Abstract

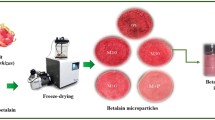

Betalains of pitaya (Stenocereus pruinosus) fruit can be used as natural pigment, but they are susceptible to deterioration by temperature, pH, and presence of sugars. In this work, a refined extract (Er) of betalains was obtained through aqueous two-phase extraction, which reduced significantly sugar and mucilage contents. In order to favor stability, the encapsulation of the refined extract was evaluated, with native potato starch that was modified through phosphorylation or succinylation and reactive extrusion. Starches were evaluated in terms of degree of substitution, Fourier transform infrared spectroscopy, scanning electron microscopy, and viscous behavior. Microcapsules were formed by spray drying and their stability was evaluated at 40 °C for 39 days and by using them as pigmenting agent of yogurt at 4 °C during 32 days. The behavior of modified starches during encapsulation was superior to that of commercial N-Lok® starch. Microcapsules based on modified starches showed better pigmenting potential and higher stability than Er and microcapsules based on N-Lok® starch. The separation of betalains from pitaya fruit may be a good alternative for adding value to this plant genetic resource.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Color is an important attribute in food quality. The food industry uses pigmenting substances for purposes such as restoring color lost during processing, enhance color, minimize color variations between batches, and coloring otherwise colorless foods (Aberoumand 2011). In recent years a trend towards replacing colorants of synthetic origin by natural pigments has been developed (Wrolstad and Culver 2012) due to several reasons. First, artificial dyes may have adverse effects in health (Swaroop et al. 2011); second, natural pigments can be treated as ingredients instead of as additives in food preparation (Stintzing et al. 2006), according to FDA regulations (Aberoumand 2011), and third, the intake of natural pigments can have positive effects on human health (Rodriguez et al. 2016). However, natural pigments are generally less stable and have higher cost than synthetic dyes (Wrolstad and Culver 2012).

Recently, the interest for using betalains as providers of color in foods has increased (Aberoumand 2011). Betalains are vacuolar pigments that comprise nitrogen in their structure, are water soluble, and include the red-violet betacyanins and the yellow betaxanthins (Moreno et al. 2008). These compounds are responsible for the color of flowers, fruit and, in some cases, roots and leaves in plants of the Order Cariofilales, except the families Cariofilaceae and Moluginaceae (Tanaka et al. 2008). Betalains are conjugate compounds of the betalamic acid with cyclo-dihydroxyphenylalanine (DOPA-cycle) and amino acids in the case of betacyanins or amines in the case of betaxanthins (Moreno et al. 2008).

Stability of betalains is influenced by presence of sugars, light, oxygen, water activity, pH, and temperature (Cai et al. 2001). It has been shown that through encapsulation the stability of betalains can be lengthened (Cai and Corke 2000) and several substances like maltodextrin, guar gum, Arabic gum, pectin, and xanthan gum have been evaluated as coating material (Ravichandran et al. 2014). On other hand, modified starches have proved to be a good alternative to be used in encapsulation of other natural pigments like anthocyanins (García-Tejeda et al. 2016), but their behavior with betalains has not been studied.

Fruit of several Cactaceae species have been identified as a source of betalains to be used as natural pigments (Cejudo-Bastante et al. 2016; Saénz et al. 2009) and efforts to identify conditions that maintain them stable have been made (Wong and Siow 2015). The fruit of pitaya (Stenocereus pruinosus) exhibits attractive colors in peel and flesh, derived from presence of betalains (García-Cruz et al. 2013). Due to this, such fruit has been identified as a potential source of betalains that can be used as natural pigment of foods. However, the fruit has high sugar (Chuck-Hernández et al. 2016) and mucilage content, which may limit the use of these compounds as pigment in foods, since sensory properties can be affected and fermentation processes may be favored. In this context, the objectives of this work were to obtain a refined extract of pitaya fruit through the elimination of sugars and mucilage and to implement a strategy of encapsulation with modified starch to favor stability of the pigment during its use in foods.

