Abstract

The industrial processing of acerola (Malpighia emarginata D.C.) produces huge quantities of waste material that are badly discarded or undervalued. In spite of this, acerola wastes have a high content of antioxidant compounds. The aim of this work was to study the extraction of antioxidant compounds from acerola residues using ultrasound assisted extraction. Using multiple regression techniques, the effects of ethanol concentration in the hydroethanolic solution (C), extraction time (t), temperature (T), and liquid–solid ratio (R) on the total phenolic content, total flavonoid content and antioxidant potential were investigated. The best extraction conditions were identified using the desirability function, which is a multi-response optimization technique. The optimal processing parameters were 67.5% of ethanol concentration, temperature of 80.9 °C, liquid/solid ratio of 59.8 mL/g, and extraction time of 13.6 min. HPLC–UV has been used to identify the main antioxidant compounds obtained under these optimal condition. Based on the results, acerola waste has high potential for better use, such as in food and pharmaceutical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Acerola (Malpighia emarginata D.C.), which originates from tropical America, is a fruit widely cultivated in Brazil. Due to its high levels of vitamin C and others antioxidant compounds like phenols and flavonoids, this fruit have been industrially used to produce juice and jelly (Duzzioni et al. 2013; Silva et al. 2016).

Huge quantities of wastes are produced by the acerola processing industry that may correspond to approximately 40% of the processed volume (Duzzioni et al. 2013). These wastes are usually discarded or undervalued, which cause environmental impact and in wastage of a material that could be better used. In addition, Nogueira et al. (2019b) found that the acerola wastes had high levels of phenols and flavonoids and other antioxidant compounds, some of which are higher in values than those in the edible parts of the fruit (Bortolotti et al. 2013; Silva et al. 2013). This fact has led to the growing effort to find a better use of the residues from the acerola processing industry (Andrade et al. 2016). The extraction of the antioxidant compounds from acerola wastes could be an important step in the better use of this waste, enabling the incorporation of these compounds in products of the food, cosmetic, and pharmaceutical industry (Silva et al. 2016).

Solid phase extraction step is generally used prior to chromatographic determination of bioactive compounds. Therefore, the solvent and the extraction method can influence the final result. In addition to conventional solid–liquid extraction (SLE), there are various other methods for extracting antioxidant compounds from plants, including pressurized liquid–solid extraction (Taham et al. 2015), microwave-assisted extraction (Cardoso-Ugarte et al. 2014) and ultrasound-assisted extraction (Goula et al. 2016). The conventional solid–liquid extraction has some disadvantages such as the need for long periods of time during the extraction process and relatively low yields (Cardoso-Ugarte et al. 2014; Barrozo et al. 2013).

Ultrasound-assisted extraction is an alternative technique, which has various advantages compared with the conventional extraction, including lower process time, smaller amounts of solvents, and a higher extraction rate. This extraction technique has been studied in the extraction of antioxidant compounds from various materials, such as medicinal herbs, fruits and plants (Xu et al. 2017; Jovanović et al. 2017; Goula et al. 2016).

During the ultrasound assisted extraction (UAE), a combination of several mechanisms occurs enhancing the extraction efficiency of organic compounds. The ultrasound waves cause the collapse of cavitation bubbles in the liquid leading to a fragmentation of friable solids. The reduction of particle size increases the surface area resulting in higher mass transfer. The sonocapillarity and the sonoporation effects may also be involved in the UAE. The first one refers to the increase of penetration of liquid into canals and pores under some conditions of sonication and the second is the modification of the cell membrane permeability through sound waves, usually ultrasonic frequencies (Chemat et al. 2017).

In this work, the extraction of antioxidant compounds from acerola residues using UAE was investigated. Multiple regression technique was used to quantify the effects of the process time, solvent concentration, temperature, and liquid/solid ratio on the total content of the main antioxidant compounds (phenolic and flavonoid) and antioxidant potential. The desirability function was used to identify the best extraction conditions. The main antioxidant compounds obtained under optimum operating conditions were identified using HPLC method with ultraviolet (UV) detector (HPLC–UV).

