Abstract

Pandanus amaryllifolius is a plant with aromatic leaves, which impart the characteristic flavour of aromatic rice. The quality of aromatic Pandanus leaves dried at low temperature (35 °C) and low RH (27%) in a heat pump dryer was evaluated and compared with those obtained from hot air drying at 45 °C. Thin-layer drying kinetics has been studied for both the conditions. To determine the kinetic parameters, the drying data were fitted to various semi-theoretical models. The goodness of fit was determined using the coefficient of determination, reduced chi square, and root mean square error. Aroma, colour, and overall acceptability determination of fresh and dried leaves were made using sensory evaluation. Drying of leaves took place mainly under the falling-rate period. The Page equation was found to be best among the proposed models to describe the thin-layer drying of Pandanus leaves with higher coefficient of determination. The effective moisture diffusivity values were also determined. The effect of low RH was prominent during the initial drying when the product was moist. The effect of temperature was prominent in the later part of drying, which acted as a driving force for moisture diffusion and hence the total drying time was reduced. Retention of aromatic compound 2-acetyl-1-pyrroline content was more in low temperature dried samples with higher sensory scores.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pandanus amaryllifolius is a plant belonging to Pandanaceae family, with aromatic leaves, which impart the characteristic flavour of aromatic rice. This characteristic feature is attributed to the presence of 2-acetyl-1-pyrroline (2 ACPy). The essential oil of Pandanus leaves is known to impart 10 times more flavour than the scented rice. The plants are grown as ornamental in pots or in kitchen garden in addition to its growth in wild state. It is widely cultivated in Thailand, Malaysia, Indonesia and India. There is a wide scope for use of this leaf as source of 2 ACPy. Pandanus leaves are traditionally used while cooking non-aromatic rice to impart a resemblance of basmati aroma to the cooked rice. It can also be used to flavour meat and vegetable products or blended with other flavour enhancing sauces. The fresh leaves are perishable in nature because of high moisture content. Dehydration is an essential method of preserving the leaves. Standardization of drying parameters is vital for producing quality leaves.

The most common change that occurs during hot air drying of green leaves is the loss of chlorophyll and aroma. The retention of naturally occurring aromatic compounds in thermally processed foods has been a major challenge in food processing industries. So, selection of proper drying conditions is necessary to minimize thermal stress and to maintain the relevant compounds that determine the quality of the product. Many researchers have established the positive effect of low temperature drying in conjunction with low RH in improving the product quality (Prasertsan et al. 1996; Adapa et al. 2002; Alves-Filho 2002; Sosle et al. 2003). Modern methods for designing air drying operations depend on the mathematical description of food moisture movement during the process (Hernandez et al. 2000). Even though there are reports on the extraction and preservation of 2 ACPy from Pandanus leaves, the studies conducted on drying as a potential method of preservation of these aromatic leaves and their drying kinetics are scrace.

Therefore, the objectives of this study were to examine the effect of drying conditions on the quality of dried Pandanus leaves and to compare the fitting ability of several drying equations to express the thin-layer drying kinetics of Pandanus leaves with the most suitable drying model.

Materials and methods

Fresh leaves of plants of Pandanus amaryllifolius were plucked, washed free of dirt, wiped with a cloth and sliced into portions of 10 cm length. Moisture content was measured by the gravimetric method using an electric convection oven. Three 30 g leaf samples were dried in an oven at 105 °C for 24 h to determine initial moisture content. The initial moisture content of the Pandanus leaves was 3.82 kg of H2O per kg dry matter. For the mass determination, a digital balance of 0.0001 g accuracy (ANAMED, M7000, Mumbai, India) was used. For calculation of effective moisture diffusivity values of the Pandanus leaves, thickness of 50 samples was measured and the average thickness of leaves was found to be 0.8 mm.

Quantification of 2 ACPy

Likens–Nickerson concurrent steam-distillation-solvent extraction method was used to extract 2 ACPy from Pandanus leaves. The procedure was similar to that developed by Laksanalamai and Ilangantileke (1993).

