Abstract

The effect of ultrasound treatments (40 kHz, 300 W) for different times (10, 20, 30 and 40 min) combined with different salt contents (1.0 %, 1.5 % and 2.0 %) on gel properties and water holding capacity (WHC) of chicken breast meat batter were investigated. Results showed salt level significantly (p < 0.05) affected the texture, storage modulus (G′), loss modulus (G″), cooking loss and WHC. Ultrasound treatments for 10 min and 20 min improved the texture and WHC, and had higher G′ values. Compared with the controls (2 % salt), ultrasound treatment for 20 min with reduced-salt (1.5 %) had not significant effect (p > 0.05) on texture, cooking loss or WHC. However, longer ultrasound (40 min) treatment resulted in a decrease in hardness, G′ value and WHC. Microstructural analysis revealed that gels treated with ultrasound for 20 min had a compact structure whereas those treated for 40 min contained more protein aggregations and more cavities. Low-field nuclear magnetic resonance (LF-NMR) indicated that ultrasound treatment for 20 min lowered the values of spin-spin relaxation time (T2) and increased the proportion of myofibillar water. Overall, high power ultrasound technology is a promising process which can improve the gelation properties and thereby allowing for a partial reduction in the salt levels in chicken meat gels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

High power ultrasound has been widely used commercially in various food processing operations for its beneficial effects through cavitation on mechanical, chemical and/or biochemical effects on food materials (Chandrapala et al. 2012). The application of ultrasound in meat and meat products can change its physical, biochemical and microbial properties (Jayasooriya et al. 2004). Many researchers have found that the use of ultrasound can have effects on meat tenderization, curing and changes in meat color and color stability (Cárcel et al. 2007; Jayasooriya et al. 2007; Lyng et al. 1998; Pohlman et al. 1997a; Stadnik et al. 2008; Stadnik and Dolatowski 2011). Some authors have reported that ultrasound caused physical disruption of meat tissues and accelerated mass transfer through cavitation related mechanisms, which significantly improved the fragmentation and the solubility of myofibrillar proteins and caused disintegration of connective tissues in meat (Chang et al. 2012; Latoch 2010).

Myofibrillar proteins are of great significance for the functional properties of meat products, such as texture and WHC. Ultrasound has been shown to improve the extraction of salt-soluble proteins in ground cured ham roll and to increase the cooking yield and bind strength (Reynolds et al. 1978). However, reducing salt limits protein extractability and alters thermal protein denaturation and aggregation patterns of the major muscle proteins (Trout and Schmidt 1986), which affects the textural characteristics and WHC of meat products. A partial reduction of salt level in meat and meat products was possible when using ultrasound processing, which therefore has very important health advantages (Weiss et al. 2010). Little information is available on ultrasound treatment as a possible means of improving the gel-forming properties in processed meat products at low-salt levels. The gel-forming ability of myofibrillar proteins is of much interest because it is responsible for the enhanced texture of comminuted meat products. Gelation is a multi-step thermodynamic process that involves denaturation, aggregation and formation a three-dimensional network resulting in an elastic gel (Lesiów and Xiong 2001). The process is governed by a combination of weak intermolecular forces, including hydrogen bonding, electrostatic forces and hydrophobic interactions (Gordon and Barbut 1992). High-intensity ultrasound may have the potential to alter the gelation behavior of proteins, since cavitation within the muscle tissue can lead to chemical changes by the formation of free radicals which can alter the structure of proteins and the intermolecular forces (Jayasooriya et al. 2004).

In addition, Ito et al. (2003) reported that ultrasonic treatment improved the protein solubility of washed myofibrillar suspensions (low protein concentration: 0.5 %) by the physical force which disrupted the structure of chicken breast muscle myofibrillar proteins in water. To our knowledge, only a few studies have been reported the changes in functional properties of chicken breast meat batter containing high protein concentrations with the application of high power ultrasound. For our work we chose chicken breast meat because it is readily processed, nutritious, being low in fat and rich in protein, has light color and good texture (Barbut 2012) and is relatively inexpensive compared with other type of meats (Petracci and Cavani 2012). Furthermore, with the changes in consumers’ attitude towards on poultry further processed products, there is a greater requirement for high quality poultry meat to ensure optimal sensory characteristics and functional properties of meat products (Petracci et al. 2013).

Therefore, the objective of the study was to investigate the effects of ultrasound on chicken breast meat batters containing different salt levels on the functional and structural properties of chicken meat gels using the dynamic rheological measurement, LF-NMR and scanning electron microscopy.

Materials and methods

Sample preparation

Fresh chicken breast meat (mean values of 73.50 % moisture, 22.68 % protein, 2.36 % fat, 24–36 h postmortem and pH 5.96) (AOAC 2000) was purchased from a local meat market (Nanjing, China). All visible connective tissue, fat and skin were trimmed off. The meat were cut into small cubes (10 mm × 10 mm × 10 mm) and mixed, then packed in polyethylene bags. Finally, the meat samples were frozen and stored at −18 °C, and were used within 2 weeks.