Materials and methods

Material

The acerola wastes used in the experiments were obtained from the Frutpres Company (Presidente Olegário, Brazil). The acerola wastes had been previously dried, triturated, sieved (0.6 mm), packed and stored at − 18 °C. The acerola waste used in the experiments had a moisture content of 7.1 ± 0.5 g/100 g (dw), a pH of 3.88 and an ascorbic acid content of 3558.7 ± 131.0 mg/100 g (dw).

Gallic, caffeic, p-coumaric acids, rutin, and 2,2-diphenyl-1-picrylhydrazyl (DPPH) were purchased from Sigma-Aldrich (St. Louis, USA). Acetonitrile, methanol, ethanol, acetic, and phosphoric acids were supplied by Merck (Darmstadt, Germany).

Extraction procedures

The ultrasound-assisted extractions (UAE) were performed in an Embrasol ultrasonic bath model LS-55DA-2X (Itanhém, Brazil) with frequency of 33 kHz and power of 1050 W. During the tests, the fruit residues were protected from light exposure. The variables temperature (T), ethanol concentration (C), process time (t), and liquid/solid ratio (R) were analyzed. The volume of the hydroethanolic solution was kept constant (40 mL) in all experiments. After extraction, the filtrate was analyzed in order to determine its total contents of phenolic and flavoinoid compounds, and its antioxidant potential.

A conventional solid–liquid extraction (SLE) was performed in a vortex using ethanol as solvent. The liquid/solid ratio used in this experiment was the same that found in the optimum condition of the UAE. The solution volume used was 40 mL (Silva et al. 2016).

Bioactive compounds and DPPH

The analyses for determination of bioactive compounds in this work were: Total phenolic content (TPC) and Total flavonoid content (TFC). In addition to these bioactive compounds determination, the DPPH (radical scavenging activity) analyses were also performed, as an indicative of antioxidant capacity. These analyses were carried out in a Pró-análise UV–Vis spectrophotometer model V-1200 (Porto Alegre, Brazil).

The TPC was measured by the Folin-Ciocalteu assay (Singleton and Rossi 1965). Gallic acid monohydrate (99%) was used as a standard to prepare the calibration curve, which reading was from 0.2 to 2.0 mg/mL. The TPC in the extract was presented in term of milligram gallic acid equivalent (GAE)/100 g (dw).

The aluminium chloride colorimetric assay (Zhishen et al. 1999) was used to measure the TFC. Rutin hydrate (94%) was used as a standard. The linear standard curve reading was from 20 to 80 µg/mL.The TFC was presented as µg of rutin/100 g (dw).

The 2,2-diphenyl-1-picryl-hydrazyl (DPPH) radical scavenging method, as described by Brand-Wiliams et al. (1995), was used for evaluating the antioxidant potential of the extracts. The IC50 of the acerola waste was measured by spectrophotometric method (at 515 nm). The IC50 is the amount of an antioxidant required to decrease the initial DPPH concentration by 50%. The lower IC50 value indicates the greater overall effectiveness of the antioxidant.

HPLC characterization

The extract generated under optimum point was analyzed using a HPLC–UV for identification of the main bioactive compounds. The obtained extract was concentrated by rotary evaporation and re-dissolved using methanol. Then, it was filtered using a 0.22 µm microporous membrane. Phenolic acids and flavonoids were identified by comparing the retention times and peaks area with those of pure standards. The analyses were performed in a Shimadzu HPLC (model LC-20AT Prominence) (Kyoto, Japan) equipped with a controller CBM-20A system, an automatic liquid sampler (ALS), an UV–Vis Detector (model SPD-20AV), and a Discovery HS C18 column. The flow rate was set to 0.7 mL/min at 40 °C and the injection volume was set to 20 µL.

