios 995/1022 and 1047/1022 are common considered respectively as indices of hydrated structures and short-range ordered structures (e.g., double-helices) relative to amorphous domains (van Soest et al. 1995). Figure 4b presents an example of the deconvolution of the starch fingerprint region, showing that the response signal can be accurately described by the three peaks aforementioned. Figure 4c presents the variation of the FTIR ratio 995/1022 as function of the leavening time. It is noted that this ratio was higher for the BBP at all leavening times. This result is in line with the moisture content shown in Fig. 2b. In fact, the compactness of DBP allows the higher retention of water molecules, and hence the higher content of hydrated starch domains. Relative to the leavening time, the ratio 995/1022 showed a monotonous decreasing pattern. The expansion of the dough structure by effect of the gas cells allowed an improved convective heat transfer in the baking process, which in turn allowed the removal of more water molecules. Figure 4d shows the variation of the FTIR ratio 1047/1022 with respect the leavening time. BBDY exhibited highest 1047/1022 ratio, and hence the highest content of crystalline domains in the starch contained in the bread bulk. Besides, the ratio increased with leavening time for BBDY. The highest value of the 1047/1022 ratio of BBDY relative to BBP can be explained from the amylolytic activity of the yeast strain used for leavening (Vernon-Carter et al. 2018). Amylolytic enzymes undergo hydrolysis of starch chains, mainly from amorphous regions, to produce sugars (Reyes et al. 2016), which are subsequently used for biomass and carbon dioxide production. Hence, the ordered domains in the starch granules increase with the leavening time. In contrast, the FTIR ratio for breads made with baking powder showed only small variations with leavening.

Hydrolysis kinetics

The progress curve of the starch hydrolysis from amylolytic enzymes is shown in Fig. 5a. A fast hydrolysis phase was shown for the first 15–20 min, which might be related to the outer amorphous layers of the starch granule. The second phase, from approx. 20 min to approx. 80 min, exhibited an inflexion pattern, with slower hydrolysis rate. Starch granules are blended with diverse flour components (e.g., proteins and lipids), forming complexes that hamper the action of amylolytic enzymes. The final phase presents a rather slow hydrolysis rate, reflecting the presence of a starch fraction that resists the hydrolytic activity of amylolytic enzymes. Importantly, for all leavening times the hydrolyzed starch percentage was higher for BBP. This is in line with the values of the FTIR ratio 1047/1022 (Fig. 4d), which reflect that the starch in these breads have higher ordering (i.e., short-range crystallinity domains). This effect induced by the yeast amylolytic activity in the leavening process led to reduced rates of hydrolysis during the digestion process. Although the progress curves in Fig. 4a exhibited a complex pattern, the dominant rate constant of the hydrolysis kinetics was computed according with the Goñi et al. (1997) equation \(X(t) = \left( {1 - e^{{ - k_{H} t}} } \right)X_{\infty }\), where \(X(t)\) is the hydrolysis advance, \(X_{\infty }\) is the maximum hydrolysis advance, and \(k_{H}\) is the hydrolysis rate constant Goñi et al. 1997). Figure 5b shows the hydrolysis rate constant as function of the leavening time. Interestingly, the rate constant increased with the leavening time for BBP. This means that leavening with baking powder facilitated the action of amylolytic enzymes, an effect that might be ascribed to reduced ordering (Fig. 4d). In contrast, the rate constant for BBDY decreased with the leavening time. This means that leavening with yeast had a detrimental effect in the amylolysis of starch chains in breads. The limiting hydrolysis percentage is shown in Fig. 5c. As already observed in Fig. 5a, BBP presented higher values of the limiting hydrolysis percentage. Besides, this percentage increased with the leavening time. However, for BBDY the limiting hydrolysis percentage showed only slight variations with leavening time.

