Abstract

The use of trifoliate yam (Dioscorea dumetorum) flour for stiff dough ‘amala’ production is one of the ways to curb under-utilization of the tuber. The study evaluates the textural and sensory properties of trifoliate yam flour and stiff dough. Freshly harvested trifoliate yam tubers were peeled, washed, sliced and blanched (60 °C for 10 min). The sliced yam were soaked in water for 12 h, dried and milled into flour. Pasting viscosities, functional properties, brown index and sensory attributes of the flour and stiff dough were analyzed. Peak, holding strength and final viscosities ranged from 84.09 to 213.33 RVU, 81.25 to 157.00 RVU and 127.58 to 236.17 RVU respectively. White raw flour had higher viscosity than the yellow flours. The swelling index, water absorption capacity and bulk density ranged from 1.46 to 2.28, 2.11 to 2.92 ml H2O/g and 0.71 to 0.88 g/cm3 respectively. Blanching method employed improved the swelling index and water absorption capacity of flour. The brown index values of flour and stiff dough ranged from 6.73 to 18.36 and 14.63–46.72 respectively. Sensory evaluation revealed significant differences in the colour, odour and general acceptability of the product when compared with the stiff dough from white yam.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Yam is an important food in many tropical countries particularly in West Africa, South Asia and Caribbean, where it also has a social and cultural importance for about 300 million people throughout the world (Manuel et al. 2005; Ettien et al. 2009). Total world production of yam had been estimated to be 40 million tonnes per year while Nigeria (the leading producer) produced 34 million tonnes which accounts for 69.8 % of the yam (FAO 2006; IITA 2007). Yam flour production is a way of preserving yam tubers in a storable form so as to make it available during the off season (Oni 2006), thereby reducing storage losses as well as marketing and transportation costs (Iwuoha 2004). The process involved in yam flour production includes harvesting, sorting, peeling, slicing, blanching, drying and milling. This is the age-old traditional method of processing yam into dry yam (gbodo), and subsequently yam flour (elubo). The quality of gbodo and elubo varies with the processor location, yam species, processing methods and conditions (Akissoe et al. 2003, 2004; Hounhonigan et al. 2003).

The dried chip and its flour (elubo) are one of the traditional transformation methods for processing and storage of yam (Abiala et al. 2011). Yam flour is the major ingredient in making ‘amala’ largely eaten by ethnic Yorubas of South Western part of Nigeria when reconstituted. Amala is a popular starchy food that is prepared by reconstituting (cooking and stirring with boiling water) fermented or unfermented yam flour (elubo), produced traditionally from the processed tuber flesh of white yam (D. rotundata or D. alata) (Awoyale et al. 2010). It is a traditional thick paste prepared from blanched dried yam flour with a particular texture (Akissoe et al. 2006). Color and taste are permanent features of amala obtained from yam chips flour (Akissoe et al. 2004). Literature is available on the production of yam chips and amala from other white yam, water yam and other yam species (Akissoe et al. 2003, 2006; Babajide et al. 2006; Jimoh et al. 2009; Abiala et al. 2011).

The use of trifoliate yam tubers in making amala had not been explore due to the alkaloid contents which cause bitterness in the tuber. Trifoliate yam being among the neglected tuber crop was reported to be highly nutritious with yield higher than other yam species (Treche and Agbor-Egbe 1996; Afoakwa and Sefa-Dedeh 2001, 2002). Various researchers have studied the chemical, biochemical and textural changes of trifoliate yam tubers, flours and starch after harvesting (Afoakwa and Sefa-Dedeh 2001, 2002; Medoua et al. 2005, 2007; Akinoso and Abiodun 2013). The aim of this work was to prepare flour from trifoliate yam tubers, reconstitute the flour into stiff dough and analyze the properties of the flour and the stiff dough ‘amala’.

Materials and methods

Freshly harvested trifoliate yam cultivars (white and yellow) were obtained on a farm in Osogbo, Osun State, Nigeria. The white yam tubers (Abuja cultivar) and white yam flour (commercial) was obtained at Oluode market, Osogbo, Osun State, Nigeria.