The phenolic acids were identified using the methodology reported by Ribeiro et al. (2015). The mobile phases were acetic acid 2% (eluent A) and a mixture of acetic acid 0.5% and acetonitrile (50:50; eluent B). The gradient program was from 10 to 24% B (20 min), from 24 to 30% B (20 min), from 30 to 55% B (20 min), from 55 to 100% B (15 min),100% B isocratic (8 min), from 100 to 10% B (2 min). The run time was 90 min and the phenolic acid elution was monitored at 280 nm.

The procedures outlined in Haminiuk et al. (2012) were used to identify the flavonoid compounds. The mobile phases were acidified water with phosphoric acid 1% (v/v, eluent A) and acetonitrile (eluent B). The gradient program was from 0 to 15% B (2 min), 15–25% B (3 min), 25–30% B (5 min),30–35% B (5 min), 35–50% B (10 min), 50–60% B (5 min), 60–80% B (5 min), 80–100% B (10 min), and 100–5% B (15 min) with total run time of 60 min. The flavonoid elution was monitored at 320 nm.

Spectral analysis FT-IR

The FT-IR spectrum was obtained using a Bruker Equinox 55 spectrometer (Ettlingen, Germany). The spectrum was scanned in the range from 4000 to 400 cm−1 with KBr (potassium bromide) tablets and the sample/KBr ratio was kept constant.

Experimental design and data analysis

The ultrasound-assisted extractions of antioxidant compounds from acerola waste were performed under different operating conditions. The investigated factors were ethanol concentration in the hydroethanolic solution (× 1), extraction time (× 2), temperature (× 3), and liquid/solid ratio (× 4). For each variable, 5 levels were selected according to a central composite design (CCD) with five replicates at central levels and orthogonal alpha of 1.547 (Barrozo et al. 1998). The experimental runs were performed randomly in order to minimize systematic errors. The analyzed responses included the total contents of phenolic and flavonoid compounds (TPC and TFC) and the IC50. The independent variables were transformed into dimensionless (coded) forms using Eqs. (1–4).

where C is in %, t is in min, T is in °C, and R is in mL/g.

Regression equations were obtained by fitting the experimental data of each response into a polynomial model (Eq. 5) (Barrozo et al. 2014).

where y is the specific dependent variable (TPC, TFC or IC50), βo is the independent parameter, βi, βii and βij are respectively the coefficients related to the linear, quadratic and interaction effects.

The effects of the independent variables on each dependent variable were calculated and the significant parameters determined by an analysis of variance (ANOVA). Non-significant coefficients (p > 0.05) were then eliminated and the final prediction equation was fitted. The adequacy of the fitted equations were evaluated based on the values of the correlation coefficient, F and p.

The multiple response optimization used in this work was the desirability function (Derringer and Suich 1980). To verify the suitability of this methodology, extraction under the optimized conditions was performed and the results compared with the predicted values calculated by the regression equations.

Results and discussion

Experimental results

Table 1 shows the TPC, TFC and IC50 results for each run of the experimental design. These three responses show great sensitivity to variations in the operating conditions. The TPC ranged between 100.7 mg GAE/100 g dw (run 23) and 910.5 mg GAE/100 g dw (run 6). Run 23 yielded the lowest TPC, which was performed at the lowest liquid/solid ratio (R = 4.2 mL/g) and an intermediate ethanol concentration (C = 81.8%), temperature (T = 50 °C) and process time (t = 60 min). The highest TPC was obtained in run 6, which was performed at a high (1) extraction time (t = 90 min) and liquid/solid ratio (R = 50 mL/g) and a low (− 1) ethanol concentration (C = 70%) and temperature (T = 30 °C).

Run 23 also yielded the lowest TFC (0.6 µg of rutin/100 g dw), whereas the greatest TFC was obtained in run 12, which was performed at a high (1) ethanol concentration (C = 93.6%), temperature (T = 70 °C), and liquid/solid ratio (R = 50 mL/g), and a low (− 1) process time (t = 30 min). The IC50 ranged between 6.3 µg/mL (run 4) and 41.9 µg/mL (run 9).

