Abstract

The seeds of Terminalia catappa from Malaysia were analyzed for their physicochemical properties. The following values were obtained: moisture 6.23 ± 0.09 %, ash 3.78 ± 0.04 %, lipid 54.68 ± 0.14 %, protein 17.66 ± 0.13 %, total dietary fibre 9.97 ± 0.08 %, carbohydrate 7.68 ± 0.06 %, reducing sugar 1.36 ± 0.16 %, starch 1.22 ± 0.15 %, caloric value 593.48 ± 0.24 %. Studies were also conducted on amino acid profile and free fatty acid composition of the seed oil. Results revealed that glutamic acid was the major essential amino acid while methionine and lysine were the limiting amino acids. The major saturated fatty acid was palmitic acid, while the main unsaturated fatty acid was oleic acid followed by linoleic acid. In addition, the seed was rich in sucrose and had trace amount of glucose and fructose. Briefly, the seed was high in proteins and lipids which are beneficial to human.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nuts have been the food of man from the earliest times and they are appreciated as a source of nutritious food because of their availability, economical sources of protein, high lipid content and their sensory characteristics (Shakuntala and Shadadsharaswamy 1987; Grane-Teruel et al. 2001). There are a lot of studies on the nutritional content of common nuts such as groundnut, pea nut, cashew nut, walnut and etc.

Terminalia catappa Linn tree is known as tropical almond, wild almond, India almond, sea almond, almond tree, castanheiracastanhola, castanholeira, chapeu-de-sol esete-copas etc. and belongs to the Combretaceae family (Nwosu et al. 2008). It is normally grown in full sun on well-drained soil. The branches are arranged in obvious tiers forming layers of canopy, giving the tree a pagoda-like shape. It is originally from South Asia (especially India, Malaysia, Philippines and Indonesia) and even occurs in the West African region in areas with high rainfall (1000–3500 mm) and elevations below 300–400 m from Senegal to West Cameroon (Oboh et al. 2009; Thomson and Evans 2006). The major countries growing this plant include Italy, Spain, Morocco, France, Greece and Iran (Akpakpan and Akpabio 2012).

It was introduced to Brazil, the Caribbean, and East Africa for shade and ornamental purposes in urban and rural afforestation and reforestation (Gilman and Watson 1994; Oliveira et al. 2000; Thomson and Evans 2006; Ezeokonkwo 2000). The flowering season occurs between April-May and September-October while its fruiting season is from October to April (Salvo et al. 1983). It has a large nutty fruits that is edible and taste very much like commercially grown almonds which can be eaten raw with roasting or boiling (Ezeokonkwo and Dodson 2004; Christian and Ukhun 2006). The fruit is ellipsoidal in shape and about 7.51 cm × 5.05 cm with a bluntly pointed apex (Gilman and Watson 1994; Akpakpan and Akpabio 2012).

The tropical almond finds wide use amongst different tribal groups in Africa and Asia. In Nigeria, India and Asia, children eat the seed raw (Ezeokonkwo 2000) and there has been no report of associated toxicity (Grant et al. 1995). In Taiwan, the nut of tropical nut is commonly used as folk medicine and is claimed to have aphrodisiac and antibacterial properties (Christian and Ukhun 2006). Scientifically, the fruit has demonstrated anti-diabetic activity (Lin et al. 1999; Chen and Dong 2000; Nagappa et al. 2003) and helpful in the treatment of leprosy and headaches. The leaves contain many hydrolysable tannins (Tanaka et al. 1986) which contribute to medicinal uses of the leaves that include: the treatment of liver related diseases, sickle cell disorders, cancers, anemia (Moody 2003; Oboh et al. 2008), tuberculosis (Adeleye et al. 2008), fungal infections (Masoko and Eloff 2005), treatment of eye and intestinal parasites, wounds, and liver ailments (Kirtikar and Basu 1991; Corner 1997), treatment of dermatitis and hepatitis (Kinoshita et al. 2006), inhibition of HIV replication in infected H9 lymphocytes with little cytotoxicity (Nonaka et al. 1990; Atsu Barku et al. 2012), and reduction of ear inflammation (Fan et al. 2004).

Proximate analysis of the tropical almond shows that it is rich in protein (18.39–40.9 %) and oil (43.36–63.65 %). This can be supported by the publications of Oliveira et al. (2000), Ezeokonkwo (2007), Biego et al. (2012), Monnet et al. (2012) and Atsu Barku et al. (2012). Ezeokonkwo and Dodson (2004) reported that the seed has essential amino acids that can support growth and a high dietary protein quality. Ezeokonkwo (2007) found out that the limiting amino acids in the tropical almond seed were tyrosine, lysine and methionine.

According to Safari and Alizadeh (2007), the fatty acids composition of the tropical almond seed oil shows oleic acid as the major ones. Similar findings were found in reports by Monnet et al. (2012) and Venkatachalam and Sathe (2006). However, this finding was in contrast with the results obtained by Ajayi et al. (2008) and dos Santos et al. (2008) that reported linoleic acids as the major fatty acids. For sugar composition, research revealed that small amount of sugar was found in the seed (Ezeokonkwo 2007; Nwosu et al. 2008; Nanos et al. 2002).

