Abstract

The effects of protein removal on the physicochemical and structural properties of normal and waxy wheat and their A- and B-type granule fractions were investigated. No evident changes were observed in the morphological, birefringence pattern and X-ray diffraction pattern after treatment, but there was evidence showing that the relative crystallinity, swelling power and percentage syneresis of all samples were significant increased. Protein removal treatment increased the peak, setback, final viscosity, breakdown viscosity of normal and waxy native wheat starch, and their A- and B-type starch granule fractions, whereas it decreased the pasting temperature, peak time and trough viscosity. Meanwhile, the thermal transition temperatures (To, Tp, Tc) and gelatinization temperature range (ΔTr) of normal and waxy wheat and their isolated A- and B-type granules were increased, but the enthalpy decrease slightly. The different genetic factors and amylose content in normal and waxy wheat starch and their A- and B-type wheat starch granules fractions were related to the different physicochemical and structural characteristics of those starches.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wheat (Triticum aestivum L.) is one of the world’s most important cereals consumed as the staple food in different forms such as steamed bread, bread, noodles, snacks and various bakery products. Wheat grains consist of endosperm, bran and germ, and starch is the main component in the wheat endosperm and exists in two forms including A- (diameters greater than 10 μm) and B-type granules (diameters less than 5 μm). Wheat A-type and B-type starch granules have been reported to exhibit a very different chemical composition including amylose, amylopectin, amylopectin/amylose ratio, lipid, and protein content, as well as physicochemical and functional properties such as gelatinization and pasting properties, hydrolysis property, digestible property, swelling, crystallinity and baking properties (Sahlström et al. 2003; Singh et al. 2010a). The starch granule is mainly composed of amylose (AM) and amylopectin (AP), and the structure of AM and AP and their organization forms in the intact granule have been greatly discussed and documented.

With the exception of AM and AP, starch granules also contain small quantities of other “minor” non-starch components, such as proteins, lipids, pentosans, and minerals (Baldwin 2001). Among those components, proteins and lipids are by far the most abundant and technologically important. The exact content of protein and lipid associated with the starch granules is determined from both the botanical origin of the starch and its degree of purification during extraction (Baldwin 2001). In general, cereal starch granules contained more granule-associated proteins and lipids on the surface compared to tuber, root and legume starches (Baldwin 2001; Wang et al. 2014). Although these two constituents are deemed minor, they have been reported to affect the properties of the starch granule and the starch-derived products, starch digestibility, and chemical reaction activity with modifying reagents (Tester and Morrison 1990; Baldwin 2001; Debet and Gidley 2006; Singh et al. 2010a; Chan et al. 2010; Wang et al. 2014).

There two types of protein which is tightly associated with starch granules from all botanical sources, including starch granule-associated proteins (SGAPs), as well as storage proteins (e.g. gluten and gliadin proteins), which remain adsorbed to the surface of starch granules after starch extraction (Baldwin 2001). SGAPs are defined as the proteins biologically distinct from plant storage proteins and are tightly bound in and on starch granules (Baldwin 2001). Surface proteins in starches are often dominated by storage proteins, particularly endosperm storage proteins for cereals (Debet and Gidley 2006). These surface proteins always exhibit a low molecular weight (<30 kDa) in wheat and maize (Debet and Gidley 2006), and some proteins seem to be present both on the surface and inside granules, such as a 30 kDa wheat protein (Rayas-Duarte et al. 1995).

As the first barrier for starch granules to react with water, chemical reagents, and enzymes, starch surface characteristics such as associated components determine largely the initial rate of these reactions (Wang et al. 2014). It has been reported that removal of surface proteins and lipids can alter the structural, physiochemical and functional properties of starch, and increase the chemical reaction activity with modifying reagents (Tester and Morrison 1990; Debet and Gidley 2006; Singh et al. 2010a; Chan et al. 2010; Wang et al. 2014). The efficient reagent used to remove the surface proteins and lipids usually including sodium dodecyl sulphate (SDS) (Debet and Gidley 2006), and alkali reagents (such as sodium hydroxide) (Nadiha et al. 2010; Wang et al. 2014).

Several studies on the effects of surfactants treatment were conducted on wheat, maize, cassava, potato, mung bean, and sago starches (Debet and Gidley 2006; Chan et al. 2010; Wang et al. 2014). However, studies on these effects on wheat A-type and B-type starch are limited. Therefore, this study was designed to determine the comparative susceptibilities of normal and waxy A- and B-type wheat starch granules to alkali treatment. The sodium hydroxide (NaOH) was chosen as the surfactant treating agent to remove the surface proteins of starch granules, and its effects on physicochemical and structural properties of wheat A- and B-type starch granules were investigated. The results are expected to be useful in understanding the role of surface proteins on the properties of wheat A- and B-starch.

