Abstract

Effect of dehydrated green pea flour (DGPF) and additives like glycerol mono stearate (GMS), sodium stearoyl lactylate (SSL) and dry gluten on the rheological characteristics and pasta making quality made from Indian Triticum aestivum was studied. 5–10% of amaranth seed flour was used in the formulation to enhance the protein and fiber contents of the product. Increase in DGPF from 0 to 30% decreased the maximum consistency values from 550 to 513 FU, whereas the mixing tolerance index values decreased from 108 to 52 FU. The cooked weight and cooking loss increased from 320.8 to 332.9 g% and 5.0 to 8.2% respectively and the firmness values decreased from 104 to 75 g. Sensory evaluation of pasta showed that addition of DGPF above 20% resulted in greenish colour pasta of mashy texture. Addition of additives improved the quality of pasta at 30% level as seen in the reduction in the cooking loss from 8.2 to 5.9%, increase in the firmness values to 140 g and improvement in the eating quality. Protein content of pasta improved from 9.56 to 16.57%. Scanning electron microscopic studies revealed that the addition of additives in combination helped in the formation of rupture free structure with a continuous network.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pasta/macaroni, a traditional cereal based product is manufactured in larger quantities in Italy and USA. Popularity of these products are increasing worldwide because of convenience, nutritional quality and palatability (Cubadda 1994). Several workers (Dexter and Matsuo 1979; Feillet and Dexter 1998) have judged the preference of durum wheat in the preparation of macaroni products. Several workers reported that protein content and its composition (Mac Ritchie 1992), and starch influence the cooking quality of pasta (Resmini and Pagani 1983). Several authors have studied high protein pasta formulations. Replacement of wheat flour by whole corn flour upto 75% level was used by Molina et al. (1982). Torres et al. (2006) used germinated Cajanus cajan seed flour as an ingredient to increase the protein content and vitamins to improve the nutritional value of pasta without affecting the sensory properties. Prabhasankar et al. (2007) studied the influence of whey protein concentrate on the quality of vermicelli and found that addition of WPC at 5% level increased the protein content of pasta. Limroongreungrat and Huang (2007) studied that alkaline treated sweet potato flour could be used as an alternative ingredient in the preparation of nutritious pasta. Depigmentation of pearl millet was carried out by Rathi et al. (2004) to use it in the preparation of pasta. Their results indicated that depigmentation was an effective processing technique to develop acceptable pearl millet products having improved invitro protein and starch digestibility. Next to soybeans, peanuts and dry green peas are major food legumes in many parts of world (Adsule et al. 1989). These are good source of protein and carbohydrates, and also rich in lysine, leucine and arginine and can fulfill the amino acids requirement (Iqbal et al. 2006). Alonso et al. (2001) reported that thermal treatment of peas improved their nutritional quality without reducing the hyper cholesteromic properties. To retain the vitamin C and chlorophyll pigments in peas, blanching for 2 min at 80°C inactivated 90% of peroxidase (Gökmen et al. 2005). Pea products increased the protein content by about 23% and also the textural quality of spaghetti produced was similar to durum spaghetti (Nielsen et al. 1980). Uma Devi and Sharma (2007) have studied the effect of processing on the physicochemical properties of dry peas. Amaranth is considered to be a good source of high quality balanced protein as it has naturally high amounts of lysine, methionine and cysteine apart from large amounts of dietary fiber and minerals (Marcone 1999). Matsuo et al. (1978) studied the scanning electron microscopy (SEM) of spaghetti processing stages and reported that there was no continuous network of protein indicating the lack of gluten development as against the bread dough preparation. SEM of developed dough has a good protein matrix as against the undeveloped dough. Dexter et al. (1978) studied the changes in dough structure during the preparation of Japanese noodles using scanning electron microscopy. Lee et al. (2001) reported that the commonly used procedures for evaluating dough properties are farinography and mixography techniques. Studies relating to pasta making quality from dicoccum wheat varieties have been reported (Bhuvaneswari et al. 2005). Durum wheat is preferred for pasta making; and studies involving the use of aestivum are scanty. In the present study, pasta production using aestivum wheat was carried out. The dehydrated peas and amaranth seed flour have been used in the study along with aestivum flour to assess its suitability for pasta preparation with respect to cooking quality, sensory and micro structural characteristics of pasta. Additions of additives like gluten powder, glycerol mono stearate and sodium stearoyl lactylate have also been used to evaluate the quality characteristics of pasta.