Chicken breast meat gels were formulated according to the method of Sikes et al. (2009) with slight modifications. Prior to the experiment, the meat was thawed overnight at 0–2 °C. The chicken meat batters were prepared by mixing chicken meat (75 %) with ice/water (23–24 %) containing different level of salt (Table 1). The preparation procedure was as follows: the chicken breast meat was homogenized in a chilled cutter (Grindomix GM 200, Retsch, Germany) at a speed of 3,000 rpm for 10 s, followed by addition of ice water and salt, then chopping at the same speed for 15 s. Final batter temperature remained less than 7 °C. The batters were then filled approximately 80 g (thickness less than 3 mm) and sealed in barrier bags.

Ultrasound treatment

Ultrasound treatment of the samples was carried out in an ultrasonic processor (KQ-300DE, Kunshan Ultrasonic Instrument Co., Ltd., China) having an internal tank dimensions of 300 mm × 240 mm × 150 mm (width × depth × height) and using a frequency of 40 kHz and power of 300 W. Sonication of the samples were carried out for 0, 10, 20, 30, 40 min. The non-ultrasound treated samples as the control group and were also maintained in water below 15 °C. All experiments were performed in triplicate. After ultrasonic processing, all the meat batters were stored at 4 °C until analysis.

Textural Profile Analyses (TPA)

The TPA of the chicken meat gels was determined according to the procedures of Bourne (1978). After the ultrasound treatment, the batters were transferred to the 50 mL polypropylene containers and then hermetically sealed. These containers were centrifuged (Model 225, Fischer Scientific, Pittsburgh, Pa., U.S.A.) at 500 g (4 °C) setting for 3 min to remove any remaining air bubbles. The containers of the different ultrasound treatments were heated in a water bath at 80 °C for 20 min, and then cooled to room temperature. The samples were cut into cylindrical shapes (2.0 cm deep and 2.5 cm in diameter) for TPA. TPA tests were performed using a texture analyzer (TA-XT2i, Stable Micro Systems Ltd., Godalming, UK) fitted with a cylindrical probe (P/50, 50 mm stainless cylinder) and a 25 kg load cell. A double compression cycle test was performed up to 75 % compression of the original height. The elapsed time between the two compression cycles was 5 s. The trigger force used for the test was 5 g with a test speed of 1.5 mm/s. When the test was completed, the software (TA-XT Express software) calculated TPA parameters for hardness (maximum force required to compress the sample), springiness (ability of the sample to recover its original form after deforming force was removed), chewiness (work needed to chew a solid sample to a steady state of swallowing), cohesiveness (extent to which the sample could be deformed before rupture). Six replicates were performed for each treatment group.

Gel strength

Gel strength was measured according to the method of Huang et al. (2010). Gels were prepared as described in the section on TPA to determine gel strength. The samples were cut into cylindrical shapes (20 mm deep and 25 mm in diameter) at room temperature. Then the samples were tested using a Texture Analyser (TA.XT2i, Stable Micro Systems, Godalming, UK) equipped with a spherical plunger (5 mm diameter) at a speed of 1 mm/s. The Gel strength was expressed as the multiplication of the breaking strength (kg) and deformation (mm). Six replicates were performed for each treatment group.

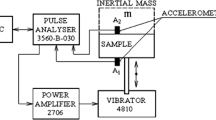

Dynamic rheological measurements

Dynamic oscillatory measurements of chicken meat batters were carried out after ultrasound treatment using a Rheometer (Anton Paar, Physica MCR 301, Austria) under oscillatory mode, equipped with a 25 mm parallel plate measuring geometry, according to the procedure described in Omana et al. (2010) with slight modifications. Rheological measurements were conducted within the linear range, at a strain of 0.5 % and a constant frequency of 0.1 Hz. The samples were heated between parallel plates with a programmable circulating water bath and the probe was set with a gap of 1 mm. Edges of samples were covered with silicone oil to prevent dehydration. Heating was performed from 25 °C to 80 °C at a scan rate of 2 °C/min using a temperature control unit. The storage modulus (G′) and loss modulus (G″) were obtained during dynamic oscillatory measurements. Each measurement was performed at least in triplicate.

Cooking loss

Cooking loss of chicken meat gels was measured as described by Pietrasik (2003). After ultrasound treatment, meat batters were loaded into 50 mL polypropylene centrifuge tubes and centrifuged at 500 g (Model 225, Fischer Scientific, Pittsburgh, Pa., U.S.A.) for 3 min to pack the meat. Subsequently, tubes were heated (80 °C for 20 min) in a water bath and then cooled to room temperature. The exudates were drained, the surface was gently dried with paper towels, and the cooked chicken gels were weighted. Cooking loss was determined as the amount of released liquid divided by the initial samples weight. Six replicates were performed for each treatment group.

