Abstract

A conveyor-belt dryer was developed using a combined infrared and hot air heating system that can be used in the drying of fruits and vegetables. The drying system having two chambers was fitted with infrared radiation heaters and through-flow hot air was provided from a convective heating system. The system was designed to operate under either infrared radiation and cold air (IR-CA) settings of 2000 W/m2 with forced ambient air at 30 °C and air flow of 0.6 m/s or combined infrared and hot air convection (IR-HA) dryer setting with infrared intensity set at 2000 W/m2 and hot at 60 °C being blown through the dryer at a velocity of 0.6 m/s or hot air convection (HA) at an air temperature of 60 °C and air flow velocity 0.6 m/s but without infrared heating. Apple slices dried under the different dryer settings were evaluated for quality and energy requirements. It was found that drying of apple (Golden Delicious) slices took place in the falling rate drying period and no constant rate period of drying was observed under any of the test conditions. The IR-HA setting was 57.5 and 39.1 % faster than IR-CA and HA setting, respectively. Specific energy consumption was lower and thermal efficiency was higher for the IR-HA setting when compared to both IR-CA and HA settings. The rehydration ratio, shrinkage and colour properties of apples dried under IR-HA conditions were better than for either IR-CA or HA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruits and vegetables are agricultural products that are known for their rich vitamins, high concentration of moisture and low fats. They are highly perishable due to excess moisture present in the product especially at harvest. Fruits and vegetables are seasonal crops and are mostly available during the production season. Wills et al. (1998) stated that there was a high increase in production of vegetable and fruits from 112 million tons in 1970 to 203 million tons in 1994. The demand for vegetables by the growing population has not been met despite the increase in production. This is as a result of wastes that result from biological and biochemical activities taking place in the fresh product and unfavourable storage conditions, inefficient handling, transportation, inadequate postharvest infrastructure and poor market outlets. Fruits and vegetable can be successfully preserved by reducing their moisture content to a level that will discourage the activities of micro-organisms and fungi from deteriorating them. Microbial activities of most products are low when the moisture content is below 10 % w.b.

Drying of food products is one of the most common processes used to improve their stability. As the water activity of a product decreases it in turn reduces microbiological activity and minimizes physical and chemical changes during storage (Mayor and Sereno, 2004). Hot air drying is the most commonly employed commercial technique for drying of food materials. However, low energy efficiency, longer drying time and poor product quality are some of the drawbacks of hot air drying. Emerging drying techniques include dielectric heating (radio frequency and microwave), (Maskan, 2001), electromagnetic heating (infrared), (Celma et al., 2009) inductive heating, ohmic heating, and heating in the presence of external fields such as pulsed electric field, ultrasound and UV light (Bircan and Erenturk, 2010). While the application of microwaves in food dehydration is established to some extent the use of other techniques such as infrared and radiofrequency drying has gained momentum only in the recent past. Increasing concern for product quality and the need for minimized processing and energy costs has led to a more detailed study and understanding of drying of food materials. This has also revolutionized the design and development of drying systems (Kiranoudis and Markatos, 2000).

Application of infrared radiation heating is gaining popularity in food processing because of its definite advantages over conventional heating. Faster and efficient heat transfer, lower processing cost, uniform product heating and better organoleptic and nutritional value of processed material are some of the important features of infrared radiation drying (Hebbar and Ramesh 2005). Infrared radiation drying has been investigated as a potential method for obtaining high quality dried food stuffs, including fruits, vegetables and grains (Zhu et al., 2002, Baysal et al., 2003, Celma et al., 2008).

The combination of infrared with hot air provides the synergistic effect, resulting in an efficient drying process. When the material is exposed to infrared radiation, it impinges on the material surface and penetrates it. The increased molecular vibration (Wanyo et al. 2011) due to absorption of radiation generates heat in the material both at surface and inner layers simultaneously. The rapid heating of the material increases the rate of moisture movement towards the surface. The convective flow of air removes the moisture from the surface, besides lowering its temperature, which results in increased mass transfer.

The objectives of this study were to evaluate the design and characteristics of a dryer with three different types of heat source through a series of performance indicators in order to establish (1) dryer efficiency and energy consumptions and (2) product quality under the different dryer settings.