Materials and methods

Materials

Commercial aestivum wheat farina and dehydrated green peas (DGP) were procured from a local market. Dehydrated green peas were ground into flour (DGPF) using a laboratory hammer mill. Amaranth seeds were procured from local market and ground into flour using a laboratory hammer mill. Commercially available dry gluten powder, glycerol mono stearate (GMS) and sodium stearoyl lactylate (SSL) were used as additives in the studies.

Chemical characteristics

Moisture, ash, protein were determined according to the standard AACC methods (2000). Protein content of DGPF was obtained by using the conversion factor of 6.25. Dietary fiber content of the raw materials and pasta was estimated according to Asp et al. (1983). All analyses for samples were carried out in triplicates, expressed as the mean value and standard deviation was calculated.

Farinograph characteristics

Farinograph characteristics of farina and blends (100:0, 90:10, 80:20, and 70:30) of farina and Dehydrated Green Pea Flour (DGPF) were determined according to Irvine et al.(1961) using Farinograph (Brabender, OHG, Duisburg, Germany) at constant water absorption of 31.5%. A modified software version of 2.3.2 specifically used for farina was used in the study.

Pasta preparation

Farina and dehydrated green pea flour (DGPF) blends were prepared in the ratio of 100:0, 90:10, 80:20, and 70:30 respectively. Farina blend (500 g) and water (31–35%) were mixed in a Hobart mixer (Model N-50 Richmond Hill, Ontario, Canada) at first speed (59 rpm) for 7 min. The dough was extruded using laboratory pasta machine (La Monferrina, Model-Dolly, Italy) fitted with S type pasta die. The extruded samples were cut to a length of 4–5 cm long. Extruded spiral shaped pasta was spread in stainless steel trays initially at room temperature (27°C) for 1 h and then dried at 80°C for 4 h in a hot air drier. Amaranth flour was used at 5 and 10% level to the optimized level of DGPF and additives namely gluten powder, GMS and SSL were used to improve the quality characteristics of pasta.

Cooking quality of pasta

Twenty five grams of dry pasta was cooked in 250 ml boiling water for 10 min and drained for 5 min. Cooked weight was determined by weighing the drained pasta. The volume of the gruel collected was measured. The gruel was stirred and 20 ml of the gruel was pipetted out into a previously weighed petriplates and evaporated to dryness on a water bath. Later the petriplates were transferred into hot air oven maintained at 105 ± 2°C and dried to constant weight and cooking loss was expressed as g/100 g (ISI 1993). Cooking test was carried out in triplicates, expressed as the mean value and standard deviation was calculated

Texture analyses of cooked pasta

AACC (1995) method was slightly modified to determine the pasta firmness using a Universal texture measuring system (Lloyds Instruments, LR-5K, Hanyshire, UK) equipped with a 50 N load cell and a cutting blade. Three strands placed next to each other were sheared at a crosshead speed of 5 mm/min. The maximum force (gf) required to shear the pasta was measured.

Sensory evaluation

Freshly cooked pasta was subjected to sensory evaluation to six panelists who were given scorecards describing the desirable and undesirable attributes of different sensory characteristics. Coded samples were served and the panelists were asked to evaluate in terms of colour and appearance, firmness (handfeel), texture (mouthfeel) taste and overall quality using a nine-point hedonic rating scale according to Rathi et al. 2004.

Statistical analysis

Statistical analysis of the sensory evaluation data was carried out using analysis of variance (ANOVA) followed by Duncan’s Multiple Range Test (DMRT). The statistical significance was at a p < 0.05 (Steel and Torrie 1960).

Colour measurements

The colour of the ingredients (farina, DGPF and amaranth flour) and cooked pasta were measured using a UV-visible recording spectrophotometer (Model UV 2100, Shimadzu Corporation, Kyoto, Japan) with a reflectance attachment of illuminant C. Samples were placed in the sample cup for measurement. Different colour values were recorded as “L” (lightness), “a” (redness), and “b” (yellowness), the hue angle (tan -1 b/a) and chroma [(a2+b2) 1/2] were calculated.

Scanning electron microscopy (SEM)

Farina, DGPF and dried pasta samples were prepared by carefully sprinkling the sample on double-sided scotch tape stuck to the stubs. Cooked pasta samples were drained and freeze-dried using Heto freeze dryer (model DW3, Denmark). All samples were mounted on the specimen holder using double-sided scotch tape and were exposed to gold sputtering (2 min, 2 mbar). The samples were subjected to scanning electron microscopic examination using a Leo Scanning Electron Microscope, (Model-435 VP, UK) at an accelerating voltage of 15 kv and a vacuum of 9.75 × 10−5 Torr. Micrographs of appropriate magnifications were selected for presentation of results (Sudha et al. 2011).