In vitro digestibility

Table 1 shows the results of in vitro digestibility of starch, using Englyst et al. (1992) method. The unleavened breads BBP,0 and BBDY,0 showed non-significant (p < 0.05) different values of RDS, SDS and TS contents. However, leavening time affected the digestibility of starch in the breads, and this affectation was dependent on the leavening agent. For BBP, the RDS fraction increased with the leavening time, and this increase was at the expense of a decreasing RS fraction. This trend contrasts with the pattern observed for BBDY. In fact, the RDS and SDS fractions showed an important decrement after 2 h of leavening time. For higher leavening times, these starch fractions showed a non-significant difference in value. It is noted that while BBD showed a significant decrease in RS, BBDY exhibited a significant increase with leavening time. This effect is not surprising at all given, since BBDY showed an increased short-range crystallinity with leavening time as detected by the FTIR ratio 1047/1022. In fact, enzymes initiate hydrolysis preferably at amorphous domains of starch granules, while in domains with increased crystallinity, the rate of acid hydrolysis is limited (Reyes et al. 2016). Finally, the variation of the glycemic index (GI) is also shown in Table 1. Bread leavened with baking powder presented higher values of the GI, indicating that baking powder produced beads with higher glucose release. Similar to the results presented by the digestible starch fractions, the higher the leavening time, the higher the GI value for the bread obtained with baking powder. The opposite pattern was obtained with dried yeast as leavening agent.

Conclusion

The leavening time and the type of leavening agent played important role in the textural and in vitro digestibility properties of white bread. Besides providing gas cells for expanding the dough structure, the leavening agents produced structural changes in the molecular organization of starch in the bread crumb. Yeast produced breads with increased hardness as compared with bread produced with baking powder. This feature was interpreted in terms of the stability of the crust, such that yeast led to more consolidated bread structure. In general, leavening time had a positive effect in bread hardness and cohesiveness. On the other hand, the RS content of bread made with baking powder decreased, while that of bread made with yeast increased with leavening time. The latter behavior was attributed to the amylolytic activity of yeast, which reduced the number of amorphous domains of starch granules. The RDS fraction increased with the leavening time for bread made with baking powder. However, this trend was not observed for bread made with baking yeast. Overall, the results shown in this work indicated that the leavening agent not only acts as a generator of gas cells, but also modifies the structure and functionality of the wheat flour components. In particular, in vitro digestibility is largely affected by the choice of agent used for leavening the dough.

Availability of data and material

Experimental data is available under request.

References

AACC (2010) International AACC approved methods of analysis, 11th edn. AACC, St. Paul, MN

Alvarez-Ramirez J, Rodriguez-Huezo E, Meraz M, Garcia-Diaz S, Flores-Silva PC, Mondragon-Reinoso L (2018) Spatial variation of in vitro starch and protein digestibility in white wheat bread. Starch-Stärke 70:1800025. https://doi.org/10.1002/star.201800025

Alvarez-Ramirez J, Carrera-Tarela Y, Carrillo-Navas H, Vernon-Carter EJ, Garcia-Diaz S (2019) Effect of leavening time on LAOS properties of yeasted wheat dough. Food Hydrocoll 90:421–432. https://doi.org/10.1016/j.foodhyd.2018.12.055

Arendt EK, Ryan LA, Dal Bello F (2007) Impact of sourdough on the texture of bread. Food Microbiol 24:165–174. https://doi.org/10.1016/j.fm.2006.07.011

Brodie J, Godber J (2000) Bakery processes, chemical leavening agents. Kirk-Othmer Encycl Chem Technol. https://doi.org/10.1002/0471238961.0308051303082114.a01.pub2

Cepeda M, Waniska RD, Rooney LW, Bejosano FP (2000) Effects of leavening acids and dough temperature in wheat flour tortillas. Cereal Chem 77:489–494. https://doi.org/10.1094/CCHEM.2000.77.4.489

Chen L, Tian Y, Sun B, Cai C, Ma R, Jin Z (2017) Measurement and characterization of external oil in the fried waxy maize starch granules using ATR-FTIR and XRD. Food Chem 242:131–138. https://doi.org/10.1016/j.foodchem.2017.09.016