Materials and methods

Extract of pitaya fruit

Fruit of pitaya (Stenocereus pruinosus) that came from Huaquechula, Puebla, Mexico (18°46′05″ N, 98°32′31″ W; 1622 masl) were used. The skin of fruit was removed and flesh was macerated with a blender (T-fal, Turbomix; GSEB Mexicana, Mexico), mixed with a solution of ethanol–water (1:1) in 1:2 proportion (flesh:solution), and left in rest during 15 h. Solids with higher size were removed with mesh of 250 μm and filtration under vacuum conditions. The alcohol was removed in a rotary evaporator (Heidolph Instruments GmbH & Co. KG, Germany) and a crude extract (Ec) was obtained. The method of aqueous two phase extraction (ATPE) was applied with mixtures of polyethylene glycol 4000 (Peg4000; Sigma-Aldrich, Co., Germany) and ammonium sulfate ([AS, (NH4)2SO4]; J. Bayer, Mexico), in quantities that were defined through the cloud point method (Raja et al. 2011). The mixture 9.0–11.0% Peg4000-AS was selected and sugars were separated in the saline phase, betalains in the polymeric phase, and mucilage in a third intermediate phase. The polymeric phase was mixed with chloroform (Química Meyer, Mexico) (Pereira et al. 2013) and two phases were again formed, which contained a mixture Peg4000-chlorofom and a refined extract (Er), respectively. Thereafter, the Peg4000 was recovered through evaporation of the chloroform in a rotary evaporator (Heidolph Instruments GmbH & Co. KG, Germany).

Extract evaluation

Ec and Er extracts were subjected to evaluation of total soluble solids (TSS, °Brix) with a portable refractometer (Abbe Atago Co., Japan), sugars with the method of antrona (Witham et al. 1971), betalains with the method described by Stintzing et al. (2005), and mucilage with the method of Álvarez and Peña-Valdivia (2009). In the case of betalains, the extracts were diluted in buffer pH 6.5 (phosphate-citrate), until absorbance was between 0.9 and 1.0. A spectrophotometer (Cintra 3030, GBC Scientific Equipment Pty Ltd) was used to measure concentration with the calculation [\( B = (1000)(A\,D_{f} M)/(\varepsilon \,L) \)], where B is content (mg/kg) of betacyanins (Bc) or betaxanthins (Bx), A is absorbance (538 nm for Bc and 483 nm for Bx), Df is dilution factor, L is the cross distance of the medium in the cell (1 cm), M is molecular weight (550 g/mol for betanin and 308 g/mol for indicaxanthin), and ε is extinction coefficient (60,000 and 48,000 L/mol cm for betanin and indicaxanthin). To quantify mucilage (mg/g), 0.5 g of lyophilized sample were mixed with 5 mL of distilled water. Heating was applied at 92 °C for 15 min and centrifugation at 113,000 × g for 5 min. The supernatant was mixed in 1:4 proportion with ethanol acidified with HCl 0.1%. The mixture was left in rest at 8 °C for 24 h and then it was submitted to centrifugation at 113,000 × g for 15 min. The precipitate was dried at 85 (± 2) °C for 5 h in convection oven (Riossa, México) and was weighed to determine mucilage content.

Wall material for betalain encapsulation

Potato native starch (PNS; Corn Products International, Inc., USA) was used as basis to obtain a wall material to encapsulate betalains. Acid hydrolysis was applied mixing a suspension of 40% PNS with HCl in proportion 100:3.4. Agitation was applied for 4 h at 50 °C, the pH was adjusted to 5.0, centrifugation was applied at 113,000 × g for 10 min in a Herle X513 K unit (Germany), the sediment was recovered, and this was washed twice with distilled water to eliminate residues of acid. The paste of starch was dried in oven (Felisa; Feligneo S.A. de C.V., Mexico) at 40 °C for 15 h. The dried material was milled (Pulvex 200 unit, Maquinaria Pulvex S.A. de C.V., Mexico) and sieved with mesh of 250 μm. The hydrolyzed starch was submitted to modification through phosphorylation with sodium tripolyphosphate (STP; Sigma-Aldrich S.A de C.V., Mexico). A solution with 4 g STP/100 g was sprayed on powder of hydrolyzed starch and the sample was stored at 4 °C for 12 h. The pH was adjusted to 5.0–5.2 and the moisture content to 20%. Another sample of hydrolyzed starch was submitted to modification through succinylation with n-octenyl succinic anhydride (n-OSA; Sigma-Aldrich S.A. de C.V., Mexico). A solution of n-OSA with concentration of 1% in relation to the starch was added drop by drop to the sample. The material was sieved with mesh of 250 μm, the pH was adjusted to 8.0, and the moisture content to 20% (Murúa-Pagola et al. 2009).