Results and discussion

Farina used in the preparation of pasta had 12.45% moisture, 0.54% ash and 9.97% protein. The moisture content of amaranth flour and DGPF were 9.04 and 10.2% respectively. The ash contents for farina (S), amaranth flour (AF) and dehydrated green pea flour (DGPF) were 0.4, 2.5, and 2.3% respectively, while the protein content was 9.97%, 17.5% and 19.8% respectively (all expressed in dry weight basis). Similar chemical characteristics for amaranth flour have been reported by Sindhuja et al. (2005).

Farinograph characteristics

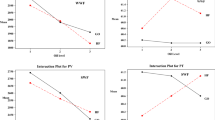

The farinograph characteristics data carried out at constant water absorption of 31.5% are presented in Table 1. The results showed that addition of DGPF at 0, 10, 20 and 30% did not show any effect in the dough development time (DDT) where as the maximum consistency (MC) values gradually decreased from 550 FU to 513 FU and mixing tolerance index values decreased from 108 to 52 FU. This could be due to the difference in the particle size of farina and DGPF. This could also be due to the addition of non-glutinous material, which might have diluted the wheat protein strength. Irvine et al. (1961) studied that use of farina with reduced particle size or with heterogeneous particle size resulted in decrease in maximum consistency and tolerance index values. Addition of amaranth flour (5 or 10%) to a blend consisting of 30% DGPF increased the DDT and MC value from 4.5 to 5.2 min and 513 to 536 FU respectively. Increase in DDT with addition of amaranth may be due to higher fiber content of amaranth, which picked up water slowly. These results are similar to those reported by Irvine et al. (1961), which showed that with increase in fiber content, farinograph maximum consistency values also increased. Addition of gluten to a blend containing farina, DGPF, and AF in the ratio of 60:30:10 at 2 and 4% further increased the DDT and MC values to 5.4 and 684 FU respectively. This may be again due to the addition of gluten protein, which strengthened the dough as indicated by Irvine et al. (1961). Addition of glycerol mono stearate increased the maximum consistency value to 578 FU where as sodium stearoyl lactylate increased the MC value to 522 and slightly reduced the DDT from 5.2 to 4.4 min. Addition of 0.5% of either GMS or SSL along with 2% of dry gluten powder increased the DDT to 6.2 and 7.5 min respectively and MC values also increased where as the MTI values decreased.

Cooking quality of pasta

Results regarding the cooking quality of pasta are presented in Table 2. The control pasta had a cooked weight of 320.8 g/100 g. With increase in DGPF from 0 to 30%, cooked weight increased to 332.9 g/100 g. Higher cooked weight may be due to higher swelling ability of starch from pea flour as reported by Dexter et al. (1978), who found cooked weight to be directly related to degree of swelling of starch granules. Increased water absorption could be also due to the nature of interaction of legume starch with fibre and protein (Urooj and Puttaraj 1994). Batey and Curtin (2000) associated cooking loss with starch pasting characteristics and protein quality. It was observed that with increase in DGPF in the blend the cooking loss also increased from 5.0 to 8.16%. Substitution of wheat flour by legume flour attributed to the structural changes in the protein network, which reflected on the cooking loss. Increase in cooking loss by substitution with defatted corn, cassava, and cowpea were also observed by Granito et al. (2002) and Torres et al. (2006) in pasta products. Zhao et al. (2005) reported that the cooked weight of spaghetti was not significantly affected but cooking loss increased with increase in the content of legume flours like green pea, chickpea, yellow pea and lentil. Nielsen et al. (1980), while studying the fortification of pasta with either pea flour or pea concentrate at 33% and 20% respectively found an increase in cooking loss. Fortification of spaghetti with legumes were carried also by Bahnassey and Khan (1985) who found that cooking loss of fortified spaghetti increased with increase in the substitution level. With addition of DGPF, firmness values decreased from 104 to 75 g. Addition of 10% amaranth flour (Table 3) to the formulation containing 30% DGPF marginally increased the cooked weight but significantly reduced the cooking loss at p < 0.05, from 8.2 to 6.9% and gradually increased the firmness value from 75 g to 105 g. Addition of gluten at 2% and 4% increased the cooked weight to 340.8 and 348.3% and decreased the cooking loss to 6.3% and 6.1% respectively. Addition of 3% gluten was found to reduce the cooking loss as reported by Kim et al. (1989) and Jyotsna et al. (2004). Matsuo and Irvine (1974) reported that addition of egg albumin and wheat protein improved the cooking quality. Addition of vital gluten had the greatest effect on the texture of pasta as seen by the higher values of shear force/firmness values. Kim et al. (1989) also reported that addition of 3% gluten increased the cutting stress and at 1.5 or 3% vital gluten the shear values increased from 53 to 64 g. Matsuo et al. (1972) in their studies reported that addition of gluten as a source of protein had acceptable quality. Addition of GMS and SSL showed a marginal influence on the cooked weight and cooking loss, whereas addition of GMS or SSL in combination with gluten further reduced the cooking loss to 5.9%. Kim et al. (1989) also reported that addition of 1% GMS decreased the cooking loss. Addition of GMS increased the firmness value to 120 g while SSL increased it to 128 g. Jyotsna et al. (2004) reported that GMS had a softening effect on the texture when compared to SSL, which improved the firmness of the pasta, and hence the shear force values were slightly higher. Kim et al. (1989) also reported that addition of GMS softened the texture of cooked pasta when compared to SSL. Addition of GMS or SSL, in combination with gluten, increased the texture values to 140 g. This is well supported by the results obtained by Prabhasankar et al. (2007), wherein addition of combination of additives increased the quality of vermicelli to a greater extent. The protein content of pasta with 30% DGPF and 10% AF was 16.57% when compared to control pasta at 9.56%.

