Abstract

Fermented cucumber pickles are the lactic acid fermentation products formed through the influence of microorganisms present in the environment. This study investigated the impacts of starter cultures, namely, Lactobacillus plantarum, Lactobacillus pentosus and Lactobacillus paraplantarum, typically utilized for the fermentation of traditional pickled gherkins, on fermentation process. The chemical (pH, total acidity and salt) and microbiological (total mesophilic aerobic bacteria, lactic acid bacteria and yeast-mould) changes were observed against the control sample during fermentation process. Moreover, the amounts of biogenic amines (BAs) and metabolites formed as a consequence of fermentation were determined using HPLC. It was found that the chemical analyses provided similar results for all the samples. The amount of total mesophilic aerobic bacteria and yeast-mould colonies in pickle sample containing L. plantarum 49 strain appeared to reduce significantly. The amount of BAs was the lowest for the pickle samples where L. plantarum strains were added. The amount of BAs was below the toxic value that could affect human health. More BAs were synthesized as the fermentation period increased. Lactate was seen to exist in the samples when pyruvate was present, and acetoin was converted into 2.3-butanediol during the fermentation period. It was concluded that the pickle sample for which L. plantarum 49 strain was used displayed a better fermentation profile (i.e., metabolite and biogenic amines) than the remaining samples. Producing a more delicious and reliable product using such characteristics of L. plantarum strains in pickled gherkins is believed to significantly contribute to the food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pickles are one of the important non-dairy probiotic products that form as a consequence of the lactic acid fermentation (Panghal et al. 2018). Pickles are produced through the fermentation of fruits and vegetables in brine or in their own juices that contain certain salt concentrations with Lactic Acid Bacteria (LAB), and they are frequently associated with cucumber (Aktan et al. 1998).

Lactic acid bacteria possess the feature of important microorganisms due to their organoleptic, nutritional and physicochemical properties (Sáez et al. 2018). In the initial and primary phase of pickle fermentation, the dominant lactic acid bacteria in the medium are Enterococcus faecalis, Leuconostoc mesenteroides, Lactobacillus brevis, Pediococcus pentocaceus, Lactobacillus plantarum and Lactobacillus pentosus species (Liao et al. 2017). L. plantarum completes the fermentation of fruits and vegetables since it has higher acid tolerance than other lactic acid bacteria (Plenghvidhya et al. 2007). It has a significant impact on the provision of microbial balance and on the quality of the final product in cucumber and cabbage fermentation (Lu et al. 2003).

Biogenic amines (BAs) are formed based on the decarboxylation of some specific amino acids in foods or depending on the transamination of aldehydes and ketones (Doeun et al. 2017). Although the most commonly known types of biogenic amines are histamine and tyramine, amines such as tryptamine, putrescine, cadaverine, serotonin, spermidine, spermine, agmatine and phenylethylamine also appear as a consequence of many food decarboxylase activities (Rabie et al. 2011).

The metabolites in fermented products such as phenols and flavonoids have led to a promising new approach in the determination of the metabolite profiles of microorganisms (Panghal et al. 2017). Lactic Acid Bacteria convert sugars into lactic acid, formic acid, acetic acid, ethanol, acetoin and 2.3-butanediol through pyruvate and using EMP pathway (Hutkins 2006). It is known that the starter cultures are used to produce fermented foods, and they are known to be effective directly and indirectly in the formation of BAs and metabolites as a result of their interaction with normal microbial flora when foods are produced and stored (Liu et al. 2017).

The present study aims to use Lactobacillus as a starter culture in traditional gherkin cucumber pickle production. During the fermentation process, chemical (pH, total acidity and salt) and microbiological (total mesophilic aerobic bacteria, lactic acid bacteria and yeast-mould) changes were observed against the control sample. The BAs and metabolites, formed as a result of starter culture effects depending on external factors (pH, salt, acidity and microbial flora), were analyzed with High-Performance Liquid Chromatography (HPLC).

