Abstract

Fresh dried and old (6–12 months) dried kachri (Cucumis callosus) were treated with 0, 2.5, 5 and 7 kGy of gamma radiation in a cobalt 60 gamma cell (GC-1200). The irradiated samples of kachri were stored at room temperature (28 ± 2 °C). Total bacterial count and nutrient composition were evaluated immediately after irradiation and at regular intervals of 1 month during 3 months of storage. Results indicated that gamma radiation reduced the total bacterial counts of dried samples of both fresh and old dried kachri. Dose of 5.0 kGy was sufficient to eliminate total bacterial count and there was no microbial growth in 5.0 kGy irradiated samples during the storage period. No significant differences were observed in the proximate composition of both types of kachri at all irradiation doses. It was concluded that irradiation treatments of kachri improves keeping quality of both freshly dried and old dried Kachri.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Kachri (Cucumis callosus) is an annual climber belongs to family Cucurbitaceae. Fruit is small, egg shaped, pale yellow in colour and at ripening its taste turns into sweetness. Kachri fruits are used for preparation of pickles, vegetables, salad and chutney. The dehydrated kachri is also used in vegetables, chutney etc. Kachri powder is extensively used in combination with chilli, turmeric, coriander, cumin, methi and other spices to produce curry powder and ready to use spices (Goyal and Sharma 2009).

Kachri is available only for a short duration. During this short period, a very little part of total produce is being used profitably that too mostly in form of vegetable preparation. Rest of the produce get spoiled either due to over ripening or due to lack of knowledge about different processing techniques. The post harvest losses in kachri vary from 30 to 40% due to its perishable nature and glut during harvesting time, which also reduces the market value of the fruits. In times of scarcity, preserved foods can be sold for a good price.

Fruits and vegetables are important sources of essential dietary nutrients such as vitamins, minerals and fibre. Since the moisture content of fresh fruits and vegetables is more than 80%, they are classified as highly perishable commodities (Orsat et al. 2006). Keeping the product fresh is the best way to maintain its nutritional value, but most storage techniques require low temperatures, which are difficult to maintain throughout the distribution chain. On the other hand, drying is a suitable alternative for post harvest management especially in countries like India where exist poorly established low temperature distribution and handling facilities. It is noted that over 20% of the world perishable crops are dried to increase shelf-life and promote food security (Grabowski et al. 2003).

In arid region (Bikaner), intense solar radiation is available in major part of the year; therefore, open sun drying is very common. In some places shade drying is also in practice. The method of open sun drying or shade drying is very simple and does not require any capital investment. But at the same time quality of open or shade drying product may be poorer due to prolong period of drying (Sagar and Kumar 2010; Singh et al. 2006). The rate of contamination may also be very high because of direct exposure of food to the atmosphere dirt and dust both in sun and shade drying. At the time of storage, further spoilage may be occurring owing to exposure of environmental microbial contamination. A review by McKee (1995) on microbial contamination of dry vegetables conducted in several countries confirmed that potential food borne pathogens such as Salmonella, Escherichia coli, Clostridium perfringens, Bacillus cereus and toxigenic molds are observed in dry onions.

Fumigation of dry vegetables with ethylene oxide effectively reduces the microbial population by 90%. However, ethylene oxide fumigation is prohibited in many countries because of possible human-health hazards resulting from fumigation by-products (Baxter and Holzapfel 1982). \An alternative safe and effective technique for inactivating contaminating microorganisms on dry vegetables is gamma irradiation (Diehl 1995). Food irradiation is an economically viable technology for effectively eliminating food-borne pathogens and reduction of post harvest losses, extension of self-life of perishable commodity and improvement of hygienic quality of food (Labuza and Breene 1989).