Materials and methods

Materials

The normal and waxy wheat (T. aestivum L.) were provided as grains by the College of Agriculture, Northwest A&F University, Yangling, China, from the 2013 harvest. The wheat grain was milled by using a laboratory mill (mill type Perten 3100, Swedish Perten Company, Sweden) to obtain a whole-wheat meal. All the chemicals and reagents used were of analytical grade.

Wheat starch isolation

The wheat starch granules were isolated from the flours following the method described by Singh et al. (2010b). Briefly, stiff dough was prepared by mixing 100 g flour and 50 ml water in a pan, and the dough ball was subsequently kept at 30 °C for 1 h. The dough ball was then kneaded by hand in distilled water, and the starch slurry was collected. Starch was suspended in distilled water, passed through a 100-mesh nylon cloth for twice to remove bran and endosperm cell-wall impurities. The material retained on the cloth was discarded. Starch slurry was then centrifuged at 2500 g for 10 min. The upper pigmented layer was carefully removed, and decanted from any more starch, which had settled after 30 min. The starch fraction along with starch from decanting step was purified by resuspending in distilled water and centrifugation before drying in an oven at 40 °C for 24 h.

Separation of the A-and B-granule

The A- and B-granules were separated by the method as described by Zeng et al. (2011). The wheat starch suspension with a concentration about 10 % was sedimented using a 2 l cylinder. The fraction of 1 h precipitate was collected as A-granules and the sediment resuspended and sedimented as before after three times was collected as B-granules. The separated A- and B-granule suspensions were centrifuged at 7000 rpm for 20 min and washed with three volumes of ethanol one time. These starches were recovered by using filter and then dried in a convection oven at 40 °C for 24 h.

Granule size distribution

Starch granule size distribution was analyzed by using a laser light-scattering particle size analyzer (Mastersizer–2000, Malvern Instruments Ltd., Malvern, UK). About 0.1 g starch sample was dissolved in 100 ml distilled water and mixed using a magnetic stirrer for 30 min at room temperature before measurement. The focal length of 100 mm and obscuration level of 20 % was maintained during measurements on the analyzer.

Protein removal treatment

Each starch sample (3 mg, dry weight) was weighed into 100 ml conical flask, and 25 mL of 0.2 % NaOH solution were added into samples. The samples were brought to 30 °C with stirring at 250 rpm for 30 min, and the starch slurry was then centrifuged at 4000 rpm for 10 min. The supernatant liquid was discarded and the starch granules were re-suspended into NaOH solution, such step was repeated three times. Next, the starch cake was washed with distilled water for 5 times until the pH value of the filtrate was 7. The resulting protein free starch (PRMS) was dried for further analysis.

Chemical composition

The starch content, lipid, protein and ash content were performed by the standard AACC Methods 76–13, 30–25, 46–30 and 08–01, respectively (AACC 2000).

Microscopy analysis

Light microscopy

Starch sample was suspended in a glycerol solution (glycerol/H2O2, V/V) and was observed using a polarizing light microscope (DMBA400, Motic China Group Co., Ltd, Guangzhou, China) with a 40× objective.

Scanning electron microscopy (SEM)

A starch sample was mounted on an SEM stub with double-sided adhesive tape and coated with gold. Scanning electron micrographs were taken using a scanning electron microscope (JSM–6360LV, JEOL, Japan).

X-ray diffraction

X-ray powder diffraction (XRD) measurements were analyzed using an X-ray diffractometer (Rigaku D/max–2551/PC, Rigaku Corporation, Tokyo, Japan) with the following operating conditions: radiation source, CuKa; angle of diffraction scanned from 5° to 60°; step size, 0.02; step time, 2 s. To avoid the influence of relative humidity on relative crystallinity, the starch samples were equilibrated in a 100 % relative humidity chamber for 48 h at room temperature. The relative crystallinity degree of the samples was calculated as the proportion of crystalline area to total area multiplied by 100.

Pasting properties

Pasting properties of starches were determined using a Rapid Visco-Analyser (RVA) model Master (Newport Scientific, Pty Ltd, Australia). Deionized water (25.0 g) was added to starch (2.0 g, db) in the RVA canister to obtain a total constant sample weight of 27.0 g. The slurry was then manually homogenized using the plastic paddle to avoid lump formation before the RVA run. The starch slurry was heated from 50 to 95 °C at the rate of 12 °C/min, maintained at 95 °C for 2.5 min, and then cooled to 50 °C at the same rate.