Preparation of raw trifoliate yam flour

The freshly harvested yam tuber was washed, drained and peeled. The peeled tuber was sliced and dried in the hot air oven at 60 °C for 48 h. The dried chips were milled into flour with hammer mill and sieved with 600 μm mesh size. The flour samples were sealed in polythene bag.

Preparation of blanched/soaked trifoliate and white yam flour samples

The freshly harvested yam tuber was washed, drained and peeled. The peeled tuber was diced and blanched (65 °C) for 10 min. The sample was soaked in the blanched water for 12 h at ambient temperature and dried in the oven 60 °C for 48 h. The dried chips were milled into flour with hammer mill and sieved with 600 μm mesh size.

Starch contents determination

Free sugar was extracted from the flour with hot ethanol while the starch was hydrolyzed to its monosaccharide with perchloric acid. The sugar was quantified colorimetrically using phenol and sulphuric acid. Sugar obtained from the hydrolysis of the starch was converted to starch by multiplying by a factor of 0.9. Flour sample (25 mg) was weighed into a centrifuge tube and wetted with 1 ml of 95 % (v/v) hot ethanol at room temperature. Then, 2.0 ml of distilled water and 10 ml of ethanol was added. The mixture was vortexed and centrifuged for 10 min at 2,000 rpm. The supernatant obtained was decanted into a test-tube and made up to 20 ml extract before being used for sugar analysis. To 0.2 ml of the extract, 0.8 ml of distilled water and 0.5 ml of 5 % phenol was added. The mixture was vortexed before subsequent addition of 2.5 ml of conc. H2SO4. The absorbance of the solution was read on a spectrophotometer (Milton Roy Spectronic 601) at 490 nm after it cooled. The residue, after decantation of supernatant, was hydrolyzed with 7.5 ml perchloric acid into monosaccharide sugars for 1 h. It was diluted with 17.5 ml-distilled water and filtered through Whatman no. 2 filter paper. The sugar filtrate was used for starch analysis.

An aliquot of each of the sugar solutions (0.1 ml) was made up to 1 ml with distilled water and colour was developed for the standard curve preparation. The standard curve was prepared by pipeting 0, 0.1, 0.2, 0.3, and 0.4 ml of glucose solution into test tubes and made up to 1.0 ml with distilled water. These corresponded to 0, 10, 20, 30, and 40 μm glucose/ml, respectively. Into these solutions, 0.5 ml of phenol was added with subsequent addition of 2.5 ml concentrated sulphuric acid. The solutions was mixed thoroughly and then allowed to cool before being read at 490 nm on the spectrophotometer (Milton Roy Spectronic 601) (Mcready 1970). A calibration standard curve of absorbance against glucose concentration was plotted from which the percentage sugar and starch in the sample was calculated.

Calculation:

Where

- A:

-

Absorbance of sample

- I:

-

Intercept of standard curve

- DF:

-

Dilution factor based on the aliquot of sample extract taken for assay.

- V:

-

Total extract volume

- B:

-

Slope of the standard curve

- W:

-

Sample weight.

Amylose content

Flour sample (0.1 g) was weighed into 50 ml test tube and 1 ml of 95 % ethanol was added to wet and disperse the sample. Subsequently, 9.0 ml of 1 N NaOH was added and the test tube was heated in a boiling water bath for 10 min to solubilize the sample. From the solution, 1 ml was pipetted and made up to 10 ml with distilled water in another test tube while 0.5 ml aliquot was drawn into another test tube from this solution and assayed by the addition of 0.1 ml 1 N acetic acid and 0.2 ml of iodine solution to allow colour development The solution was diluted to 10 ml with distilled water, vortexed and left for 20 min for colour development after which the absorbance was read on a spectrophotometer (Milton Roy Spectronic 601) at 620 nm (Juliano 1971).