Joint Expert Committee on food irradiation (FAO/IAEA/WHO) in 1981 reported that medium dose of 1 to 10 kGy are necessary to eliminate spoilage microorganism and to extend the shelf of dried fruits and vegetables (Kooij 1981; Chakraverty et al. 2003). No significant changes due to irradiation in the composition of dried fruits and nuts (Inayatullah et al. 1987) have been reported within a range of exposure doses sufficient to kill all infesting insects. Moreover, no adverse effects on the nutritional value or the sensory quality of dried fruits and nuts have been reported by Khan (1993). The objective of this study was to investigate the effect of gamma irradiation on microbial safety and nutritional quality of kachri produced in Rajasthan State of India.

Materials and methods

Plant material

Locally available variety of small sized Kachri in fresh and ripe forms as well as old (6–12 months) dried kachri was purchased from market of Bikaner city of Rajasthan State in India. Damaged and non-edible portions were discarded. Fresh kachri were thoroughly washed with water to remove adhering impurities and peeled. Peeled kachri were spread singly on a clean and dry muslin cloth. Drying process was continued till the samples become brittle. Both types of kachri were weighed and transferred to poly bags and sealed properly.

Gamma radiation process

Gamma irradiation was carried out in cobalt-60 based gamma chamber at Radio Tracer Laboratory, S.K. Rajasthan Agriculture University, Bikaner (GC-1200, BARC, Mumbai, India) at a dose rate of 2.617 kGy/h at 24 °C. Samples were packed, sealed in polythene bags and irradiated with different doses of 2.5, 5.0 and 7.0 kGy. Treated and control samples were stored at ambient temperature until the analyses were carried out.

Total bacterial counts

For determining total bacterial counts (TBC) method of Collins and Lyne (1976) was used after some modifications using nutrient agar (NA) medium. A 10 g sample was taken aseptically in the blender jar, to which 90 ml of sterilized saline (0.85%) water was added and blended for 2 min. This provided a 1:10 dilution. Further required dilutions were made by transferring 1 ml of this homogenate to 9 ml of sterile saline water. One millilitre of each dilution (in triplicate) was poured into petri plates using sterilized pipettes. A sterilized nutrient medium (15 to 20 ml) was added to each plate and incubated for 24 h at 37 ± 1 °C. Calculations were made by multiplying the total number of colonies by the dilution factor.

Nutritional analysis

Dried Kachri was ground using electronic food grinder before analysis. Moisture content of both types of kachri was estimated by oven dry method. Protein content of kachri samples were measured by Kjeldahl procedure (total nitrogen X 6.25), using standard methods of the AOAC (1995).

Fat content was extracted from dried kachri powder with petroleum ether (b.p. 60-80 °C) by Soxhlet apparatus, while ash content was measured by charring the sample in hot plate and placing in muffle furnace at 600 °C for at least 3 h then cooled in desiccators and weighed (AOAC 1995). The ash was almost white or greyish white in colour. Crude fibre was determined by treating oil-free sample by sulphuric acid (0.26 N) and potassium hydroxide (0.23 N) solution in refluxing systems, followed by oven drying and muffle furnace incineration (AOAC 1995).

Total sugar was estimated by refluxing the samples in ethanol for 30 min, cooled the extract and centrifuged at 8,000 rpm for 15 min, then supernatant was separated. The extract was kept on boiling water bath to evaporate ethanol, then residue was dissolved in 50 ml of distilled water and used for total sugar estimation. Freshly made anthrone reagent was taken in test tubes and kept in ice bath, then different concentrations of supernatant were poured from the side of test tubes to cooled the solutions for 5 min and the contents were thoroughly mixed. The tubes were heated in boiling water bath for 10 min, again cooled and absorbance was read at 625 nm in spectrophotometer using suitable blank (Yemm and Willis 1954).

Starch content was estimated with the method described by Clegg (1956). The residue remaining after centrifugation in total sugar estimation was used for the estimation of starch content. The perchloric acid was added in test tubes containing samples and vortexed for 5 min, centrifuged at 8,000 rpm for 20 min and diluted to 100 ml, then filtered the solution and absorbance was measured at 600 nm using spectrophotometer.