Water Holding Capacity (WHC)

WHC of chicken meat gels was determined as described by Kocher and Foegeding (1993) with a slight modification. Chicken meat gels were placed in centrifuge tubes and then centrifuged at 10 000 × g for 10 min (0–4 °C). The pellet weight (g) after centrifugation and the weight (g) of the batters before centrifugation were determined. Then WHC was expressed as the amount of released water divided by the original weight (g) of the gel before centrifugation. Low values indicate that the gels have superior water holding properties compared to those gels having high values. Six replicates were performed for each treatment group.

NMR spin-spin relaxation (T2) measurements

NMR relaxation measurements were performed according to the method of Han et al. (2009) with a slight modification. Approximately 2 g of the sample was placed in a 15 mm glass tube and inserted in the NMR probe of a PQ001 Niumag Pulsed NMR analyzer (Niumag Electric Corporation, Shanghai, China). The analyzer was operated at a resonance frequency of 22.6 MHz at 32 °C. Spin-spin relaxation time (T2) was measured using the Carr–Purcell–Meiboom–Gill sequence. T2 was measured made a τ-value of 350 μs. Data from 10,000 echoes were acquired as 32 scan repetitions. The repetition time between subsequent scans was 8,000 ms. Post processing of NMR T2 data distributed exponential fitting of CPMG (Carr-Purcell-Meiboom-Gill) decay curves were performed by Multi-Exp Inv Analysis software (Niumag Electric Corp., Shanghai, China). Four relaxation times (T2b, T21, T22 and T23) and their corresponding water populations (P2b, P21, P22 and P23) were recorded. Each measurement was performed at least in triplicate.

Scanning Electron Microscopy (SEM)

SEM of the chicken meat gels was determined according to the method of Han et al. (2009). Samples for SEM were cut into cubes (3 × 3 × 2 mm3) and fixed with 2.5 % glutaraldehyde in 0.1 M phosphate buffer (pH 7.0) for 48 h at 4 °C. The post-fixed samples were then washed 3 times with 0.1 M phosphate buffer (pH 7.0) for 10 min, followed by dehydration in incremental concentrations of ethanol (30, 50, 70, 75, 80, 90, 95 %, and 3 times with 100 %, respectively) for 15 min per solution, and finally in iso-amyl acetate for 10 min. The dehydrated samples were dried using carbon dioxide supercritical drying. The dried samples were gold-coated (about 10-nm layer) using a high-vacuum ion sputter. Sample observation and photomicrography were performed using a scanning electron microscope (S-3000, Hitachi Science System Ltd., Hitachinaka, Japan) with an accelerating voltage of 7.0 kV.

Statistical analyses

All data are expressed as mean ± SD. Analysis of variance (p < 0.05) was used to assess the effects and interaction factors (ultrasound treatment time, salt levels) on functional properties and WHC of chicken meat gels. The means of variables among different treatments were compared using the Duncan’s multiple comparisons. Statistical analyses of results were performed using Statistical Analysis System (SAS 8. 2, SAS Inst. Inc., Cary, N.C., U.S.A., 2000).

Results and discussion

TPA and gel strength

Table 2 shows that the textural properties and gel strength of chicken meat gels were significantly (p < 0.05) affected by ultrasound treatments and various amounts of salt. Increasing the salt level of the meat batters from 1 to 2 % increased hardness, springiness, cohesiveness and chewiness and gel strength (Tables 2 and 3). Similar results have been reported showing that increased salt concentration of meat batters improved the textural properties of Chinese-style meatballs and frankfurter-type sausages (Hand et al. 1987; Kang et al. 2014; Matulis et al. 1995).

The ultrasound treatment significantly (p < 0.05) influenced the texture of meat batters (Tables 2 and 3). Compared with the control at the same salt contents, hardness, springiness, cohesiveness, chewiness and gel strength were improved in the samples treated with ultrasound for either 10 min or 20 min. The hardness and gel strength of meat batters treated with ultrasound 20 min with 1 % salt tended to increase but they were not significantly different (p > 0.05) from the control with 1.5 % salt. A Similar effect was observed with the ultrasound treatment for 20 min with 1.5 % salt compared with the control. Reynolds et al. (1978) and Vimini et al. (1983) reported that ultrasound treatment increased the breaking strength of restructured rolls at lower salt addition. However, ultrasound treatment at 30 min or 40 min did not increase (p > 0.05) the hardness, springiness, cohesiveness, chewiness and gel strength. Furthermore, ultrasound treatment at 40 min with 1 % or 1.5 % salt actually decreased significantly (p < 0.05) hardness of meat gels compared to the corresponding controls. The decrease in hardness has been attributed to the functional deterioration of the meat protein (Carballo et al. 2000). Siró et al. (2009) reported that ultrasound treatment for longer times caused denaturation of proteins and produced variation in the hardness of the meat. There was no interaction effect between ultrasound treatment and salt content for hardness, springiness, chewiness and gel strength (Table 3). The results obtained in this study clearly show that the hardening effects of salt addition to meat batters. On the other hand, ultrasound treatment for 30 min or 40 min partially counteracted the hardening effect of salt addition.