Sensory evaluation

Aroma, colour, and overall acceptability determinations of fresh and dried leaves were made using sensory panel evaluations (9-point Hedonic scale). It was speculated that the market value of the product will be influenced by the colour of leaves whereas the aroma and overall acceptability of the cooked rice will establish the consumers’ preference. Ten number of trained panel members were considered for sensing the cooked non-aromatic rice added with fresh and dried samples. Average of the scores obtained was calculated and analysed. One aromatic and one non-aromatic variety were included as control samples (two extreme limits).

Drying technique

Thin-layer drying experiments under controlled conditions were conducted for Pandanus leaves in a heat pump dryer at 35 °C (27 ± 2% RH) and in hot air dryer at 45 °C (60 ± 5% RH). A convective dryer (IIC, Model TD-12) was used in this investigation. The experimental dryer consisted of a centrifugal blower, an electrical resistance air heating section, the measurement sensors and the displaying unit. A door was provided in front of side of the chamber for placing and removing the sample tray. The blower and heater of dryer were switched on for 30 min for drying air to reach a stable temperature. The air velocity was continuously measured using an anemometer (Lutron AM-4201, Vikram Scientific instruments, Kolkata, India). A heat pump-assisted batch dryer with special features of variable drying air temperatures has been fabricated (Pal and Khan 2008). The developed dryer consisted of a dehumidifier unit (evaporator, compressor, condenser and expansion device) and drying chamber. The inlet drying air passed through the drying chamber and picked up moisture from the product. In the air circuit, the moist hot air leaving the dryer is directed to pass through the evaporator, where dehumidification takes place. The air leaving the evaporator is heated in the condenser and then passed to the dryer for drying the product.

After attaining the desired drying air temperature, samples of about 2.5 kg/m2 were loaded onto the drying trays in single layer. The sample tray was removed from the dryer and weighed regularly, initially at intervals of 15 min, then onwards at 30 min intervals. The drying tests were terminated when the weights of the samples got stabilized, which was assumed to be the stage of dynamic equilibrium. All the experiments were carried out at 1 ± 0.1 m/s air velocity. The drying rates were computed from the experimental data and corresponding drying characteristic curves were plotted.

Drying analysis and thin-layer drying models

The moisture ratio and drying rate of the Pandanus leaves were calculated using the following equations:

Where, MR is the moisture ratio, drying rate is in g/100 g bone dry matter per unit time, Mt is the moisture content at a specific time (g water/g dry base), Mo is the initial moisture content (g water/g dry basis), Me is the equilibrium moisture content (g water/g dry basis), Mt+dt is the moisture content at t + dt (g water/g dry base) and t is the drying time (min).

In order to determine the moisture ratio as a function of drying time, three popular thin-layer drying models were used (Table 1). In order to estimate and select the appropriate drying model among different semi-theoretical and/or empirical models, mathematical modelling was carried out to describe the drying curve equation of Pandanus leaves. The non linear regression analysis was performed to determine the parameters of thin-layer drying models by fitting experimental data to the model equation. Although the coefficient of determination (R 2) was one of the primary criterions for selecting the best model to describe thin-layer drying curves of leaves, the reduced chi-square (χ 2) and root mean square error (RMSE) as described in Eqs. 3 to 5, were also used to evaluate the goodness of fit of the models. The lower chi-square (χ 2) and RMSE values and the higher R 2 values, were chosen as the basis for goodness of fit (Yaldiz and Ertekin 2001; Midilli and Kucuk 2003; Günhan et al. 2005).

where, MRexp,i is the ith experimentally observed moisture ratio, MRpre,i the ith predicted moisture ratio, MRi is the average observed moisture ratio, N the number of observations and p is the number constants. It may be assumed that diffusivity explained with Fick’s diffusion equation is the only physical mechanism to transfer the water to surface during drying process (Dincer and Dost 1995; Dadali et al. 2007; Wang et al. 2007). Effective moisture diffusivity which is affected by composition, moisture content, temperature and porosity of the material, was used due to the limited information on the mechanism of moisture movement during drying and complexity of the process (Abe and Afzal 1997). For the solution of Fick’s diffusion equation, the Pandanus leaves were assumed as a slab.