Sensory evaluation of pasta

The acceptability scores for sensory attributes of pasta with increasing levels of DGPF are given in Table 2. At 30% incorporation of DGPF, the color attribute was liked moderately, but the colour measurement values showed that addition of DGPF improved the green colour of the pasta, indicating that DGPF imparted natural green colouration to pasta. At 30% incorporation, the mouthfeel or texture of the pasta was slightly soft as also seen by the reduction in firmness values measured objectively. Addition of amaranth flour at 5 and 10% slightly improved the sensory quality of pasta (Table 3). It was noted that slightly higher sensory scores were assigned for colour, firmness and texture quality for pasta prepared using 10% amaranth flours. Similarly addition of gluten powder (2%) improved the sensory quality of pasta. The above pasta sample was firm without much stickiness and had improved strength. Addition of GMS improved further the quality score of pasta with respect to mouthfeel and appearance. GMS had a softening effect on the texture of pasta as seen in the slight reduction in the shear force values (firmness values), which was slightly higher for pasta where SSL was used. These results are supported by the results obtained by Kim et al. (1989), who reported that GMS reduced the cutting strength of the cooked spaghetti and softened the texture of the cooked pasta. Similarly, Grant et al. (1993) reported that addition of mono glycerides in combination with high temperature drying helped in reducing the stickiness of the pastas and also addition of additives, in combination, namely gluten powder (1%), GMS (0.25%) and SSL (0.25%) improved the quality characteristics of pasta when compared to the quality of pasta prepared with either GMS or SSL or gluten added individually.

Colour measurement

The colour values of the flour samples are given in Table 4. The redness, “a” values of pea flour was −8.2 indicating green tinge (-a), which was higher than those of farina (−1.5) and amaranth flour (0.9). The yellowness “b” value of DGPF (19.7) was higher than those of farina (17.7) and amaranth flour (15.0). However the lightness “L” value of DGPF (77.87) was comparable to that of amaranth flour (76.3) whereas farina had an “L” value of 84.5. The hue angle of DGPF was 91.1 indicating the green colour of pea flour, while the hue angles of farina and amaranth flour were 85.3 and 86.3 respectively, which indicated the creamish yellow colour of the sample. Incorporating DGPF in the pasta formulation significantly affected the colour of cooked products. Addition of DGPF decreased the L values and the hue angle value ranged from 92.4 to 99.3 indicating the yellowish green colour of the cooked pasta (Table 4).