Materials and methods

Description and operation of the developed conveyor-belt dryer

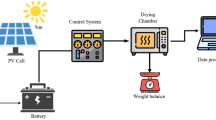

A schematic diagram of the dryer is presented in Fig. 1. It has overall dimensions of 300 × 80 × 150 cm in length, width and height, respectively, and is made up of a drying chamber, infrared heat system, hot air convection system, conveyor-belt system, and feeder and product collection.

Drying chamber

The drying area is made of two chambers of equal dimension (80 × 80 cm) made of stainless steel sheet of 2 mm thickness. The inner surface of the drying chamber walls was covered with 0.15 cm thick aluminium that could reflect infrared rays. The outer surface of the walls was insulated using a 5 cm thick asbestos layer.

Infrared heating system

The efficiency of any infrared based heating system mainly depends on the type of heat source used. The infrared emitters emitting radiation between the medium to far infrared region of 2.4 to 7 μm were found suitable for drying of agricultural and food product (Sandu, 1986). The main components of foodstuff, that is, water and organic compounds such as proteins and starches, absorb far infrared radiation energy at wavelengths greater than 2.5 μm (Sakai and Hanzawa 1994). Hence, in the developed dryer an infrared heater source having wavelengths greater than 2.4 μm was selected.

The dryer was equipped with infrared heater halogen lamps (Philips, tube type) of 1000 W having a diameter of 0.6 cm and length of 35.5 cm. This was fitted on the top inside surface of the drying chambers. The infrared heat sources were placed parallel to the conveyor-belt and the distance between the infrared heater and conveyor-belt was maintained constant at 15 cm. The infrared radiation intensity or output power of the lamps could be varied by regulating the voltage through a power regulator.

Hot air convection system

The hot air convection unit consisted of a 1.4 kW fan that provided the desired drying air velocity and two electrical heaters. The air passed through a PVC pipe and entered the drying chamber through two inlets as shown in Fig. 1. A control valve was placed at the inlet of the PVC pipe in order to control the amount of air entering the drying chamber. Air was heated as it flew through two spiral type electrical heaters, having a capacity of 1.5 kW each. These electrical heaters turned off or on separately via a temperature control unit (TZ4STAutonics, Taiwan), depending on the settings of the temperature.

The drying air temperature and velocity were measured directly at the point of entering into the drying chamber. The air velocity was kept at a constant value of 0.6 m/s just above the conveyor-belt surface at all the different dryer settings under this study and was measured using a hot wire digital anemometer (Test, 405 V1) measuring to an accuracy of ±0.1 m/s.

The air temperature was measured using T-type thermocouples (Test 925) connected to a data logger measuring to an accuracy of ±1 °C. The thermocouples were fixed at five positions on the drying conveyor-belt surface to measure the air temperature in the drying chamber. The temperatures T1 and T4 as presented in Fig. 1 were measured on the air entry side while temperatures T2 and T5 were measure on the air exit side. The air temperature T3 was recorded at the centre of drying chamber.

Conveyor-belt system

The conveyor-belt was made of a stainless steel wire mesh and was used to carry the material into and out of the drying chambers. The conveyor could be stopped using a switch when the product was positioned directly under the infrared heaters. Drying proceeded as the material remained stationary.

Feeder and product collection

The feeder and discharge hopper were made of a stainless steel. The feeder had a flow control valve that ensured uniform loading of raw material on to the conveyor. The discharge chute was positioned in a way so as to scrap the product off the conveyor.

Operation flexibility was provided in the system so that it could be used independently in three different dryer settings: hot air convection (HA) only, Infrared and cold air (IR-CA) only or combined infrared and hot air convection (IR-HA) dryer setting. Through-flow hot air heating was provided at the desired temperature of 60 °C for both HA and IR-HA combination dryer settings. During IR-CA setting the hot air generation system was switched off but the fan still blew in cold air at about 30 °C. In all three setting the air whether cold or hot was blown through the dryer at a velocity of 0.6 m/s.