Thermal properties

Thermal properties were measured by a differential scanning calorimeter (DSC2000, New Castle, USA). Starch (3 mg) was directly measured into the aluminum DSC pan and distilled water (12 μl) was added with a microsyringe, and an empty pan was used as reference for all measurements. The scanning temperature and the heating rates were 30–120 °C and 10 °C/min, respectively.

Swelling power

Swelling power was determined following the modified method of Leach et al. (1959). The starch suspension was stirred at 90 °C for 30 min, cooled, and centrifuged at 3000 g for 15 min. The values for swelling power were calculated in grams per gram and that of solubility index in percent at 90 °C.

Freeze thaw stability (syneresis)

Freeze thaw stability was determined by the method of Wu and Seib (1990) with little modification, starch paste prepared by heating a 6 % (w/v) in a boiled water bath maintained for 30 min. Then the starch paste was stored at −18 °C for 24 h and thawed at 25 °C for 2 h, followed by centrifugation at 3000 rpm for 20 min. The freeze thaw stability was calculated as percentage weight of exudates per weight of paste.

Statistical analysis

All the experiments were performed at least in triplicate and experimental data also were analyzed using Analysis of Variance (ANOVA), and expressed as mean value ± standard deviation. A Duncan’s multiple range test was conducted to assess significant differences among experimental mean values (P < 0.05). All statistical computations and analyses were conducted using SPSS version 13.0 for Windows.

Results and discussion

Particle size distribution

Granule size distribution profiles for native, fractionated A- and B-type wheat starches from normal and waxy wheat grains are presented in Fig. 1. Both of the native normal and waxy wheat starches showed the typical bimodal particle size distributions patterns. The A- and B-type granules isolated from both normal and waxy wheat grains, as expected, exhibited a unimodal distribution (Fig. 1a, b). In addition, the granule size distribution profiles of purified A- and B-type starch granules are good enough to match with those of their respective native starches (Fig. 1a, b). This demonstrated that both of the fractionated normal and waxy A- and B-type starch granules are reasonably representative of the A- and B-type granules within their respective original wheat starch granules.

Compositions

The proximate composition of native wheat starch and isolated A- and B-granules before and after protein removal treatment is presented in Table 1. For both normal and waxy wheat genotype, small B-type (relative to large A-type) granule fractions possessed higher protein content (Table 1). This may be due to their greater surface to volume ratio which could be associated with more protein compared to their large counterparts. After protein removal treatment, the protein content of native, A- and B-type granule fractions from normal and waxy wheat lines decreased significantly. The protein associated with starch granules didn’t completely removed after protein removal treatment, this may be due to some of the starch granule-associated proteins are still existed within the starch granules. Meanwhile, the starch purity, fat and ash content of normal and waxy native, A- and B-type wheat starch granule fractions remained essentially unchanged after treatment (Table 1).

Morphological characteristics

Scanning electron micrographs and polarized light micrographs of native, A- and B-granules of normal and waxy wheat starches before and after protein removal treatment are shown in Fig. 2. As expected, both normal and waxy native wheat starch granule exhibited a bimodal distribution for the small B-type (granule size less than 10 μm in diameter) and large A-type (the granule diameter ranged from 10 to 40 μm). As observed by SEM, normal and waxy A-type granules possessed the typical disc-like, oval or lenticular shape with smooth surfaces, the purity of A-type starch granule populations from two genotypes is very high, and the A-type starch fractions were not contaminated by smaller B-type starch granules. Similarly, the B-type starch granule fractions of both normal and waxy type exhibited small, spheroidal, irregular and disc-like shapes, also no contaminating A-type starch granules were observed. These measurements coincided with granule size distribution profiles analysis (Fig. 1).

In addition, there was no visual difference in the morphologies of the normal native, fractionated A- and B-type wheat starches compared to their waxy counterpart. However, Kim and Huber (2010) have reported that the starch from waxy wheat had a more spherical disc-like morphology compared with the normal varieties, and the starch granules from normal wheat showed thicker than the starch from waxy wheat was reported by Zhou et al. (2014). The difference may be due to the different wheat varieties used in respective research.