Scanning electron microscopy (SEM)

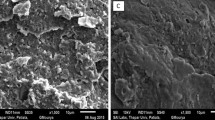

Microstructure of the farina particles showed that they were irregularly shaped and variable in size. Close examination of the particles revealed that most of the starch granules were intact and few of them were damaged. The starch in amaranth flour seems to be scattered, where as the structure in DGPF flour was compact, with few visible starch granules (Fig. 1). Microscopic examination of dried pasta (Fig. 2) revealed a compact structure with few visible starch granules deeply embedded in the protein matrix. The entire pasta surface appeared to be coated with smooth protein film. SEM of pasta containing 30% DGPF showed cracks and the formulated pasta with additives had uniform cracks, which facilitated the penetration of water during cooking. In SEM of cooked pasta without DGPF the gelatinized starch granules were found to be entrapped in protein network. In the case of 30% pea incorporated cooked pasta there were cracks and disrupted gluten matrix. In Fig. 2 (c) and (d) the starch granules have been probably enveloped by protein network, which is due to the addition of additives like vital gluten, GMS or SSL. Matsuo et al. (1978) also reported that spaghetti appeared to be coated with a thin protein film, which retained its integrity during cooking.

Scanning electron micrographs of dry pasta (a, b, c); exterior surface of cooked pasta (a’, b’, c’); cross section of cooked pasta (a”, b”, c”) – magnification × 3000. a, a’, a” – dehydrated green pea flour (0 g/100 g); b, b’, b” – dehydrated green pea flour (30 g/100 g); c, c’, c” – dehydrated green pea flour (30 g/100 g) + additives

Conclusion

The present study has indicated that DGPF could be an alternative ingredient for the production of nutritive pasta with natural green colour. Addition of additives like gluten, GMS or SSL, in combination, improved the quality characteristics of pasta. Pasta fortified with 30% DGPF had more greenish colour. This also enabled to increase the protein content by about 70%. The structural micrographs of pasta before and after cooking indicated that addition of pea flour showed slight distortion in the protein film possibly because the amount of water used in pasta dough preparation did not allow the formation of gluten network. On the other hand, addition of additives helped in building a continuous gluten structure and helped in strengthening the network of protein.

References

AACC (2000) Approved methods of the AACC (10th ed) American Association of Cereal Chemists, St. Paul, MN. (Methods 08-01, 30-25, 44-15A, 46-110, 54-10, 54-21)

Adsule RN, Lawande KM, Kadam SS (1989) Pea. In: Salunkhe DK, Kadam SS (eds) Handbook of world food legumes; nutritional chemistry, processing technology and utilization. CRC Press, Inc, Boca Raton, pp 215–251

Alonso R, Grant G, Marzo F (2001) Thermal treatment improves nutritional quality of pea seeds (Pisum Sativum L) without reducing their hypocholesterolemic properties. Nutr Res 21:1067–1077

Asp NG, Johansson CG, Hallma H, Siljestron M (1983) Rapid enzymatic assay of insoluble and soluble dietary fiber. J Agric Food Chem 31:476–482

Bahnassey Y, Khan K (1985) Fortification of spaghetti with edible legumes II, Rheological, processing and quality evaluation studies. Cereal Chem 63:216–219

Batey IL, Curtin BM (2000) The effects on the pasting viscosity of starch and flour of different operating conditions for Rapid Visco analyzer. Cereal Chem 77:754–760

Bhuvaneswari G, Yenagi NB, Hanchinal RR (2005) Pasta making and extrusion qualities of dicoccum wheat varieties. J Food Sci Technol 42:314–318

Cubadda R (1994) Nutritional value of pasta, Effects of processing conditions. Ital Food Beverage Technol 3:27–33

Dexter JE, Matsuo RR (1979) Effect of starch on pasta dough rheology and spaghetti cooking quality. Cereal Chem 56:190–195

Dexter JE, Dronzek BL, Matsuo RR (1978) Scanning electron microscopy of cooked spaghetti. Cereal Chem 55:23–30

Feillet P, Dexter JE (1998) Quality requirements of durum wheat for semolina milling and pasta production. In: Kruger JE, Matsuo RB, Dick JW (eds) Pasta and noodle technology. American Association of Cereal Chemists, St. Paul, pp 95–131

Gökmen V, Bahçeci KS, Serpen A, Acar J (2005) Study of lipoxygenase and peroxidase as blanching indicator enzymes in peas: change of enzyme activity, ascorbic acid and chlorophylls during frozen storage. Lebensm Wiss Technol 38:903–908

Grant LA, Dick JW, Shelton DR (1993) Effect of drying temperature, starch damage, sprouting and additive on spaghetti quality characteristics. Cereal Chem 70:676–684

Granito M, Frías J, Doblado R, Guerra M, Champ M, Vivdal-Valverde C (2002) Nutritional improvement of beans (Phaseolus Vulgaris) by natural fermentation. Eur Food Res Technol 214:226–231