A calibration curve was obtained from different solutions of amylose concentrations using corn amylose. Concentration factor (F) was obtained from the curve and amylose content was calculated as follows:

Where

- F:

-

Concentration factor from standard

- A:

-

Absorbance of solution

- DF:

-

Dilution factor

Pasting properties determination

The pasting profile of the starch sample was studied using a Rapid Visco-Analyzer (RVA) (Newport Scientific Pty. Ltd) with the aid of a thermocline for windows version 1.1 software (1998). The RVA was connected to a PC where the pasting properties and curve were recorded directly. Flour suspension was prepared by addition of the equivalent weight of 3.0 g flour to distilled water to make a total of 28.0 g suspension in the RVA sample canister. The flour suspension temperature was held at 50 °C for 1 min and later heated to 95 °C for 3 min. It was held at 95 °C for 3 min before the sample was subsequently cool to 50 °C over a 4 min period. This was followed by a period of 1 min where the temperature was kept at constant temperature of 50 °C. The equivalent sample weight (S) and volume of water (W) was calculated using formulas below:

Where

- A:

-

3 g

- S:

-

Calculated sample weight for RVA

- M:

-

Moisture content of the sample

- W:

-

Volume of water

Parameters measured (RVA units) were:

-

Peak viscosity: Highest viscosity during 95 °C heating stage

-

Holding strength: Lowest viscosity at the end of 95 °C heating stage

-

Breakdown: Change in viscosity from peak to holding strength

-

Cold paste (final) viscosity: Highest viscosity at the end of 50 °C cooling stage.

-

Setback: Change in viscosity from holding strength to final viscosity

Bulk density

The method used by Udensi and Okaka (2000) was adopted. Bulk density was determined by weighing 3 g of each sample into 10 ml graduated cylinders and tapping ten times against the palm of hand. The volume of the flour after tapping was recorded and bulk density was expressed as g/ml.

Water absorption capacity determination

Flour sample (1 g) from each treatment was weighed into dry centrifuge tube. Distilled water was mixed with the flour to make up to 10 ml dispersion. It was then centrifuged at 3,500 rpm for 15 min. The supernatant was discarded while the tube with its content was reweighed. The gain in mass is the water absorption capacity of the flour sample (Iwuoha 2004).

Swelling index

Determination of swelling index and solubility was carried out according to the method of Iwuoha (2004). Three grammes (3 g) portions of each flour sample were transferred into clean, dry, and graduated (50 ml) cylinders. The flour sample was gently leveled and the volume was noted before addition of 30 ml distilled water. The cylinder was swirled and allowed to stand for 60 min while the change in volume (swelling) was recorded after 15 min. The swelling power of each flour sample was calculated as a multiple of the original volume.

Colour measurement

The colour attributes (Hunter L, a, and b values) of the yam flours and pastes (obtained with a Rapid Visco Analyser) were measured using a Minolta portable chroma-metre. The hunter lab colour coordinates system L* a* and b* values were recorded and the brown index (BI) was calculated (Babajide et al. 2006). Each sample was measured at four spots using standard L* = 53.44, a* = −24.94, b* = 12.94 values.

where: L*, a*, and b* were Hunter L* = Whiteness, a* = Redness and b* = yellowness values.

Sensory analysis of stiff dough ‘amala’

The stiff dough (amala) was prepared by adding flour into 250 cm3 of boiled water, stirred thoroughly with a wooden spoon to avoid lumps, and cooked for 15 min to form soft dough. The dough was wrapped in nylon and kept in the warmer (Nwaegbute et al. 1995). Sensory analysis of the stiff dough was carried out by selecting 20 trained panelists drawn from Yoruba ethnic group among the lecturers of Department of Food Science and Technology, Osun State Polytechnic, Iree, Osun State, who were used to eating stiff dough made from yam flour. The panelists were requested to examine the dough and score according to their degree of likeness with a 7-point hedonic scale ranging from 1 (like extremely) to 7 (dislike extremely). The parameters evaluated were the colour, texture, smoothness, odour and overall acceptability.

Statistical analysis

Statistical analyses were performed using SPSS 17.0 for Windows (SPSS Inc., Chicago, IL).

All experiments were performed in triplicate and the mean values were reported. Comparisons between means were performed with Turkeys test. Differences between means were evaluated as significant at P < 0.05.