Starches treated with TPS or n-OSA were submitted to reactive extrusion on a single screw equipment (Cinvestav, IPN, Mexico), which used barrel of 20 mm and temperatures of 70, 140, and 170 °C in feeding, transition, and high pressure zones, respectively. The screw speed was 80 rpm, the feed rate was 35 g/min, the compression ratio of the screw was 2:1, and the die diameter (head) was 4.0 mm at the output. The extruded material was dried in convection oven (Felisa; Feligneo SA de CV, Mexico) at 45 °C for 8 h, milled in a Pulvex 200 unit (Maquinaria Pulvex SA de CV, Mexico), and sieved with mesh of 250 μm (Chang and Lii 1992).

Starch characterization

The modification of PNS was verified through the substitution degree (SD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and viscous behavior. The phosphorus content and the substitution degree (SD) were evaluated in the phosphorylated starch with the method of Smith and Caruso (1964) and the calculation [\( SD = 162\;P/(3100 - 124\;P) \)], where P is percent of phosphorus determined with a standard curve of KH2PO4. SD was also determined in the succinylated starch with the method of Jeon et al. (1999). A sample of known weight was dissolved in 10 mL of dimethyl sulfoxide with heating at 70 °C for 10 min. After cooling, phenolphthalein was added, and titration was performed with NaOH 0.05 M. SD was determined as [\( SD = (0.162\;A\;M/W)/(1 - 0.210\;A\;M/W) \)] (Song et al. 2006), where A and M are volume (mL) and molarity of NaOH, and W is the dry weight of the sample (g). The external morphology of granules of modified starch was observed with scanning electron microscopy (SEM; JEOL JXA-8530F, Japan) with magnification of 250×. Observations were conducted also with PNS and with commercial starch (N-Lok®; Heamz–405; National Starch and Chemical Co., USA), which were used as control. The modification of the structure of PNS starch was analyzed with FTIR using a Perkin Elmer Spectrum GX (USA) spectrometer. In addition, the viscosity of the modified starches and PNS was measured with a Rapid Visco Analyzer unit (RVA, model 3D, Newport Scientific, Australia) and was expressed in centipoise (Cp).

Microcapsule preparation

Microcapsules of Er were prepared using the modified starches and the commercial N-Lok® starch as wall material. Starches were hydrolyzed in distilled water at 45 °C for 12 h (Saénz et al. 2009) and were mixed with Er in proportion of 10% of solids. Dispersions were stored at 4 °C, sieved with mesh of 250 μm, and fed to a spray dryer (Lab Plant Spray Dryer SD–Basic, UK), which used temperatures of 140 and 80 °C at the input and output, a feeding flow of 210 mL/h, air pressure of 4 bar, and 0.5 mm nozzle. Moisture content and water activity (Aw; Aqualab equipment; CX-2; Decagon Devices Inc., USA) were assessed in microcapsules. The morphology of microcapsules was also observed through SEM (Jeol JXA–8530F, Japan) and the particle size was determined using the software ImageJ (Versión 1.49). In addition, the encapsulation efficiency (%EE) was calculated as \( [\% EE = (m_{br} /m_{bt} )100] \), where mbr and mbt are actual and theoretical quantity of betalains, which were evaluated in 100 mg of microcapsules that were dispersed in 5 mL of distilled water, shaken in vortex during 1 min at 25 °C, and submitted to sonication for 20 min twice. Samples were centrifuged for 20 min at 113,000 × g and supernatants were recovered and subjected to evaluation of betalains (Stintzing et al. 2005).

Evaluation of stability of encapsulated betalains

Three tests were performed to evaluate the stability of encapsulated betalains. First, samples of 100 mg of microcapsules were maintained at 40 °C for 39 days and were evaluated in terms of betaxanthins and betacyanins contents with the procedure of Stintzing et al. (2005). Second, the concentration of betalains within the superficial region of microcapsules was evaluated in 100 mg of microcapsules that were treated with 2 mL of a mixture of ethanol-methanol (1:1). Dispersions were shaken in vortex for 1 min at 25 °C and centrifuged at 113,000 × g for 20 min. The supernatant was recovered and passed through Acrodisc® Syringe Filters (Pall Corporation, USA) of 0.45 μm. In the third procedure, natural yogurt was prepared with a formulation that contained 90.22, 0.45, 9.04, 0.01, and 1.00% of low-fat milk, milk powder, sucrose, lactic culture, and microcapsules, respectively. Pasteurization at 80 °C during 30 min and quickly cooling to 45 °C were applied before the lactic culture was added. The yogurt had pH of 4.6 and was stored at 4 °C for 12 h. Four groups of 30 glass vials with 100 mL of yogurt were formed. Microcapsules based on phosphorylated starch (P), succinylated starch (S), and N-Lok® starch (N), were added in three groups as pigmenting agent. The fourth group was incorporated with refined extract (Er) of betalains. All units were placed in isolated room at 4 °C. Each third day and during 32 days, color was assessed in three units from each group with a colorimeter (HunterLab, MiniScan® XE Plus, USA) and was expressed as hue angle, chroma, and lightness.