Dynamic rheological measurements

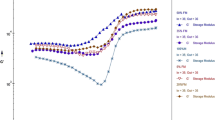

Changes in G′ and G″ values of chicken meat batters with different salt contents when subjected to ultrasound treatment when heated from 25 °C to 80 °C are presented in Fig. 1. In the controls with different salt contents (1–2 %), the G′ of chicken meat batters increased slightly up to approximately 48 °C, because of the protein-protein interaction (Acton et al. 1981; Egelandsdal et al. 1986). Then G′ decreased sharply to a minimum at 55 °C, which was attributed to denaturation of light meromyosin, resulting in the increased filamental “fluidity” (Egelandsdal et al. 1986). Xiong and Blanchard (1994) reported that the reduction in G′ of chicken breast salt-soluble proteins and myofibrils may be caused by partially redistribution of intra- and inter-molecular forces, assuming that protein denaturation is reversible below 55 °C. Then with further heating, G′ increased steadily indicating that a stiff protein matrix had developed as a result of enhanced hydrophobic and sulfhydryl-disulfide interactions between the proteins (Ferris et al. 2009; Montejano et al. 1984). The rheological transition of the controls was typical of poultry meat with low added salt (Carballo et al. 2001; Egelandsdal et al. 1995). It was obvious that the values of G′ significantly different in the controls with different salt contents in raw state (25 °C) and at the end of cooking (80 °C). The meat batter containing 2 % salt showed the highest G′ value and the 1 % had the lowest value. This was probably related to different contents of protein extraction by the different salt levels (Fretheim et al. 1986).

Changes in dynamic storage modulus (G′) and loss modulus (G″) with temperature (T, °C) for the different samples: (a and d) ultrasound treated meat batters with 1 % salt; (b and e) ultrasound treated meat batters with 1.5 % salt; (c and d) ultrasound treated meat batters with 2 % salt. The storage modulus G′, represents elasticity of the gels. C: no ultrasound treatment; U10: ultrasound time 10 min; U20: ultrasound time 20 min; U30: ultrasound time 30 min; U40: ultrasound time 40 min

Compared with the controls, the ultrasound treatments produced some differences in the G′ values. At the beginning of heating processing, all ultrasound treatments had higher initial G′ values than the controls, and were significantly different in the meat batters containing 1 % salt. When further heating above 55 °C, the G′ of meat batters treated with ultrasound either 10 min or 20 min increased steadily up to 80 °C, and finished higher than the controls. The results were indicative of typical heat induced protein gels which showed formation of stable, stiff and elastic matrix structures. However, the G′ of meat batters treated with ultrasound for 30 min or 40 min increased rapidly, reaching a plateau at 75 °C or 72 °C, respectively. Afterwards a decline in G′ was observed up to 80 °C. Ultrasound treatments for 40 min had a greater negative effect on raw meat batters, which showed a sharp decrease in G′ value upon subsequent heating. In each case, these had the lowest G′ values. These results indicated that ultrasound technology could considerably change the gel network formation and gel elasticity. These differences in G′ values may be related to protein denaturation induced by ultrasound (Siró et al. 2009). Another possibility is that the physical force applied by ultrasound may partially damage the structures of myofibrillar proteins partly, although concurrently it may promote solubilization of myofibrillar proteins (Ito et al. 2003). The changes of G′ and G″ had been used to monitor the visco-elastic behavior of meats, and what have been related to the denaturation and accompanying aggregation of its myofibrillar proteins (Egelandsdal et al. 1995; Xiong and Blanchard 1994). The denaturation of proteins leads to changes in the native conformation of the molecules and the eventual unfolding of the proteins. At shorter times ultrasound treatment induced certain protein modifications, which improved gel forming ability. However, at longer times, ultrasound treatment may excessively increase the protein denaturation and complete protein aggregation well before 75 °C is reached. With further heating the decrease in G′ above 75 °C was probably a consequence of a temperature effect after completion of protein aggregation (Liu et al. 2007).

During gelation, changes in the G′ value indicated the transformation into an elastic gel network and reflected the changes in stiffness or rigidity of the protein gel (Ding et al. 2012). A high G′ usually indicates that the product is more rigid (Xiong and Blanchard 1994). The trend was in accordance with that observed for the texture and gel strength (Table 2), which indicated that ultrasound treatment for 20 min gave the highest G′ and the highest hardness values, whereas ultrasound treatment for 40 min gave the lowest G′, thus having the lowest hardness values. The effects of ultrasound treatment on changes in G″ of batters with different salt contents were similar to those found for G′ values. At the same salt content, the highest G″ values of meat batters were obtained in samples treated with ultrasound for 20 min.