The objective of this study is to evaluate the physicochemical composition, amino acid and fatty acid characteristics of seeds from Terminalia catappa harvested in Selangor (Malaysia). Such information will expand the scope of knowledge on the utilization of tropical almond in various foods and to bring together data to support the uses, health and economic benefits of the almond nut that is completely unexploited commercially in Malaysia.

Experimental

Almond samples

The Indian almond nuts were collected between October and November, 2013 from T. catappa trees from the University Putra Malaysia, Selangor. The fruits were sun-dried for 7 days and then cracked to obtain the seeds.

Sample preparation

When needed, samples (100 g) were ground into powder form using mortar and pestle and homogenized by using a blender. The process of quartering and mixing was used to obtain a representative sample of the seed. The sample was mixed adequately, forming an even and square-shaped heap, and was then divided diagonally into four equal parts. The two opposite parts were then taken, carefully mixed and the process was repeated until the required mix was obtained (WHO 1992; Ezeokonkwo and Dodson 2004).

Chemicals

All the chemicals, reagents and solvents used in the experiments were of analytical grade and were products of Merck Sdn. Bhd. Solvents such as methanol and acetonitrile were of HPLC (high performance liquid chromatography) grade from Merck Sdn. Bhd. Mixed FAME (fatty acid methyl esters, C8-C24) standard was purchased from Sigma-Aldrich Chemical Co. Amino acid standards AAS-18 was from IT Technology Research (M) Sdn Bhd. For dietary fiber, the enzymes such as α-amylase, protease and amyloglucosidase were from Megazyme K-TDFR TDF-kit.

Analytical testing

Proximate analysis

The proximate analysis was done according to the methods of the Association of Official Analytical Chemists (AOAC 1995). Moisture content was determined by using AOAC Official Method 925.40. 3.0 g sample was placed in the crucibles and dried in the oven at 105 °C. The moisture content (%) was calculated based on the wet basis. Ash content was determined by gravimetric method (AOAC Official Method 923.03) whereby approximately 3.0 g sample was weighed into ceramic crucible and ashed in the muffle furnace at 550 °C until a constant weight was obtained. Protein was determined by micro-Kjeldahl method (AOAC Official Method 950.48). The sample (0.15 g) was digested with sulphuric acid (2.5 mL) in the presence of catalysts. Sample was then boiled on a heating unit in a fume cupboard until the liquid in the tube turns clear and has a bluish-green color. The digest was diluted with 10 mL of distilled water, followed by addition of 10 mL 45 % sodium hydroxide. The micro-Kjeldahl flask was attached to the distillation unit and the released ammonia was collected into a boric acid solution containing the indicators methylene blue and methyl red. Protein (%) was calculated as (total N (%) × appropriate factor). For sample, the conversion factor used for almond was 5.18 (Venkatachalam and Sathe 2006). Lipids were determined by the Soxhlet method (AOAC Official Method 948.22). Approximately 10 g sample was weighed into a thimble and defatted in a Soxhlet apparatus using petroleum ether (boiling point 40–60 °C). The carbohydrate content was estimated as difference obtained after subtracting the values of protein, lipid, ash, moisture and total dietary fiber from the sample.

Total dietary fiber determination

Total dietary fiber was determined on samples of dried and defatted material according to AOAC Method 991.43 (2005). Samples were cooked at ~100 °C with heat stable α-amylase to hydrolyze and depolymerized the starch. The sample was incubated at 60 °C with protease (to solubilize and depolymerize proteins) and amyloglucosidase (to hydrolyze starch fragments to glucose). The mixture was subsequently treated with four volumes of ethanol to precipitate soluble fibre and removed depolymerized protein and glucose from the starch. The residue was filtered; washed with 78 % ethanol, 95 % ethanol, and acetone respectively. The residue was dried and weighed. One duplicate was analyzed for protein and the other was incubated at 550 °C to determine ash. The total dietary fibre was the weight of the filtered and dried residue less the weight of the protein and ash. Dietary fibre content in % was calculated using the Eq. 1 (AOAC Method 991.43 2005)

Where: TDF = Total dietary fiber; BR1, BR2 = Residual weights (mg) of duplicate blank; Bprotein, Bash and B = Weights (mg) of protein, ash and blank respectively; R1, R2 = Residual weights (mg) of samples in duplicate; mg protein, mg ash = weights (mg) of protein and ash in residue; M1, M2 = Initial weights (mg) of samples.

The conversion factor used in protein calculation was 5.18 for almond (Venkatachalam and Sathe 2006).

Caloric value

The caloric value of the sample was derived by multiplying the amounts of crude protein, carbohydrate and oil by the factors of 4, 4, and 9 (kcal) respectively, and taking the sum of the products (EEC 1990).