To quantify the effects of the independent variables on the studied responses, polynomial models were fitted to the experimental data and response surfaces constructed. Table 2 shows the multiple regression results for the three responses. The prediction equations for TPC, TFC, and IC50 yielded r2 of 0.98, 0.93, and 0.91, respectively.

The TPC was mainly affected by the linear parameters of the ethanol concentration (negative effect) and the liquid/solid ratio (positive effect), as well as the quadratic contributions of ethanol concentration and liquid/solid ratio. In addition to these parameters, two interactions were significant, i.e., the interaction between temperature and ethanol concentration (β13), and that between ethanol concentration and the liquid/solid ratio (β14).

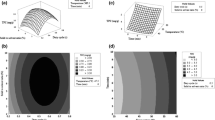

These effects can be clearly observed in Fig. 1a–c, in which these response surfaces reveal the stronger effects on the TPC of the ethanol concentration (coded x1) and liquid/solid ratio (coded x4). High TPC values can be obtained with a low C value and high R value. Adding a low amount of water in organic solvents generally generates a medium more polar, which helps the phenolic-compounds extraction. Most plant materials contain polar phenols that are more easily extracted in hydroethanolic mixtures instead of absolute ethanol (Tsakona et al. 2012). In addition, an excess of solvent (high R) favors the mass transfer process due to the greater antioxidant compounds concentration gradient. It can also be noted that the extraction times used in the experiments were sufficient for phenolic-compounds extraction. Goula et al. (2016) emphasized that UAE enables extraction times up to 100 times shorter than those required when using conventional methods. This may occur due to the solids fragmentation caused by the cavitation bubbles collapse, the sonocapillarity, the sonoporation, and the mixing effect generated by the waves propagation (Chemat et al. 2017).

The parameters that significantly (p < 0.05) affected the TFC were the linear coefficients of the liquid/solid ratio and temperature (positive effects), and the quadratics contributions of C and R, as well as the parameter related to the T and R interaction (β34). The response surfaces presented in Fig. 1d–f show the strongest effects on the TFC of temperature (coded x3) and liquid/solid ratio (coded x4). The best results were obtained with high levels of these variables (T and R). As the temperature increases, the solubility of the analytes enhances and facilitates the diffusion and extraction of these compounds (Lou et al. 2010).

Lower values of IC50 is an indicative of higher antioxidant activity. The parameters that negatively and significantly affected the IC50, i.e., indicating an improvement in the antioxidant activity, were the linear coefficients of temperature and liquid/solid ratio, which is the same trend observed for TFC. The linear effect of ethanol concentration, as well as the quadratic contributions of ethanol concentration and liquid/solid ratio, were also significant. Figure 1g–i show the response surfaces with these significant effects. The similar behavior of the three responses in relation to the independent variables are clearly verified in Fig. 1.

Ghitescu et al. (2015) extracting polyphenols from spruce wood bark and Tomšik et al. (2016) extracting bioactive compounds from wild garlic (Allium ursinum L.) observed similar behavior than that found in this work related to the effect of ethanol concentration and temperature on the extraction of these compounds. Furthermore, Paz et al. (2015) observed that an increase in the liquid–solid ratio led to a enhancing in extraction of polyphenols from native plants in the Mexican desert using UAE.

Optimization study

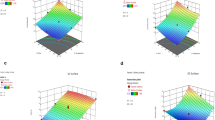

In order to determine the best operating conditions, i.e., those that lead to the highest TPC and TFC values and the lowest IC50, a multiple response optimization study based on desirability functions was performed. Figure 2 shows the overall desirability function data, from which can observed that the extraction time (coded × 2) did not influenced the optimazion of TPC, TFC, and IC50.