Polarized light micrographs of the normal and waxy native, fractionated A- and B-type wheat starches showed a characteristic birefringence pattern with a Maltese cross centered at the hilum, indicating an arrangement of starch molecules (Fig. 2). Granule birefringence indicated orderly radial orientation of the constituent polymer, and its intensity is influenced by granule shape and by the orientation of the granule with respect to the light beam (Buléon et al. 1998). The shape and birefringence of fractionated A- and B-type from normal and waxy wheat genotypes was similar. However, it is seen that both the normal and waxy B-type wheat starches displayed lower intensity of birefringence than their A-type counterparts. Moreover, the intensity of birefringence depends on the granular size, relative crystallinity, and microcrystalline orientation (Zhang et al. 2013). This suggests that the crystalline areas in A-type wheat starches are better ordered than in B-type wheat starches.

After protein removal treatment, no appreciable changes on the shape, surface and Maltese cross of the normal and waxy native, A- and B-type wheat starch granules surface could be observed, and no obvious changes between native and treated starch could be found (Fig. 2). The fact that in our experiment suggests that both normal and waxy wheat starch has a relatively high granular structural integrity. The 0.2 % NaOH solution treatment probably affected only the non-covalent bonding between starch and protein without damaging the starch molecular or granular structures.

X-ray diffraction

The X-ray diffraction pattern and related crystal parameters of native normal and waxy wheat starches and their isolated A- and B-type starch granules determined before and after protein removal treatment are presented in Fig. 1c, d and Table 1, respectively. The X-ray diffraction patterns of normal and waxy wheat starches and their isolated A- and B-type were A-type, which was mainly displayed at 15°, 17°, 18°, 20° and 23°, while the diffraction peak at 17° and 18° showed a connected doublet; weak diffraction peaks appeared at 20° (Fig. 1c, d). Meanwhile, Powder X-ray diffraction patterns exhibited major peaks at a d-spacing around at 5.90, 5.20, 4.90, 4.40 and 3.80 nm for all wheat starch granule fractions (Table 1), indicative of an A-crystalline packing arrangement.

The relative crystallinity of native waxy starch and its A- and B-type granule fractions were generally higher than their normal wheat starch counterparts (Table 1). The X-ray diffraction patterns of starch granules regular array of double helices that are formed by the singly branched and unbranched amylopectin side chains with more than 10 glucose units (Gidley 1987). Meantime, amylopectin has generally been considered responsible for starch crystallinity, while amylose disrupts the crystalline packing of amylopectin (Cheetham and Tao 1998). In comparison with normal wheat starch, waxy wheat starch has more amylopectin molecules, and in turn more side chains with appropriate glucose units to form double helices, which accounts for the its higher relative crystallinity degree.

Within a genotype, A-type granule fractions exhibited higher relative crystallinity degree value than its native and B-type granules for both normal and waxy wheat varieties (Table 1), which was in agreement with the previous studies (Kim and Huber 2010). However, Ao and Jane (2007) reported that the wheat starch granules with the average diameters about 2 μm exhibited greater relative crystallinities than larger granules. The different literature reports about A- and B-type starch granule relative crystallinities degree might be attributed to differing granule size distributions for wheat starch small granule fractions analyzed in different studies (Kim and Huber 2010).

The protein removal treatment did not alter the A-type X-ray diffraction pattern of all starch samples, as expected (Fig. 1c, d), because this treatment did not melt the double-helical crystalline structure. Israkarna et al. (2014) also reported that the X-ray diffraction patterns of mung bean and cassava starch did not change after 100 mM NaOH solution treatment for 18 h. However, it was observed that protein removal reduced the absorbance of 20° 2θ peak on X-ray diffraction curves (Fig. 1c, d). The peak at 2θ = 20° corresponding to the presence of amylose-lipid complexes (Shevkani et al. 2011). This may be related to that the interaction force between amylose and lipid could be reduced by changing the amylose conformation after NaOH solution treatment.

In addition, the percentage of crystallinity of native normal and waxy wheat starches and their isolated A- and B-type starch granules increased significantly (P < 0.05) after protein removal treatment. The results are also in agreement with the previous reported by Israkarna et al. (2014) on mung bean and cassava starch, and by Singh et al. (2014) on maize starch. They attributed this increase to the drastic decrease of amylose in the amorphous region of starch, as well as the rearrangement of the double helix of amylopectin during drying in a hot-air oven at 40 °C. The results indicated that the changes of starch structure mainly occurred in the amorphous region of the wheat starch granules during protein removal treatment.