Data analysis

The experimental phase was conducted in accordance with a completely randomized design, where the wall material (S, P, and N) or the pigmenting agent, including Er, were the variation factor. Data were submitted to analysis of variance and means comparison routines (Tukey, 0.05).

Results and discussion

Refining of betalain extract

Based on 15 kg of pitaya fruit, 2.5 kg of crude extract (Ec) with 26.3°Brix were obtained, which showed an extraction yield of 16.7%. Sugar and mucilage contents in Ec were 349.37 (± 28.51) and 13.7 (± 1.5) mg/g, respectively. The ATPE technique, as it was reported by Chethana et al. (2007), allowed obtaining a refined extract (Er), which had 22.0 (± 0.91) °Brix, 65.23 (+ 3.05) mg/g of total sugars, and 6.2 (± 0.2) mg/g of mucilage, indicating a reduction in such compounds of 81.3 and 54.7%, respectively. On the other hand, although the procedure was based on the use of polyethylene glycol (Peg) and ammonium sulfate (AS), during the separation of the extract the first one was recovered and could be recirculated. In the case of AS, it is a product that has wide use in fertilization agricultural activities, so that its disposal could be done by some cost recovery mechanism, allowing an inexpensive extraction alternative.

Wall material for betalain encapsulation

Potato native starch (PNS) was modified with TPS or n-OSA to be used in betalain encapsulation. The substitution degree (SD) constitutes a measure of the progress of crosslinking or esterification reactions during the process (Singh et al. 2007). The phosphorus content in the phosphorylated starch (P) was 0.85% and the value for SD was 0.047. Since it has been reported that maximum content of phosphorus must be 0.4% (García-Tejeda et al. 2016), the use of the phosphorylated starch might have limitations to be used in food applications. In the case of succinylated starch (S) the value for SD was 0.038, which was similar to the value of 0.042 obtained by Murúa-Pagola et al. (2009) in waxy maize starch.

The use of FTIR (Fig. 1a) showed that PNS developed absorption bands at 933, 995, and 1147 cm−1 that were attributed to a stretching effect on the C–O bond (Skoog et al. 2007). Also, an absorption band with peak at 1659 cm−1 was observed and may correspond to the same band that has been reported to other starches at 1652 cm−1, which has been attributed to tightly bound water present in the starch (Song et al. 2006). In the region around 2919 cm−1 two small bands were observed, which can be attributed to a stretching effect on the C–H bond. Finally, a broad band with peak at 3144 cm−1 and another with peak at 3578 cm−1 were observed, both attributed to a stretching effect on the O–H bond (Skoog et al. 2007). The absorption spectrum of the phosphorylated starch (P) showed similar characteristics to that obtained for PNS, which suggested that, although the substitution degree was high, in fact this was practically nil, since such substitution was not evidenced in the molecule structure. On other hand, in the case of starches that have been modified with n-OSA, it has been reported that the presence of absorptions bands at 1726 and 1572 cm−1 is taken as evidence of an effective substitution phenomenon (Sweedman et al. 2013). In the present work, the FTIR spectrum of the succinylated starch (S) showed an absorption band at 1575 cm−1 that was not observed in spectra of PNS and P. In addition, it was observed a slightly formation of a shoulder around the region of 1722 cm−1 which, although was not very noticeable, confirmed the structure modification of the starch during the treatment with n-OSA.

PNS showed viscosity with values close to 6800 Cp (Fig. 1b, c). In contrast, viscosity of modified starches was lesser than 100 Cp, which was coherent with reports that have indicated that the reactive extrusion causes reduction in viscosity (García-Tejeda et al. 2016). In this regard, Chang and Lii (1992) and Murúa-Pagola et al. (2009) pointed out that disintegration of the starch structure occurs during the reactive extrusion due to the temperature, pressure, and high shear conditions applied. On the other hand, this decrement in viscosity was considered as a positive feature, because during the formation of microcapsules by spray drying, a low viscosity favors the flow through the outlet nozzle (Duarte et al. 2016).