Materials and methods

Obtaining the gherkins

The Vertina gherkins (Cucumis sativus) that would be used in preparing pickle were obtained from the Bilge villages in Mazidagi District of Mardin.

Obtaining the starter culture and preparation of it

In this study, 5 Lactobacillus strains (L. plantarum 49, L. plantarum 51, L. plantarum 13, L. pentosus 2 and L. paraplantarum 16) were used as the starter culture. The functional characteristics (i.e., BAs synthesis, metabolite amounts and antibiotic resistance) of these strains were determined previously (Alan 2015; Alan et al. 2018). LAB isolates were cultured in MRS broth at 37 °C for 18 h to obtain 9 Log CFU/mL concentration. Each of the cultured 10 mL isolates was centrifuged at 4500 rpm for 20 min. The cell pellets were then collected, and were washed twice in 0.85% NaCl. In order to produce 6 Log CFU/mL LAB suspension for initial inoculation, 1 mL of 9 Log CFU/mL culture was added to 650 mL brine juice containing 5% rock salt.

Preparation of pickled gherkins

Seven different gherkin pickle samples were prepared. The prepared samples were encoded as control (5% salty water), S2 (5% salty water + 100% wine vinegar (50 mL)), S3 (5% salty water + L. plantarum 49), S4 (5% salty water + L. plantarum 51), S5 (5% salty water + L. plantarum 13), S6 (5% salty water + L. pentosus 2) and S7 (5% salty water + L. paraplantarum 16), respectively. A total of 400 g of washed and dried gherkins were put into 1.3 L pickle jars. A total of 650 mL brine water containing 5% rock salt was added into each jar; and 1 mL of the stock culture with ca. 9 Log CFU/mL of the starter culture was added. The pickle jars were left at 20–25 °C for 60 days. The pH, total acidity, salt and microbiological analyses (total mesophilic aerobic bacteria, LAB and yeast-mould) of the pickle samples were conducted on the 15th, 30th and 60th days of the fermentation, and the chemical and microbiological changes occurring during the fermentation process were observed. Furthermore, the amount of biogenic amines and metabolite was determined with the HPLC on the 30th and 60th days of the fermentation process. In this study, the pickle trials were made in 3 repetitions.

Determination of the total acidity, salt and pH values

For the purpose of the determination of the total acidity in the brine samples, 9 mL distilled water was added to 1 mL sample. Then, the alkali amount was determined by titrating the samples until adjusted solution of 0.1 N NaOH (Merck, Germany) became slightly pink. Then 2–3 drops of 1% phenol phthalate (Merck, Germany) was added. Total acidity was calculated as lactic acid and acetic acid percentages (Fernández-Diez et al. 1985). The pH values of the brine samples were measured with a pH meter that was calibrated by using standard buffer at pH 4.1, 7.0 and 10.1 (HACH, HQd Field Case, USA).

The amount of salt in the brine samples was determined by using the Mohr Method. For this purpose, 1 mL was taken from the brine samples and diluted with 9 mL distilled water. Then, 1 mL 5% potassium dichromate (K2CrO4) (Merck, Germany) solution was added to the dilution and was titrated with 0.1 N AgNO3 (Merck, Germany) solution until the color became red. The amount of AgNO3 solution consumed for total was recorded, and the total amount of salt was calculated as percentage (Aktan and Kalkan 2000).

Microbiological analyses

The count of total mesophilic aerobic bacteria and LAB was respectively carried out in the Plate Count Agar (PCA) and De Man, Rogosa and Elisabeth Sharpe (MRS) broth medium and using the Spread Cultural Counting Method (Aryal 2016). The samples were incubated at 37 °C for 24–48 h, and the colonies were then counted. The yeast-mould count was made in Potato Dextrose Agar (PDA) following the Spread Cultural Counting Method. The samples were incubated at 25 °C for 48–72 h in order to conduct colony counts (Xiong et al. 2016). Colony-forming units were calculated as Log CFU/mL. For cell counting, isotonic solution (0.85% NaCl) was used, and appropriate decimal dilutions were prepared.