Cooking loss and WHC

Table 4 shows the cooking loss and WHC of chicken meat batters having different salt contents as affected by ultrasound treatment. Ultrasound treatment and salt levels had significant (p < 0.05) effects on cooking loss (Table 3). WHC is also a term commonly used to describe the ability of meat gels to bind or hold water (Labuza and Busk 1979). It is evident that as salt contents of chicken meat batters were increased the WHC and cooking losses were reduced. Ultrasound treatment for 10 min and 20 min also improved the cooking loss. The best result was achieved by ultrasound treatment for 20 min with different salt contents. However, increased treatment time resulted in an increase in the cooking loss at the same salt content. Based on the results of WHC at the same salt content, ultrasound treatment for 20 min produced significant (p < 0.05) difference in WHC compared with the controls. Nevertheless, ultrasound treatment time affected the WHC of chicken meat gels compared with untreated samples with high salt concentrations. This agrees with the observations of Jayasooriya et al. (2007) who found that drip loss of beef (M. longissimus lumborum et thoracis and M. semitendinosus) was not affected by ultrasound treatment, but it significantly reduced the cooking loss and total loss. Stadnik et al. (2008) investigated that the effect of ultrasound treatment on water holding properties of beef (M. semimembranosus), and found that the minced samples of ultra-sonicated meat had significantly higher water holding capacity than the control. Siró et al. (2009) reported that ultrasound treatment improved water-binding properties of meat tissue, but did not significantly alter the water holding capacity of porcine meat. It may result from the fact that the meat was treated by ultrasound in a refrigerated water bath, which would limit thermal denaturation of protein and consequential loss of water holding ability (Pohlman et al. 1997b). These differences may result from the used of the specific ultrasound conditions, different meats and different methods used for determining WHC. In the present study, ultrasound treatment improved the water holding properties (including cooking loss) of chicken meat gels at each of the salt levels. An explanation for these behaviors on cooking loss and WHC are explored further in the following section making use of LF-NMR.

NMR spin-spin relaxation (T2) measurements

The registration of proton transverse relaxation time (T2) weighted signals has been used to study the water distribution and water properties in myofibrillar proteins (Bertram et al. 2004; Sun et al. 2011). Figure 2 shows a representative distribution of NMR T2 measurements after multi-exponential fitting. In the chicken meat gels, we detected four relaxation populations centered at approximately 0–10 ms, 40–55 ms, 150–300 ms and >1,000 ms (designated T2b, T21, T22 and T23, respectively). A minor component, T2b (bound water), was assigned to water tightly associated to protein and macromolecular constituents of meat. A major component T21, was assigned to myofibrillar water and water within the protein structure. The third component T22, was likely associated with extra-myofibrillar water. The fourth component T23, was assigned to expelled bulk water released after heating. This is in agreement with Bertram et al. (2001) who reported T2b, T21, and T22 values for whole, minced, and homogenized meats in the range of 0–10 ms, 40–60 ms and 150–400 ms, respectively. Upon heating, a relaxation population with relaxation times >1,000 ms (T23) corresponding to expelled bulk water was identified (Bertram et al. 2006).

Table 5 shows the effect of ultrasound treatment on T2 relaxation times and the NMR proportion of chicken meat gels with different salt levels. The relaxation times of all four components were significantly affected by salt level and ultrasound treatment (Table 3). There was no significant interaction effect (p > 0.05) between salt levels and ultrasound treatment on NMR parameters. In the control chicken meat gels, there was an increase in T2b with increasing salt level. The same trend was observed for the T21 and T22 relaxation times. The opposite was observed for T23, where the relaxation time decreased with increasing salt level. At the same salt level, ultrasound treatment for 20 min or 40 min did not significantly (p > 0.05) change T2 relaxation times, compared with the controls. Although the differences were not all statistically significantly (p > 0.05), ultrasound treatment for 20 min had slightly lower T21, T22 and T23 relaxation times compared with the control. This indicated that ultrasound treatment could decrease the water mobility in the chicken meat gels.

Table 6 shows the effect of ultrasound treatment on the proportions of P2b, P21, P22 and P23 at different salt contents. The proportions of P2b were not significantly (p > 0.05) affected by ultrasound treatment or salt content. The ratios of P21 and P23 decreased with increasing salt contents, and the ratios of P22 did not change. Less free water (P23) and more myofibrillar protein water (P21) in the gels may contribute to the increase of binding water. At the same salt content, the chicken meat gels treated with ultrasound treatment for 20 min had a higher proportion of P21, and decreased proportion of P23, which was significantly different (p < 0.05) from the controls. Ultrasound treatment for 40 min did not increase the ratios of P21 compared with that of the controls.