Figure 2 also show a synthesis of the best experimental range. Based on the results, the optimum conditions were as follows: the highest temperature (80.9 °C) and liquid/solid ratio (59.8 mL/g), the ethanol should be between 67.2 and 67.8%, so the average value (67.5%) was chosen. Since, the time was not statistically significant for any of the responses, the shortest time used in the CCD (13.6 min) was selected.

Confirmatory experiments were performed at this optimum conditions and the results obtained were 931.2 ± 40.1 mg/100 g (dw) for TPC, 4.8 ± 0.3 mg/100 g (dw) for TFC, and 5.6 ± 0.3 µg/mL for IC50. The predicted values from the regression equations under these conditions were 912.1 mg/100 g (dw), 5.2 mg/100 g (dw), and 5.9 µg/mL for TPC, TFC, and IC50, respectively. This means that the prediction deviations were 2.1% for TPC, 8.3% for TFC, and 5.4% for IC50, indicating that the regression equations were able to successfully predict the responses analyzed.

Figure 3 shows the TPC, TFC and IC50 results obtained in the 27 CCD experiments, as well as those obtained under optimized conditions. The responses obtained under the optimized conditions are indicated by a horizontal line. The highest TPC and TFC values and the lowest IC50 value, obtained under optimized conditions as compared with those obtained in all the CCD experiments confirm the appropriateness of the methodology used in this study.

An extra extraction of antioxidant compounds of the acerola residue was performed using the conventional solid–liquid extraction (SLE). This experiment was carried out in the liquid–solid ratio indicated in the optimized conditions of ultrasound-assisted extraction, i.e., 59.8 mL/g. The results obtained using the SLE were: TPC = 211.8 ± 4.5 mg/100 g (dw), TFC = 2.5 ± 0.3 mg/100 g (dw), and IC50 = 18.8 ± 0.4 µg/mL. It can be observed that the values found using the UAE were 339.7% and 92% greater than those obtained using the SLE for TPC and TFC, respectively. On the other hand, the IC50 obtained in UAE was 70.2% lower than that obtained in conventional extraction.

HPLC results

An HPLC assay of the extracts generated at the optimum conditions was performed, which showed a major presence of gallic acid (111.7 ± 16.0 mg/100 g dw), caffeic acid (1.4 ± 0.2 mg/100 g dw), p-coumaric acid (4.9 ± 0.2 mg/100 g dw) and rutin (1.2 ± 0.2 mg/100 g dw). No quercetin, kaempferol or ferulic acid were detected. The levels of the compounds obtained from acerola residues in this work are consistent with those obtained in previous studies of acerola. For example, Nogueira et al. (2019b) found the 84.58 mg/100 g (dw) of gallic acid, 2.92 mg/100 g (dw) of p-coumaric acid, and 0.91 mg/100 g (dw) of rutin for acerola residues. Therefore, the results found in this work were 32.1%, 67.8% and 31.9% higher for gallic acid, caffeic acid, p-coumaric acid, and rutin, respectively, as compared with this previous study.

The antioxidant properties of phenolic acids are related to heart disease and cancer prevention, cholesterol inhibition, and healthy aging (Zhao et al. 2017). Gallic and caffeic acids can inhibit the lipid peroxidation process and p-coumaric acids may have useful therapeutic effects in the prevention of vascular disorder, as thrombosis (Janicke et al. 2005). Rutin has antidiabetic and anti-inflammatory properties, and may have useful effect in Parkinson's disease treatment (Gullón et al. 2017). Therefore, the bioactive compounds extraction from acerola residues is a good alternative that can add value to this material, such as for use by the pharmaceutical industry.

Infrared spectroscopy

Figure 4 shows the infrared spectrum of the acerola residues, which is similar to the one described by Nogueira et al. (2019a) also for the acerola residue. These spectra also have similarities with those of other lignocellulosic biomasses, differing only in the intensity of the peaks and bands (Ghitescu et al. 2015).