Reducing sugar determination

The reducing sugar content was determined by using the Somogyi-Nelson method (Somogyi 1952). A blank and standard solutions containing between 0 and 450 μg glucose were prepared. 2.5 g of nuts sample was mixed with 50 mL of cold water and allowed to stand for 1 h. Then, 20 mL concentrated HCl and 150 mL distilled water were added and refluxed for 1.5 h. The solution was cooled and neutralized using 5 N NaOH and made up to 250 mL with distilled water. A sample solution containing not more than 2 mL of solution was made. A series of dilution was prepared and the volume of the dilution was made up to 2 mL with distilled water. After that, 2 mL of copper reagent was added to all samples, blanks and standard sugar solutions and mixed well. All the solutions were then heated for 10 min in a vigorously boiling water bath and then cooled under running water for 5 min. 1 mL of arsenomolybdate reagent was added to all the tubes and mixed well. When all the cuprous oxide was dissolved after mixing, the solutions were diluted to 10 mL using a volumetric flask and then allowed to stand for at least 15 min, but not more than 40 min. The absorbance was read at 520 nm using a spectrophotometer. The average absorbance of a blank was subtracted from the average absorbance of the samples; then the sugar content was computed from a curve established with standard sugar solutions.

Starch content determination

The method for this determination is as enunciated by Radley (1976) and explained in the reducing sugar determination as shown above. The amount of glucose obtained by acid hydrolysis of starch was multiplies by a factor of 0.90 (Radley 1976) to determine the starch content.

Color determination

The color of the nut samples were measured using a Minolta CM-3500D colorimeter after calibration against white and black glass standards. The colors were expressed in HUNTERLAB color values (L-, a-, b-) where the L- value represents the lightness to darkness gradation, a- value represents the greenness to redness spectrum and the b- value represents the blueness to yellowness spectrum. The color values (L-, a-, and b-) were the three dimensions which gives specific color values of the products.

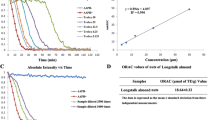

Sugar composition analysis

Sugar was determined by HPLC method (Hunt et al. 1977) with slight modification in the solvent used. The eluent used was acetonitrile and distilled water (80/20, v/v). The sugar standards used were glucose, sucrose and fructose in the concentration range of 0.5 to 2 % (w/v). A calibration curve was obtained for each of the three sugars. Sugars in the sample were quantified by comparing peak areas of sample with those of the sugar standards. The extraction and preparation were done prior to injection into HPLC according to Wills et al. (1980). 10 g of sample was heated with 100 mL methanol on steam bath at 180 °C for 30 min. The mixture was filtered into a round bottom flask and the residue was re-extracted twice in 75 mL portions of methanol, and filtered. The filtrate was evaporated to about 10 mL under vacuum at 50 °C in a rotary evaporator. The solution was then filtered through 0.45 μm syringe filter, using a syringe. The sugar analysis was performed by HPLC (JASCO RI-1530 Detector with Shimadzu Liquid Chromatograph LC-6A pump) using 4.6 m × 250 mm amine-modified silica column. A known volume of the extract within the range of 10–50 μl, was injected into the column with the flow rate of the mobile phase within 1.0 ml/min. The same volume of the standard solutions was used. Areas or peak heights of each sugar peak in sample and standard were measured, and the amount of the sugar was calculated.

Amino acid composition

Total amino acid composition of the sample was analyzed by an HPLC gradient system with pre-column phenylisothiocyanate (PITC) derivatization (Khan et al. 1994). A 20 μl sample was injected into an HPLC system (JASCO DU-2080 Plus Intelligent HPLC Pump, JASCO CO-2065 Plus Intelligent Column Oven, JASCO MD-2010 Plus Multiwavelength Detector) using a gradient system of buffer A (100−0 % after 60 min) and buffer B (0–100 % after 60 min). The operating temperature was 43 °C. A RP-18 reversed phase column from Merck (4.6 m × 250 mm) was used. The absorbance at 220 nm was used. AABA was used as an internal standard to calculate percentage recovery for each amino acid. Amino acid composition was reported as %.

Fatty acids profile

Gas chromatograph was employed to perform analyses of fatty acids according to Nielson (2010). Preparation of fatty methyl esters (FAME) was carried out as described by AOCS Official Method Ce 2-66 (1997) prior to gas chromatographic (GC) analysis. Approximately, 0.1 g of sample oil was weighed into a universal bottle. Then 5 mL LC (liquid chromatography) grade hexane was added and the solution was vortexed vigorously. Then, 250 μl sodium methoxide was added and vortexed for another 1 min with slight pause every 10 s. After that 5 mL saturated NaCl solution was added to the bottle and vortexed again for 15 s. The solution was allowed to stand for 3 min until two layers were formed. The upper layer was transferred to a small vial and left to stand for 15 min. The upper clear solution was then transferred into a small, clean vial for injection. The GC methodology details were as follows: A GC Agilent 6890 N with flame ionization detector (FID), 7863 series with auto-injection (10 μl syringe) was used. The GC conditions were: helium carrier gas (ultrapure, combination trap). Inlet temperature: 250 °C, 1 μl injection volume with 200:1 split. The column used was: BPX 70, 30 m × 0.32 μm internal diameter, 0.25 mm film thickness, 250 °C maximum temperature, 2.0 mL/min flow rate, average velocity was 36 cm/s, and a pressure of 11.54 psi. Oven temperature: 100 °C for 2.0 min ramp at 5.0 °C/min to 230 °C, held for 5 min for a total run time of 33 min. Detector: FID detector at 290 °C, hydrogen (ultrapure, hydrocarbon/moisture trap) and air (ultrapure, combination trap), helium (same as above) makeup gas. All data were corrected for recoveries and expressed as % of fatty acid.