Determination of the amounts of the biogenic amines

The main stock of BAs was prepared by weighing the final concentrations of spermidine (Chem Service, USA), histamine dihydrochloride, putrescine dihydrochloride, cadaverine and tyramine hydrochloride (Dr. Ehrenstorfer, Germany) as 1 mg/mL and by dissolving with 0.4 M perchloric acid (Sigma-Aldrich, USA) in 10 mL falcon tubes. A total of 5 mL of the stock solutions of each BA was diluted with 0.4 M perchloric acid to prepare different concentrations of the standard solution. Each standard stock solution was used to prepare 6 different dilutions (5, 10, 25, 50, 75 and 100 ppm). A total of 10 g pickle samples and 10 mL of brine juice were taken and were homogenized (IKA T18 D Ultra Turrax, Germany), and 2 mL of the homogenate was taken into 10 mL falcon tubes. 5 mL 0.4 M perchloric acid was then added and shaken for 60 min. After that, it was made to 10 mL with 5% trichloroacetic acid (Sigma-Aldrich, USA). Following this step, 400 μL was taken from the solution prepared from the pickle extract and was added into 10 mL falcon tubes with caps wrapped with aluminum foil before performing derivatization. Sodium carbonate, dansyl chloride and sodium glutamate (Sigma-Aldrich, USA) solutions utilized in derivatization were prepared daily. The phase obtained in the derivatization was taken and filtered through filters with 0.45 μm pore diameter. It was then transferred to Eppendorf tubes and were stored at − 20 °C until HPLC analysis. For the mobile phase, solvent A was prepared with 30 mL buffer (0.1 M Tris, 0.1 M acetic acid and pure water were added at a rate of 2, 1, 2, respectively), 550 mL acetonitrile, 420 mL pure water. On the other hand, solvent B was prepared with 2 mL buffer, 900 mL acetonitrile and 100 mL pure water (Alan et al. 2018).

Determination of the amount of the fermentation metabolites

The stock standards were prepared with the final concentrations of pyruvate, lactate, ethanol, acetoin, hydrogen peroxide (H2O2), acetic acid and 2.3-butanediol standards as 1 mg/mL by dissolving with 0.5% metaphosphoric acid (MPA) in 10 mL falcon tubes. The stock standards were prepared as 4-point dilution (50, 100, 150 and 200 ppm), and were loaded to the HPLC. A total of 10 g pickle sample and 10 mL brine juice were homogenized; and 5 mL homogenate was put into 10 mL falcon tubes, and was centrifuged at 8000 rpm for 5 min. Then, 1 mL supernatant was put to Eppendorf tube that had 1 mL 1% MPA. After the tube was stirred for 2 min with vortex, it was centrifuged for 2 min at 12,000 rpm. The supernatant part was passed through filters with 0.45 μm pore diameter, and ca. 0.5 mL was then transferred to vials. The samples were loaded to the HPLC in order to determine the metabolites in the supernatants. For the mobile phases, 0.5% MPA was used (Alan et al. 2018).

For BAs and metabolite analysis, the Agilent Technologies 1260 Infinity II HPLC (Agilent, USA) was used. The HPLC configuration consisted of a 1260 DAD WR detector (BAs; 254 nm and metabolites; 192 and 210 nm wavelength), 1260 Quat Pump VL pump (BAs; 1.3 mL/min and metabolites; 1 mL/min flow rate), 1260 Vial sampler (20 μL injected) and G7130A column furnace (28 °C). The analytical column used for the analysis was ACE 5 C18 (V17-1586; 250 × 4.6 mm id).

Statistical evaluation

All the statistical analyses were carried out using the GraphPad Prism 8 Statistical Software, and Dunnett and Tukey tests. The mean values of the data (n 3) were given by calculating the ± SD. The Two-Way (ANOVA) Variance Analysis was applied on the data obtained during the fermentation. The differences were considered significant at p < 0.05.