Results and discussion

Starch and amylose contents of yam flour

The starch and amylose contents are shown in Table 1. The starch content of white yam (oven dried) flour (75.13 %) was higher and significantly different (p < 0.05) from trifoliate yam flours. White yam (oven dried) flour had higher amylose content (24.68 %) and lower amylopectin content (75.32 %). There was no significant difference (p > 0.05) in starch, amylose and amylopectin contents of yellow and white trifoliate yam flours. The starch contents of trifoliate yam flours were low when compared with the values observed for water yam (80.00–85.30 %) (Daiuto et al. 2005; Huang et al. 2006). The starch content varies with species and cultivars of yam. The amylose fraction in the yam starches ranges from 20.80 to 33.11 % (Okorie et al. 2011; Otegbayo et al. 2011; Brunnschweiler et al. 2005). Lower amylose contents observed in trifoliate yam flours indicate higher swelling power than the white yam flour. The higher the amylose contents the lower the swelling power (Otegbayo et al. 2011; Lorenz and Collins 1990).

Pasting properties of flour

The pasting properties of trifoliate yam flours are shown in Fig. 1. Peak, holding strength and final viscosities ranged from 84.09 to 213.33 RVU, 81.25 to 157.00 RVU and 127.58 to 236.17 RVU respectively. The raw flour had higher peak viscosity, holding strength, breakdown, final viscosity and setback than the blanched flour. The raw and blanched white trifoliate yam flour had higher viscosity values than the raw and blanched yellow flours. The peak (148.75 RVU) and final (164.67 RVU) viscosities of blanched white yam flour were higher than the blanched trifoliate yam flours and white yam (commercial) flour. Increase in viscosity of gelatinized food was explained to depend more on the starch content of the product (Adeyemi and Beckley 1986). The peak viscosity indicates the water-binding capacity of the flour samples, and was reported to be important to the user in order to obtain a useable starch paste (Adeyemi 1989). Bhattacharya et al. (1999) indicated that high holding strength generally represents low cooking loss and superior eating quality. During the holding period, the flour sample was subjected to a period of constant high temperature and mechanical shear stress, which further disrupted the starch granules. The final viscosities of the raw and blanched flours increased signifying the ability of the flour samples to withstand the heating and shear stress and had been reported to be an important factor for many processes (Newport Scientific 1998).

Functional properties of flours

Table 2 showed the functional properties of trifoliate yam flour. The swelling index, water absorption capacity and bulk density ranged from 1.46 to 2.28, 2.11 to 2.92 ml H2O/g and 0.71 to 0.88 g/cm3 respectively. The blanched yellow trifoliate yam flour had higher swelling index than the blanched white trifoliate yam flour and was significantly different (p > 0.05) from other flours. Blanched white trifoliate yam flour had higher value (2.92 ml H2O/g) in water absorption capacity but was not significantly different (p < 0.05) from other flours. The swelling index and water absorption capacity values of the blanched flours from the two cultivars were higher than the raw flours. The swelling index values were within the range observed for raw white yam flour (1.89), water yam flour (2.46) and yellow yam (2.83) (Iwuoha and Nnanemere 2003). The differences in swelling index were due to different analytical methods used. The swelling index was reported to change in direct proportionality with tuber steaming time. Swelling index of steamed cassava from two varieties ranged from 3.66 to 4.14 depending on the cassava varieties (Iwuoha et al. 2003). Percentage of water absorption capacity recorded for different varieties of D. rotundata ranged from 21.30 to 193.30 % (Ekwu et al. 2005). The high water absorption capacity was attributed to loose association of starch polymers in the native granule (Ekwu et al. 2005). The differences observed in water absorption capacity of the samples was due to the differences in the degree of association of starch granules in them.

There was significant difference (p > 0.5) in the bulk densities of the raw and blanched flours. The raw flours had higher values than the blanched flours but raw white trifoliate yam was significantly different from other samples. The bulk density of cooked trifoliate yam flour observed by Ezeocha et al. (2011) was 0.86 g/cm3. Igyor et al. (2004) reported bulk density values of 0.50–0.62 g/ml for the raw flour samples of D. cayenensis, D. bulbifera and D. rotundata. The density of the flour is important in determining the packaging requirement and material handling (Ezeocha et al. 2011).