Statistical analysis

The mean values and standard deviations of each analysis were reported. Determinations were done in triplicates.

Results and discussion

The results of the proximate and physicochemical compositions of Terminalia catappa L. grown in Malaysia is shown in Table 1. The moisture content of T. catappa seed was found to be 6.23 % (wet basis). The result is high when compared to 5.5 and 5.1 % (wet basis) for cashew nut (Fetuga et al. 1974) and African oil bean (Osagie et al. 1986) respectively; however it is relatively low when compared to 25.5 % for T. catappa nut (Akpakpan and Akpabio 2012) and other common nuts such as cashew nut, almond nut (Prunus Amygdalus), groundnut etc. (NIN 1984). The low moisture content is important for the keeping quality and shelf life of seeds as low moisture (low Aw) reduces microbial activities (Hassan et al. 2005, 2007; Atsu Barku et al. 2012; Abbas et al. 2009), besides low moisture decreases unwarranted fermentation, premature seed germination, and many undesirable biochemical changes normally associated with these processes (Venkatachalam and Sathe 2006).

The ash content of tropical almond seed was 3.78 %. Ash content signifies the level of mineral present in the sample. The ash content of the seeds was lower than those reported for the seeds from Ivory coast (4.60 %, Monnet et al. 2012), Nigeria (4.55 %, Omeje et al. 2008), Brazzaville (4.27 %, Kimbonguila et al. 2010), etc., The low ash content of seeds could be attributed to the fact that during maturation, inorganic ions migrate from different parts of the plant to the region of active growth (Sanchez et al. 1991). However, it is higher compared to 2.4 % for the seeds from Ceara (Oliveira et al. 2000) and the 3.3 % for cashew nut (Fetuga et al. 1974) and the value of 2.7 % obtained for African oil bean (Osagie et al. 1986).

Protein requirements are fundamental of all food nutrients, and life would be impossible without it. High protein content is important as it serves as a dietary protein especially for those people suffering from hypertension (Akpakpan and Akpabio 2012). WAO/WHO (1973) suggests a daily intake of 0.88 g of protein per kg body weight for children in the age range of 1–10 years. The protein content was 17.66 % in tropical almond seed. The value is low when compared to that of almond nut which is within the range 23.78–29.4 % (Ezeokonkwo and Dodson 2004; Omeje et al. 2008; Kimbonguila et al. 2010; Oliveira et al. 2000; Akpakpan and Akpabio 2012), melon seed which is 30.8 % (Ige et al. 1984), African oil bean with 28.1 % (Osagie et al. 1986) and cashew nuts with 21.2 % (Fetuga et al. 1974). However, this value (17.66 %) was higher than those reported for the seeds of cereal such as corn, triticale and wheat (8.4 to 14.8 %, Heger and Eggum 1991). The variation of the protein content might be due to several reasons such as species, geographical location, season and temperature (Kaehler and Kennish 1996; Dawes et al. 1993). For example, Mbah et al. (2013) had proved that the protein of almond seed from three states of Eastern Nigeria was significantly affected by location, with the highest (24.2 %) found in Anambra and the lowest (14.5 %) in Imo all different regions in Nigeria.

Almond nut oil is reported as a possible source of nutritional oil (Agunbiade and Olanlokun 2006). In this study, the seed oil content was found to be higher (54.68 %) than those reported for grape seed, corn (15.8 %) (Wang et al. 1996), Chinese chive seed (15.8 %) (Hu et al. 2006), tiger nut oil (26.3 %) (Lasekan and Abdulkarim 2012) and various soybean cultivars (18.3–21.5 %) (Vasconcelos et al. 1997). The crude fat value is similar to the values report by Oliveira et al. (2000), Atsu Barku et al. (2012) and Matos et al. (2009) which are 58.0, 52.11 and 51.8 % respectively. The high seed oil content indicated that the almond seed is a cheap source of edible oils that can be used as an alternative to some conventional oilseeds such as palm oil, groundnut oil and soybean oil (Bailey’s 1979).

The carbohydrate content obtained by difference was found to be as high as 7.68 %. This value is higher than carbohydrate content reported by Omeje et al. (2008) which was 6.50 %. The high carbohydrate content of the seed represents good dietary energy source for human body and livestock to survive high biochemical activities taking place within their system especially in the tropics (Brand and Maggiore 1992; Ojewola and Scholastica 2006).

The caloric value of the tropical almond seed was 593.48 kcal and this was higher than that reported by Akpakpan and Akpabio (2012) which was 534.20 kcal. This value is high and as such could be recommended as a dietary supplement for people who require a lot of energy, example the athletes. In present study, the total dietary fibre obtained was found to be 9.97 % and this is good for diabetic patients (Anderson 1986 and Osilesi et al. 1997); reduces blood cholesterol (Liu et al. 2000); regulation of body weight (Koh-Banerjee and Rimm 2003); reducing the rate of childhood obesity (Edwards and Parrett 2003) and colorectal cancer risk (La-Vecchia et al. 2003). Thus, the sample could be recommended for incorporation into the diet of diabetic and antherosclerotic patients.