Pasting properties

The pasting viscosity profiles of native normal and waxy wheat starches and their isolated A- and B-type starch granules analyzed using the Rapid Visco-Analyzer are shown in Fig. 3a, b, and the specific pasting characteristic values obtained from the pasting profiles are given in Table 2. Waxy wheat starches and its isolated A- and B-type starch exhibited a sharp peak and jagged pasting profile (Fig. 3b). This was due to the enormous swelling when cooked in water and a rapid dispersion when swollen to the largest extent of the of waxy wheat starch granules (Huang et al. 2014). Meanwhile, the normal wheat starches and its isolated A- and B-type starch showed broader peaks and smoother pasting profiles than waxy wheat starch (Fig. 3a). The pasting profiles gave evidence of the spatial structure diversity between normal and waxy wheat starch granules. Normal wheat starch and its isolated A- and B-type starch exhibited a higher trough, final and setback viscosity, and pasting temperature and peak time, compared to their waxy counterparts, while waxy wheat starch and its isolated A- and B-type starch had a higher peak and breakdown viscosity compared to their normal counterparts (Table 2). The high pasting temperature of normal wheat starch indicates that it has a higher resistance to swelling and rupture as proved by its pasting viscosity profiles in Fig. 3a.

A-type granule fractions from both normal and waxy wheat genotype exhibited higher viscosities at practically all points of the pasting profile (Fig. 3a, b), and thus exhibited higher peak, trough, final, breakdown, and setback viscosities compared to B-type starch granule fractions (Table 2). The results are coincided with the results reported by Kim and Huber (2010). The higher viscosities for large A granules may be due to their loose packing ability leading to occupancy of a relatively larger volume than the smaller granules (Singh et al. 2010b; Shevkani et al. 2011; Kaur et al. 2015). Generally, the differences in the pasting properties for different starch granules have been associated with their amylose, lipid, and protein contents, and the extent of amylose leaching, granular swelling, friction between swollen granules, phosphate monoester content and/or the proportion of long amylopectin branch chains, and granule size of starches (Jane et al. 1999; Jayakody et al. 2007; Shevkani et al. 2011). Amylose acts both as a diluent and as an inhibitor of swelling, which can form insoluble complexes with some of the amylose during swelling and gelatinization (Tester and Morrison 1990).

In both kind of genotype, protein removal treatment increased peak, setback, final viscosity, breakdown viscosity of native, A- and B-type granule fractions. However, the protein removal treatment decreased pasting temperature, peak time and trough viscosity of starches both wheat varieties (Table 2). Lim et al. (1999) reported that peak viscosity of rice starch pastes increased and pasting temperature decreased when starch was purified to remove more proteins. The study of Han et al. (2002) also showed that granule-associated protein reduced paste viscosity and breakdown viscosity of maize starch pastes. The lower pasting temperature of wheat starch after protein removal indicates that it has a lower resistance to swelling and rupture.

The higher setback viscosity of normal and waxy wheat starch granules after protein removal indicates more extensive amylose leaching. This could be attributed to the removal of surface protein by NaOH solution would facilitate the amylose leaching from starch granule. These results indicated that the normal and waxy wheat starch and their A- and B-type granule fractions treated by extractions of protein tend to swell or gelatinize in a low temperature range and the swollen starch granules become readily ruptured by the mechanical shear. These data also indicated that amylose and protein played an important role in granule swelling restriction and starch pasting properties.

Thermal properties

The gelatinization transition temperatures including To (onset), Tp (peak), Tc (conclusion), the gelatinization temperature range ΔTr (Tc–To) and the enthalpy (ΔH) of gelatinization of normal and waxy wheat starches are analyzed using DSC and the results are presented in Table 2 and Fig. 3c, d. Normal and waxy wheat starches and their A- and B-type granule fractions displayed a characteristic endothermic transition occurring between 60 and 80 °C (Fig. 3c, d). Native waxy wheat starch and its A- and B-type starch granule fractions generally presented higher gelatinization temperatures (To, Tp, Tc), gelatinization temperature range (ΔTr), and gelatinization enthalpies (ΔH) compared to their corresponding normal starch granule counterparts. Within a genotype, A-type starch fractions exhibited higher To, Tp and ΔH, while B-type starch fractions possessed higher gelatinization temperature range (ΔTr) (Table 2). These results are agrees with the results reported by Kim and Huber (2010).

The protein removal treatment increased gelatinization temperatures (To, Tp, Tc) of normal and waxy wheat starch and their A- and B-type granule fractions significantly (P < 0.05) compared to their untreated counterparts, and this was more pronounced in the waxy starches than in the normal starches. The protein removal treatment seemed to increase ΔH and decrease the ΔTr of both normal and waxy wheat starch and their isolated A- and B-type granules slightly, whereas no significant difference (P < 0.05) for each of these characteristic values could be found before and after treatment (Table 2). Nadiha et al. (2010) also reported that the onset and peak temperatures of gelatinization of sago, corn, and potato starch increased significantly, while the gelatinization enthalpy decreased after 0.025 M of NaOH solution treatment. Similar findings were also previously reported for alkali-treated wheat starch, showing that the gelatinization temperature (To, Tp, and Tc) of wheat starch increased and the thermal transition temperature range (ΔTr) decreased after treatment (Wang et al. 2014). The decreased ΔTr were indicative of the increase in the homogeneity of crystallites within protein removed starch granules. ΔH is the energy needed for the dissociation of double helices order, which reflect the integrity of crystalline or double helical order of starch granules. The little gelatinization reduction of protein removal-treated wheat starch compared to untreated starch granules suggests that the energy transformation that occurs during melting and uncoiling of the double helices of crystallite amylopectin was decreased.