Brown index values of trifoliate yam flour and amala

The amala from white trifoliate yam and oven dried white yam (Abuja cultivar) flour were light brown in colour when compared to the amala from yellow trifoliate yam flour and commercial yam flour (Table 3). White yam flour (commercial) had higher brown index value (18.36) which was significantly different (p < 0.05) from other flours. There was significant difference (p < 0.05) in the brown index values of the amala made from the four flours with higher value in amala from white yam (commercial flour).

Jimoh et al. (2009) observed higher brown indices for oven dried white yam (Abuja cultivar) flour (21.87) and amala (56.67). Babajide et al. (2006) also reported higher brown indices for yam (Ijedo cultivar) flour (26.54) and amala (57.45) respectively. Dark coloured amala was reported to be due to inability to control the drying process and parameters, weather uncertainties, high labour costs, the requirement of a large drying area, insect infestation, and contamination with dust and other undesirable materials (Sankat and Mujaffar 2004; Ojokoh and Gabriel 2010; Abiala et al. 2011; Adejumo et al. 2013). Brown index value showed the extent of discoloration and could be linked to the total phenol content of the flour and dough (Babajide et al. 2006). This is in agreement with the earlier finding of Akissoe et al. (2003) and Jimoh et al. (2009). The brown index of the paste, increased due to the thermal degradation of the originally colourless complex polyphenols (proanthocyanidins and lignins) to coloured phenols (anthogaridins) during steaming of the paste (Akissoe et al. 2003).

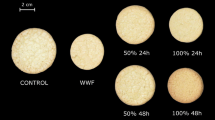

Sensory evaluation of amala

Sensory evaluation of amala from yam tubers is shown in Table 4. There were significant differences (P < 0.05) in the colour values of the amala prepared (Plate I). The white yam (commercial) amala was preferred, followed by white yam (oven dried) and white trifoliate yam amala. White trifoliate yam amala was lighter in colour than white yam (oven dried). Amala produced from oven dried flours were observed to be lighter in color than sundried flour (Jimoh et al. 2009; Akissoe et al. 2006). In Yoruba land, color of stiff dough ‘amala’ (dark brown) is one of the important factor that affects the acceptability of the product. The dark brown colour in white yam (commercial) amala may be due to bad drying conditions the chips were subjected to (Akissoe et al. 2006; Abiala et al. 2011). The texture of white yam dough (Commercial) was more acceptable than other amala. Yellow trifoliate yam dough was sticky and was not as firm as the white trifoliate yam amala and this may be attributed to the low starch content of the tuber which lead to poor binding properties of trifoliate yam flour (Martins et al. 1983; Abiodun and Oladapo 2010). There was no significant difference (p > 0.05) in the values of white yam (oven dried) and white trifoliate yam amala in texture.

There was no significant difference (p > 0.5) in the smoothness of the amala from trifoliate yam flour and white yam flour. Amala from the white yam and trifoliate yam flours were very smooth after reconstitution. There were significant differences (p < 0.05) in the odour values of the amala. The odour of the white yam amala was more preferable than the white trifoliate yam amala. The white yam stiff dough was significantly different (p < 0.05) from trifoliate yam amala in the odour values. The white yam dough (commercial) was more acceptable followed by white yam (oven dried) and white trifoliate yam amala.

Conclusion

The pasting and functional properties of the trifoliate yam flours were comparable to other yam species. Sensory evaluation conducted on the amala revealed that the amala from white trifoliate yam flour was acceptable and comparable to amala made from white yam. The yellow trifoliate yam flour though not acceptable as amala but could be used as composite flour.

References

Abiala MA, Ezekiel CN, Chukwura NI, Odebode AC (2011) Toxigenic Aspergillus section Flavi and aflatoxins in Dried Yam Chips in Oyo State, Nigeria. Acad Arena 3(5):42–49

Abiodun OA, Oladapo AS (2010) Effect of cassava starch and defatted soybeans substitution on the properties of trifoliate yam (Dioscorea dumetorum) flours. J Appl Biosci 36:2340–2345

Adejumo BA, Okundare RO, Afolayan OI, Balogun SA (2013) Quality attributes of yam flour (elubo) as affected by blanching water temperature and soaking time. Int J Eng Sci 2(1):216–221