Results and discussion

Total acidity in gherkin fermentation, the changes in pH and salt values

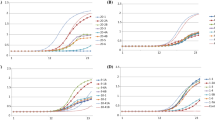

It was found that the titrable acetic acid and lactic acid rates of the gherkin pickles increased from the 0th day to the 30th day during the fermentation, whereas on the 60th day these rates were observed to decrease to the values measured on the 15th day (Fig. 1). The gherkin pickle samples were compared with the control sample, and the acidity of sample S3 was seen to show significant difference from the others (p < 0.0001). In the previous studies, it was reported that a total amount of 0.8–1.2% lactic acid was produced in the gherkin fermentation (Franco et al. 2012). Titrable acidity increased rapidly in the first days of the fermentation and stabilized in the following days (Nilchian et al. 2016). In this study, it was observed that there was a rapid increase in the first 15 days of the fermentation, and the acidity rate became relatively stable as the fermentation time increased. For the gherkin pickles prepared using 5% salt, the amount of salt decreased rapidly in the first 15 days. The salt rate increased again on the 30th day, and it started to decrease on the 60th day, and then became stable (Fig. 1). Compared to the control sample, S5, S6 and S7 pickle samples showed a high-level significant difference (p < 0.0001). During the fermentation, a rapid decrease was observed in the pH rates in all pickle samples until the first 15 days (Fig. 1). In the following periods of the fermentation, the pH showed a stable state. Only the S2 pickle sample exhibited a significant difference (p < 0.0001). In the previous studies, Tamang et al. (2009) reported that 38% of the LAB strains showed a strong acidification by decreasing the pH below 5. Excessive salt concentration limited the ability of LAB to produce acid. With a decrease in the salt concentration, the pH decreased as a result of increasing acid production (Rodríguez-Gomez et al. 2012). The pH values dropped sharply at initial stages, and then gradually reached a stable level (Nilchian et al. 2016). The results presented in this study correlate well with the findings of previous studies.

Microbiological changes in gherkin fermentation

As seen in Fig. 2, the total LAB count increased at a high rate until the 15th day for the samples of control and S2. Figure 2 also shows that a high-level and significant difference was detected for the total number of LABs in 6 pickle samples when compared to that in the control sample (p < 0.0001). The total LAB count decreased from the 15th day to the 30th day, and then remained stable until the 60th day. Wouters et al. (2013) indicated that LABs may have short metabolic cycle, poor salt tolerance and acid resistance. The decrease in the total LAB count in sample S2 following the 15th day of the fermentation is considered to be associated with the aforementioned properties of the LAB. Xiong et al. (2016) suggested that the LAB probably dominant in the fermentation medium formed the homo-fermentation with strong salt tolerance and acid resistance. In this study, the total LAB count remained stable in the samples, excluding S2, on the 30th and 60th days. This may be ascribed to the homo-fermentation forming feature.

The total mesophilic aerobic bacteria count showed a fast increase in the control and S2 samples until the 15th day (Fig. 2). However, there was a serious decrease in S7 sample. It is considered that the decrease in the total number of mesophilic aerobic bacteria probably occurred due to dominant LABs in the medium as the fermentation period progressed. A significant and high difference was detected in the S3, S4, S5 and S6 pickles when compared with the control (p < 0.0001). It was reported that the average colony counts increased in fresh gherkins during the fermentation at 103–105 CFU/g; and in LABs at 107–108 CFU/g (Hutkins 2006; Pérez-Díaz et al. 2014). In our study, the total LAB count increased partially until the 15th day of the fermentation. It was determined that the total number of mesophilic aerobic bacterial colonies decreased in the environment with the advancement of the fermentation; however, it was also determined that the average number of colonies of LABs increased partially on the 60th day compared to the 30th day.

The total number of yeast-mould increased fast during the first 15th day of the fermentation (Fig. 2). In the initial stage of the fermentation, the total number of yeast-mould showed a fast increase in the pickle sample S3; however, as the fermentation process proceeded, a rapid decrease was seen, which was considered to be related to the number of LABs in the medium. A high-level and significant difference was detected in all pickle samples when compared to the control group (p < 0.0001). Fungi are considered as unwanted microorganisms in the pickle fermentation (Wouters et al. 2013; Xiong et al. 2016). It is considered important that L. plantarum strain that was used in pickle sample S3 caused a significant decrease in the total number of yeast-mould colonies in the medium as a result of the progression of the fermentation.

