Abstract

Drying kinetics of watermelon pomace was investigated in fluidized-bed and cabinet dryers using 2–6 kg/m2 tray loads at 50–70 °C. Drying behavior was described by the Page’s model with high coefficient of determination (≥0.96), lower standard error (≤0.03) and scattered residual plot. Effective moisture diffusivity of pomace during drying varied from 0.880 × 10−8 to 3.541 × 10−8 m2/s for fluidized bed and 0.347 × 10−8 to 0.868 × 10−8 m2/s for cabinet dryers. Arrhenius’s equation adequately explained the relationship between the drying rate constant/effective moisture diffusivity and drying air temperature. Lycopene content of dehydrated watermelon pomace was 11.0–17.3 mg/100 g dry basis in fluidized-bed dryer and 9.3–15.4 mg/100 g dry basis in cabinet dryer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Watermelon (Citrullus lanatus Thunb) is cultivated throughout the warmer parts of the world. The watermelon production of the world was 105 million tons and leading growers are China, Turkey, Iran, Brazil and United States (FAO 2014). Fruit is consumed in hot and dry season on account of its cool, refreshing and sweet taste. Processing of watermelon yields major solid waste pomace rich in pigments. Fresh pomace contains 20 mg/100 g lycopene content which is about 4.5 times higher than the flesh (Arocho et al. 2012). Watermelon pomace has moisture content of about 95 % making it susceptible to microbial deterioration leading to environement problems (Kerje and Grum 2003). However, it can be preserved by reducing the moisture to a safe level where microorganisms cannot grow and cause spoilage (Falade et al. 2007).

Lycopene is the main carotenoid in watermelon, accounting for 84–97 % of total carotenoids (Perkins-Veazie and Collins 2006; Kang et al. 2010) with higher relative antioxidant potential (Perkins-Veazie et al. 2006; Pinto et al. 2011). Lycopene quenches free radicals formed during normal metabolism and deactivate DNA chain breaking agents that are implicated in some cancers (Sies and Stahl 1998). Lycopene undergoes degradation via isomerization and oxidation which has direct impact on the sensory quality and health benefits of finished products (Shi et al. 2002). Watermelon pomace is an excellent source of lycopene having potential application in food products to increase their aesthetic and therapeutic value. It can also be used in animal feed like poultry, cattle, swine, aquaculture etc. or as a fuel in boilers or extraction of pectin and fibers. This investigation has been carried out to study drying behavior of watermelon pomace.

Materials and methods

Materials

Mature ripe fruits of watermelons cultivar “Namdhari” were procured from the farm located in Kapurthala (India). Fruits were thoroughly washed, cut into quarters and rind was removed by stainless steel knife manually. Flesh was cut into small pieces and passed through the screw juice extractor (Kalsi Industries Ltd., Ludhiana, India). The pomace was collected and used for study.

Drying of watermelon pomace

Pomace was dried in a fluidized bed dryer (Endecotts Ltd., London, U.K.) and cabinet dryer (La Parmigiana, Fidenza, Italy) at different temperatures (50, 60 and 70 °C) and feed rates (2, 4 and 6 kg/m2). The initial weight was considered as the mass at zero time. The change in weight was observed at 10 min interval in fluidized bed dryer and at hourly interval in cabinet dryer. The drying was carried out till three constant readings were obtained. The initial moisture content of watermelon pomace was determined by keeping in a vacuum oven (Narang Scientific Pvt Ltd., New Delhi, India) at 60 ± 2 °C and 100 mm Hg pressure for 24 h.

Drying model

The Page’s model was used to describe drying behavior of watermelon pomace:

where MR- moisture ratio; mt –moisture content dry basis (% db) at any given instant time t; me - equilibrium moisture content (% db); mo - initial moisture content (% db); t - time (h); k – drying rate constant (l/h); n - dimensionless coefficient.

