Abstract

Upma, a popular breakfast of southern India, traditionally made from wheat, was prepared using pearl millet semolina (PMS). Prior to preparation of semolina, pearl millet grains were hydro-thermally treated to reduce anti-nutritional factors and inactivate lipase activity. Hydrothermal treatments (soaking up to moisture 30 ± 2%, steaming 1.05 kg cm−2, 20 min) reduced the anti-nutritional factors significantly (p ≤ 0.05). No lipase activity was detected after steaming. Central composite rotatable design (CCRD) with three independent variables i.e. vanaspati (vegetable fat), citric acid and water for rehydration were used to design the experiments. Sensory responses and rehydration ratio were used to study the individual and interactive effects of variables. Sensory score for taste varied from 6.5 to 8.1, mouth feel 6.7–8.0, overall acceptability 6.7–8.1 and rehydration ratio from 2.4 to 3.3. Based upon the experiments, the optimized level of ingredients was: vanaspati 46.5 g 100 g−1 PMS, citric acid 0.17 g 100 g−1 PMS and water for rehydration 244.6 ml 100 g−1 dry mix with 98.5% desirability. The prepared upma mix was monitored for peroxide value, free fatty acids and thiobarbituric acid value as well as sensory quality during storage and was found stable for 6 months at ambient conditions (20–35 °C) in poly ethylene pouches (75 μ).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rapid urbanization, industrialization and consequent changes in eating habits of people have lead to development of instant dry mixes and ready-to-eat convenience foods. Dry mixes of several traditional Indian foods such as idli mix, vada mix, kheer mix have gained worldwide popularity. Popular choice of most of these products has been wheat and rice. Other food grains such as pearl millet have remained underutilized due to lack of technology or some inherent shortcomings.

Pearl millet (Pennisetum typhoides) is a coarse cereal grain cultivated mostly in semi-arid parts of Africa and Asia. India leads the world in production of pearl millet with 8.59 MT production (FAO 2009). The nutritive content of pearl millet is equivalent or even superior to those of other cereals (Obilana and Manyasa 2002). It has high levels of calcium, iron, zinc, lipids and high quality proteins. Pearl millet has well-balanced protein, with high concentration of threonine and tryptophan along with less (but adequate) leucine, than other cereals. Pearl millet is especially suitable for developing products for celiacs which is a chronic malabsorption disorder of the small intestine caused by exposure to gluten in the genetically predisposed individual (Laurin et al. 2002; Porpora et al. 2002). Despite the numerous potential benefits, this crop has limited commercial demand, especially in the urban areas. Several problems associated with pearl millet include anti nutritional factors, bitter taste, storability, grittiness or difficulty to cook etc. In order to realize the full potential of pearl millet as food crop, there are possibilities for alternate uses of pearl millet in the preparation of novel foods, convenience mixes etc. Thus, standardization and commercialization of alternative food is one of the ways to increase demand for pearl millet.

Upma, a popular breakfast of south Indian origin, is traditionally made from wheat semolina. Generally it is prepared afresh each time and takes 15–25 min depending on quantity to be prepared at household level. Convenience mixes reduce the time for preparation via eliminating several steps of cooking. Premavalli et al. (1987) developed an instant wheat semolina based upma mix, which could be reconstituted within 4–6 min in boiling water and well accepted by the consumers. Yadav and Sharma (2008) optimized soy-fortified instant upma mix ingredients using response surface methodology (RSM). RSM is a collection of statistical and mathematical techniques for developing, improving and optimizing processes (Myers and Montgomery 2002). The relative contribution of predictor variables to product characteristics is evaluated which allows determination of optimum ingredients (Crowley et al. 2000). This statistical tool has been successfully used in the product/process optimization studies such as sweet potato based pasta (Singh et al. 2004), halwa dry mix (Yadav et al. 2007), baking parameters of chapatti (Yadav et al. 2008), peanut curd (Yadav et al. 2010) and rabadi-like fermented milk beverage using pearl millet (Modha and Pal 2011).

Therefore, this work was planned to develop a convenience mix i.e. upma from pearl millet using RSM and to evaluate its shelf-life at ambient conditions in order to harness the nutritional potential of this valuable crop.