Rehydration ratio

Rehydration ratio was used to express rehydration of dried kachri. The rehydration ratio of the dried kachri was evaluated by immersing 20 g samples in water at room temperature. Samples were drained and weighed after 6 h. The ratio of the sample weight before and after rehydration expressed as a percentage which was taken as measure of the rehydration ratio (Jayaraman et al. 1990; Farkas and Singh 1991; Lewicki 1998).

Statistical analysis

Experiment was laid out in complete randomized design with three replications Cochran and Cox (1975). Data was analyzed by factorial design with three factors: (1) three doses of gamma irradiation (2) three storage periods, and (3) two types of kachri (fresh and old dried) and least significant differences were calculated for mean differences between controls and irradiated (2.5–7.0 kGy) samples for all the parameters.

Results and discussion

Effect of gamma irradiation on total bacterial counts (TBC)

The total bacterial counts (Table 1) for non-irradiated samples of FDK (Fresh dried kachri) and ODK (Old dried kachri) were found 5.55 and 5.60 log CFU/g, respectively. No significant change was observed in TBC during the storage of 3 months in FDK and ODK samples, respectively. However, the radiation dose of 2.5 kGy reduced the initial microbial load by 3 log cycles in both FDK and ODK samples. This reduction in TBC remained constant throughout the storage period of 3 months and there was no increase in the TBC within this period.

Further doses of 5 and 7 kGy eliminated the bacterial count completely in both the samples. In present study TBC was not significantly changed during storage possibly due to low moisture content of these samples. Gupta et al. (2009) reported that gamma irradiation at a dose of 2.5 kGy resulted in 2 log reduction in the total viable counts (105 CFU/g) whereas no microbial load was recorded in T. foenum-graecum samples irradiated with 5 kGy. Similarly, Saroj et al. (2007) studied that aerobic plate counts for seeds were 2.0 to 2.6 log CFU/g, which were reduced to 0.9 to 1.2 log CFU/g on treatment with a 2 kGy radiation dose.

Pezzutti et al. (2005) reported that irradiation doses between 7 and 11 kGy reduced the aerobic plate counts by three log cycles in imported onion flakes. Reduction in bacteria and fungi has also been achieved in coffee beans at 1 and 5 kGy, respectively (Nemtanu et al. 2005). Similarly, Hitoshi and Islam (1994) demonstrated that 4 kGy of Electron Beam Irradiation (EBI) was efficient in reducing the microbial load (coliforms, osmophilic molds and fungi) in spices (black pepper, turmeric, rosemary and coriander). Sarrias et al. (2003) reported that EBI at 3.2 kGy effectively reduced bacteria and moulds, while 7.5 kGy completely decontaminated unhusked rice samples. Ionizing gamma radiation is capable of demolishing some living cells in a direct or indirect way. Irradiation may affect DNA directly or may cause denaturation of proteins, cell death or mutations. Indirectly formed free radicals such as the hydroxyl radical (OH•) damage cells additionally (Lado and Yousef 2002; Gaber 2005).

Effect of gamma irradiation on nutritional qualities

Effect of gamma radiation on moisture content of FDK and ODK is shown in Table 2. These results indicated that the irradiation dose of 2.5, 5.0 and 7.0 kGy had slightly reduced the moisture content of the FDK and ODK. However, in present study no significant differences were observed between moisture content of non-irradiated and irradiated kachri samples at all doses in both types of kachri. These results are in agreement to those obtained by Hassan et al. (2009) in irradiated maize cultivators at 2 kGy. Pezzutti et al. (2005) also reported no significant change in water content of imported onion flakes when they were exposed to various doses of irradiation from 5 to 25 kGy.