Materials

The apples (Golden Delicious cultivar) used in this study were obtained from the local market. They were then stored in a refrigerator at 4 °C. After removal from refrigerator and a stabilization period for 2 h at the ambient temperature, apples of uniform size were selected and peeled. After removing their centre core the apples were cut in to the cylindrical shapes of about 5 ± 1 mm in thickness. The thickness of each slice was measured using a dial micrometer.

Drying procedure

The dryer was run without the sample for about 30 min in order to reach set conditions before each drying experiment. The system was designed to operate under either of the following three settings; 1) infrared radiation and cold air (IR-CA) setting of 2000 W/m2 with forced ambient air at 30 °C and air flow of 0.6 m/s, 2) combined infrared and hot air convection (IR-HA) dryer setting with infrared intensity set at 2000 W/m2 and hot at 60 °C being blown through the dryer at a velocity of 0.6 m/s, and 3) hot air convection (HA) dryer setting at an air temperature of 60 °C and air flow velocity 0.6 m/s but without infrared heating.

The apple sample was weighed and distributed into a thin layer on a pan that was then placed on the conveyor. The belt conveyor was then used to carry the pan to a position such that the slices were directly under the infrared heaters. Drying commenced immediately because steady drying conditions already existed. The power meter reading was taken before and soon after completion of drying run. The initial weight of sample was kept constant at approximately 200 g for all drying experiments. The slices were weighed every 10 min using an electronic balance (METTLER PM30, Germany) having an accuracy of ±0.01 g. The drying process continued until the final moisture content of apple slices fell to or below 11 % w.b. from an initial moisture content of about 82 % w.b. There were three dryer settings and drying of apple slices at each setting was triplicated. Dry samples were then cooled and evaluated for quality.

Determination of dry matter content

Dry matter content of apple slices was determined by vacuum drying a 10 g sample at 70 °C to constant mass (AOAC, 1990). These experiments were replicated thrice in order to obtain a reasonable average. The initial moisture content of the samples was found to be about 82 ± 1 % w.b.

Analysis

Based on its initial value the moisture content during the drying process was obtained from the measured mass loss using Eq. 1 (EL-Sebaii et al. 2002):

Where, M t is moisture content at time t, % d.b; M o is the initial moisture content, % d.b; W o is initial mass, g; and W t is the mass loss at time t, g.

The drying curve is drawn using the moisture ratio rather than the moisture content because of the fact that the initial value for the moisture ratio is a constant value for all the drying processes. The moisture ratio was determined using Eq. 2:

Where MR is the moisture ratio and Mt, M o and Me are moisture contents after time t, initial moisture content and equilibrium moisture content, respectively. Moisture ratio (MR) was simplified to Mt/M i because Me is relatively small compared to M t or Mi (El-Beltagy et al., 2007 and Wang et al., 2007).

The drying rate (DR) of apple slices was calculated using Eq. 3:

where M t+dt is moisture content at t + dt in g water/g dry matter and dt is the ten minutes reading interval.

Specific energy consumption

The total energy consumption (ET) was defined as the sum of the electrical energy consumed during drying process and included the energy used to heat the air (EH), energy to drive fan (EF), energy to drive the conveyor (EC) and energy used in the infrared heaters (EIR). This energy was measured using a digital electric counter (Kaan, type 101) with 0.01 KWh precision and is presented in Eq. 4.

Specific energy consumption (SEC) of apple slices during drying was expressed in MJ/kg of water evaporated, and calculated according to Eq. 5 (Wang and Sheng, 2006; and Tarhan et al. 2010):

where MW is mass of water evaporated, and ET is a total electrical energy supplied in the drying process and is presented in form of Eq. 4.

Thermal efficiency

The drying efficiency is defined as the ratio of the heat energy utilized for evaporating moisture from the fruits to total energy consumption (El-Mesery and Mwithiga 2012; Soysal, 2004 and Tippayawong et al., 2009).

where MW is mass of water evaporated, kg, L is the latent heat of vaporization of water, kJ/kg. The latent heat of vaporization of water at average evaporating temperature of 60 °C (HA), 85 °C (IR-CA) and 100 °C (IR-HA) was taken to be 2358.5, 2295.62 and 2256.7 kJ/kg (Popiel and Wojtkowiak, 2007), respectively Eq. 6.