Materials and methods

Pearl millet grains (var. PHB-2168), grown in the year 2010 were obtained from Punjab Agricultural University, Ludhiana, India. The grains were destoned using Destoner (Model 6276, Indosaw, Ambala, India). The cleaned grains were stored in gunny bags at 10 °C till further use. The other ingredients i.e. salt, bengal gram, black gram, mustard seeds and green chillies were procured from the local market, cleaned and used. Citric acid, and reagents used for chemical analysis were of analytical grade and procured from Central Drug House, New Delhi, India.

Preparation of pearl millet semolina (PMS)

Soaked pearl millet grains (10–12 h, moisture 30 ± 2%) were steamed for 20 min at 1.05 kg cm−2 in order to inactivate lipase activity and anti-nutritional factors (Shobhana and Malleshi 2007). Steamed grains were dried to 12 ± 0.5% moisture content and pearled in millet pearler (Mathesis Engineers, Hyderabad, India) upto 80% pearling efficiency. The pearled grains were passed through a pulverizer (Lakshmi Industries, Ludhiana) and sieved in a sieve shaker (Model 7290; Indosaw, Ambala, India) to obtain different sized particles. Based on pre-trials, the 0.336 mm sized particles were chosen for upma preparation and mentioned as pearl millet semolina (PMS) throughout the manuscript.

Experimental design

Response surface methodology was used to optimize the levels of vanaspati (vegetable fat), citric acid and water for rehydration of PMS based upma mix. After preliminary tests, upper and lower levels for these variables were established. A central composite rotatable design (CCRD) was prepared to select level of variables i.e. vanaspati 40–50 g 100 g−1 PMS, citric acid 0.15–0.25 g 100 g−1 PMS and water for rehydration 220–260 ml 100 g−1 dry mix in each experiment. The levels of these variables along with the experimental plan have been given in Tables 1 and 2. For the analysis of experimental design by the response surface, it was assumed that n-mathematical functions, f k (k = 1, 2….. n), Y k in terms of m independent processing factors X i (i = 1,2, …., m) existed for each response variable.

In this case, n = 4, m = 3

Full second-order equation was fitted in each response to describe it mathematically and to study the effect of variables. The equation was as follows:

where, Y k = response variable, β 0 is the value of the fitted response at the centre point of the design i.e. (0,0) and βi, βij, βii are the linear, quadratic and interactive regression coefficients, respectively. X i and X j are the coded independent variable.

Preparation of upma mix

The PMS samples (1 kg) were roasted in stainless steel vessel on flame with constant stirring till (20–25 min) the roast attained 150 ± 3 °C and started to give characteristics aroma and colour of a cooked product. Vanaspati (Table 2) was heated (180 ± 5 °C) in a pan and bengal gram (12.5 g), black gram (6.5 g), mustard seeds (3 g) and green chillies (15 g) were shallow fried (Yadav and Sharma 2008). Roasted PMS was added in the pan and mixed properly with vanaspati. Salt (30 g) and citric acid (Table 2) was added to the contents of the pan. The samples were cooled and packed in polyethylene pouches (75 μ) and stored at ambient condition (20–35 °C).

Reconstitution of upma dry mix

Dry mixes of PMS based upma were reconstituted with measured amount of water (Table 2) and stirred on low flame until the desired constituency was attained (started to leave the pan).

Chemical analysis

Pearl millet (whole, steamed and pearled), PMS and prepared upma samples were analyzed for moisture (method 44-19), protein (method 46-12), fat (method 30-25) and ash (method 8-01) using AACC (2000) methods. Minerals were determined using atomic absorption spectrophotometer (EC Ltd. Model Nr AAS 4141) following the digestion of samples in tertiary acid mixture (HNO3:H2SO4: HCl;10:1:4 v/v) (Semwal et al. 1995). Carbohydrate was calculated by subtracting the sum of moisture, protein, fat and ash from 100 (Merrill and Watt 1973). The changes in chemical parameters in the form of peroxide value and free fatty acids were monitored by AOCS (1990) methods. Thiobarbituric acid value was estimated by the distillation method of Tarladgis et al. (1960). Phytic acid, tannins, total phenols and lipase activity was analyzed as per the method described by Sadasivam and Manickam (2008).

Sensory analysis

The re-constituted samples were served in numbered plates to a semi-trained panel of judges (ten) selected from the Institute staff. Four samples were presented at a time to the judges in plates containing approximately 100 g sample at separate booth and asked to rate the samples in terms of taste, mouth feel and overall acceptability (OAA) using nine point hedonic scale (Larmond 1977) from liked extremely (9) to disliked extremely (1).