Effective moisture diffusivity

Fick’s second law of diffusion assuming uni-dimensional moisture movement without volume change, constant diffusivity, uniform initial moisture distribution and negligible resistance was used to compute moisture diffusivity from experimental drying data (Crank 1975; Sinija and Mishra 2009). The second law of diffusion can be transformed in the form of following equation (Doymaz et al. 2004; Akpinar and Toraman 2013; Koua et al. 2013).

where D: effective moisture diffusivity (m2/s); l: average sample thickness (2 kg/m2 is 0.007 m, 4 kg/m2 is 0.009 m, 6 kg/m2 is 0.011 m).

The correlation between drying rate constant and effective moisture diffusivity was also found using linear, exponential and power models. The adequacy of the model was evaluated on the basis of coefficient of determination (R2).

Effect of temperature on drying rate constant and effective moisture diffusivity

The Arrhenius law can be used to relate ‘k’ and ‘D’ with drying air temperature and to calculate the activation energy:

where ko- frequency factor (l/h); Do – Reference diffusion coefficient at infinitely high temperature; Ea- activation energy (kJ/mol); R- Universal gas constant (8.314 kJ/mol.K); T -Absolute temperature (K).

Lycopene retention and visual color

Sample (2 g) was extracted with acetone in a pestle and mortar till residues became colorless. Lycopene was transferred into petroleum ether phase by diluting acetone extract in a separating funnel, passed through sodium sulfate, volume made to 50 ml and absorbance was measured at 503 nm using UV visible spectrophotometer (Shimadzu, Kyoto, Japan) (Sadler et al. 1990). The extinction coefficient (17.2 × 104 mol cm−1) was verified with standard lycopene solution (Sigma Chemical Co, St. Louis, U.S.A.) and used to determine lycopene in the sample.

Visual color was measured using a Hunter colorimeter (Hunter Associates Laboratory, Virginia, U.S.A.) in terms of L (lightness), a (redness and greenness) and b (yellowness and blueness). ΔE = √L2 + a2 + b2 indicates the magnitude of color difference between fresh vacuum dried sample and dried samples of different dryers at different temperatures.

Statistical analysis

The parameters were estimated by fitting the mathematical model to experimental data, using nonlinear regression. The adequacy of models was evaluated by the R2, standard error (SE) and the pattern of residual plots. The data on drying and effective moisture diffusivity were analyzed following one way analysis of variance (ANOVA) using Microsoft Excel (Microsoft Inc., Redmond, USA).

Results and discussion

Watermelon processing

On processing, the ‘Namdhari’ cultivar of watermelon yielded 55.28 % juice, 31.47 % rind and 10.44 % pomace (including seeds). The previous studies on processing of watermelon state that watermelon yields 41.5–60 % juice, 31–49.55 % rind and 8.9–23.59 % pomace (Shin et al. 1978; Crandall and Kesterson 1981; Uddin and Nanjundaswamy 1982; Hayoglu and Fenercioglu 1990; Sogi 2003). The present findings are in agreement with the previous results.

Drying characteristics

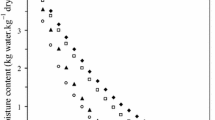

The initial moisture content of watermelon pomace was found to be 925.41 % dry basis (db). The moisture content was reduced to about 6 % (db) at 50–70 °C using 2–6 kg/m2 feed rate in a fluidized bed or cabinet dryer. Drying curves of watermelon pomace at 50–70 °C with feed rates of 2–6 kg/m2 for fluidized bed dryer (Fig. 1 a-c) and for cabinet dryer (Fig. 1 d-f) showed that moisture content decreased continuously with increase in the time indicating that drying of watermelon pomace took place in the falling rate period. Sogi and Bawa (1998) reported that drying of tomato pomace followed the falling rate period pattern during cabinet and sun drying. Kaur et al. (2006) studied drying characteristics of peel isolated from tomato pomace in cabinet and fluidized bed dryer and concluded similar findings.