The bands observed at 3398 cm−1 and 2924 cm−1 are characteristic for hydroxyl stretching vibrations and the axial deformation of CH that can be attributed to phenolics and carboxylic acids (Anjos et al. 2015; Liao et al. 2015). The peaks from 1631 cm−1 to 1452 cm−1 are due to the OH vibrations of water molecules and polyphenols, stretching of the carbonyl (C=O), and the phenyl ring (C=C) (Cascant et al. 2016; Movasaghi et al. 2008). The absorption band at 1294 cm−1 can be related to the C=C–O–C stretch (Jin et al. 2007). The peak at 1151 cm−1 corresponds to the C–OH of phenyl (Hu et al. 2016). The bands between 1200 and 1050 cm−1 are associated to phenolic compounds and the C-O stretching vibration of the polysaccharide. The region between 800 and 550 cm−1 is related to the vibrations of various carbonates as well as being characteristic of aromatic C–H and N–H amines (Cascant et al. 2016).

Conclusion

The main conclusions of this study were as follows:

-

The extracts of acerola residue were rich in antioxidant compounds

-

The optimum operating conditions were ethanol concentration of 67.5%, extraction time of 13.6 min, temperature of 80.9 °C, and liquid/solid ratio of 59.8 mL/g.

-

These optimum conditions yielded a TPC of 931.2 ± 40.1 mg GAE/100 g (dw), a TFC of 4.8 ± 0.3 mg rutin/100 g (dw), and an IC50 of 5.6 ± 0.3 µg/mL.

-

The HPLC analyses and FT-IR results enabled the identification of antioxidant compounds that are associated with disease prevention

-

Ultrasound Assisted Extraction yielded better results when compared with those obtained using conventional extraction.

References

Andrade LA, Barrozo MAS, Vieira LGM (2016) Thermo-chemical behavior and product formation during pyrolysis of mango seed shell. Ind Crops Prod 85:174–180. https://doi.org/10.1016/j.indcrop.2016.03.004

Anjos O, Campos MG, Ruiz PC, Antunes P (2015) Application of FTIR-ATR spectroscopy to the quantification of sugar in honey. Food Chem 169:218–223. https://doi.org/10.1016/j.foodchem.2014.07.138

Barrozo MAS, Murata VV, Costa SM (1998) The drying of soybean seeds in countercurrent and concurrent moving bed dryers. Dry Technol 16(9–10):2033–2047. https://doi.org/10.1080/07373939808917510

Barrozo MAS, Santos KG, Cunha FG (2013) Mechanical extraction of natural dye from Bixa orellana seeds in spouted bed. Ind Crops Prod 45:279–282. https://doi.org/10.1016/j.indcrop.2012.12.052

Barrozo MAS, Mujundar A, Freire JT (2014) Air-drying of seeds: a review. Dry Technol 32(10):1127–1141. https://doi.org/10.1080/07373937.2014.915220

Bortolotti CT, Santos KG, Francisquetti MCC, Duarte CR, Barrozo MAS (2013) Hydrodynamic study of a mixture of west indian cherry residue and soybean grains in a spouted bed. Can J Chem Eng 91(11):1871–1880. https://doi.org/10.1002/cjce.21870

Brand-Wiliams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Cardoso-Ugarte GA, Sosa-Morales ME, Ballard T, Liceaga A, San Martín-González MF (2014) Microwave-assisted extraction of betalains from red beet (Beta vulgaris). LWT Food Sci Technol 59(1):276–282. https://doi.org/10.1016/j.lwt.2014.05.025

Cascant MM, Sisouane M, Tahiri S, Krati MEL, Cervera ML, Garrires S, Guardia M (2016) Determination of total phenolic compounds in compost by infrared spectroscopy. Talanta 153:360–365. https://doi.org/10.1016/j.talanta.2016.03.020