Some Studies have reported that NMR T2 relaxation showed highly significant correlations between NMR time constants (T21, T22) and WHC of meat. Components (T21, T22) and their populations may contribute to the estimation of the juiciness of cooked products (Bertram et al. 2003; Bertram and Andersen 2004). In the present study, the water distribution and mobility in chicken meat gels were examined by NMR T2 relaxation measurement. Ultrasound treatment for 20 min had a lower T21 in comparison with the control samples, indicating an overall decrease in water mobility of gels. There was more water contained within this component as reflected by the increased ratio of P21. Therefore this increased content of myofibrillar water contributes to the higher water holding capacity and lower cooking loss which supports the work of Stadnik et al. (2008) who reported that ultrasound treatment decreased relaxation times (T21) and improved the water holding capacity of comminuted samples.

Scanning electron microscopy

Figure 3 shows scanning electron micrographs of the control and ultrasound treatments (20 min and 40 min) for chicken meat gels with various salt levels. In the control meat gels (Fig. 3a, d and g), as the salt level increased from 1 to 2 %, there were significant variation in the structures of the meat gels. The meat gels having 1 % salt showed a plate-like and disorganized structure with a large number of aggregates (Fig. 3a). As the salt content was increased, the structure showed a continuous matrix with a small honeycomb-like appearance having less aggregation (Fig. 3d). When the salt levels increased to 2 %, structures formed with small open spaces between the protein strands (Fig. 3g). Carballo et al. (2000) also showed the microstructure of the control meat batters was an open protein matrix with thick protein structure. Unlike the control meat gels, ultrasound-treated gels exhibited different the microstructures. The meat gels treated with ultrasound treatment for 20 min contained many protein filaments as well as fine strands (Fig. 3b, e and h). A porous network structure (Fig. 3b) and more compact structure was observed (Fig. 3e and h). Ultrasound treatment for 40 min created a microstructure which comprised of larger cavities and a greater number of protein aggregates (Fig. 3c, f and i), although the fine strands did remain. The control meat matrix exhibited less compact and more irregular appearance than the meat gels treated with ultrasound for 20 min. Schmidt (1984) reported that cook yield and texture of products were governed by protein aggregation and capillary formation. Therefore, the tightly aggregated protein (Fig. 3c, f and i) may be expected to have a negative effect on the water-holding capacity. The spaces between protein aggregates allow moisture to escape from the meat gels. Youssef and Barbut (2009) reported that in gels having good water retention the proteins were not tightly aggregated. It is possible that the cavitation created by ultrasound provided the mechanism for improved protein association during gelling to produce more compact structures to form firmer gels.

Scanning electron micrographs of ultrasound treated and the control chicken breast gels with various salt levels at 7.0 kv, 3,000 magnification. a, b and c represent treatment with no ultrasound, ultrasound-20 min and ultrasound-40 min respectively with 1 % salt. d, e and f represent treatment with no ultrasound, ultrasound-20 min and ultrasound-40 min respectively with 1.5 % salt. g, h and i represent treatment with no ultrasound, ultrasound-20 min and ultrasound-40 min respectively with 2 % salt

Conclusions

In the present study, high power ultrasound treatment for 20 min significantly improved the textural properties and WHC of chicken breast meat batter. In the ultrasound treatment for 20 min with 1.5 % salt level was found to increase the textural properties and WHC of chicken meat gels containing 1.5 % salt were similar to the control samples (2 % salt). The samples treated with ultrasound treatment for 20 min had better gel forming abilities as revealed by dynamic visco-elastic behavior. Scanning electron microscopic examination of the samples indicated that ultrasound treatment for 20 min resulted in a compact microstructure with protein filaments and finely strands that contributed to the texture. According to LR-NMR, ultrasound treatment for 20 min resulted in an increased proportion of entrapped water within the myofibrillar proteins. However, ultrasound treatment for 30 and 40 min did not affect the texture, G′ or WHC properties. It should be prudent in apply ultrasound treatment for longer time on the meat batter. In further studies, we will investigate the effects of ultrasound treatment on the physicochemical and gelation properties of myofibrillar proteins in model systems.

References

Acton JC, Hanna MA, Satterlee LD (1981) Heat-induced gelation and protein-protein interaction of actomyosin. J Food Biochem 46:101–103

AOAC (2000) Official methods of analysis of AOAC international, 17th edn. AOAC International, Gaithersburg

Barbut S (2012) Convenience breaded poultry meat products-New developments. Trends Food Sci Tech 26:14–20

Bertram HC, Andersen HJ (2004) Applications of NMR in meat science. Annu Rep NMR Spectro 53:157–202

Bertram HC, Karlsson AH, Rasmussen M, Pedersen OD, Dønstrup S, Andersen HJ (2001) Origin of multiexponential T2 relaxation in muscle myowater. J Agric Food Chem 49:3092–3100