It took 7–12 h for drying the pomace in cabinet dryer while 2–2.5 h in fluidized bed dryer with tray load of 4 kg/m2 at 50–70 °C. With decrease in tray load to 2 kg/m2, the drying process got completed in 5–7 h in cabinet dryer and 1.2–2 h in fluidized bed dryer at 50–70 °C. With increase in tray load to 6 kg/m2, the drying of watermelon pomace took 8–14 h in cabinet dryer and 2–3 h in fluidized bed dryer at selected temperatures. Hence, fluidized-bed dryer took less time for drying than cabinet dryer. Dehydration of tomato peel in cabinet and fluidized bed dryer revealed that the latter gave good quality product in minimum time (Kaur et al. 2006).

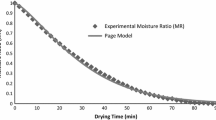

Regression analysis was carried out using Page’s model and the coefficients were determined (Table 1). The drying rate constant (k) varied from 1.244 to 3.705 1/h for fluidized bed dryer and from 0.036 to 0.848 1/h for cabinet dryer respectively. Dimensionless constant (n) varied from 0.806–1.043 to 1.102–1.976 for fluidized-bed dryer and cabinet dryer respectively. The values for the R2 between experimental and predicted values were greater than 0.964 while the SE was less than 0.03 for given temperatures and tray loads. The residual plots showed scattered pattern for both the dryers for given feed rates and drying temperatures. The Page’s model adequately describes the drying behavior of watermelon pomace over the range of temperature used in the study. Two way ANOVA indicated that the drying rate constant (k) significantly (p ≤ 0.05) increased with increased drying air temperature and decreased tray loads for both dryers. This means as the drying air temperature increased, the drying time of watermelon pomace decreased. Similar reports are available on tomato seeds and mushrooms (Sogi et al. 2003; Shivhare et al. 2004).

Effective moisture diffusivity

The effective moisture diffusivity (D) for watermelon pomace varied from 0.880 × 10−8 to 3.541 × 10−8 m2/s for fluidized bed dryer and from 0.347 × 10−8 to 0.868 × 10−8 m2/s for cabinet dryer respectively (Table 2). It was observed that effective moisture diffusivity increased with increase in temperature as well as tray load for both fluidized bed and cabinet dryer. It may be due to increase in vapor pressure inside the pomace at higher temperature. The highest value of diffusivity was found to be 3.541 × 10−8 m2/s and 0.868 × 10−8 m2/s for fluidized bed dryer and cabinet dryer at higher temperature 70 °C and 6 kg/m2 tray load.

Falade et al. (2007) studied kinetics of mass transfer during osmotic dehydration of watermelon slices and concluded that water diffusivities for variable thickness of watermelon slices at different temperatures was in the range between 0.1030 × 10−9 and 3.549 × 10−9 m2/s. Thus water diffusivity of watermelon slices increased with the temperature but decreased by increasing the thickness of the samples.

Akpinar and Toraman (2013) estimated the moisture diffusivity in thin layer drying of ginger slices and found the average effective moisture diffusivity values varied from 2.807 × 10−10 to 6.977 × 10−10 m2/s over the temperature range of 40–70 °C and velocity range 0.8–3 m/s. Similar trend for temperature has been observed in hot air drying but the diffusivity increased with increase in tray load indicating that the thickness of the watermelon pomace did not affect the diffusivity.

Correlation between drying rate constant and effective moisture diffusivity

Different models such as linear, exponential and power were fitted to find out the correlation between ‘k’ and ‘D’. The R2 was maximum using exponential model (0.920) followed by power (0.869) and linear (0.758). The exponential model for ‘k’ and ‘D’ is as follows:

This model can be used for the prediction of ‘D’ for any value of ‘k’ and vice-versa with good level of confidence.