Biogenic amines amount in pickled gherkins

The cadaverine, tyramine, spermidine putrescine and histamine amounts were determined in the pickles that were made by using starter culture in traditional method with the HPLC (Table 1). The S3, S4 and S5 coded pickles in which we did not used L. plantarum strains did not produce putrescine on the 30th day and showed a significant difference (p < 0.0001). On the 60th day of the fermentation, the low putrescine amounts in S2, S5, S6 and S7 pickle samples showed a high-level and significant difference (p < 0.0001). A high and significant difference was determined in the S3, S4 and S5 samples because the presence of cadaverine and histamine was detected during the fermentation (p < 0.0001). In terms of tyramine, a significant difference was observed (p < 0.0001) and it was not observed in the pickle sample S2 (p < 0.0001). The presence of spermidine was not detected in any pickle samples. The toxic limits, which are determined for some BAs, which are frequently found in fermented products like pickles, were 50–100 mg/kg histamine, 100–800 mg/kg tyramine, 30 mg/kg 2-phenylethylamine and 100–200 mg/kg total BAs (Nout 1994). In our study, the histamine, tyramine and total BAs levels of all our pickle samples were determined to be below the determined toxic limits.

On the 30th day of fermentation, there was a significant difference (p < 0.0001) because L. plantarum strains did not contain a total amount of BA in the pickle samples (S3, S4 and S5). A significant difference was detected on day 60 in S2, S3, S4 and S5 pickle samples (p < 0.0001) and the total BA amount was determined in the least amounts. Factors like long storage times or increased temperatures during processing might affect BA formation at a significant level in food products (Halasz et al. 1994). In our study, it was determined that the BA amount increased as the fermentation progressed. As BAs inhibit the detoxification ability in humans when they are found in high amounts in foods, they may be transformed into toxic metabolites that are responsible for serious human health problems. More than 40 mg BA intake in each meal may increase the risk of food poisoning at a significant level (Nout 1994). In our study, it was determined that the total 5 different BA amounts were below the toxic levels that could affect human health.

Different initial cultures may affect the BA formation in different ways. In addition to BA producing strains, there are also some other strains that have negative decarboxylase activity or that are able to oxidize BA in foods (La Gioia et al. 2011). It was reported that the BA content in the control groups of self-fermented cabbage pickle was higher than in the inoculated samples (Sahu et al. 2016). It was proven that L. plantarum strains could be used to reduce the BAs in different plant-based fermented products (Lee et al. 2016). The detection of the least BA amount in the S3, S4 and S5 pickle samples to which we added L. plantarum strains as starter culture is similar to the results of the studies mentioned above.

The metabolite amounts in pickled gherkin fermentation

The amounts of the metabolites including pyruvate, lactate, acetic acid, H2O2, ethanol, acetoin and 2.3-butanediol, which are fermentation products, were determined for the traditional pickles in which starter cultures were used (Table 2). It was observed that the amount of pyruvate was comparatively less for the samples with starter cultures on the 30th day of the fermentation, showing a significant difference (p < 0.0001). It was also seen that the amount of lactate was similar for all the samples with starter cultures (expect for sample S7) on the 30th day of the fermentation. All pickle samples showed a significant difference by producing less lactate than the control group (p < 0.0001). As the acetic acid amount was determined at the highest rate on the 30th day of L. paraplantarum strain in S7 pickle sample, a high-level and significant difference was detected. The presence of acetic acid in all samples was determined to be close to each other on the 60th day.

The presence of H2O2 and ethanol were observed as close to each other in all pickle samples during the fermentation. The presence of the least acetoin amount on day 30 was determined in the S7 and S2 samples. The 2.3-butanediol amount showed a significant increase on the 60th day. The 2.3-butanediol amount was detected more in the control sample than all other samples on day 60. When the total metabolite amount on day 30 was evaluated, it was found that the least amounts were detected in samples S7 and S2; and a high-level and significant difference was detected when compared to the other samples (p < 0.0001). It was determined that the total metabolite amounts in S5 and S6 samples were close to each other on the 60th day, and a high-level and significant difference was detected when compared to control and S2 samples (p < 0.0001).