Starch gelatinization involves the uncoiling and melting of the external chains of amylopectin, which are packed together as double helices in clusters. Higher thermal transition a temperature has been associated with a higher degree of crystallinity or more ordered crystalline structure, which provides structural stability and resistance to gelatinization (Singh et al. 2003). Therefore, the higher gelatinization temperature observed for normal and waxy starch and their isolated A- and B-type granule fractions after protein removal treatment is in harmony with their higher crysatlliniy degree values (Table 2). According to Mondragón et al. (2004), the higher gelatinization temperature of alkali-treated starch might be attributed to the rearrangement of polymer chains into more stable configurations when the steeped starch is held below the gelatinization temperature. Besides, the Na+ likely diffuse into starch granules through small pores on the granule surfaces that would enhance the stability of the granule through electrostatic interaction between the Na+ ions and the hydroxyl groups of starch (Méndez-Montealvo et al. 2007; Nadiha et al. 2010).

Swelling power

The swelling power of normal and waxy wheat starches and their A- and B-type granule fractions before and after protein removal treatment are measured at 50–90 °C, and the result are presented at Table 3. The swelling power of all starch samples increased as heating temperature increased. Normal wheat starch had a lower swelling power throughout the range of temperatures compared with waxy wheat starch. The swelling power of normal native, A- and B-type wheat starch showed no distinct difference compared to their waxy counterpart from 50 to 60 °C. A sharp increase in swelling power of waxy wheat starch and its A- and B-type granule fractions was observed from 70 °C, whereas the change in normal wheat starch and its A- and B-type granule fractions was much less marked. In addition, purified B-type starch granule fractions of both normal and waxy wheat types possessed slightly greater swelling power than purified A-type starch counterparts (Table 3).

The swelling power is influenced by the amylose to amylopectin ratio and by the characteristics of the amylose and amylopectin in terms of molecular weight/distribution, degree of branching and branch length, and conformation (Singh and Kaur 2004). Besides, Tester and Karkalas (1996) reported that the starch granules with higher amylose content were being better reinforced and thus more rigid and swell less freely, while the starch granules with low amylose content were less rigid and can swell freely when heated. The relative lower swelling power values of normal wheat starch and its isolated A- and B-type granule fractions compared to their corresponding normal starch granule fractions at high temperature (70–90 °C) are relevant to their high amylose content. Shevkani et al. (2011) also reported the detrimental effect of amylose and amylose-lipids on swelling power and viscosity of wheat starches.

The swelling power of normal wheat starch and its A- and B-type granule fractions decreased at 50–60 °C while increased at 70–90 °C after subjecting to protein removal treatment. Meanwhile, the swelling power of waxy wheat starch and its A- and B-type granule fractions decreased at 50–70 °C while increased at 80–90 °C after treatment (Table 3). This is consistent with the results of peak viscosity (Table 2). These results are remarkably similar with the results reported by Debet and Gidley (2006) and Wang et al. (2014), wherein a great increase of swelling power was observed after sodium dodecyle sulphate and alkali reagents treatment, respectively. The increases in swelling power of protein removal treated wheat starch granules can be attributed to the disruption of the amorphous region in the granule, which presumably reduce the restraining effect of amylose and approximately allow the amorphous region in starch granule to absorb water easily, thus allowing the granule to swell more freely (Chan et al. 2010).

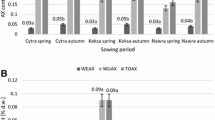

Freeze thaw stability

The percentage syneresis of normal and waxy wheat starch and their A- and B-type starch gels with or without protein removal treatment as a function of one time freeze-thaw cycling is shown in Fig. 3e, f. The syneresis values of normal and waxy A-type starch gels were much higher than that of their parent native wheat starch gels and B-type starch gels. The protein removal treatment significantly increased the syneresis values of both normal and waxy native wheat starch and their A- and B-type starch gels (Fig. 3e, f). Syneresis is an important parameter critical to the tendency of retrogradation and the stability of a gel system, which is important in the food industry. During cold storage, the reorganization of starch molecules may result in the release of water (or syneresis) and this may affect the functional properties in terms of viscosity or gel behavior (Pongsawatmanit and Srijunthongsiri 2008).