Effect of temperature on drying rate constant and effective moisture diffusivity

Dependence of both ‘k’ and ‘D’ on temperature for fluidized-bed and cabinet dryer was evaluated using Arrhenius Eqs. (3 and 4). Results obtained are presented in Fig. 2 a, b. The activation energy obtained from the slope of plot for ‘k’ were varied from 22.05–32.20 to 19.25–36.66 kJ/mol for fluidized bed and cabinet dryer respectively (Table 3). The activation energy obtained from ‘D’ value varied between 15.67–29.34 and 18.87–31.21 kJ/mol for fluidized bed and cabinet dryer respectively (Table 3). Kaur et al. (2006) found the activation energy was 36.80 kJ/mol in cabinet dryer and 20.59 kJ/mol in fluidized bed dryer for tomato peel at 4 kg/m2 feed rate. Relation between drying temperature and moisture diffusivity was satisfactorily described by an Arrhenius type relationship in thin layer drying of ginger slices (Akpinar and Toraman 2013). An activation energy value of 19.3 kJ/mol was obtained with temperature range of 40–70 °C and air velocity of 0.8–3 m/s in ginger slice drying. Thus results obtained in present study are in close agreement with previous studies.

Effect of drying on lycopene retention and visual color

Lycopene content of fresh watermelon pomace was 19.2 mg/100 g dry basis (db). Lycopene retention varied from 11.0 to 17.3 mg/100 g (db) in fluidized bed dried pomace and 9.3–15.4 mg/100 g (db) in cabinet dried pomace at 50–70 °C (Table 4). Increase in temperature and feed rate had a negative effect on the retention of lycopene. It may be attributed to the fact that drying time increased with the increase in feed rate while lycopene gets degraded at high temperature. Maximum retention of lycopene content was in case of watermelon pomace dried in fluidized-bed which might be due to short drying time. Chawla et al. (2008) reported that lycopene retention was higher in fluidized bed dried tomato pulp as compared with cabinet dried pulp. Shi et al. (2002) studied the kinetics of lycopene degradation in tomato puree and found 0.15–3.47 % relative loss in lycopene during treatment at 90–150 °C for 5–60 min.

Visual color of dried watermelon pomace in terms of ‘L’, ‘a’, ‘b’ is given in Table 4. In fluidized bed dried pomace, ‘L’, ‘a’ and ‘b’ value decreased from 46.23–40.60, 6.37–4.83 to 9.41–6.81 respectively with increase in feed rate and temperature. In the case of cabinet dried pomace, ‘L’, ‘a’ and ‘b’ value decreased from 46.16–39.56, 6.12–4.59 to 9.36–6.59 respectively with increase in feed rate and temperature. It indicated the increase in darkness and decrease in redness and yellowness in watermelon pomace on drying. The color difference increased with increase in temperature and feed rate. Previous results on thin layer drying of tomato slices revealed that ‘L’, ‘a’, ‘b’ decreased with increase in temperature from 50 to 70 °C (Purkayastha et al. 2011).

Conclusion

Drying behavior of watermelon pomace followed the falling rate period pattern and adequately described by Page’s model over the range of temperatures and tray loads used. The effective moisture diffusivity increased with increase in temperature and tray load for both the dryers. Arrhenius’s equation explained well the relationship between the drying rate constant/effective moisture diffusivity and drying air temperature. Effective moisture diffusivity and drying rate constant are correlated by exponential model. Lycopene retention was found to be higher in fluidized dried pomace and can be utilized to make value added products.

References

Akpinar EK, Toraman S (2013) Estimation of the moisture diffusivity and activation energy in thin layer drying of ginger slices. World Acad Sci Eng Technol 78:1308–1311

Arocho YD, Bellmer D, Maness N, Mcglynn W, Patricia RD (2012) Watermelon pomace composition and the effect of drying and storage on lycopene content and color. J Food Qual 35:331–340

Chawla C, Kaur D, Oberoi DPS, Sogi DS (2008) Drying characteristics, sorption isotherms and lycopene retention of tomato pulp. Dry Technol 26(10):1257–1264

Crandall PG, Kesterson JW (1981) Components of processed watermelon fruit. J Am Soc Hortic Sci 106:493–495

Crank J (1975) The mathematics of diffusion. Claredon Press, Oxford

Doymaz I, Gorel O, Akgun NA (2004) Drying characteristics of the solid by-product of olive oil extraction. Biosyst Eng 88:213–219