The use of SEM (Fig. 2) showed that PNS had oval granular structure, which has been reported before for other starches (Bhandari 2012). After the modification, the granules of P and S starches showed very irregular shape, which contrasted with the structure found in N-Lok®, where the shape was more regular and with smooth external surface. Bhandari (2012) suggested that the loss of structure in extruded starches is due to a gelatinization phenomenon, although in this case, due to applied conditions, the process could correspond to a thermo-mechanical gelatinization.

Microphotographs of granules of potato native starch (PNS; a), succinylated starch (b), phosphorylated starch (d), and N-Lok® starch (f), with magnification of 250×. Microphotographs of microcapsules of betalains prepared with succinylated starch (c), phosphorylated starch (e), and N-Lok® starch (g), with magnification of 2500×

Betalain microencapsulation

Microcapsules had spherical shape with collapsed surface or indentations (Fig. 2). This is usually attributed to a phenomenon of contraction due to a drastic loss of water (Krishnaiah et al. 2015). Particles had heterogeneous morphologies with average diameters of 6.93, 6.60, and 4.66 μm for starches S, P, and N-Lok®, respectively (Table 1). Microcapsules prepared with modified starches showed rigid structures without apparent breaks or cracks (Fig. 2), which was considered an advantage, because a damaged surface could reduce protection and retention of material in the core of particles. Microcapsules had moisture between 5.2 and 5.3%, without difference (p > 0.05) among products obtained with modified starches and N-Lok®. The moisture content is an important factor in the shelf life of dry materials and contents between 3 and 10% favor stability (Reid and Fennema 2007). On the other hand, the water activity (Aw) was higher in microcapsules prepared with succinylated starch (S; 0.31) than in those made with phosphorylated starch (P; 0.29) and with N-Lok® starch (0.24) (Table 1), suggesting that these last may have greater stability. However, the region of Aw with values lower than 0.65 is considered a region of high stability in foods (Reid and Fennema 2007), which suggests that the contrasts found may have no practical importance.

The use of different wall materials did not cause difference in hue angle and chroma of microcapsules. However, the N-Lok® starch caused the highest value of lightness (Table 1). Although hue angle of microcapsules suggested important proximity to an absolute red color, the low values of chroma and lightness created a rather opaque and with low sharpness appearance in all the cases. The color of microcapsules is provided by betalains (García-Cruz et al. 2013). The concentration of betacyanins (Bc) in materials with starches S, P, and N-Lok® was 0.55, 0.54, and 0.35 mg/g of capsules. In the case of betaxanthins (Bx), the content was 0.53, 0.54, and 0.40 mg/g, respectively. These values were higher than those reported by Saénz et al. (2009) for Bc obtained from Opuntia ficus-indica and encapsulated with maltodextrin and inulin. The concentrations obtained in microcapsules made with modified starches were significantly higher (p ≤ 0.05) than those found in materials of N-Lok® (Table 1), suggesting that the use of modified starches can develop microcapsules with greater pigmenting potential. On the other hand, based on HPLC determinations, García-Cruz et al. (2013) found five different types of betalains in tissue of pitaya (Stenocereus pruinosus) fruit, among which two corresponded to betaxanthins and three to betacyanins. In addition, García-Cruz et al. (2017), through HPLC with diode array detector (DAD) and electrospray ionization mass spectrometry (ESI/MS), identified that the most abundant betalains in this type of fruit were isoindicaxanthin, gomfrenin I, filocactin, and their respective isomers, which may be considered as the compounds responsible for the color of extracts.

The encapsulation efficiency (%EE) had values of 97.56% with S, 96.69% with P, and 93.98% with N-Lok®, with significant difference among them (p ≤ 0.05). This pointed out that a higher quantity of betalains can be protected with the modified starches than with the commercial one. Murúa-Pagola et al. (2009) evaluated the encapsulation of oil extracted from orange using waxy maize starch and the modification was also made with TPS or n-OSA. Authors explained that the better performance of modified starches was due to a higher emulsification capacity in relation to N-Lok®. In addition, the %EE was similar to that found by Duarte et al. (2016) during encapsulation of crude palm oil with cassava starch and Arabic gum or whey protein and these authors indicated that a high value in this parameter means higher protection of the biomolecule. On the other hand, although small quantities of reagents were used to obtain modified starches, a cost analysis of the encapsulation process should be carried out considering that during an industrial implementation analytical reagents would not be used.