Rehydration ratio

Rehydration ratio (RR), a measure of water absorption by the dehydrated product, was calculated using following equation as given by Basantpure et al. (2003).

where:

- Wr(g):

-

weight of the rehydrated upma mix

- W d (g):

-

weight of the dry upma mix used for rehydration

Statistical analysis

Response surface methodology (RSM) was adopted in experimental design and analysis (Khuri and Cornell 1987). Multiple regression analysis was used to fit the model, represented by an equation, to the experimental data. Maximization and minimization of the polynomials thus fitted was done by numeric techniques, using the numerical optimization technique given in the software package (Design expert (r) software version 8.0.4.1, 2010; Minneapolis, MN, USA). The response surfaces for the models were plotted as a function of the two variables while keeping the other one at optimum level. The storage data were analysed using the analysis of variance (ANOVA) by the method of Snedecor and Cochran (1968) using factorial Completely Randomized Design (CRD).

Results and discussion

Effect of processing operations on anti-nutritional factors

The various processing operations such as soaking, steaming, pearling and size reduction resulted in lowering of anti-nutritional factors. (Table 1). Whole pearl millet contained 975.0 ± 8.50 mg 100 g−1 phytic acid, which was reduced to 436.0 ± 6.25 mg following all these operations. About 55.28% reduction was observed, while maximum (50.76%) reduction was observed during pearling operation. This indicated that maximum of phytic acid was concentrated in outer layer of the grain. However, soaking and steaming also significantly (p ≤ 0.05) reduced the phytic acid, which may be associated due to heat induced degradation of phytic acid. Shobhana and Malleshi (2007) reported reduced phytate and polyphenol contents due to hydrothermal treatment and decortication of finger millet. Tannins and total phenol contents also reduced significantly (p ≤ 0.05) during these processing operations. It was interesting to note that during soaking, higher amount (12.5%) of total phenols was reduced than tannins (7.9%). However, pearling reduced 29.92% tannins and 21.63% of total phenols, which showed that tannins were more concentrated in outer layer among total phenolic compounds. Higher tannins content in outer layer might result in bitterness of whole pearl millet flour. Reduction in polyphenols and tannins due to soaking, sprouting and roasting has been reported by (Jood et al. 1987; Nithya et al. 2006; Sade 2009) in pearl millet. Heat induced degradation of tannins and polyphenols is also reported by Shinde et al. (1991). Though there was reduction in each of the anti-nutritional factors after size reduction but it was not significant. Overall, there was 55.28%, 39.47% and 41.25% decrease in phyic acid, tannins and total phenols, respectively due to the various operations performed on whole grains to obtain semolina.

Effect of processing operations on lipase activity

Lipase activity increased significantly (p ≤ 0.05) from 137.5 ± 5.00 to 157.42 ± 7.00 μmol FFA h−1 g−1 in whole grains during soaking (Table 1). Nithya et al. (2006) also observed increase in activity of several enzymes due to soaking treatment. This may have resulted from induction of enzyme activity due to initiation of seed germination during soaking. Further, enzyme activity was not detected after steaming as steam at high pressure (1.05 kg cm−2) may have inactivated lipase enzyme. Bookwalter et al. (1987) also reported inactivation of lipase and extended storage after hydrothermal treatment of pearl millet.

Effect of processing operations on minerals

All the above processing operations like soaking, steaming and pearling caused reduction in minerals content. Similar trend in mineral contents due to several processing treatments have been reported by (Nithya et al. 2006; Sade 2009). Soaking caused significant (p ≤ 0.05) reduction in Ca, P, Fe, Cu and Zn contents, while Mn was not affected significantly (p ≤ 0.05). This indicated that Mn is much more distributed in endosperm than outer layer. Maximum loss of Ca (15.78%) and Zn (8.65%) followed by Fe (7.32%), Cu (5.6%) and P (5.47%) was observed during soaking. The reduction of minerals may be attributed to loss of nutrients due to leaching during soaking (Charan and Kadam 1989). Steaming caused slight reduction in minerals but it was not significant (p ≤ 0.05) and this may be due to effect of high temperature (Malik et al. 2002). Pearling of pearl millet caused maximum reduction in all the minerals except manganese. Thus it was re-confirmed that manganese is concentrated in endosperm rather than outer layer. Similar results were also observed by Shobhana and Malleshi (2007). Maximum reduction in P (24.7%) and Zn (24.3%) was observed followed by Ca (14.3%), Cu (13.3%) and Fe (8.6%) during pearling. Size reduction of pearled grains caused insignificant reduction in minerals content.