Bertram HC, Andersen HJ, Karlsson AH, Horn P, Hedegaard J, Nogaard L, Engelsen SB (2003) Prediction of technological quality (cooking loss and Napole Yield) of pork based on fresh meat characteristics. Meat Sci 65:707–712

Bertram HC, Kristensen M, Andersen HJ (2004) Functionality of myofibrillar proteins as affected by pH, ionic strength and heat treatment: a low-field NMR study. Meat Sci 68:249–256

Bertram HC, Kohler A, Bocker U, Ofstad R, Andersen HJ (2006) Heat-induced changes in myofibrillar protein structures and myowater of two pork qualities. A combined FT-IR spectroscopy and low-field NMR relaxometry study. J Agric Food Chem 54:1740–1746

Bourne MC (1978) Texture profile analysis. Food Technol 32(7):62–66

Carballo J, Cofrades S, Solas MT, Jiménez-Colmenero F (2000) High pressure/thermal treatment of meat batters prepared from freeze-thawed pork. Meat Sci 54:357–364

Carballo J, Cofrades S, Fernández-Martín J-CF (2001) Pressure-assisted gelation of chemically modified poultry meat batters. Food Chem 75:203–209

Cárcel JA, Benedito J, Bon J, Mulet A (2007) High intensity ultrasound effects on meat brining. Meat Sci 76:611–619

Chandrapala J, Oliver C, Kentish S, Ashokkumar M (2012) Ultrasonics in food processing. Ultrason Sonochem 19:975–983

Chang HJ, Xu XL, Zhou GH, Li CB, Huang M (2012) Effects of characteristics changes of collagen on meat physicochemical properties of beef semitendinosus muscle during ultrasonic processing. Food Bioprocess Technol 5:285–297

Ding YQ, Liu R, Rong JH, Liu YM, Zhao SM, Xiong SB (2012) Rheological behavior of heat-induced actomyosin gels from yellowcheek carp and grass carp. Eur Food Res Technol 235:245–251

Egelandsdal B, Fretheim K, Samejima K (1986) Dynamic rheological measurements on heat-induced myosin gels: effect of ionic strength, protein concentration and addition of adenosine triphosphate or pyrophosphate. J Sci Food Agric 37:915–926

Egelandsdal B, Martinsen B, Autio K (1995) Rheological parameters as predictors of protein functionality: a model study using myofibrils of different fibre-type composition. Meat Sci 39(1):97–111

Ferris JJ, Sandoval AJ, Barreiro JA, Sanchez JJ, Muller AJ (2009) Gelation kinetics of an imitation-mortadella emulsion during heat treatment determined by oscillatory rheometry. J Food Eng 95:677–683

Fretheim K, Samejima K, Egelandsdal K (1986) Myosins from red and white bovine muscles: part 1-gel strength (elasticity) and water-holding capacity of heat-induced gels. Food Chem 22:107–121

Gordon A, Barbut S (1992) Mechanisms of meat batter stabilization: a review. Crit Rev Food Sci 32(4):299–332

Han MY, Zhang YJ, Fei Y, Xu XL, Zhou GH (2009) Effect of microbial trans-glutaminase on NMR relaxometry and microstructure of pork myofibrillar protein gel. Eur Food Res Technol 228(4):665–670

Hand LW, Hollingsworth CA, Calkins CR, Mandigo RW (1987) Effects of preblending, reduced fat and salt levels on frankfurter characteristics. J Food Sci 52:1149–1151

Huang XJ, Li C, Yang F, Xie LX, Xu XY, Zhou Y, Pan SY (2010) Interactions and gel strength of mixed myofibrillar with soy protein, 7S globulin and enzyme-hydrolyzed soy proteins. Eur Food Res Technol 231(5):751–762

Ito Y, Tatsumi R, Wakamatsu J, Nishimura T, Hattori A (2003) The solubilization of myofibrillar proteins of vertebrate skeletal muscle in water. Anim Sci J 74:417–425

Jayasooriya SD, Bhandari BR, Torley P, D’Arcy BR (2004) Effect of high power ultrasound waves on properties of meat: a review. Int J Food Prop 7(2):301–319

Jayasooriya SD, Torley PJ, D’Arcy BR, Bhandari BR (2007) Effect of high power ultrasound and ageing on the physical properties of bovine semitendinosus and longissimus muscles. Meat Sci 75:628–639

Kang ZL, Zou YF, Xu XL, Zhu CZ, Wang P, Zhou GH (2014) Effect of a beating process, as a means of reducing salt content in Chinese-style meatballs (kung-wan): a physico-chemical and textural study. Meat Sci 96:147–152

Kocher PN, Foegeding EA (1993) Microcentrifuge-based method for measuring water-holding of protein gels. J Food Sci 58(5):1040–1046

Labuza TP, Busk GC (1979) An analysis of the water binding in gels. J Food Sci 44:1379–1385