Adeyemi IA (1989) Cereals as food and industrial raw materials. In: Aribisala OA, Olorunfemi BN (eds) Proceedings of the first meeting of the Action Committee on Raw Materials. Raw Materials Research and Development Council, Lagos, pp 131–138

Adeyemi IA, Beckley O (1986) Effect of period of maize fermentation and souring on chemical properties and Amylograph pasting viscosity of ogi. J Cereal Sci 4:353–360

Afoakwa EO, Sefa-Dedeh S (2001) Chemical composition and quality changes occurring in Dioscorea dumetorum pax tubers after harvest. Food Chem 75(1):85–91

Afoakwa EO, Sefa-Dedeh S (2002) Changes in cell wall constituents and mechanical properties during post-harvest hardening of trifoliate yam Dioscorea dumetorum (Kunth) pax tubers. Food Res Int 35(5):429–434

Akinoso R, Abiodun OA (2013) Effect of harvesting periods on the morphology and physico-chemical properties of trifoliate yam starches. Starch-Starke. doi:10.1002/star.201200171

Akissoe WH, Hounhouigan JD, Akissoes C, Nago M (2003) How blanching and drying affects the colour and functional characteristics of yam (D. cayenesis-rotundata) flours. Food Chem 82:257–264

Akissoe N, Akissoes C, Hounhouigan J, Nago M (2004) Prediction of sensorial properties (color and taste) of amala, a paste from yam chips flour of west africa, through flour biochemical properties. Plant Foods Hum Nutr 59(3):93–99

Akissoe N, Akissoes C, Hounhouigan J, Nago M (2006) Prediction of the sensory texture of a yam thick paste (amala) using instrumental and physicochemical parameters. J Texture Stud 37(4):393–402

Awoyale W, Maziya-Dixon B, Sanni L, Shittu TA (2010) Nutritional and sensory properties of amala supplemented with distiller’s spent grain (DSG). J Food Agric Environ 8(3&4):66–70

Babajide JM, Oyewole OB, Henshaw FO, Babajide SO, Olasantan FO (2006) Effect of local preservatives on quality of traditional dry yam slices ‘Gbodo’ and its products. World J Agric Sci 2(3):267–273

Bhattacharya M, Zee SY, Corke H (1999) Physico-chemical properties related to quality of rice noodles. Cereal Chem 76(6):861–867

Brunnschweiler J, Luethi D, Handschin S, Farah Z, Escher F, Conde-Petit B (2005) Isolation, physicochemical characterization and application of yam (Dioscorea spp.) starch as thickening and gelling agent. Starch-Starke 57:107–117

Daiuto E, Cereda M, Sarmento S, Vilpoux O (2005) Effects of extraction methods on yam (Dioscorea alata) starch characteristics. Starch-Starke 57:153–160

Ekwu FC, Ozo NO, Ikegwu OJ (2005) Quality of fufu flour from white yam varieties (Dioscorea spp). Niger Food J 23:107–113

Ettien DJB, Kone B, Kouadio KKH, Kouadio NE, Yao-Kouame A, Girardin O (2009) Mineral fertilization of ferralsols for yam production in Guinean Savanna zone of West Africa: the case of traditional varieties of yam on dystric ferralsols Centre Cote d’Ivoire. J Appl Biosci 23:1394–1402

Ezeocha VC, Omodamiro RM, Oti E, Chukwu GO (2011) Development of trifoliate yam: cocoyam composite flour for fufu production. J Stor Prod Postharvest Res 2(9):184–188

FAO (2006) Statistics on world production of roots and tubers. FAO, Rome

Hounhonigan JD, Kayode AP, Bricas N, Nago CM (2003) Desirable culinary and sensory characteristic of yam in Urban Benin. Benin J Agric Sci 21(12):2815–2820

Huang CC, Lin MC, Wang CCR (2006) Changes in morphological, thermal and pasting properties of yam (Dioscorea alata) starch during growth. Carbohydr Polym 64(4):524–531

Igyor MA, Ikyo SM, Gernah DI (2004) The food potential of potato yam (Dioscorea bulbifera). Niger Food J 22:209–215