The crude protein content was also not affected in the irradiated and non irradiated kachri samples (Table 2). It was marginally reduced from 7.7 to 7.5% in FDK and from 7.3 to 7.1% in ODK after irradiation at a highest dose of 7.0 kGy. Results showed that crude protein profile of both FDK and ODK were very much stable to irradiation and showed no significant changes (p > 0.05) after irradiation. Likewise, storage period also did not alter the crude protein contents significantly in both control and irradiated samples of FDK and ODK. Boonchoo et al. (2005) also observed that protein content was not significantly influenced by irradiation in brown rice. Similarly, protein content was not affected in irradiated as well as in non irradiated onion and potato (Nouri and Toofanian 2001).

Crude fat content of both FDK and ODK are presented in Table 2. The fat content in FDK was found 14.7% in control sample while it was 14.6% when irradiated at 7.0 kGy. Similarly in ODK, fat content was observed 14.3% before irradiation which was not affected by irradiation significantly (14.2%) at 7.0 kGy treatment. No significant change was observed in the fat content after storage of these samples. These results are in accordance with Al-Bachir (2004) who reported no significant difference in fat content between irradiated and non-irradiated samples of walnuts. Wu et al. (2004) revealed that crude lipid content was unchanged at irradiation dose of 1–7.0 kGy in transgenic rice. Similarly, Hassan et al. (2009) also found insignificant change in fat content when the grains of sorghum and maize were irradiated at 2.0 kGy. However, Boonchoo et al. (2005) reported that within the period of storage (after 35 days) the free fatty acid content decreased continuously while total lipid content was not affected at irradiation dose of 6 kGy in brown rice.

Table 2 summarises ash content of FDK and ODK. Total ash content of both FDK and ODK was 8.9 and 8.5% in control samples, respectively, whereas it varied from 8.8 to 8.3% in irradiated samples of FDK and ODK at 7 kGy dose, respectively, during storage. It was found that both the treatment of irradiation and storage period did not affect the total ash content of the controls as well as in irradiated sample. Crude fibre content of both FDK and ODK are depicted in Table 2. The results indicate that no significant difference was observed in crude fibre content in control and irradiated samples (2.5, 5.0 and 7.0 kGy) of stored Kachri. These results are in agreement with the work reported by Bhattacharjeea et al. (2003) who found that irradiation with 0.25–1.0 kGy had no significant effect on ash and fibre content of cashew nuts. Inayatullah et al. (1987) also reported that irradiation with 0.25, 0.5, 1.0, 2.5 and 5 kGy had no significant effect on the proximate composition (water, fat, ash and carbohydrate) of soybean.

The values of proximate composition of our study were in agreement with the observations reported by Al-Bachir (2004) in walnuts. He studied that irradiation at doses ranging from 0.5 to 2.0 kGy did not cause any significant change in proximate composition. Khattak et al. (2009) also reported that there were no substantial changes in proximate constituents of Nelumbo nucifera rhizome at a dose rate of 1 to 6 kGy.

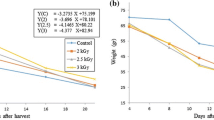

Figure 1 summarises the changes in total sugars in irradiated and control samples of FDK and ODK during storage at ambient temperature. Results demonstrated that immediately after irradiation, there was no difference in total sugar content of irradiated and non-irradiated samples. However, there was gradual increase in total sugar content with increasing storage time for all the samples. Maximum levels were obtained at the end of storage. The significant increase in total sugar content could have been due to degradation of starch during post-irradiation storage. Results reported in the literature on the effect of irradiation on sugar content are ambiguous. Auda et al. (1977) found that irradiation had no effect on reducing sugar and major components, whereas Al-Kahtani et al. (1998) showed that irradiation at doses ranging from 0.3 to 0.9 kGy followed by 3 or 6 months storage at room temperature, sugar contents increased gradually with increasing storage time. EI-Sayed and Baeshin (1983) studied the effect of irradiation on total carbohydrates, reducing and non-reducing sugars of two varieties of dates (Tamar stage) produced in Saudi Arabia. Irradiation dose up to 25 krad had no effect on sugars even after storage up to 12- months at 20–35 °C. Roushdi et al. (1981) observed that irradiation of dried corn increased the reducing sugars and total soluble sugars in proportion to dose.