Diagnostic checking of the fitted models

The estimated regression coefficients of the fitted quadratic equation as well as the correlation coefficients for each model were given in Table 3. The models were considered adequate when the coefficient of correlation (R2) was more than 80% and the lack of fit test was insignificant (Henika 1982). The proposed models approximate the response surfaces and can be used suitably for prediction at any values of the parameters within experimental range. The R2 values for the responses i.e. taste, mouth feel, overall acceptability (OAA) and rehydration ratio were 86%, 77.8%, 81.9% and 88%, respectively (Table 3). The calculated F-values (Table 4) were more than the table values (3.02). All four responses were considered adequate to describe the effect of variables on the quality of PMS based upma samples.

Effect of variables on sensory quality

The actual values for the test variables and the experimental results for taste, mouth feel and OAA ranged between 6.5–8.1, 6.7–8.0 and 6.7–8.1, respectively (Table 2). Water had positive linear and negative quadratic effect (p ≤ 0.05) on taste while vanaspati and citric acid had negative effect (p ≤ 0.05) at quadratic level. Citric acid had positive effect (p ≤ 0.05) on mouth feel at linear level while both citric acid and water affected (p ≤ 0.05) mouth feel at quadratic level. Citric acid and water had positive effect (p ≤ 0.05) on OAA at linear level, indicating that increase in water and citric acid improved the overall quality of the product. At quadratic level, vanaspati and water had significant (p ≤ 0.05) negative effect on OAA. Figure 1 reveals the effect of citric acid and water on OAA of upma. The contour plot is elliptical and the minimum optimum point is attained at the centre as moving along the major and minor axis. The graph implied that OAA score tended to rise with added water at constant amount of citric acid within the selected range (0.15–0.25 g 100 g−1 PMS).

Effect of variables on rehydration ratio

The observed rehydration ratio with different combinations of the ingredients (Table 2) varied from 2.4 to 3.3 within the combination of variables studied. The adequate precision ratio of 9.98 indicates an adequate signal and can be used to navigate the design space. Table 2 reveals that RR decreased with an increase in level of vanaspati. This might be attributed to the fact that it makes fat layer surrounding the PMS and thus prevents the water absorption. Patki et al. (2002) observed that incorporation of vanaspati and spices in pre-cooked dried kabuli channa increased the re-constitution time due to formation of hydrophobic coating of oil, which decreased the water penetration in the grain. Water had positive linear effect (p ≤ 0.05) on rehydration ratio. The increase in RR with increase in amount of water might be due to more water availability as well as more time for reconstitution to get desired consistency which decreased with increase in vanaspati level (Fig. 2). This is in agreement with the findings of Yadav and Sharma (2008) as observed in soy fortified upma.

Analysis of variance

When a model had been selected, an analysis of variance was calculated to assess how well the model represented the data. F-value for all the responses indicated that all the three variables affected the responses significantly (p ≤ 0.05) (Table 4). On this basis, it can be concluded that the selected models adequately represented the data for sensory quality and RR of upma samples.

Optimization of the level of independent variables

Numerical optimization was carried out for the level of ingredients to obtain the best product. The desired goals for each factor and response were chosen and different weights were assigned to each goal to adjust the shape of its particular desirability function (Table 5). Among the solutions obtained, the solution with maximum desirability was selected as optimum ingredients composition. The observed experimental values (mean of 3 measurements) and values predicted by the equations of the model are presented in Table 5. Closeness between the experimental and predicted values of the quality parameters indicated the suitability of the corresponding models. Figure 3 depicts overlay plot showing the optimum level of ingredients and corresponding response values as vanaspati 46.5 g 100 g−1 PMS, citric acid 0.17 g 100 g−1 PMS and water for rehydration 244.6 ml 100 g−1 dry mix. Developed upma dry mix had protein 6.7 g, fat 29.5 g, ash 0.91 g, carbohydrates 62.9 g, Ca 16.3 mg, P 129.7 mg, Fe 4.3 mg, Cu 0.52 mg, Zn 1.4 mg and Mn 0.65 mg per 100 g, respectively.