Lactic Acid Bacteria (LAB) convert the pyruvate that is formed by fermenting the glucose into lactate with lactate dehydrogenase (Liu et al. 2006). As shown in Table 2, it was determined that there was pyruvate, there was lactate on the 30th day of the fermentation; and there was no lactate on the 60th day of the fermentation when there was no pyruvate, which supports this situation. Ethanol is a fermentation product formed when LABs reduce the acetaldehyde. The pyruvate decarboxylase activity of LAB and different organisms being at varying levels limits the increase in ethanol production (Solem et al. 2013). The analyses of the obtained data showed that for all cases the amount of ethanol was high on the 30th day, whereas it was quite low on the 60th day. The lactate that is formed during glycolysis is used to reduce the equivalent proportion of pyruvate (Williams et al. 2001). It confirms the use of equivalent rate of pyruvate in the formation of lactate in our study.

Tsuji et al. (2013) determined the presence of fermentation by-products such as acetoin, lactate and ethanol which are among LABs. In this study, the presence of lactate, ethanol and acetoin was determined on the 30th day of the fermentation. As 2.3-butanediol is an important chemical feedstock that has economic value, its biotechnological production is important. The dehydrogenation of 2.3-butanediol results in acetoin and diacetyl (Gaspar et al. 2013). On the 30th day of the fermentation, it was determined that the acetoin amount was high in other samples except for the samples S7 and S2. It was determined that there were high amounts of 2.3-butanediol on the 60th day of the fermentation although there was no acetoin. This confirms that acetoin is converted into 2.3-butanediol depending on the time that is spent in fermentation. Many LABs have flavoprotein oxidase allowing them to produce H2O2 in the presence of oxygen, lactate, pyruvate and NADH (Schnürer and Magnusson 2005). As shown in Table 2, it was determined that the amount of H2O2 was half of the total metabolites on the 60th day of the fermentation in all samples. LABs produce some compounds that have antimicrobial activity; and during the fermentation, they cause decreases in the pH. Also, lactic and acetic acid are produced as the final products (Lind et al. 2005). In addition to these, other substances like H2O2, formic acid, propionic acid, acetone and diacetyl are also formed (Herreros et al. 2005). When the data obtained in our study were evaluated, it was determined that the presence of the metabolites that are mentioned above have antimicrobial effects on pH and microorganisms.

Conclusion

This study examined the effects of 5 different starters, namely, L. plantarum 49, L. plantarum 51, L. plantarum 13, L. pentosus 2 and L. paraplantarum 16 on the fermentation profile of the gherkin pickle produced with traditional methods. The results of the chemical analyses were similar for all pickles samples. The total number of mesophilic aerobic bacteria and yeast-mould colonies decreased significantly for the sample of S3 (L. plantarum 49) during the fermentation process. The amount of BAs was observed to be the lowest for the pickle samples of S3, S4 and S5 containing the L. plantarum strains. In all cases, the amount of BAs was below the toxic value that could affect human health. It was found that more BAs could be synthesized with a longer fermentation time. Another observation was that lactate existed in the presence of pyruvate during the fermentation process, and acetoin was converted into 2.3-butanediol completely.

In general, the pickle sample containing L. plantarum 49 (S3) did appear to exhibit a much better fermentation profile (metabolites and biogenic amines) than all the other samples. On the other hand, the effects on microbial flora and metabolite production associated with traditional gherkin cucumber pickle fermentation have not been fully elucidated. It is of great significance to conduct comprehensive studies on the activities of enzymes which are effective in the metabolism of LABs showing similar features with L. plantarum 49. In the lights of the findings presented in this study, it can be said that the use of starter cultures showing such features can make a great contribution to the production of high-quality traditional pickled cucumbers.