In controls, starch content decreased from 8.87 to 8.34% and 8.29 to 7.93% in FDK and ODK, respectively, while in samples treated at 7.0 kGy the decrease in starch content recorded in FDK and ODK respectively from 8.78 to 8.31% and 8.18 to 7.8% for a storage period of 3 months (Fig. 1). The results revealed that starch content continuously decreased with increase in storage time and irradiation dose. The progressive decrease in starch content as the irradiation dose was raised may be due to the breakdown acceleration of glucosidic linkages (Roushdi et al. 1982). Stewart (2001) reported that irradiation leads to the degradation of polysaccharides such as starch and pectin. Ajlouni and Hamdy (2006) reported that in sweet potato starch reduced from 16.8% to 6% after 16 days following a 500 krad treatment. Lu et al. (2007) studied that starch and texture tended to decrease with increase in dose rate in sweet potato. Present study indicates that the decrease in starch content is mainly due to storage in comparison to irradiation treatment as in control the starch content also decreases. However, data indicate that irradiation further enhances breakdown of starch during storage.

Figure 2 shows the rehydration ratio of dried samples of both FDK and ODK. The rehydration ratio of control samples was higher than that of irradiated ones in both FDK as well as ODK. Based on the results, it was concluded that the rehydration ratio gradually decreased with increasing irradiation dose. Similar results were observed by Wang and Chao (2003) who found that irradiation dose of 6 kGy affected rehydration ratio more as compare to lower doses in dried apple samples. Wang and Du (2005) stated that rehydration ratio were greatly affected by irradiation dose in dried potato and also explained that greater the dose of irradiation lower the rehydration ratio. Rastogi (2005) reported that irradiated samples of carrot could not rehydrate as well, as in control samples, due to lack of cell integrity.

Conclusion

Gamma irradiation at 5 kGy was found to be very effective and sufficient in reducing total bacterial contamination by eliminating food borne microbes of kachri. No significant differences were observed in the proximate composition of both types of kachri at the irradiation doses of 2.5, 5.0 and 7.0 kGy. However, starch content reduced significantly due to its conversion into sugar in both the samples. It is concluded that gamma irradiation of Kachri improves shelf life of both freshly dried and old dried kachri.

References

Ajlouni S, Hamdy MK (2006) Effect of combined gamma-irradiation and storage on biochemical changes in sweet potato. J Food Sci 53:477–481

Al-Bachir M (2004) Effect of gamma irradiation on fungal load, chemical and sensory characteristics of walnuts (Juglans regia L.). J Stored Prod Res 40:355–362

Al-Kahtani HA, Abu-Tarboush HM, Al-Dryhim YM, Bajabe AS, Adam E, El-Mojaddidi MA (1998) Irradiation of dates: insect disinfestations, microbial and chemical assessments and use of thermoluminscence technique. Radiat Phys Chem 53:181–187

AOAC (1995) Official method of analysis, 16th edn. Association of Official Analytical Chemists, Washington

Auda H, Khalaf Z, Mirjan J (1977) Effect of gamma irradiation on the sugar and protein composition of Iraqi dates. Int At Energy Agency Rep SM 221/29a:459–465

Baxter R, Holzapfel WH (1982) A microbial investigation of selected spices, herbs and additives in South Africa. J Food Sci 47:570–578

Bhattacharjeea P, Rekha S, Achyut Gholapb S, Variyarb S, Dilip R (2003) Compositional profiles of gamma-irradiated cashew nuts. Food Chem 80:159–163