Dequin S (2001) The potential of genetic engineering for improving brewing, wine-making and baking yeasts. Appl Microbiol Biotechnol 56:577–588. https://doi.org/10.1007/s002530100700

Englyst HN, Kingman SM, Cummings JH (1992) Classification and measurement of nutritionally important starch fractions. Eur J Clin Nutr 46:S33-50

Flores-Morales A, Jiménez-Estrada M, Mora-Escobedo R (2012) Determination of the structural changes by FT-IR, Raman, and CP/MAS 13 C NMR spectroscopy on retrograded starch of maize tortillas. Carbohyd Polym 87:61–68. https://doi.org/10.1016/j.carbpol.2011.07.011

Gökmen V, Açar ÖÇ, Serpen A, Morales FJ (2008) Effect of leavening agents and sugars on the formation of hydroxymethylfurfural in cookies during baking. Eur Food Res Technol 226:1031–1037. https://doi.org/10.1007/s00217-007-0628-6

Goñi I, García-Alonso A, Saura-Calixto F (1997) A starch hydrolysis procedure to estimate glycemic index. Nutr Res 17:427–437. https://doi.org/10.1016/S0271-5317(97)00010-9

Heidolph BB (1996) Designing chemical leavening systems. Cereal Foods World 41:118–126 (ZDBID: 193391-7)

Hoover R, Ratnayake WS (2002) Starch characteristics of black bean, chick pea, lentil, navy bean and pinto bean cultivars grown in Canada. Food Chem 78:489–498. https://doi.org/10.1016/S0308-8146(02)00163-2

Randez-Gil F, Sanz P, Prieto JA (1999) Engineering baker’s yeast: room for improvement. Trends Biotechnol 17:237–244. https://doi.org/10.1016/S0167-7799(99)01318-9

Reyes I, Cruz-Sosa F, Roman-Guerrero A, Vernon-Carter EJ, Alvarez-Ramirez J (2016) Structural changes of corn starch during Saccharomyces cerevisiae fermentation. Starch-Stärke 68:961–971. https://doi.org/10.1002/star.201600088

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids: expanding the markets. Trends Biotechnol 26:100–108. https://doi.org/10.1016/j.tibtech.2007.11.006

Tuhumury HCD, Small DM, Day L (2014) The effect of sodium chloride on gluten network formation and rheology. J Cereal Sci 60:229–237. https://doi.org/10.1016/j.jcs.2014.03.004

van Soest JJ, Tournois H, de Wit D, Vliegenthart JF (1995) Short-range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohydr Res 279:201–214. https://doi.org/10.1016/0008-6215(95)00270-7

Vernon-Carter EJ, Alvarez-Ramirez J, Bello-Perez LA, Garcia-Hernandez A, Garcia-Diaz S, Roldan-Cruz C (2018) The in vitro digestibility of starch fractions in maize tortilla can be rendered healthier by treating the nixtamalized masa with commercial baking yeast. J Cereal Sci 82:216–222. https://doi.org/10.1016/j.jcs.2018.07.001

Warren FJ, Gidley MJ, Flanagan BM (2016) Infrared spectroscopy as a tool to characterize starch ordered structure—a joint FTIR–ATR, NMR, XRD and DSC study. Carbohydr Polym 139:35–42. https://doi.org/10.1016/j.carbpol.2015.11.066

Funding

None.

Author information

Authors and Affiliations

Contributions

AGH conceived and carried out experiments; CRC processed experimental data; EJVC supervised the experiments and wrote the first MS draft; JAR carried out experiments.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

The results contained in the manuscript are original and have not submitted or published elsewhere.

Consent to participate

All authors agreed to participate in the experimental project and the manuscript writing.

Consent for publication

All authors agreed to publish the results in JFST.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Garcia-Hernandez, A., Roldan-Cruz, C., Vernon-Carter, E.J. et al. Effects of leavening agent and time on bread texture and in vitro starch digestibility. J Food Sci Technol 59, 1922–1930 (2022). https://doi.org/10.1007/s13197-021-05206-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05206-1