Latoch A (2010) Selected properties of I-Z-I properties of sonicated beef. Pol J Food Nutr 60:51–55

Lesiów T, Xiong YL (2001) Mechanism of rheological changes in poultry myofibrillar proteins during gelation. Avain Poult Biol Rev 12:137–149

Liu R, Zhao SM, Xiong SB, Xie BJ, Liu HM (2007) Studies on fish and pork paste gelation by dynamic rheology and circular dichroism. J Food Sci 72(7):E399–E403

Lyng JG, Allen P, McKenna BM (1998) The effect on aspects of beef tenderness of pre- and post-rigor exposure to a high intensity ultrasound probe. J Sci Food Agric 78:308–314

Matulis RJ, McKeith FK, Sutherland JW, Brewer MS (1995) Sensory characteristics of frankfurters as affected by fat, salt and pH. J Food Sci 60:42–47

Montejano JG, Hamann DD, Lanier TC (1984) Thermally induced gelation of selected comminuted muscle systems-rheological changes during processing, final strengths and microstructure. J Food Sci 49:1496–1505

Omana DA, Moayedi V, Xu Y, Betti M (2010) Alkali-aided protein extraction from chicken dark meat: textural prop-erties and color characteristics of recovered proteins. Poult Sci 89:1056–1064

Petracci M, Cavani C (2012) Muscle growth and poultry meat quality issues. Nutrients 4(1):1–12

Petracci M, Bianchi M, Mudalala S, Cavani C (2013) Functional ingredients for poultry meat products. Trends Food Sci Technol 33:27–39

Pietrasik Z (2003) Binding and textural properties of beef gels processed with κ-carrageenan, egg albumin and microbial transglutaminase. Meat Sci 63(3):317–324

Pohlman FW, Dikeman ME, Zayasq JF (1997a) The effect of low-intensity ultrasound treatment on shear properties, color stability and shelf-life of vacuum-packaged beef semitendinosus and biceps femoris muscles. Meat Sci 45(3):329–337

Pohlman FW, Dikeman ME, Kropf DH (1997b) Effects of high intensity ultrasound treatment, storage time and cooking method on shear, sensory, instrumental color and cooking properties of packaged and unpackaged beef pectoralis muscle. Meat Sci 46:89–100

Reynolds JB, Anderson DB, Schmidt GR, Theno DM, Siegel DG (1978) Effects of ultrasonic treatment on binding strength in cured ham rolls. J Food Sci 43:866–869

Schmidt GR (1984) Processing effects on meat product microstructure. Food Microstruct 3:33–40

Sikes AL, Tobin AB, Tume RK (2009) Use of high pressure to reduce cook loss and improve texture of low-salt beef sausage batters. Innov Food Sci Emerg 10:405–412

Siró I, Cs V, Cs B, Jónás G, Zeke I, Friedrich L (2009) Application of an ultrasonic assisted curing technique for improving the diffusion of sodium chloride in porcine meat. J Food Eng 91:353–362

Stadnik J, Dolatowski ZJ (2011) Influence of sonication on Warner-Bratzler shear force, colour and myoglobin of beef (m. semimembranosus). Eur Food Res Technol 233:553–559

Stadnik J, Dolatowski ZJ, Baranowska HM (2008) Effect of ultrasound treatment on water holding properties and microstructure of beef (M. semimembranosus) during ageing. LWT Food Sci Technol 41:2151–2158

Sun J, Li X, Xu XL, Zhou GH (2011) Influence of various levels of flaxseed gum addition on the water-holding capacities of heat-induced porcine myofibrillar protein. J Food Sci 76:C472–C478

Trout GR, Schmidt GR (1986) Water binding ability of meat products: effect of fat level, effective salt concentration and cooking temperature. J Food Sci 51:1061–1062

Vimini RJ, Kemp JD, Fox JD (1983) Effects of low frequency ultrasound on properties of restructured beef rolls. J Food Sci 48:1572–1573

Weiss J, Gibis M, Schuh V, Salminen H (2010) Advances in ingredient and processing systems for meat and meat products. Meat Sci 86:196–213

Xiong YL, Blanchard SP (1994) Rheological properties of salt-soluble protein from white and red skeletal muscles. J Agric Food Chem 42:1624–1628

Youssef MK, Barbut S (2009) Effects of protein level and fat/oil on emulsion stability, texture, microstructure and color of meat batters. Meat Sci 82:228–233

Acknowledgments

This work was funded by the CARS-42 from the Ministry of Agriculture of the People’s Republic of China and the National Natural Science Foundation (BK 2011649).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, K., Kang, ZL., Zou, YF. et al. Effect of ultrasound treatment on functional properties of reduced-salt chicken breast meat batter. J Food Sci Technol 52, 2622–2633 (2015). https://doi.org/10.1007/s13197-014-1356-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1356-0