Iqbal A, Khali IA, Ateeq N, Khan MS (2006) Nutritional quality of important legumes. Food Chem 97:331–335

Irvine GN, Bradley JW, Martin GC (1961) A farinograph technique for macaroni dough. Cereal Chem 38:153–164

Indian Standards Institution (ISI) (1993) Vermicelli making IS 1485–1993

Jyotsna R, Prabhasankar P, Indrani D, Venkateswara Rao G (2004) Effect of additives on the quality and microstructure of vermicelli made from Triticum aestivum. J Food Eng 218:557–562

Kim HI, Sieb PA, Posner E, Deyoe CW, Yang HC (1989) Milling hard red winter wheat to farina: comparison of cooking quality and colour of farina and semolina spaghetti. Cereal Foods World 31:810–810

Lee L, Ng PKW, Whallon JH, Steffe JH (2001) Relationship between rheological properties and microstructural characteristics of nondeveloped, partially developed and developed doughs. Cereal Chem 78:447–452

Limroongreungrat K, Huang YW (2007) Pasta products made from sweet potato fortified with soy protein. Lebensm Wiss Technol 40:200–206

Mac Ritchie F (1992) Wheat protein physicochemistry/functionality. Adv Food Nutr Res 36:3–87

Marcone MF (1999) Possible nutritional implications of varietal influence on the 7S/11S seed globulin ratios in amaranth. Plant Foods Hum Nutr 54:375–380

Matsuo RR, Irvine GN (1974) Rheology of Durum wheat products. Cereal Chem 52:131–135

Matsuo RR, Bardley JW, Irvine GM (1972) Effect of protein content on the cooking quality of spaghetti. Cereal Chem 49:707–711

Matsuo RR, Dexter JE, Dronzek BL (1978) Scanning electron microscopy study of spaghetti processing. Cereal Chem 55:744–753

Molina MR, Gudiel H, Baten MA, Bressani R (1982) Production of high protein quality pasta products using semolina/corn/soy flour mixture III. Effect of cooking on the protein nutritive value of pasta. Cereal Chem 59:34–37

Nielsen MA, Sumner AK, Whalley LL (1980) Fortification of pasta with pea flour and air classified pea protein concentrate. Cereal Chem 57:203–206

Prabhasankar P, Jyotsna R, Indrani D, Venkateswara Rao G (2007) Influence of whey protein concentrate, additives, their combinations on the quality and microstructure of vermicelli made from Indian Triticum Durum wheat variety. J Food Eng 80:1239–1245

Rathi A, Kawatra A, Sehgal S (2004) Influence of depigmentation of pearl millet (pennisetum glaucum L) on sensory attributes, nutrient composition, in-vitro protein and starch digestibility of pasta. Food Chem 85:275–280

Resmini P, Pagani MA (1983) Ultra structure studies of pasta, A review. Food Microstructure 2:1–12

Sindhuja A, Sudha ML, Rahim A (2005) Effect of incorporation of amaranth flour on the quality of cookies. Eur Food Res Technol 221:597–601

Sudha ML, Ramasarma PR, Venkateswara Rao G (2011) Wheat bran stabilization and its use in the preparation of high fiber pasta. Food Sci Technol Int. doi:10.1177/1082013210368463

Steel RGD, Torrie JH (1960) Principles and procedures of statistics. McGraw-Hill, New York

Torres A, Frias J, Granito M, Vidal-Valverde C (2006) Germinated Cajanus cajan seeds as ingredients in pasta products: chemical, biological and sensory evaluation. Food Chem 101:202–211

Urooj A, Puttaraj S (1994) Effect of processing on starch digestibility in some legumes—An invitro study. Nahrung 38:38–46

Uma Devi, Sharma GK (2007) Effect of processing and storage on the physico-chemical properties of dry peas (Pisum sativum L). J Food Sci Technol 44:212–215

Zhao YH, Manthey FA, Chang SKC, Hou HJ, Yuan SH (2005) Quality characteristics of spaghetti as affected by green and yellow pea, lentil and chickpea flours. J Food Sci 70:371–376

Acknowledgements

The authors are thankful to Mr. Anbalagan, CIFS, CFTRI, Mysore, for his help in carrying out scanning electron microscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sudha, M.L., Leelavathi, K. Effect of blends of dehydrated green pea flour and amaranth seed flour on the rheological, microstructure and pasta making quality. J Food Sci Technol 49, 713–720 (2012). https://doi.org/10.1007/s13197-010-0213-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-010-0213-z