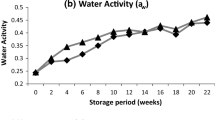

Shelf life studies on optimized upma

In foods, lipid peroxidation and enzymatic hydrolysis cause shelf-life problems. The most limiting factor in determining the shelf-life of dehydrated convenience mixes is the auto-oxidation of fats and oils causing off flavours (Semwal et al. 1999). The optimized pearl millet upma samples were stored in polyethylene pouches at ambient conditions (20–35 °C) and continuously monitored for peroxide value (PV, meqO2 kg−1 fat), free fatty acids (FFA, %oleic acid), thiobarbituric acid (TBA, mg melonaldehyde kg−1 sample) and sensory quality in terms of OAA during storage (Table 6). The PV values did not show any significant (p ≤ 0.05) increase during the first 2 months and increased slightly, thereafter. After 6 months storage, PV increased from 2.5 ± 0.05 to 17.6 ± 0.20 meqO2 kg−1 fat and FFA from 0.27 ± 0.021 to 0.56 ± 0.042% as oleic acid which may be due to the breaking of long chain fatty acid chains in to individual fatty acid moieties. The overall increase in PV and FFA was lower than earlier reported by Yadav and Sharma (2008) during storage of wheat semolina based upma. This might be due to the presence of good amount of polyphenolic compounds in PMS as compared to wheat semolina which worked as antioxidants. According to Decker (2002), phytochemicals, which possess more than one hydroxyl group in phenolic structure, can donate hydrogen atom from hydroxyl groups to lipids free radicals such as peroxyl radicals (ROO.) efficiently and retard the rate of formation of new lipid radicals. The TBA value which is an index of secondary lipid oxidation also followed similar pattern and ranged from 0.021 to 0.085 mg melonaldehyde kg−1 sample throughout the storage. The upma samples were acceptable up to 6 months of storage as indicated by OAA score (7.2).

Conclusion

Pearl millet upma mix was developed and the ingredients were optimized using RSM technique. Optimized upma mix consisted of vanaspati 46.5 g 100 g−1 PMS, citric acid 0.17 g 100 g−1 PMS and water for rehydration 244.6 ml 100 g−1 dry mix with 98.5% desirability. Shelf-life studies indicated that the upma dry mix was acceptable up to 6 months of storage at ambient conditions. Being a high energy (29.5% fat) and good amount of protein (6.7%) source, this can be used in mid-day meals and other feeding programmes. It could also serve to increase pearl millet utilization and add to diversification in the market which is mostly dependent on products from wheat and rice.

References

AACC (2000) Approved methods of the AACC, 10th edn. American Association of Cereal Chemists, St. Paul

AOCS (1990) Official methods and recommended practices, 4th edn. American Oil Chemist’s Society, Champaign

Basantpure D, Kumbhar BK, Awasthi P (2003) Optimization of level of ingredients and drying air temperature in development of dehydrated carrot halwa using response surface methodology. J Food Sci Tech 40:40–44

Bookwalter GN, Lyle SA, Warner K (1987) Millet processing for improved stability and nutritional quality without functional changes. J Food Sci 52:399–402

Charan JK, Kadam SS (1989) Nutritional improvement of cereals by sprouting. Crit Rev Food Sci Nutr 28:401–437

Crowley P, Grau H, Arendt EK (2000) Influence of additives and mixing time on crumb grain characteristics of wheat bread. Cereal Chem 77:370–375

Decker EA (2002) Antioxidant mechanisms. In: Akoh CC, Min DB (eds) Food lipids. Marcel Dekker, New York, pp 397–401

FAO (2009) Production: crops. Food and agricultural organization of the United Nations, http://faostat.fao.org cited on 02.03.11

Henika RG (1982) Use of response surface methodology in sensory evaluation. Food Tech 36(11):96–101

Jood S, Chauhan MB, Kapoor CA (1987) Polyphenols of chickpea and black gram as affected by domestic processing and cooking methods. J Sci Food Agric 39:145–149

Khuri AI, Cornell JA (1987) Response surfaces: design and analysis. Marcel Dekker, New York, pp 127–145

Larmond E (1977) Laboratory methods for sensory evaluation of foods. Publication No. 1637, Department of Agriculture, Ottawa, pp 17–22

Laurin P, Wolving M, Falth-Magnusson K (2002) Even small amounts of gluten cause relapse in children with celiac disease. J Pediatr Gastroenterol Nutr 34:26–30