Shrinkage ratio

The shrinkage of foodstuff is a common physical phenomenon observed during different dehydration processes. These changes affect the quality of the dehydrated product and should be taken into consideration when predicting moisture and temperature profiles in the dried material (Mayor and Sereno, 2004; Krokida and Maroulis, 2001).

The shrinkage ratio of the dried apple was evaluated by a volumetric displacement method using n-heptane as the working liquid. The volumes of ten slices were measured and the average values were reported (Koc et al., 2008). The shrinkage ratio (Sr) was calculated as presented in Eq. 7.

where Vo and Vd represent the average volume of a slice before drying and the average volume of the dried apple slices, respectively.

Rehydration ratio

Most of the dehydrated products are usually rehydrated during their use so that the additional indicators of quality are the rate and extent of rehydration. The optimal reconstitution properties can be achieved through the control of the dehydration process and the rehydration conditions (Planinić et al., 2005). Rehydration ratio has been widely used as a quality evaluation method after drying has been performed. In fact, it is a complex process that indicates the chemical and physical changes caused by the drying procedures (Lewicki, 1998).

Approximately 10 g of the dried apple slices was placed into a 500 ml beaker containing 150 ml of distilled water. The beaker was covered and heated to boil for 5 min (Prakash, et al., 2003; and Al-Khuseibi et al., 2005). The rehydrated slices were removed from the beaker and then drained over a mesh for 30 s and quickly but gently blotted with a tissue paper 4–5 times in order to eliminate the surface water, and then weighed. The rehydration ratio (Rr) of dried apple slices was calculated using Eq. 8.

where Mr is the mass of the rehydrated slices and Md is the mass of dry slices used for rehydration.

Colour measurement

The colour of fresh and dried apple samples was measured using a colour measuring devices (CR-400, Minolta). Measurements were individually taken for five fresh apple pieces and another five dried apple slices, and the average of the five readings was calculated. Three parameters, L* (lightness), a* (redness), and b* (yellowness) were recorded. The total colour difference (ΔE) from fresh apple slices was calculated using Eq. 9.

where the subscript “o” refers to colour reading of fresh apples while “*” refer to colour parameters of dried apple samples. A higher ΔE represents greater colour difference from the reference fresh material.

Results and discussion

Drying air temperature

The temperatures of air as measured at five locations just above the conveyor belt and throughout the drying duration are presented in Fig. 2. For the hot air convection (HA) dyer setting it can be seen that the temperature is approximately 60 °C at the beginning of the drying process but increases to about 63 °C at the end of the drying process. The air temperature for the Infrared and cold air (IR-CA) dryer setting rose steadily from 60 °C at the beginning to reach 110 °C after 180 min of drying and then remained almost constant thereafter. The air temperature for the combined infrared and hot air convection (IR-HA) dryer setting rose from 80 °C at the beginning of the drying process to reach 130 °C degrees by the end of the drying period.

Influence of dryer setting on drying rate

The variations in the moisture ratios of the apple slices as a function of drying time at different dryer settings are presented in Fig. 3. It can be seen that the moisture ratio of apple slices decreased with the increase in drying time for all three dryer settings in this study. Apple slices dried under IR-HA setting dried faster than those dried under IR-CA or HA setting. The reduction in drying time was nearly 57.5 % and 39.1 % when compared to drying under HA and IR-CA settings, respectively. This significant reduction in drying time could be attributed to the synergistic effect of infrared and hot air. The rapid diffusion of moisture to the surface of material due to infrared heating and simultaneous removal of moisture from the surface by forced convection resulted in a quicker drying process. Hebbar et al. (2004) obtained similar findings while investigating the effects of combined infrared and hot air drying of vegetables. Their performance evaluation studies indicated that the combined mode drying of carrots and potatoes at 80 °C with air at a velocity of 1 m/s could reduce the drying time by 48 %.