References

Aktan N, Kalkan H (2000) Şarap teknolojisi. Kavaklıdere Eğitim Yayınları, Ankara

Aktan N, Yücel U, Kalkan H (1998) Turşu teknolojisi. Ege Üniversitesi Ege Meslek Yüksek Okulu Yayınları, İzmir

Alan D (2015) Doğal turşulardan Lactobacillus paraplantarum ve Lactobacillus pentosus suşlarının moleküler tanımlanması ve plazmid içeriklerinin belirlenmesi. K.S.Ü, Fen Bilimleri Enstitüsü, Kahramanmaraş

Alan Y, Topalcengiz Z, Dığrak M (2018) Biogenic amine and fermentation metabolite production assessments of Lactobacillus plantarum isolates for naturally fermented pickles. LWT Food Sci Technol 98:322–328

Aryal S (2016) Spread plate technique- principle, procedure and uses. Accessed from: http://www.microbiologyinfo.com/spread-plate-techniqueprinciple-procedure-and-uses. Accessed 5 May 2017

Doeun D, Davaatsere M, Chung MS (2017) Biogenic amines in foods. Food Sci Biotechnol 26:1463–1474

Fernández-Diez MJ, Castro RR, Garrido FA, Heredia MA et al (1985) Biotecnologia de la aceituna de mesa. Instituto de la Grasa y sus Derivados, Sevilla

Franco W, Perez-Dıaz IM, Johanningsmeier SD, McFeeters RF (2012) Characteristics of spoilage-associated secondary cucumber fermentation. J Appl Environ Microbiol 78:1273–1284

Gaspar P, Carvalho AL, Vinga S, Santos H, Neves AR (2013) From physiology to systems metabolic engineering for the production of biochemicals by lactic acid bacteria. Biotechnol Adv 31:764–788

Halasz A, Barath A, Sımon-Sarkadı L, Holzapfel W (1994) Biogenic amines and their production by microorganisms in food. Trends Food Sci Technol 5:42–49

Herreros MA, Sandoval H, González L, Castro JM, Fresno JM, Tornadijo ME (2005) Antimicrobial activity and antibiotic resistance of lactic acid bacteria isolated from Armada cheese (a Spanish goats’ milk cheese). Food Microbiol 22:455–459

Hutkins RW (2006) Microbiology and technology of fermented foods. IFT Press, Blackwell Publishing Professional, Lowa

La Gioia F, Rizzotti L, Rossi F, Gardini F, Tabanelli G, Torriani S (2011) Identification of a tyrosine decarboxylase gene (tdcA) in Streptococcus thermophilus 1TT45 and analysis of its expression and tyramine production in milk. Appl Environ Microbiol 77:1140–1144

Lee YC, Kung HF, Huang YL, Wu CH, Huang YR, Tsai YH (2016) Reduction of biogenic amines during miso fermentation by Lactobacillus plantarum as a starter culture. J Food Prot 9:1468–1646

Liao M, Wu ZY, Yu GH, Zhang WX (2017) Improving the quality of Sichuan pickle by adding a traditional Chinese medicinal herb Lycium barbarum in its fermentation. Int J Food Sci Technol 52:936–943

Lind H, Jonsson H, Schnürer J (2005) Antifungal effect of dairy propionibacteria contribution of organic acids. Int J Food Microbiol 98:157–165

Liu S, Nichols NN, Dien BS, Cotta MA (2006) Metabolic engineering of a Lactobacillus plantarum double ldh knockout strain for enhanced ethanol production. J Ind Microbiol Biotechnol 33:1–7

Liu Q, Wu J, Lim ZY, Aggarwal A, Yang H, Wang S (2017) Evaluation of the metabolic response of Escherichia coli to electrolysed water by 1H NMR spectroscopy. LWT Food Sci Technol 79:428–436

Lu Z, Breidt F, Fleming HP, Altermann E, Klaenhammer TR (2003) Isolation and characterization of a Lactobacillus plantarum bacteriophage, øJL-1, from a cucumber fermentation. Int J Food Microbiol 84:225–235