Stability of microencapsulated betalains

The content of Bc diminished in linear form, at a rate of 0.0032, 0.0032, and 0.0058 mg/g per day in microcapsules obtained with S, P, and N-Lok®, which means a loss of 22.60, 23.20, and 65.45% of the pigment, respectively, in a period of 39 days. In the case of Bx, losses were 41.06, 45.60, and 39.70%, respectively, since such compounds diminished at a rate of 0.0056, 0.0063, and 0.0041 mg/g per day (Fig. 3a). While the behavior of Bx was similar in the microcapsules prepared with modified starches and N-Lok®, the information obtained for Bc suggested that with the former a better betalain encapsulation potential can be obtained because, on one hand, modified starches showed higher encapsulation efficiency and, on the other, a lesser quantity of betalains is lost with time, which favors the pigmenting potential.

Variation of total (a) and superficial (b) betacyanins (Bc) and betaxanthins (Bx) in microcapsules prepared with succinylated starch (S), phosphorylated starch (P), and N-Lok® starch (N), during storage of 40 °C. Different capital or lower case letters between parentheses indicate significant difference (p ≤ 0.05) among kinetics of betacyanins or betaxanthins, respectively. Legends ns and * indicate non-significant and significant modification with time. Error bars correspond to standard errors

The yogurt formulated to evaluate stability of microcapsules had pH of 4.6 (± 0.2). The best pigmenting potential was obtained with microcapsules of succinylated starch (S), which caused hue angle of 8.26°, followed by those made with phosphorylated starch (P; 9.96°) and those of N-Lok® (10.86°), with significant difference (p ≤ 0.05) between the former and the last two (Table 2). The lowest pigmenting potential was obtained with the refined extract (Er), which caused hue angle of 40.73° and a pink pale appearance. The highest chroma was also obtained with S (21.49), whose value was different (p ≤ 0.05) to that obtained with P (19.10) and N-Lok® (18.61), although these caused higher chroma than Er (8.80). The use of Er only caused better performance in lightness (84.26%) in relation to microcapsules, that produced values of 70.63 (P), 67.94 (S), and 71.23% (N-Lok®) (Table 2).

The storage time affected color (Fig. 4). In yogurt pigmented with Er, a linear modification (R2 = 0.91 in average; Table 2) was observed in attributes. The most sensitive attribute was tonality, since an important change occurred in hue angle (8.1°), which was probable due to a rapid degradation of betalains when contacted the product. However, chroma and lightness had only a slight modification (1.4 and 0.3%, respectively) along the storage of 32 days at 4 °C. On the other hand, when microcapsules of P, S, and N-Lok® were used, the modification had logarithmic tendency (R2 = 0.90 in average; Table 2) and the main changes occurred during the first 8 days of storage and thereafter values remained practically constant (Fig. 4). The lowest changes in color attributes were observed in yogurt pigmented with S, which indicated that this type of starch was the better alternative to encapsulate betalains. The study of superficial betalains in microcapsules showed total concentration of 0.0265, 0.0357, and 0.0451 mg/g in materials of S, P, and N-Lok®, respectively (Table 1), but during the evaluation of stability, such content diminished linearly with time, resulting in total loss of pigments at the 7 days (Fig. 3b). This situation suggested again that a more direct exposition with the yogurt affected rapidly the stability. In this regard, it has been reported that the spray drying method is rather a technique of immobilization, since compounds may be exposed on the surface, which has been considered a disadvantage (Celli et al. 2015). In addition, the rapid degradation of superficial betalains explained changes during the first 8 days in the logarithmic behavior of color attributes.

Color attributes expressed as hue angle (a), chroma (b), and lightness (c) in yogurt pigmented with refined pitaya extract (Er), and microcapsules prepared with succinylated starch (S), phosphorylated starch (P), and N-Lok® starch (N). Symbols correspond to experimental data and solid lines to adjustments by linear regression \( (y = ax + b ) \) in the case of Er or logarithmic regression \( (y = y_{0} + a(1 - e^{ - bx} )) \) in the case of S, P, and N. Different letters between parentheses mean significant difference (Tukey, 0.05). Legends ns and * indicate non-significant and significant modification with time. Error bars correspond to standard errors

Murúa-Pagola et al. (2009) determined that with the modification through phosphorylation or succinylation the starch undergoes an increase in the water absorption index, which favors that betalains, which are water-soluble compounds, are easily incorporated in the starch molecule before drying. In addition, with the modification, the water retention in the starch molecule is favored even after cooling (Reid and Fennema 2007), which allows that betalains are kept inside the microcapsules favoring its stability, since the contact with the pigmented material is reduced.