The sugar content of nut seeds is known to vary considerably, depending on growing conditions, seed maturity, cultivar, and growth location (Venkatachalam and Sathe 2006). Except sucrose (95.82 %), other sugars were present in low amount in the seed. For example, Holland et al. (1992) has reported that the English almond (Prunus amygadalis) contains sucrose as the major sugar with traces of glucose and fructose, with no lactose and maltose. The low sugar level of T. catappa seeds makes it a good snack for diabetics.

The color of the seed oil was golden yellow. The L* value shows lightness, a- value shows redness while b* value shows yellowness of seed oil from T. catappa seed. b* Value was 8.40 and this value suggested the presence of more yellow pigments (carotenoids) in the tropical almond seed. These carotenoids are beneficial since it stimulated the appearance of butter without the use of primary colorants such as carotenes, annattos, and apo-carotenals commonly used in the oil and fat industry (Oomah et al. 2000).

Approximately 33 g of protein are lost each day by the average adult male and can be replaced in the diet. The body has no means of storing amino acids, but reserves are depleted in only a few hours (Ukoha 2003). The amino acid profile of the seeds revealed that glutamic acid was the first essential amino acid in tropical almond nut followed by arginine, whereas histidine, methionine, tyrosine and lysine were the limiting amino acids (Table 2). In view of the fact that high lysine levels negatively influence in-vivo arginine uptake by cells (Wu and Meininger 2002), low lysine levels in edible seeds may therefore not necessarily be a negative attribute. High arginine content of tropical almond nuts offers opportunities for judicious selection of edible nuts as a part of well-balanced food intake with potential for several health benefits. From literature, arginine is a precursor of nitric oxide (NO) which has many bioactivities including vasodilatation, anti-oxidative, and anti-platelet effects with implications for cardiovascular disease (CVD) risks (Wells et al. 2005; Wu and Meininger 2002). On the other hand, Venkatachalam and Sathe (2006) revealed methionine and cysteine were the first limiting essential amino acid in almonds when compared with the FAO/WHO recommended essential amino acid amounts for a 2–5 year old child.

In terms of nuts, oil is a major component and therefore its quality and fatty acid profile is very important. The fatty acid compositions of the tropical almond nuts in this study revealed that oleic (39.28 %) and linoleic (23.01 %) were the predominant unsaturated fatty acids and palmitic acid (29.98 %) was the major saturated fatty acid (Table 3). The high linoleic acid content of the seed oils is significant since linoleic acid is undoubtedly one of the most important polyunsaturated fatty acids in human food due to its prevention of distinct cardiovascular disease (Vles and Gottenbos 1989; Dagne and Johnson 1997). This finding was supported by Safari and Alizadeh (2007) and it is encouraging because it is a desirable feature in human food (Vijayakumari et al. 1997). However, Monnet et al. (2012) revealed that palmitic acid (37.26 %) was the most abundant fatty acid in seed oil from T. catappa fruits followed by oleic (32.40 %) and linoleic (24.65 %) acids, with smaller amount of stearic (5.55 %), linolenic (0.55 %), palmitoleic (0.41 %), myristic (0.17 %) and lauric (trace) acids. The differences between the findings might be due to variety/cultivar (genetic factors), environmental factors such as the year of production and growing location, climate and mainly maturity stage are cited as factors affecting the relative fatty acid composition (Amaral et al. 2006; Venkatachalam and Sathe 2006; Canellas 1986; Mehran and Filsoof 1974).

Conclusion

It was concluded that although the Terminalia catappa nut is not commercially exploited, it has a high calorific content and can be used as a source of carbohydrate. Chemical composition analyses indicated that the seed has a good nutritional value with typically low moisture, high proteins and lipids. Moreover, seeds rich in proteins like Terminalia catappa could reduce the level of malnutrition in most impoverished countries. Thus, it should not be overlooked anymore.

References

Abbas KA, Saleh AM, Mohamed A, Lasekan O (2009) The relationship between water activity and fish spoilage during cold storage: a review. J Food Agric & Environ 7 (3 & 4): 86-90

Adeleye IA, Onubogu CC, Ayolabi CI, Isawumi AO, Nshiogu ME (2008) Screening of crude extracts of twelve medicinal plants and wonder-cure concoction used in Nigeria unorthodox medicine for activity against Mycobacterium tuberculosis isolated from tuberculosis patients sputum. Afr J Biotechnol 7:3182–3187

Agunbiade SO, Olanlokun JO (2006) Evaluation of some nutritional characteristics of Indian almond (Prunus amygdalus) nut. Pak J Nutr 5(4):316–318

Ajayi IA, Oderinde RA, Taiwo VO, Agbedana EO (2008) Short-term toxicological evaluation of Terminalia catappa, Pentaclethra macrophylla and Colophyllum inophyllum seed oils in rats. Food Chem 106:458–465

Akpakpan AE, Akpabio UD (2012) Evaluation of proximate composition, mineral elements and anti-nutrient in almond (Terminalia catappa) seeds. Res J Appl Sci 7(9–12):489–493