IITA (2007) Yam, research for development. IITA Publ 1:1–10

Iwuoha CI (2004) Comparative evaluation of physicochemical qualities of flours from steam-processed yam tubers. Food Chem 85:541–551

Iwuoha CI, Nnanemere CJ (2003) Swelling index of yam flour as affected by tuber variety, processing method and analytical temperature. Afr J Root Tuber Crops 15(2):15–17

Iwuoha CI, Ezumba CU, Nnadozie CFC (2003) Effect of steaming on the proximate composition and physico-chemical properties of fufu flour made from two cassava varieties (Manihot esculenta Crantz and Manihot palmata, Muell). Niger Food J 21:54–61

Jimoh KO, Olurin TO, Aina JO (2009) Effect of drying methods on the rheological characteristics and colour of yam flours. Afr J Biotechnol 8(10):2325–2328

Juliano BO (1971) A simplified assay for milled rice amylose. Cereal Sci Today 16:334–340

Lorenz K, Collins F (1990) Quinoa (Chenopodium quinoa) starch physicochemical properties and functional characteristics. Starch-Starke 42(3):81–86

Manuel CJ, Rafael GK, Milagros BP, Arletys SP, Victor MV, Jorge LT, Ayme RC, Magaly GG, Jose LCV (2005) Production of yam microtubers using a temporary immersion system. Plant Cell Tissue Org 83:103–107

Martins GS, Treche L, Noubi T, Agbor E, Gwangwa A (1983) Introduction of flour from Dioscorea dumetorum in a rural area. In: Terry ER, Doku EV, Arene OB, Mahungu NM (eds) Tropical root crops: production and uses in Africa. Proceeding of the second triennial symposium of the international society for tropical root crops Africa, Doaula, Cameroon, pp161–163

Mcready RM (1970) Determination of starch and dextrin. In: Joslyn AM (ed) Methods in food analysis, 2nd edn. A series of monographs. Academic, New York. pp 542–559

Medoua GN, Mbome IL, Agbor-Egbe T, Mbofung GMF (2005) Physicochemical changes occurring during post-harvest hardening of trifoliate yam (Dioscorea dumetorum). Food Chem 90(4):597–601

Medoua GN, Mbome IL, Agbor-Egbe T, Mbofung CMF (2007) Anti-nutritional factors changes occurring in trifoliate yam (Dioscorea dumetorum) tubers after harvest. Food Chem 102(3):716–720

Newport Scientific (1998) Applications manual for the Rapid Visco™ Analyser. Newport Scientific Pty. Ltd, Australia, pp 36–58

Nwaegbute AC, Osho SM, Obatokun VA (1995) Proceeding conference on post harvest technology and commodity marketing in West Africa. Accra, Ghana. 162–178

Ojokoh AO, Gabriel RAO (2010) A comparative study on the storage of yam chips (gbodo) and yam flour (elubo). Afr J Biotechnol 9(21):3175–3177

Okorie PA, Okoli EC, Ndie EC (2011) Functional and pasting properties of lesser known Nigerian yams as a function of blanching time and particle size. Adv J Food Sci Technol 3(6):404–409

Oni O (2006) Investigating in pounded yam flour production. Businessday Newspaper. Monday July 17th, p 20

Otegbayo B, Bokanga M, Asiedu R (2011) Physicochemical properties of yam starch: effect on textural quality of yam food product (pounded yam). J Food Agric Environ 9(1):145–150

Sankat CK, Mujaffar S (2004) Sun and Solar Drying of Sorted Shark Fillets. 14th

Treche S, Agbor-Egbe T (1996) Biochemical changes occurring during growth and storage of two yam species. Int J Food Sci Nutr 47:93–102

Udensi EA, Okaka JC (2000) Predicting the effect of blanching, drying temperature and particle size profile on the dispersibility of cowpea flour. Niger Food J 18:25–31

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Plate I

(DOCX 186 kb)

Rights and permissions

About this article

Cite this article

Abiodun, O.A., Akinoso, R. Textural and sensory properties of trifoliate yam (Dioscorea dumetorum) flour and stiff dough ‘amala’. J Food Sci Technol 52, 2894–2901 (2015). https://doi.org/10.1007/s13197-014-1313-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1313-y