The higher syneresis values of A-type starch gels may be related to its lower water absorption capacity, the absence of starch granules and freedom of the starch molecules to interact with each other during freezing of the starch gel. The significant increase in syneresis values of wheat starch gels that was observed after protein removal treatment may be attributed to a greater degree of molecular associations between the starch molecules. These associations occurred via hydrogen bonding between hydroxyl groups, which had important roles in the aggregation of the starch molecules. The facilitation of the hydrogen bonding interactions between the starch molecules after protein removal treatment resulting in increased retrogradation, which is consistent with the results of setback viscosity (Table 2).

Conclusion

We demonstrated that alkali treatment can effectively remove the proteins from starch granules without significantly affecting the surface morphological, birefringence pattern and X-ray diffraction pattern of normal and waxy wheat starch and their A- and B-type starch. Our results have shown that the changes of starch structure mainly occurred in the amorphous region of the wheat starch granules during protein removal treatment, which presumably reduce the restraining effect of amylose and approximately allow the amorphous region in starch granule to absorb water easily, thus allowing the granule to swell more freely. Moreover, the physicochemical properties of these wheat starch granules were affected to variable degrees. All starches showed a significant increment in crystallinity degree, swelling power, gelatinization temperatures, percentage syneresis and the overall change in the pasting profile for the treated starches was a reduction in pasting temperature, peak time and trough viscosity accompanied with increase in peak, setback, final viscosity, breakdown viscosity. The changes in physicochemical and structural properties of normal and waxy wheat starch granules and their A- and B-type granule fractions could be predominantly attributed to the removal of surface protein and their different amylose content.

References

AACC (2000) Approved methods of the AACC, 10th edn. American Association of Cereal Chemists, St. Paul

Ao Z, Jane JL (2007) Characterization and modeling of the A- and B-granule starches of wheat, triticale, and barley. Carbohydr Polym 67:46–55

Baldwin PM (2001) Starch granule-associated proteins and polypeptides: a review. Starch-Starke 53:475–503

Buléon A, Colonna P, Planchot V, Ball S (1998) Starch granules: structure and biosynthesis. Int J Biol Macromol 23:85–112

Chan HT, Bhat R, Karim AA (2010) Effects of sodium dodecyle sulphate and sonication treatment on physicochemical properties of starch. Food Chem 120:703–709

Cheetham NWH, Tao L (1998) Variation in crystalline type with amylose con-tent in maize starch granules: an X-ray powder diffraction study. Carbohydr Polym 36:277–284

Debet MR, Gidley MJ (2006) Three classes of starch granule swelling: influence of surface proteins and lipids. Carbohydr Polym 64:452–465

Gidley MJ (1987) Factors affecting the crystalline type (A–C) of native starches and model compounds: a rationalization of observed effects in terms of polymorphic structures. Carbohydr Res 161:301–304

Han XZ, Campanella OH, Guan H, Keeling PL, Hamaker BR (2002) Influence of maize starch granule-associated protein on the rheological properties of starch pastes. Part I. Large deformation measurements of paste properties. Carbohydr Polym 49:315–321

Huang JR, Chen ZH, Xu YL, Li HL, Liu SX, Yang DQ, Schols HA (2014) Comparison of waxy and normal potato starch remaining granules after chemical surface gelatinization: pasting behavior and surface morphology. Carbohydr Polym 102:1001–1007

Israkarna K, Nakornpanom NN, Hongsprabhas P (2014) Physicochemical properties of starches and proteins in alkali-treated mungbean and cassava starch granules. Carbohydr Polym 105:34–40

Jane J, Chen YY, Lee LF, McPherson AE, Wong S, Radosavlievic M, Kasemsuwan T (1999) Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem 76:629–637

Jayakody L, Hoover R, Liu Q, Donner E (2007) Studies on tuber starches. II. Molecular structure, composition and physicochemical properties of yam (Dioscorea Sp.) starches grown in Sri Lanka. Carbohydr Polym 69:148–163

Kaur A, Shevkani K, Singh N, Sharma P, Kaur S (2015) Effect of guar gum and xanthan gum on pasting and noodle-making properties of potato, corn and mung bean starches. J Food Sci Technol 52:8113–8121

Kim HS, Huber K (2010) Physicochemical properties and amylopectin fine structures of A- and B-type granules of waxy and normal soft wheat starch. J Cereal Sci 51:256–264