Amaral JS, Cunha SC, Santos A, Rui Alves M, Seabra RM, Oliveira BPP (2006) Influence of cultivar and environmental conditions on the triacylglycerol profile of hazelnut (Corylus avellana L.). J Agric Food Chem 51:7698–7701

Anderson JW (1986) Fibre and health: an overview. Am J Gastroenterol 81:892–899

AOCS Official Method Ce 2-66 (1997) Sampling and analysis of commercial fats and oils: preparation of methyl esters of fatty acids

Association Official Analytical Chemists (1995) Official Methods of Analysis. AOAC, Arlington

Association Official Analytical Chemists (2005) Official Methods of Analysis of AOAC International. AOAC International, Gaithersburg

Atsu Barku VY, Nyarko HD, Dordunu P (2012) Studies on the physicochemical characteristics, microbial load and storage stability of oil from Indian almond nut (Terminalia catappa L.). Food Sci and Q Management 8

Bailey’s (1979) Industrial oil and fat products, 3rd edn. Industrial Division of John Wiley and Sons Inc., New York, pp 527–529

Biego GHM, Konan AG, Douati TE, Kouadio LP (2012) Physicochemical quality of kernels from Terminalia catappa L. and sensory evaluation of the concocted kernels. Sustain Agric Res 1(2):1

Brand JC, Maggiore P (1992) The nutritional composition of Australian Acacia seeds. In: House APN, Harwood CE (eds) Australian Dry-Zone Acacia for Human Food. Canberra Australian Tree Seed Centre, CSIPO Division of Forestry, pp 54–67

Canellas J (1986) “Estudio de componentes quimicos de variedades de almendra de Baleares”. Doctoral thesis, The University of Illes Balears, Palma de Mallorca, Spain

Chen CC, Dong YJ (2000) Attraction of the oriental fruit fly (Bactrocera dorsalis Hendel) (Diptera: Tephritidae), to leaf extracts of five plants. Chin J Entomol 20:37–44

Christian A, Ukhun ME (2006) Nutritional potential of the nut of tropical almond (Terminalia catappa L.). Pak J Nutr 5(4):334–336

Corner EJH (1997) Wayside Trees of Malaya, 4th edn. The Malayan Nature Society, Malaya, p 217

Dagne KA, Johnson O (1997) Oil content and fatty acid composition of seeds of Cmizotia cass (Compositae). J Sci Food Agric 73(3):274–278

Dawes CJ, Kovach C, Friedlander M (1993) Exposure of Gracilaria to various environmental conditions II. The effect on fatty composition. Bot Mar 36:289–296

dos Santos ICF, de Carvalho SHV, Solleti JI, Ferreira de La Salles W, da Silva T, de La Salles K, Meneghetti SMP (2008) Studies of Terminalia catappa L. oil: Characterization and biodiesel production. Bioresour Technol 99:6545–6549

Edwards CA, Parrett AM (2003) Dietary fibre in infancy and childhood. Proc Nutr Soc 62:17–23

EEC (1990) Council directive on nutrition labeling for foodstuffs (90/496). Off J Eur Commun L 276:40–44

Ezeokonkwo CA (2000) Biochemical and nutritional evaluation of Terminalia catappa L. (tropical almond) seed as a dietary protein supplement. Ph.D. Thesis, University of Nigeria, Nsukka, Nigeria

Ezeokonkwo CA (2007) Comparative effects of dry- and moist-heating treatments on the biochemical characteristics of Terminalia catappa L. seed. Food Sci Technol Int 13(2):165–171

Ezeokonkwo CA, Dodson WL (2004) The potential of Terminalia catappa (tropical almond) seed as a source of dietary protein. J Food Q 27:207–219

Fan YM, Xu LZ, Ga OJ, Wang Y, Tang XH, Zhao XN, Zhang ZY (2004) Phytochemical and anti-inflammatory studies on Terminalia catappa. Fitoterapia 75:253–260

Fetuga BL, Batunde GM, Oyenuga UA (1974) Protein quality of some Nigerian feed crops, 1st edn. Racine Publishing Co, Ibadan, pp 58–65

Gilman EF, Watson DG (1994) Terminalia catappa tropical almond. Forest Service, Department of Agriculture, US

Grane-Teruel N, Prats-Moya MS, Berenguer-Navarro V, Martin-Carratala ML (2001) A possible way to predict the genetic relatedness of selected almond cultivars. J Am Oil Chem Soc 78:617–619

Grant G, More LJ, McKenzie NH, Dorward PM, Buchan WC, Telek L, Pusztai A (1995) Nutritional and haemagglutination properties of several tropical seeds. J Agric Sci 124:437–445

Hassan LG, Umar KJ, Abdullahi S, Mohammed AS (2005) Proximate composition and physicochemical properties of seed and oil of Cassia siamea. Bull Sci Assoc Niger 26:373–380

Hassan LG, Umar KJ, Atiku I (2007) Nutritional evaluation of Albizia lebbeck pods as source of feeds for livestock. Am J Food Technol 2(5):435–439

Heger J, Eggum BO (1991) The nutritional values of some high-yielding cultivars of triticale. J Cereal Sci 14:63–71

Holland B, Unwin ID, Buss DH (1992) Fruits and Nuts. The Royal Society of Chemistry, London, pp 88–103