Malik M, Singh U, Dahiya S (2002) Nutrient composition of pearl millet as influenced by genotypes and cooking methods. J Food Sci Tech 39:463–468

Merrill AL, Watt BK (1973) Energy value of foods: basis and derivation. In: Agriculture Handbook No. 74, United States Department of Agriculture, Washington, pp 2–4

Modha H, Pal D (2011) Optimization of rabadi-like fermented milk beverage using pearl millet. J Food Sci Tech 48:190–196

Myers RH, Montgomery DC (2002) Response surface methodology. Wiley-Interscience, New York

Nithya KS, Ramachandramurty B, Krishnamoorthy VV (2006) Assessment of anti-nutritional factors, minerals and enzyme activities of the traditional (Co7) and hybrid (Cohcu-8) pearl millet (Pennisetum glaucum) as influenced by different processing methods. J Appl Sci Res 2:1164–1168

Obilana A, Manyasa E (2002) Millets. In: Belton PS, Taylor JRN (eds) Pseudocereals and less common cereals. Springer, Berlin, pp 177–214

Patki PE, Srihari P, Arya SS (2002) Studies on development of instant whole legumes. Indian Food Packer 56:72–79

Porpora MG, Picarelli A, Porta RP, di Tola M, D’Elia C, Cosmi EV (2002) Celiac disease as a cause of chronic pelvic pain, dysmenorrhea and deep dyspareunia. Obstet Gynecol 99:937–939

Premavalli KS, Vidyasagar K, Arya SS (1987) Studies on traditional Indian foods-II. Development and storage stability of upma mix. Indian Food Packer 41:23–30

Sadasivam S, Manickam A (2008) Biochemical methods, 3rd edn. New Age Publishers, New Delhi, pp 106–107, 203–206, 215–216

Sade FO (2009) Proximate, antinutritional factors and functional properties of processed pearl millet (Pennisetum glaucum). J Food Tech 7:92–97

Semwal AD, Murthy MCN, Arya SS (1995) Composition of some commercially available biscuits. J Food Sci Tech 33:112–116

Semwal AD, Sharma GK, Arya SS (1999) Pro or anti-oxygenic activity of tezpat (Cinnamomum tamala) and red chilli (Capsicum annum) in sunflower oil. J Sci Food Agric 79:1733–1736

Shinde GB, Adsule RN, Kale AA (1991) Effect of dehulling and cooking treatments on phytate phosphorus, polyphenols and trypsin inhibitor activity of cowpea seeds. Indian Food Packer 36:63–65

Shobhana S, Malleshi NG (2007) Preparation and functional properties of decorticated finger millet (Eleucine coracana). J Food Eng 79:529–538

Singh S, Raina CS, Bawa AS, Saxena DC (2004) Sweet potato based pasta product: optimization of ingredient levels using response surface methodology. Int J Food Sci Technol 39:191–200

Snedecor GW, Cochran WG (1968) Statistical methods, 6th edn. Oxford and IBH Pubishing Company, New Delhi

Tarladgis BG, Watts BM, Younathan MT, Dugan LJ (1960) A distillation method for the qualitative determination of malonaldehyde in rancid food. J Am Oil Chem Soc 37:44–47

Yadav DN, Sharma GK (2008) Optimization of soy-fortified instant upma mix ingredients using response surface methodology. J Food Sci Tech 45:56–60

Yadav DN, Sharma GK, Bawa AS (2007) Optimization of soy-fortified instant sooji halwa mix using response surface methodology. J Food Sci Tech 44:297–300

Yadav DN, Patki PE, Mahesh C, Sharma GK, Bawa AS (2008) Optimization of baking parameters of chapati with respect to vitamin B1 and B2 retention and quality. Int J Food Sci Technol 43:1474–1483

Yadav DN, Singh KK, Bhowmik SN, Patil RT (2010) Development of peanut milk–based fermented curd. Int J Food Sci Technol 45:2650–2658

Acknowledgement

The authors thankfully acknowledge the financial support from the World Bank for this work which is part of the NAIP project “A value chain on composite dairy foods with enhanced health attributes”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balasubramanian, S., Yadav, D.N., Kaur, J. et al. Development and shelf-life evaluation of pearl millet based upma dry mix. J Food Sci Technol 51, 1110–1117 (2014). https://doi.org/10.1007/s13197-012-0616-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0616-0