Boonchoo T, Jitareerat P, Photchanachai S, Chinaphuti A (2005) Effect of gamma irradiation on Aspergillus flavus and brown rice quality during storage. Proc 2nd Int Symp on the New Frontier of Irradiated food and non food products, KMUTT, Bangkok, Thailand 22–23 September

Chakraverty A, Mujumdar AS, Raghavan GSV, Ramaswamy HS (2003) Irradiation of fruits, vegetables, nuts and spices. Handbook of postharvest technology: cereals, fruits, vegetables, tea, and spices. CRC, Boca Raton, pp 626–630

Clegg KM (1956) The application of anthrone reagent to the estimation of starch in cereals. J Sci Food Agric 7:40–44

Cochran WG, Cox GM (1975) Experimental designs. Willey, New York

Collins CH, Lyne PM (1976) Estimating bacterial numbers. In: Microbiology methods, 4th edn, Butterworths and Co Ltd, London, p 194–210

Diehl HF (1995) Safety of irradiated foods, 2nd edn. Marcel Dekker Inc, New York, pp 283–289

EI-Sayed SA, Baeshin NA (1983) Feasibility of disinfestations of date fruits produced in Saudi Arabia by gamma irradiation. Proc 1st Symp on the date palm in Saudi Arabia. King Faisal University, AI-Hassa, Saudi Arabia, p 342

Farkas BE, Singh RP (1991) Physical properties of air dried and freeze-dried chicken white meat. J Food Sci 56:611–615

Gaber MH (2005) Effect of γ-irradiation on the molecular properties of bovine serum albumin. J Biosci Bioeng 100:203–206

Goyal M, Sharma SK (2009) Traditional wisdom and value addition prospects of arid foods of desert region of North West India. Indian J Tradit Knowl 8:381–385

Grabowski S, Marcotte M, Ramaswamy HS (2003) Drying of fruits, vegetables, and spices. In: Chakraverty A, Mujumdar AS, Raghavan GSV, Rawaswamy HS (eds) Handbook of postharvest technology: cereals, fruits, vegetables, tea, and spices. Marcel Dekker, New York, pp 653–695, Ch 23

Gupta PC, Bajpai V, Mishra V, Saxena RK, Singh S (2009) Effect of gamma irradiation on microbial load, aflatoxins and phytochemicals present in Trigonella foenum-graecum. World J Microbiol Biotechnol 25:2267–2271

Hassan AB, Osman GAM, Rushdi MAH, Eltayeb MM, Diab EE (2009) Effect of gamma irradiation on the nutritional quality of maize cultivars (Zea mays) and sorghum (Sorghum bicolor) grains. Pak J Nutr 8:167–171

Hitoshi I, Islam MS (1994) Effect of dose rate on inactivation of microorganisms in species by electron-beams and gamma-rays irradiation. Radiat Phys Chem 43:545–550

Inayatullah H, Zeb A, Ahmad M, Khan I (1987) Effect of gamma irradiation on physico-chemical characteristics of soybean. Nucleus Karachi 24:31–34

Jayaraman KS, Das Gupta DK, Babu Rao N (1990) Effect of pretreatment with salt and sucrose on the quality and stability of dehydrated cauliflower. Int J Food Sci Technol 25:47–60

Khan I (1993) Techno-economic evaluation of food irradiation in Pakistan, Int Symp on Cost benefit Aspects of Food Irradiation Processing (IAEA, FAO, WHO) IAEA, Vienna, Austria, p 155–158

Khattak KF, Simpson TJ, Ihasnullah (2009) Effect of gamma radiation on the microbial load, nutrient composition and free radical scavenging activity of Nelumbo nucifera rhizome. Radiat Phys Chem 78:206–212

Kooij JV (1981) Food preservation by irradiation. IAEA Bull 23:33–36

Labuza TP, Breene WM (1989) Application of active packaging for improvement of shelf life and nutritional quality of fresh and extended shelf food. J Food Process Preserv 13:1–69