Conclusion

The refining of extract of betalains was achieved through aqueous two phase extraction, which allowed reducing sugars and mucilage contents. The use of potato native starch, modified through phosphorylation or succinylation, allowed obtaining adequate wall materials to encapsulate betalains. The potato succinylated starch was the best alternative to develop microcapsules of betalains, which showed stability during storage of 32 days at 4 °C in yogurt with pH 4.6. The separation of betalains from fruit of pitaya may be a good alternative for adding value to this plant genetic resource.

References

Aberoumand A (2011) A review article on edible pigments properties and sources as natural biocolorants in foodstuff and food industry. World J Dairy Food Sci 6:71–78

Álvarez AR, Peña-Valdivia CB (2009) Structural polysaccharides in xoconostle (Opuntia matudae) fruits with different ripening stages. J Prof Assoc Cactus 11:26–44

Bhandari P (2012) Chemical modification of polysaccharides using reactive extrusion. Biological systems engineering–dissertations, Theses, and Student Research, Paper 29

Cai YZ, Corke H (2000) Production and properties of spray-dried Amaranthus betacyanin pigments. J Food Sci 65:1248–1252

Cai Y, Sun M, Schliemann W, Corke H (2001) Chemical stability and colorant properties of betaxanthin pigments from Celosia argentea. J Agric Food Chem 49:4429–4435

Cejudo-Bastante MJ, Hurtado N, Delgado A, Heredia FJ (2016) Impact of pH and temperature on the colour and betalain content of Colombian yellow pitaya peel (Selenicereus megalanthus). J Food Sci Technol 53:2405–2413

Celli GB, Ghanem A, Brooks MSL (2015) Bioactive encapsulated powders for functional foods-a review of methods and current limitations. Food Bioprocess Tech 8:1825–1837

Chang Y, Lii C (1992) Preparation of starch phosphates by extrusion. J Food Sci 57:203–205

Chethana S, Nayak CA, Raghavarao KSMS (2007) Aqueous two phase extraction for purification and concentration of betalains. J Food Eng 81:679–687

Chuck-Hernández C, Parra-Saldívar R, Sandate-Flores L (2016) Pitaya (Stenocereus spp.). Encyclopedia Food. Health. https://doi.org/10.1016/B978-0-12-384947-2.00775-3

Duarte FC, Linhares CEJ, Souza MBA, Stahl HV, de Oliveira RA, Druzian JI, Larroza NI (2016) Physicochemical characterization and oxidative stability of microencapsulated crude palm oil by spray drying. Food Bioprocess Technol 9:124–136

García-Cruz L, Valle-Guadarrama S, Salinas-Moreno Y, Joaquín-Cruz E (2013) Physical, chemical, and antioxidant activity characterization of pitaya (Stenocereus pruinosus) fruits. Plant Food Hum Nutr 68:403–410

García-Cruz L, Dueñas M, Santos-Buelgas C, Valle-Guadarrama S, Salinas-Moreno Y (2017) Betalains and phenolic compounds profiling and antioxidant capacity of pitaya (Stenocereus spp.) fruit from two species (S. Pruinosus and S. stellatus). Food Chem 234:111–118

García-Tejeda YV, Salinas-Moreno Y, Hernández-Martínez AR, Martínez-Bustos F (2016) Encapsulation of purple maize anthocyanins in phosphorylated starch by spray drying. Cereal Chem 93:130–137

Jeon YS, Viswanathan A, Gross RA (1999) Studies of starch esterification: reactions with alkenylsuccinates in aqueous slurry systems. Starch-Starke 51:90–93

Krishnaiah D, Bono A, Sarbatly R, Nithyanandam R, Anisuzzaman SM (2015) Optimisation of spray drying operating conditions of Morinda citrifolia L. fruit extract using response surface methodology. J King Saud Univ Eng Sci 27:26–36

Moreno DA, García-Viguera C, Gil JI, Gil-Izquierdo A (2008) Betalains in the era of global agri-food science, technology and nutritional health. Phytochem Rev 7:261–280