Nilchian Z, Rahimi E, Razavi SH, Shahraki MM (2016) Isolation and identification of L. plantarum from Iranian fermented cucumbers by conventional culture and PCR methods. J Food Biosci Technol 6:69–76

Nout MJR (1994) Fermented foods and food safety. Food Res Int 27:291–298

Panghal A, Virkar K, Kumar V, Dhull SB, Gat Y, Chhikara N (2017) Development of probiotic beetroot drink. Curr Res Nutr Food Sci 5:257–262

Panghal A, Janghu S, Virkar K, Gat Y, Kumar V, Chhikara N (2018) Potential non-dairy probiotic products—a healthy approach. Food Biosci 21:80–89

Pérez-Díaz IM, Breidt F, Buescher RW, Arroyo-Lopez FN et al (2014) Fermented and acidified vegetables. Compendium of methods for the microbiological examination of foods. APHA Press, Washington, DC

Plenghvidhya V, Breidt F, Lu Z, Fleming HP (2007) DNA fingerprinting of lactic acid bacteria in sauerkraut fermentations. Appl Environ Microbiol 73:7697–7702

Rabie MA, Siliha H, El-Saidy S, El-Badawy AA, Malcata FX (2011) Reduced biogenic amines contents is sauerkraut via addition of selected lactic acid bacteria. Food Chem 129:1778–1782

Rodríguez-Gomez F, Bautista-Gallego J, Romero-Gil V, Arroyo-Lopez NF, Garrido- Fernández A, García-García P (2012) Effects of salt mixtures on Spanish green table olive fermentation performance. LWT Food Sci Technol 46:56–63

Sáez GD, Flomenbaum L, Zárate G (2018) Lactic acid bacteria from argentinean fermented foods: isolation and characterization for their potential use as starters for fermentation of vegetables. Food Technol Biotechnol 56:398–410

Sahu L, Pand SK, Paramithiotis S, Zdolec N, Ray RC (2016) Biogenic amines in fermented foods: Overview. In: Montet D, Ray RC (eds) Fermented foods Part 1: Biochemistry and biotechnology. Taylor & Francis Group, LLC, CRC Press, Florida, pp 303–317

Schnürer J, Magnusson J (2005) Antifungal lactic acid bacteria as biopreservatives. Trends Food Sci Technol 16:70–78

Solem C, Dehli T, Jensen PR (2013) Rewiring Lactococcus lactis for ethanol production. Appl Environ Microbiol 79:2512–2520

Tamang J, Tamang B, Schillinger U, Guigas C, Holzapfel WH (2009) Functional properties of lactic acid bacteria isolated from ethnic fermented vegetables of the Himalayas. Int J Food Microbiol 135:28–33

Tsuji A, Okada S, Hols P, Satoha E (2013) Metabolic engineering of Lactobacillus plantarum for succinic acid production through activation of the reductive branch of the tricarboxylic acid cycle. Enzym Microb Technol 53:97–103

Williams AG, Noble J, Banks JM (2001) Catabolism of amino acids by lactic acid bacteria isolated from cheddar cheese. Int Dairy J 11:203–215

Wouters D, Bernaert N, Conjaerts W, Droogenbroeck BV, Loose MD, Vuyst LD (2013) Species diversity, community dynamics, and metabolite kinetics of spontaneous leek fermentations. Food Microbiol 33:185–196

Xiong T, Li J, Liang F, Wang Y, Guan Q, Xie M (2016) Effects of salt concentration on Chinese sauerkraut fermentation. LWT Food Sci Technol 69:169–174

Acknowledgements

I thank Dr. Ahmet Savcı, Dr. Enver Fehim Kocpınar and Academician Neslihan Yıldız for their precious contributions to the present study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alan, Y. Culture fermentation of Lactobacillus in traditional pickled gherkins: Microbial development, chemical, biogenic amine and metabolite analysis. J Food Sci Technol 56, 3930–3939 (2019). https://doi.org/10.1007/s13197-019-03866-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03866-8