Leach HW, McCowen LD, Schoch TJ (1959) Structure of the starch granule. Swelling and solubility patterns of various patterns of various starches. Cereal Chem 36:534–544

Lim ST, Lee JH, Shin DH, Lim HS (1999) Comparison of protein extraction solutions for rice starch isolation and effects of residual protein content on starch pasting properties. Starch-Starke 51:120–125

Méndez-Montealvo G, Trejo-Espino JL, Paredes-Lópoz O, Bello-Pérez LA (2007) Physicochemical and morphological characteristics of nixtamalized maize starch. Starch-Starke 59:277–283

Mondragón M, Bello-Pérez LA, Agama-Acevedo E, Betancur-Ancona D, Peňa JL (2004) Effect of cooking time, sleeping and lime concentration on starch gelatinization of corn during nixtamalization. Starch-Starke 58:248–253

Nadiha MZN, Fazilah A, Bhat R, Karim AA (2010) Comparative susceptibilities of sago, potato and corn starches to alkali treatment. Food Chem 121:1053–1059

Pongsawatmanit R, Srijunthongsiri S (2008) Influence of xanthan gum on rheological properties and freeze thaw stability of tapioca starch. J Food Eng 88:137–143

Rayas-Duarte P, Robinson SF, Freeman TP (1995) In situ location of a starch granule protein in durum wheat endosperm by immunocytochemistry. Cereal Chem 72:269–274

Sahlström S, Bævre AB, Bråthen E (2003) Impact of starch properties on hearth bread characteristics. II. Purified A- and B-granule fractions. J Cereal Sci 37:285–293

Shevkani K, Singh N, Singh S, Ahlawat AK, Singh AM (2011) Relationship between physicochemical and rheological properties of starches from Indian wheat lines. Int J Food Sci Tech 46:2584–2590

Singh N, Kaur L (2004) Morphological, thermal, rheological and retrogradation properties of starch fractions varying in granule size. J Sci Food Agric 84:1241–1252

Singh N, Singh J, Kaur L, Sodhi NS, Gill BS (2003) Morphological, thermaland rheological properties of starches from different botanical sources. Food Chem 81:219–231

Singh J, Dartois A, Kaur L (2010a) Starch digestibility in food matrix: a review. Trends Food Sci Tech 21:168–180

Singh S, Singh N, Isono N, Noda T (2010b) Relationship of granule size distribution and amylopectin structure with pasting, thermal, and retrogradation properties in wheat starch. J Agric Food Chem 58:1180–1188

Singh N, Shevkani K, Kaur A, Thakur S, Parmar N, Virdi AS (2014) Characteristics of starch obtained at different stages of purification during commercial wet milling of maize. Starch-Starke 66:668–677

Tester RF, Karkalas J (1996) Swelling and gelatinization of oat starches. Cereal Chem 73:271–273

Tester RF, Morrison WR (1990) Swelling and gelatinization of cereal starches. I. Effects of amylopectin, amylose, and lipids. Cereal Chem 67:551–557

Wang SJ, Luo HY, Zhang J, Zhang Y, He ZH, Wang S (2014) Alkali-Induced changes in functional properties and in vitro digestibility of wheat starch: the role of surface proteins and lipids. J Agric Food Chem 62:3636–3643

Wu Y, Seib PL (1990) Acetylated and hydroxypropylated distarch phosphates from waxy barley: paste properties and freeze thaw stability. Cereal Chem 67:202–208

Zeng J, Li GL, Gao HY, Ruv ZG (2011) Comparison of A and B starch granules from three wheat varieties. Molecules 16:10570–10591

Zhang BJ, Li XX, Liu J, Xie FW, Chen L (2013) Supramolecular structure of A- and B-type granules of wheat starch. Food Hydrocolloid 31:68–73

Zhou ZK, Zhang Y, Chen XS, Zhang M, Wang ZW (2014) Multi-scale structural and digestion properties of wheat starches with different amylose contents. Int J Food Sci Tech 49:2619–2627

Acknowledgments

This study was financially supported by the Fundamental Research Funds for the Natural Science Foundation of China (31301557), Central Universities (Northwest A&F University, 2014YB019), and Doctoral Scientific Research Starting Foundation of Northwest A&F University (2011BSJJ076).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Wu, G., Luo, Q. et al. Effects of removal of surface proteins on physicochemical and structural properties of A- and B-starch isolated from normal and waxy wheat. J Food Sci Technol 53, 2673–2685 (2016). https://doi.org/10.1007/s13197-016-2239-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2239-3