The drying rates of apple slices as a function of drying time and as a function of moisture content are presented in Figs. 4 and 5, respectively. The highest drying rate was 7.40, 6.72 and 4.16 g/g of dry matter per minute when drying under IR-HA, IR-CA and HA dryer setting, respectively. Drying rate is seen to decrease continuously with both time and moisture content. However the drying rate for the IR-HA setting remained higher than that of the other two setting at all drying times and moisture contents. As can be seen, a constant rate period of drying was not observed under all three dryer settings. The drying of apple slices occurred in the falling rate period only and the diffusion mechanism controlled moisture removal. These results were in agreement with previous studies such as Togrul (2005), Sacilik and Elicin (2006) and Schultz et al. (2007). The IR-HA dryer setting had a higher rate of mass transfer, which resulted in shorter drying time. This is due to the fact that convective hot air can absorbed more moisture from the apples slices thus allowing the IR-HA dry the apples at a faster rate than the IR-CA setting. A shorter drying time has been reported for many foodstuffs, such as garlic cloves by Sharma and Prasad (2001), onion by Mongpraneet et al. (2002), apple by Sun et al. (2007) and Nowak and Lewicki (2004), carrot slices by Kocabiyik and Tezer (2009) and whole longan by Nuthong et al. (2011).

Specific energy consumption

The specific energy consumption values obtained in the drying trials carried out at the three different dryer settings are presented in Fig. 6. The highest specific energy consumption was observed when drying under the HA dryer setting. The specific energy consumption when drying under both IR-CA and IR-HA was relatively much lower than for the case of convective drying (HA). However, drying under combine hot air and infrared setting resulted in a slightly lower specific energy consumption when compared to drying under combined infrared and ambient (cold) air setting. Thus the specific energy consumption for IR-CA and the HA dryer combinations were 12 and 488 % higher, respectively, than that of the IR- HA setting. The direct heating of the apple slices by the infrared radiation thus driving the moisture to the surface combined with the hot air which readily absorbs and carries the moisture away from the surface ensures that limitations to the rate of drying are not due to convective removal. The difference in the specific energy consumption of IR-HA and IR-CA setting can be attributed to the lower vapour uptake capability of IR-CA system and the lower temperature of apple slices (Fig. 2) when operating under this dryer settings. Other researchers who had observed a reduction in specific energy consumption when drying products under a combined mode of heating include Sakai and Hanzawa (1994), Sharma and Prasad (2006) and Motevali et al. (2011). Afzal et al. (1999) reported that during the combined convective and IR drying process of barley, the total energy required was reduced by about 156, 238 and 245 % as compared with convection drying alone at 40, 55 or 70 °C, respectively. Hebbar et al. 2004 found that the evaporation of water took 48 % less time and 63 % less energy in combined mode drying as compared to convective drying.

Thermal efficiency

The thermal efficiency values of the dryer when operated under the different settings are presented in Fig. 7. It is evident from Fig. 7 that the efficiency of the dryer when operated under IR-HA setting was high (57.76 %) followed closely by that of IR-CA setting (51.57 %) while that of drying under convective drying alone was very low (10.08 %). This observation that a combined mode of heating is likely to increase the thermal efficiency was also made by Hebbar et al. (2004).

Shrinkage ratio

The effect of dryer settings on shrinkage of apple slices is shown in Fig. 8. The shrinkage ratio of dried apple slices was 0.191, 0.217 and 0.285 for IR-HA, IR-CA and HA dryer setting, respectively. It can be seen that the least shrinkage occurred under IR-HA combination dryer setting. The lower shrinkage of apple slice sunder IR-HA setting can be attributed to higher drying air temperatures and the lower moisture content of the external surfaces and on both sides of the slice (Mayor and Sereno, 2004 and Wang and Brennan, 1995).

Rehydration ratio

The rehydration ratios of dried apple slices at different dryer settings are presented in Fig. 9. The rehydration ratios were 4.57, 4.03 and 3.21 for IR-HA, IR-CA and HA dryer settings, respectively and these values are within the range that has been found for other biological materials. Sharma et al. (2005) found that the rehydration ratio of dried onion slices varied between 4.5 and 5.3 under combined convective and IR drying conditions. Higher water absorption capacity was expected for the IR-HA dryer setting because of short drying duration which improves the rehydration capacity of dried products as reported in earlier studies by Singh et al. (2006), Mongpraneet et al. (2002) and Baysal et al. (2003).