Falade KO, Igbeka JC, Ayanwuyi FA (2007) Kinetics of mass transfer and color changes during osmotic dehydration of watermelon. J Food Eng 80:979–985

FAO (2014) Food and Agriculture Organisation of United Nation. http://faostat.fao.org/site/567/default.aspx#ancor. Assessed Dec 2014

Hayoglu IA, Fenercioglu H (1990) A research on the possibility of using watermelon juice in fruit juice industry. Gida 15:329–332

Kang B, Zhao W, Hou Y, Tian P (2010) Expression of carotenogenic genes during development and ripening of watermelon fruit. Sci Hortic 124:368–375

Kaur D, Wani AA, Sogi DS, Shivhare US (2006) Sorption isotherm and drying characteristics of tomato peel isolated from tomato pomace. Dry Technol 24:1–6

Kerje T, Grum M (2003) The origin of watermelon (Cucumis melo): a review of the literature. www.vitacost.com

Koua BK, Koffi PME, Fassinou FW, Andoh HY, Gbaha P, Tourpak P (2013) Evaluation of some thin layer drying models and effective moisture diffusivity of yam (Dioscorea rotundata) slices. Pak J Food Sci 23(1):1–9

Perkins-Veazie P, Collins JK (2006) Carotenoid changes of intact watermelons after storage. J Agric Food Chem 54:5868–5874

Perkins-Veazie P, Collins JK, Davis AR, Roberts W (2006) Carotenoid content of 50 watermelon cultivars. J Agric Food Chem 54:2593–2597

Pinto MP, Santos CN, Henriquesa C, Lima G, Quedas F (2011) Lycopene content and antioxidant capacity of Portuguese watermelon fruits. Electron J Environ Agric Food Chem 10(4):2090–2097

Purkayastha MD, Nath A, Deka BC, Mahanta CL (2011) Thin Layer drying of tomato slices. J Food Sci Technol 50:654–654

Sadler G, David J, Dezman D (1990) Rapid extraction of lycopene and β- carotene from reconstituted tomato paste. J Food Sci 55:1460–1461

Shi J, Maguer ML, Bryan M, Kakuda Y (2002) Kinetics of lycopene degradation in tomato puree by heat and light irradiation. J Food Proc Eng 25:485–498

Shin DH, Koo YJ, Kim CO, Min BY, Suh KB (1978) Studies on the production of watermelon and cantaloupe melon juice. Korean J Food Sci Technol 10:215–218

Shivhare US, Arora S, Ahmed J, Raghavan GSV (2004) Moisture adsorption isotherms for mushrooms. LWT Food Sci Technol 37:133–137

Sies H, Stahl W (1998) Lycopene: antioxidant and biological effects and its bioavalibility in the human. Proc Soc Exp Biol Med 218:121–124

Sinija VR, Mishra HN (2009) Thin-layer modeling for drying of pressed tea leaf residue to produce green tea. J Food Sci Technol 46(6):515–524

Sogi DS (2003) Effect of concentration and temperature on viscosity of watermelon juice. J Food Sci Technol 40(5):509–511

Sogi DS, Bawa AS (1998) Dehydration of tomato processing waste. Ind Food Packer 52:26–29

Sogi DS, Shivhare US, Garg SK, Bawa AS (2003) Water sorption isotherm and drying characteristics of tomato seeds. Biosyst Eng 84(3):297–301

Uddin MB, Nanjudaswamy AM (1982) Studies on the processing of watermelon for juice. Bangladesh J Sci Ind Res 17:80–86

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• Watermelon pomace is generated during processing of watermelon.

• It is generally discarded as waste leading to environment problems.

• Watermelon pomace contains more lycopene as compared to its flesh.

• Dehydration can increase the shelf life of pomace.

• Pigment extracted can be used in different food products.

Rights and permissions

About this article

Cite this article

Oberoi, D.P.S., Sogi, D.S. Drying kinetics, moisture diffusivity and lycopene retention of watermelon pomace in different dryers. J Food Sci Technol 52, 7377–7384 (2015). https://doi.org/10.1007/s13197-015-1863-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1863-7