Chemat F, Rombaut N, Sicaire AG, Meullemiestre A, Fabiano-Tixier AS, Abert-Vian M (2017) Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason Sonochem 34:540–560. https://doi.org/10.1016/j.ultsonch.2016.06.035

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12(4):214–219. https://doi.org/10.1080/00224065.1980.11980968

Duzzioni AG, Lenton VM, Silva DIS, Barrozo MAS (2013) Effect of drying kinetics on main bioactive compounds and antioxidant activity of acerola (Malpighia emarginata D.C.) residue. Int J Food Sci Technol 48(5):1041–1047. https://doi.org/10.1111/ijfs.12060

Ghitescu RE, Volf I, Carausu C, Bühlmann AM, Gilca IA, Popa VI (2015) Optimization of ultrasound-assisted extraction of polyphenols from spruce wood bark. Ultrason Sonochem 22:535–541. https://doi.org/10.1016/j.ultsonch.2014.07.013

Goula AM, Thymiatis K, Kaderides K (2016) Valorization of grape pomace: drying behavior and ultrasound extraction of phenolics. Food Bioprod Process 100:132–144. https://doi.org/10.1016/j.fbp.2016.06.016

Gullón B, Lú-Chau TA, Moreira MT, Lema JM, Eibes G (2017) Rutin: a review on extraction, identification and purification methods, biological activities and approaches to enhance its bioavailability. Trends Food Sci Technol 67:220–235. https://doi.org/10.1016/j.tifs.2017.07.008

Haminiuk CWI, Plata-Oviedo MSV, Mattos G, Carpes ST, Branco IG (2012) Extraction and quantification of phenolic acids and flavonols from Eugenia pyriformis using different solvents. J Food Sci Technol 51(10):2862–2866. https://doi.org/10.1007/s13197-012-0759-z

Hu Y, Pan ZJ, Liao W, Li J, Gruget P, Kitts DD, Lu X (2016) Determination of antioxidant capacity and phenolic content of chocolate by attenuated total reflectance-Fourier transformed-infrared spectroscopy. Food Chem 202:254–261. https://doi.org/10.1016/j.foodchem.2016.01.130

Janicke B, Önning G, Oredsson SM (2005) Differential effects of ferulic acid and p-coumaric acid on S phase distribution and length of S phase in the human colonic cell line Caco-2. J Agric Food Chem 53(17):6658–6665. https://doi.org/10.1021/jf050489l

Jin GP, Chen QZ, Ding YF, He JB (2007) Electrochemistry behavior of adrenalin, serotonin and ascorbic acid at novel poly rutin modified paraffin-impregnated graphite electrode. Electrochim Acta 52(7):2535–2541. https://doi.org/10.1016/j.electacta.2006.08.068

Jovanović AA, Đorđević VB, Zdunić GM, Pljevljakušić DS, Šavikin KP, Gođevac DM, Bugarski BM (2017) Optimization of the extraction process of polyphenols from Thymus serpyllum L. herb using maceration, heat- and ultrasound-assisted techniques. Sep Purif Technol 179:369–380. https://doi.org/10.1016/j.seppur.2017.01.055

Liao N, Zhong J, Ye X, Lu S, Wang W, Zhang R, Xu J, Chen S, Liu D (2015) Ultrasonic-assisted enzymatic extraction of polysaccharide from Corbicula fluminea: characterization and antioxidant activity. LWT Food Sci Technol 60(2):1113–1121. https://doi.org/10.1016/j.lwt.2014.10.009

Lou Z, Wang H, Zhang M, Wang Z (2010) Improved extraction of oil from chickpea under ultrasound in a dynamic system. J Food Eng 98(1):13–18. https://doi.org/10.1016/j.jfoodeng.2009.11.015

Movasaghi Z, Rehman S, Rehman I (2008) Fourier transform infrared (FTIR) spectroscopy of biological tissues. Appl Spectrosc Rev 43(2):134–179. https://doi.org/10.1080/05704920701829043