Colour measurement

The colour difference values of apple slices are presented in Fig. 10. It is clear that the IR-HA dryer setting produced a dried product that had the least change in colour and that the hot air convective drying had the highest changes (Mongpraneet et al. 2002 and Reyes et al. 2008). The higher value of (ΔE) for the HA dryer setting could be attributed to the longer period of drying and hence the case hardening of product. Vishwanathan et al. (2010) studied the effect of different drying methods (HA, IR and combination IR-HA) on the product quality of potato and carrots slices, and reported that higher rehydration ratio and lower browning index values are observed from combined mode dried products.

Conclusion

This work concludes that drying of apple slices within the limits of these experiments is in the falling rate period of drying. The drying of apple slices under combined infrared and convective heating is faster and requires less energy when compared to drying under infrared heating with cold air convection or convective hot air heating alone. Furthermore, drying under the combined infrared and hot air convective heating produces a product that has less shrinkage, higher rehydration ratio and better colour retention.

References

Afzal TM, Abe T, Hikida Y (1999) Energy and quality aspects during combined FIR-convective drying of barley. J Food Eng 42:177–182

Al-Khuseibi MK, Sablani SS, Perera CO (2005) Comparison of water blanching and high hydrostatic pressure effects on drying kinetics and quality of potato. Dry Technol 23:2449–2461

AOAC. (1990). Official methods of analysis (12th ed.), Association of Official Analytical Chemists. Washington, DC.

Baysal T, Icier F, Ersus S, Yildiz H (2003) Effects of microwave and infrared drying on the quality of carrot and garlic. Eur Food Res Technol 218:68–73

Bircan K, Erenturk S (2010) Drying characteristics of mistletoe (Viscum album L.) in convective and UV combined convective type dryers. Ind Crop Prod 32:394–399

Celma AR, Rodriguez FL, Blazquez FC (2009) Experimental modelling of infrared drying of industrial grape by-products. Food Bioprod Process 87:247–253

Celma AR, Rojas S, Rodriguez FL (2008) Mathematical modeling of thin layer infrared drying of wet olive husk. Chem Eng Process 47:1810–1818

El-Beltagy A, Gamea GR, Amer Essa AH (2007) Solar drying characteristics of strawberry. J Food Eng 78:456–464

EL-Mesery HS, Mwithiga G (2012) Comparison of a gas fired hot-air dryer with an electrically heated hot-air dryer in terms of drying process, energy consumption and quality of dried onion slices. Afr J Agric Res 7(31):4440–4452

El-Sebaii AA, Aboul-Enien S, Ramadan MRI, El-Gohary HG (2002) Empirical correlation for drying kinetics of some fruits and vegetables. Energy 27:845–859

Hebbar UH, Ramesh MN (2005) Optimisation of processing conditions for infrared drying of cashew kernels with taste. J Sci Food Agric 85:865–871

Hebbar UH, Vishwanathan KH, Ramesh MN (2004) Development of combined infrared and hot air dryer for vegetables. J Food Eng 65:557–563

Kiranoudis CT, Markatos NC (2000) Pareto design of conveyor belt dryers. J Food Eng 46:145–155

Koc B, Eren I, Ertekin FK (2008) Modelling bulk density, porosity and shrinkage of quince during drying: The effect of drying method. J Food Eng 85:340–349

Kocabiyik H, Tezer D (2009) Drying of carrot slices using infrared radiation. Int J Food Sci Technol 44:953–959

Krokida MK, Maroulis ZB (2001) Structural properties of dehydrated products during rehydration. Int J Food Sci Technol 36(5):529–538

Lewicki PP (1998) Some remarks on rehydration of dried foods. J Food Eng 36:81–87

Maskan M (2001) Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng 48:177–182

Mayor L, Sereno AM (2004) Modelling shrinkage during convective drying of food materials: a review. J Food Eng 61:373–386

Mongpraneet S, Abe T, Tsurusaki T (2002) Far infrared-vacuumand -convection drying of welsh onion. Trans Am Soc Agric Eng 45:1529–1535

Motevali A, Minaei S, Khoshtagaza MH, Amirnejat H (2011) Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy 36:6433–6441