Murúa-Pagola B, Beristain-Guevara CI, Martínez-Bustos F (2009) Preparation of starch derivatives using reactive extrusion and evaluation of modified starches as shell materials for encapsulation of flavoring agents by spray drying. J Food Eng 91:380–386

Pereira ALA, Santiago NK, Alves MC, Rodrigues MVP, Minim LA (2013) Aqueous two-phase poly(ethylene glycol)–sodium polyacrylate system for amyloglucosidase purification: equilibrium diagrams and partitioning studies. Sep Purif Technol 118:888–894

Raja S, Murty VR, Thivaharan V, Rajasekar V, Ramesh V (2011) Aqueous two phase systems for the recovery of biomolecules–a review. Sci Technol 1:7–16

Ravichandran K, Palaniraj R, Saw NMMT, Gabr AMM, Ahmed AR, Knorr D, Smetanska I (2014) Effects of different encapsulation agents and drying process on stability of betalains extract. J Food Sci Technol 51:2216–2221

Reid DS, Fennema OR (2007) Water and ice. In: Damodaran S, Parkin KL, Fennema OR (eds) Fennema’s food chemistry, 4th edn. CRC Press, Boca Ratón, pp 17–82

Rodriguez EB, Vidallon MLP, Mendoza DJR, Reyes CT (2016) Health-promoting bioactivities of betalains from red dragon fruit (Hylocereus polyrhizus (Weber) Britton and Rose) peels as affected by carbohydrate encapsulation. J Sci Food Agric 96:4679–4689

Saénz C, Tapia S, Chávez J, Robert P (2009) Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chem 114:616–622

Singh J, Kaur L, Mc Carthy OJ (2007) Factors influencing the physicochemical, morphological, thermal and rheological properties of some chemically modified starches for food applications. A review. Food Hydrocolloid 21:1–22

Skoog DA, Holler FJ, Crouch SR (2007) Principles of instrumental analysis. Thomson Brooks/Cole, Grove

Smith RJ, Caruso JL (1964) Determination of phosphorus and ash. In: Whistler RL (ed) Methods in carbohydrate chemistry. Springer, Berlin, p 311

Song X, He G, Ruan H, Chen Q (2006) Preparation and properties of octenyl succinic anhydride modified early Indica rice starch. Starch-Starke 58:109–117

Stintzing FC, Herbach KM, Mosshammer MR, Carle R, Yi W, Sellappan S, Akoh CC, Bunch R, Felker P (2005) Color, betalain pattern, and antioxidant properties of cactus pear (Opuntia spp.) clones. J Agric Food Chem 53:442–451

Stintzing FC, Trichterborn J, Carle R (2006) Characterisation of anthocyanin–betalain mixtures for food colouring by chromatic and HPLC-DAD-MS analyses. Food Chem 94:296–309

Swaroop VR, Dinesh-Roy D, Vijayakumar T (2011) Genotoxicity of synthetic food colorants. J Food Sci Eng 1:128–134

Sweedman MC, Tizzotti MJ, Schäfer C, Gilbert RG (2013) Structure and physicochemical properties of octenylsuccinic anhydride modified starches: a review. Carbohyd Polym 92:905–920

Tanaka Y, Sasaki N, Ohmiya A (2008) Biosynthesis of plant pigments: anthocyanins, betalains and carotenoids. Plant J 54:733–749

Witham FH, Blaydes DF, Devlin RM (1971) Experiment in plant physiology. VanNostrand Reinhold Co., New York

Wong YM, Siow LF (2015) Effects of heat, pH, antioxidant, agitation and light on betacyanin stability using red-fleshed dragon fruit (Hylocereus polyrhizus) juice and concentrate as models. J Food Sci Technol 52:3086–3092

Wrolstad RE, Culver CA (2012) Alternatives to those artificial FD&C food colorants. Annu Rev Food Sci Technol 3:59–77

Acknowledgements

Authors wish to acknowledge the financial support received from Consejo Nacional de Ciencia y Tecnología of Mexico (CONACyT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vargas-Campos, L., Valle-Guadarrama, S., Martínez-Bustos, F. et al. Encapsulation and pigmenting potential of betalains of pitaya (Stenocereus pruinosus) fruit. J Food Sci Technol 55, 2436–2445 (2018). https://doi.org/10.1007/s13197-018-3161-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3161-7