Hu G, Lu Y, Wei D (2006) Chemical characterization of Chinese chive seed (Allium tuberosum Rottl.). Food Chem 99:693–697

Hunt DC, Jackson PA, Mortlock RE, Kirk RS (1977) Quantitative determination of sugars in foodstuffs by high-performance liquid chromatography. Analyst 102(1221):917–920

Ige MM, Ogunsua AO, Oke LO (1984) Functional properties of some Nigeria oil seeds: camphor seeds and three varieties of melon seeds. J Agric Food Chem 32:822–825

Kaehler S, Kennish R (1996) Summer and winter comparisons in the nutritional value of marine macroalgae from Hong Kong. Bot Mar 39:11–17

Khan JK, Kuo YH, Kebede N, Lambein F (1994) Determination of nonprotein amino acids and toxins in Lathyrus by high performance liquid chromatography with precolumn phenylisothiocyanate derivation. J Chrom A 687:113–119

Kimbonguila A, Nzikou JM, Matos L, Loumouamou B, Ndangui CB, Pambou-Tobi NPG, Abena AA, Silou TH, Scher J, Desobry S (2010) Proximate composition of selected Congo oil seeds and physicochemical properties of the oil extracts. Res J Appl Sci Eng Technol 2(1):60–66

Kinoshita S, Inoue Y, Nakama S, Ichiba T, Aniya Y (2006) Antioxidant and hepatoprotecive actions of medicinal herb, Terminalia catappa L. from Okinawa Island and its tannin corilagin Phytomedicine, Elsevier:1–7

Kirtikar M, Basu BD (1991) Indian Medical Plants, vol 2. Periodical Experts Books Agency, New Delhi, p 1016

Koh-Banerjee P, Rimm EB (2003) Whole grain consumption and weight gain: a review of the epidemiological evidence, potential mechanisms and opportunities for future research. Proc Nutr Soc 62:25–29

Lasekan O, Abdulkarim SM (2012) Extraction of oil from tiger nut (Cyperus esculentus) with supercritical carbon dioxide (SC-CO2). LWT-Food Sci Technol 47:287–292

La-Vecchia C, Chatenoud L, Negri E, Franceschi S (2003) Whole cereal grains, fibre and human cancer: whole grain cereals and cancer in Italy. Proc Nutr Soc 62:45–49

Lin CC, Hsu YF, Lin TC (1999) Effect of punicalagin and punicalin on carrageen-induced inflammation in rats. Am J Chin Med 27(3–4):371–376

Liu S, Manson JE, Lee IM, Cole SR, Hennekens CR, Willett WC, Buring JW (2000) Fruit and vegetable intake and risk of cardiovascular disease. The women’s health study. Am J Clin Nutr 72:922–978

Masoko P, Eloff JN (2005) The diversity of antifungal compounds of six South African Terminalia species (Combretaceae) determined by bioautography. Afr J Biotechnol 4(12)

Matos L, Nzikou JM, Kimbonguila A, Ndangui CB, Pambou-Tobi NPG, Abena AA, Desobry S (2009) Composition and nutritional properties of seeds and oil from Terminalia catappa L. Adv J Food Sci Technol 1(1):72–77

Mbah BO, Eme PE, Eze CN (2013) Nutrient potential of almond seed (Terminalia catappa) sourced from three states of Eastern Nigeria. Afr J Agric Res 8(7):629–633

Mehran M, Filsoof M (1974) Characteristics of Iranian almond nuts and oils. J Am Oil Chem Soc 51(10):433–434

Monnet YT, Gbogouri A, Koffi PKB, Kouamé LP (2012) Chemical characterization of seeds and seed oils from mature Terminalia catappa fruits harvested in Côte d’Ivoire. Int J Biosci 2(10):110–124

Moody JO (2003) Antisickling activity of Terminalia catappa leaves harvested at differet stages of growth. Niger J Nat Prod Med 7:30–32

Nagappa AN, Thakurdesai PA, Venkat RN, Singh J (2003) Antidiabetic activity of Terminalia catappa Linn fruits. J Ethnopharmacol 88:45–50

Nanos GD, Kazantzis L, Kefalas P, Petrakis C, Stavroulakis GG (2002) Irrigation and harvest time affect almond kernel quality and composition. Sci Hortic (Amsterdam) 96:249–256

Nielson SS (2010) Food Analysis. Springer, New York

NIN, ICMR (1984) Nutritive value of Indian Foods. National Institute of Nutrition, Indian Council of Medical Research, Hyderabad

Nonaka GI, Nishioka I, Nishizawa M, Yamagishi T, Kashiwada Y, Dutschman GE, Bodner AJ, Kilkuskie RE, Cheng YC, Lee KH (1990) Anti-AIDS agents, 2: inhibitory effect of tannins on HIV reverse transcriptase and HIV replication in H9 lymphocyte cells. J Nat Prod 53(3):587–595

Nwosu FO, Dosumu OO, Okocha JOC (2008) The potential of Terminalia catappa (almond) and Hyphaene thebaica (dum palm) fruits as raw materials for livestock feed. Afr J Biotechnol 7(24):4576–4580

Oboh B, Ogunkanmi B, Olasan L (2008) Phenotypic diversity in Terminalia catappa from South Western Nigeria. Pak J Biol Sci 11:135–138