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innov Food Sci Emerg Technol 5:353–360

Nuthong P, Achariyaviriya A, Namsanguan K, Achariyaviriya S (2011) Kinetics and modeling of whole longan with combined infrared and hot air. J Food Eng 102(2011):233–239

Planinić M, Velić D, Tomas S, Bilić M, Bucić A (2005) Modelling of drying and rehydration of carrots using Peleg’smodel. Eur Food Res Technol 221:446–451

Popiel CO, Wojtkowiak J (2007) Simple formulas for thermophysical properties of liquid water for heat calculations (from 0 to 150 °C). Heat transf eng 19(1):87–101

Prakash S, Jha SK, Datta N (2003) Performance evaluation of blanched carrots dried by three different driers. J Food Eng 62(3):305–313

Reyes A, Vega R, Bustos R, Araneda C (2008) Effect of processing conditions on drying kinetics and particle microstructure of carrot. Dry Technol 26:1272–1285

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73:281–289

Sakai N, Hanzawa T (1994) Applications and advances in far infrared heating in Japan. Trends Food Sci Technol 5:357–362

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Prog 2:109–119

Schultz EL, Mazzuco MM, Machado RAF, Bolzan A, Quadriand MB, Quadri MGN (2007) Effect of pre–treatment on drying, density and shrinkage of apple slices. J Food Eng 78:1103–1110

Sharma GP, Prasad S (2001) Drying of garlic (Allium sativum) cloves by microwave-hot air combination. J Food Eng 50:99–105

Sharma GP, Prasad S (2006) Specific energy consumption in microwave drying of garlic cloves. Energy 31:1921–1926

Sharma GP, Verma RC, Pathare P (2005) Thin-layer infrared radiation drying of onion slices. J Food Eng 67:361–366

Singh S, Raina CS, Bawa AS, Saxena DC (2006) Effect of pretreatments on drying and rehydration kinetics and solar of sweet potato slices. Dry Technol 24:1487–1494

Soysal A (2004) Microwave drying characteristics of parsley. Biosyst Eng 89(2):167–173

Sun J, Hu X, Zhao G, Wu J, Wang J, Chen F, Liao X (2007) Characteristics of thin layer infrared drying of apple pomace with and without hot air pre-drying. Food Sci Technol Int 13(2):91–97

Tarhan S, Telci I, TanerTuncay M, Polatci H (2010) Product quality and energy consumption when drying peppermint by rotary drum dryer. Ind Crop Prod 32:420–427

Tippayawong N, Tantakitti C, Thavornun S, Peerawanitkul V (2009) Energy conservation in drying of peeled longan by forced convection and hot air recirculation. Biosyst Eng 104:199–204

Togrul H (2005) Simple modeling of infrared drying of fresh apple slices. J Food Eng 71:311–323

Vishwanathan KH, Hebbar UH, Raghavarao KSMS (2010) Hot Air assisted infrared drying of vegetables and its quality. Food Sci TechnologyRes 16(5):381–388

Wang J, Sheng K (2006) Far infrared and microwave drying of peach. Lebensm Wiss Technol 39:247–255

Wang N, Brennan JG (1995) Changes in structure, density and porosity of potato during dehydration. J Food Eng 24:61–76

Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X (2007) Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int 40:39–46

Wanyo P, Siriamornpun S, Meeso N (2011) Improvement of quality and antioxidant properties of dried mulberry leaves with combined far-infrared radiation and air convection in Thai tea process. Food and Bioprod Process 89:22–30

Wills R, McGalsson B, Graham D, Joice D (1998) Post harvest: an introduction to physiology and Handling of Fruit, vegetables and ornaments. Hyde park press Adelaide, South Australia

Zhu K, Zou J, Chu Z, Li X (2002) Heat and mass transfer of seed drying in a two pass infrared radiation vibrated bed. Heat Transfer—Asian Res 31(2)):141–147

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Mesery, H.S., Mwithiga, G. Performance of a convective, infrared and combined infrared- convective heated conveyor-belt dryer. J Food Sci Technol 52, 2721–2730 (2015). https://doi.org/10.1007/s13197-014-1347-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1347-1