Nogueira GDR, Duarte CR, Barrozo MAS (2019a) Hydrothermal carbonization of acerola (Malphigia emarginata DC) wastes and its application as an adsorbent. J Waste Manag 95:466–475. https://doi.org/10.1016/j.wasman.2019.06.039

Nogueira GDR, Silva PB, Duarte CR, Barrozo MAS (2019b) Analysis of a hybrid packed bed dryer assisted by infrared radiation for processing acerola (Malpighia emarginata DC) residue. Food Bioprod Process 114:235–244. https://doi.org/10.1016/j.fbp.2019.01.007

Paz JEW, Márquez DBM, Ávila GCM, Cerda REB, Aguilar CN (2015) Ultrasound-assisted extraction of polyphenols from native plants in the Mexican desert. Ultrason Sonochem 22:474–481. https://doi.org/10.1016/j.ultsonch.2014.06.001

Ribeiro LF, Ribani RH, Francisco TMG, Soares AA, Pontarolo R, Haminiuk CWI (2015) Profile of bioactive compounds from grape pomace (Vitis vinifera and Vitis labrusca) by spectrophotometric, chromatographic and spectral analyses. J Chromatogr B 1007:72–80. https://doi.org/10.1016/j.jchromb.2015.11.005

Silva DIS, Nogueira GDR, Duzzioni AG, Barrozo MAS (2013) Changes of antioxidant constituents in pineapple (Ananas comosus) residue during drying process. Ind Crop Prod 50:557–562. https://doi.org/10.1016/j.indcrop.2013.08.001

Silva PB, Duarte CR, Barrozo MAS (2016) Dehydration of acerola (Malpighia emarginata DC) residue in a new designed rotary dryer: effect of process variables on main bioactive compounds. Food Bioprod Process 98:62–70. https://doi.org/10.1016/j.fbp.2015.12.008

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Taham T, Cabral FA, Barrozo MAS (2015) Extraction of bixin from annatto seeds using combined technologies. J Supercrit Fluids 100:175–183. https://doi.org/10.1016/j.supflu.2015.02.006

Tomšik A, Pavlić B, Vladić J, Ramić M, Brindza J, Vidović S (2016) Optimization of ultrasound-assisted extraction of bioactive compounds from wild garlic (Allium ursinum L.). Ultrason Sonochem 29:502–511. https://doi.org/10.1016/j.ultsonch.2015.11.005

Tsakona S, Galanakis CM, Gekas V (2012) Hydro-ethanolic mixtures for the recovery of phenols from Mediterranean plant materials. Food Bioprocess Technol 5(4):1384–1393. https://doi.org/10.1007/s11947-010-0419-0

Xu D, Zheng J, Zhou Y, Li Y, Li S, Li H (2017) Ultrasound-assisted extraction of natural antioxidants from the flower of Limonium sinuatum: optimization and comparison with conventional methods. Food Chem 217:552–559. https://doi.org/10.1016/j.foodchem.2016.09.013

Zhao G, Zhang R, Liu L, Deng Y, Wei Z, Zhang Y, Ma Y, Zhang M (2017) Different thermal drying methods affect the phenolic profiles, their bioaccessibility and antioxidant activity in Rhodomyrtus tomentosa (Ait.) Hassk berries. LWT Food Sci Technol 79:260–266. https://doi.org/10.1016/j.lwt.2017.01.039

Zhishen J, Mengcheng T, Jianming W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem 64(4):555–559. https://doi.org/10.1016/S0308-8146(98)00102-2

Acknowledgements

We would like to thank the Brazilian agencies CNPq, CAPES and FAPEMIG for supporting our investigations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silva, P.B., Mendes, L.G., Rehder, A.P.B. et al. Optimization of ultrasound-assisted extraction of bioactive compounds from acerola waste. J Food Sci Technol 57, 4627–4636 (2020). https://doi.org/10.1007/s13197-020-04500-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04500-8