Oboh BO, Ogunkanmi LA, Agwu N (2009) Rapid isolation of genome DNA suitable for PCR from tropical almond (T. catappa) plant populations. Int J Bot 5(3):250–254

Ojewola GS, Scholastica O (2006) Comparative estimation of maize, sorghum and millet in growing cockerel’s ration. Agric J 1(3):176–179

Oliveira JTA, Vasconcelos IM, Bezerra LCNM, Silveira SB, Monteiro ACO, Moreira RA (2000) Composition and nutritional properties of seeds from Pachira aquatica Aubl, Sterculia striata St Hil et Naud and Terminalia catappa Linn. Food Chem 70:185–191

Omeje EO, Okide GB, Esimone CO, Ajali U (2008) Kinetics of autoxidation of an oil extract from terminalia catappa. Ind J Pharm Sci 70(2):260–262

Oomah BD, Ladet S, Godfrey DV, Liang J, Girard B (2000) Characteristics of raspberry (Rubis idaeus L.) seed oil. Food Chem 69:187–193

Osagie AU, Okoye WI, Oluwayose BO, Dauodu AO (1986) Chemical quality parameters and fatty acid composition of oil of some under exploited tropical seeds. Nig J Appl Sci 4:151–164

Osilesi OA, Adeiyi A, Ogunyemi EO, Fakunle JB (1997) Glycemic response to selected fruits and vegetables in Nigerian diabetics. Afr J Med Pharm Sci 1:1–6

Radley JA (1976) Examination and analysis of starch and starch products. Applied Science Publishers Ltd

Safari M, Alizadeh H (2007) Oil composition of Iranian major nuts. J Agric Sci Technol 9:251–256

Salvo F, Dugo G, Stango DI, Cotroneo A (1983) Composition of almond oil II distinction of sweet almond oil from blends with peach and apricot seed oil. Rivista Italiana delle Sostanze Grasse 57:24–26

Sanchez A, Lorento FRA, Valenzuela J, Romero L (1991) Production and transport of carbohydrates in some cultivars of muskmelon. Acta Hortic 287:485–493

Shakuntala MN, Shadadsharaswamy M (1987) Food: facts and principles. Wiley Eastern Limited, New Delhi

Somogyi M (1952) Notes on sugar determination. J Biol Chem 195(1):19–23

Tanaka T, Nonaka GI, Nishioka I (1986) Tannins and related compounds. XLII.: Isolation and characterization of four new hydrolyzable tannins, terflavins A and B, tergallagin and tercatain from the leaves of Terminalia catappa L. Chem Pharm Bull 34(3):1039–1049

Thomson LAJ, Evans B (2006) Terminalia catappa (tropical almond). In: Elevitch CR (ed) Species Profiles for Pacific Island Agroforestry. Permanent Agriculture Resources (PAR), USA, pp 1–120

Ukoha AI (2003) Foundation Biochemistry in Basic Biological Sciences. Niger Publishers Ltd., Nsukka, pp 121–131

Vasconcelos IM, Siebra EA, Maia AAB, Moreira RA, Neto AF, Campelo GJA, Oliveira JTA (1997) Composition, toxic and antinutritional factors of newly developed cultivars of Brazilian soybean (Glycine max). J Sci Food Agric 75:419–426

Venkatachalam M, Sathe SK (2006) Chemical composition of selected edible nut seeds. J Agric Food Chem 54:4705–4714

Vijayakumari K, Siddhuraju P, Janardhanan K (1997) Chemical composition, amino acid content and protein quality of the littleknown legume Bauhinia purpurea L. J Sci Food Agric 73:279–286

Vles RO, Gottenbos JJ (1989) Nutritional characteristics and food uses of vegetable oils. In: Downey RG, Ashri A (eds) Oil Crops of the World. McGraw Hill, New York, pp 36–83

Wang JM, Liao DS, Zhang YJ (1996) Studies on the nutrition and food therapy value of grape seed oil. Acta Nutrimenta Sinica 18(2):221–223

WAO/WHO (1973) Report. In: Energy and Protein Requirements. Geneva, World Health Organization, WHO Technical Report Series No 522

Wells BJ, Mainous AG, Everett CJ (2005) Association between dietary arginine and C-reactive protein. Nutrition 21:125–130

WHO (1992) General advice on sampling. In: Quality Control Methods for Medicinal Plant Materials. WHO/Pharm/92.559, Geneva, World Health Organisation, pp 10–11

Wills RBH, Balmer N., Greenfield H (1980) Composition of Australian foods, 2. Methods of analysis. Food Tech in Aus

Wu G, Meininger CJ (2002) Regulation of nitric oxide synthesis by dietary factors. Annu Rev Nutr 22:61–86

Acknowledgments

We are grateful for the extensive financial support of Research University Grant Scheme (RUGS 2) at the University Putra Malaysia (UPM).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ng, S., Lasekan, O., Muhammad, K.S. et al. Physicochemical properties of Malaysian-grown tropical almond nuts (Terminalia catappa). J Food Sci Technol 52, 6623–6630 (2015). https://doi.org/10.1007/s13197-015-1737-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1737-z