Lado BH, Yousef AE (2002) Alternative food-preservation technologies: efficacy and mechanisms. J Microbes Infect 4:433–440

Lewicki PP (1998) Some remarks on rehydration of dried foods. J Food Eng 36:81–87

Lu JY, Miller P, Loretan PA (2007) Gamma radiation dose rate and sweet potato quality. J Food Qual 12:369–378

McKee LH (1995) Microbial contamination of spices and herbs: a review. Lebensm Wiss Technol 28:1–11

Nemtanu MR, Brasoveanu M, Grecu MN, Minea R (2005) Green coffee decontamination by electron beam irradiation. Nucl Instrum Methods Phys Res 240:83–86

Nouri J, Toofanian F (2001) Extension of storage of onions and potatoes by gamma irradiation. Pak J Biol Sci 4:1275–1278

Orsat V, Changrue V, Raghavan GSV (2006) Microwave drying of fruits and vegetables. Stewart Post-Harvest Rev 6:4–9

Pezzutti A, Matzkin MR, Croci CA (2005) Gamma irradiation improved the quality of onion used by argentine conaumers. J Food Process Preserv 29:120–131

Rastogi NK (2005) Impact of gamma-irradiation on some mass transfer driven operations in food processing. Radiat Phys Chem 73:355–361

Roushdi M, Harras A, El-Meligi A, Bassim M (1981) Effect of high doses of gamma rays on corn grains. II. Influence on some physical and chemical properties of starch and its fractions. Starch/Starke 35:15–18

Roushdi M, Sarhan AA, Fahmy C (1982) Effect of chemical treatments and gamma rays on starch content of sweet potatoes and its properties. Starch/Starke 34:243–246

Sagar VR, Kumar PS (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47:15–26

Saroj SD, Hajare S, Shashidhar R, Dhokane V, Sharma A, Bandekar JR (2007) Radiation processing for elimination of Salmonella Typhimurium from inoculated seeds used for sprout making in India and effect of irradiation on germination of seeds. J Food Prot 70:1961–1965

Sarrias JA, Valero M, Salmeron MC (2003) Elimination of Bacillus cereus contamination in raw rice by electron beam irradiation. Food Microbiol 20:327–332

Singh U, Sagar VR, Behera TK, Kumar PS (2006) Effect of drying conditions on the quality of dehydrated selected vegetables. J Food Sci Technol 43:579–582

Stewart EM (2001) In: Molins RA (ed) Food irradiation chemistry. Food irradiation: principles and applications. Wileys, New York, pp 37–76

Wang J, Chao Y (2003) Effect of 60Co irradiation on drying characteristics of apple. J Food Eng 56:347–351

Wang J, Du Y (2005) The effect of γ-ray irradiation on the drying characteristics and final quality of dried potato slices. Int J Food Sci Technol 40:75–82

Wholesomeness of Irradiated foods (1981) Report of a joint FAO/IAEA/WHO Expert Committee, WHO Technical Report Series, WHO, Geneva, Serial no 659

Wu D, Ye Q, Wang Z, Xia Y (2004) Effect of gamma irradiation on nutritional components and Cry1Ab protein in the transgenic rice with a synthetic cry1Ab gene from Bacillus thuringiensis. Radiat Phys Chem 69:79–83

Yemm EW, Willis AJ (1954) The estimation of carbohydrates in plant extracts by anthrone. Biochem J 57:508–514

Acknowledgements

This work has been undertaken with the financial support received from Board of Research in Nuclear Science (BRNS), Department of Atomic energy (DAE), Mumbai, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nathawat, N.S., Joshi, P., Chhipa, B.G. et al. Effect of gamma radiation on microbial safety and nutritional quality of kachri (Cucumis callosus). J Food Sci Technol 50, 723–730 (2013). https://doi.org/10.1007/s13197-011-0380-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0380-6