The effective moisture diffusivity was calculated by using the following equation (Crank 1975)

where Deff is the effective moisture diffusivity (m2 min−1), L is the full thickness of Pandanus leaves and t is the drying time (min).

For long drying times; n = 1, the Eq. 6 can be written as:

Several researchers have shown that Eq. 7 could be further simplified to a straight-line equation as Eq. 8 (Dadali et al. 2007; Wang et al. 2007):

The effective moisture diffusivities are typically determined by plotting experimental drying data in terms of ln(MR) versus time.

Results and discussion

Drying analysis

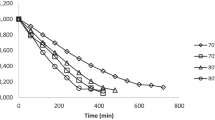

During drying at 35 °C, the heat pump dryer was able to reduce the RH to 27 ± 2%. The RH measured during hot air drying at 45 °C was 60 ± 5%. Variation in moisture content with time during air drying of Pandanus leaves at drying air temperature of 35 °C and 27% RH and 45 °C with 60% RH is shown in Fig. 1. The corresponding values of standard deviation for each data point have been shown through vertical bars. From the plot of moisture content against drying time, it is clearly evident that drying time was less in case of hot air drying at 45 °C. The total time required for drying at 35 °C was 900 min and at 45 °C was 540 min to reduce the moisture content from 382.28% db to about 5% db. The reduction of total drying time with increase in temperature may be due to increase in vapour pressure within the product, which resulted in faster migration of moisture to the product surface. The plots in Fig. 1 followed the general trend of drying curves as reported for many food materials (Ahmed and Shivhare 2001; Davinder and Shashi 2005; Pal et al. 2008). At the higher temperature, the drying curve exhibited a steeper slope, thus exhibiting an increase in drying rate.

Drying of Pandanus leaves took place mainly under falling-rate period. During this period, the migration of moisture occurred through the mechanism of diffusion. The peak drying rate for Pandanus leaves was found to be 2.035 g/100 g.min at a moisture content of 367% db at 35 °C drying air temperature as compared to 1.969 g/100 g.min at 45 °C of hot air drying. Drying in a heat pump dryer at 35 °C reduced the moisture content to 150% db within the first 3 h and was comparable to hot air drying at 45 °C for Pandanus leaves. This may be due to low RH of drying air in a heat pump dryer though the drying air temperature was less. The heat pump dryer used by Adapa et al. (2002) was found to have a more specific moisture extraction rate. Initially, the drying rate was more at low temperature but at the later part of drying, it was more in hot air drying at 45 °C (Fig. 2). This indicates that the effect of low RH is prominent during the initial period of drying when the product is moist. The effect of temperature was observed to be prominent in the later part of drying, which acted as a driving force for moisture diffusion. Thus the higher drying air temperature produced a higher drying rate and consequently faster reduction in the moisture content and hence the total drying time was reduced.

Evaluation of thin-layer drying models

Figure 3 shows the decreasing trend of moisture ratio with drying time. The three equations mentioned in Table 1 were fitted to the experimental data for Pandanus leaves. The higher the value of coefficient of determination (R 2) and lower the value of RMSE and chi-square (χ 2), the better the criteria for goodness of fit. The main parameters, R 2, chi-square and RMSE of the three model equations for Pandanus leaves dried under different conditions are shown in Table 2. It can be observed that mean values of R 2 was highest and the corresponding values of chi-square and RMSE values were lowest for the Page’s thin-layer drying model for both the conditions. Hence, Page’s model was considered as the best model to describe the thin-layer drying of Pandanus leaves. In both the cases the values of R 2 for Page model were greater than an acceptable threshold of 0.90, indicating better goodness of fit. It was concluded that Page model can be used to estimate the moisture content of Pandanus leaves at any time during the drying processes at different conditions with acceptable accuracy. The coefficients of the different models fitted at the different temperatures are reported in Table 2. The accuracy of the established model for the low temperature drying process was evaluated by comparing the predicted moisture ratio with observed moisture ratio. The performance of the model for both the drying temperatures has been illustrated in Fig. 4. The predicted data generally banded around the straight line which showed the suitability of the Page model in describing the drying behaviour of Pandanus leaves in the low temperature drying. The rate constant, K, which is a measure of the drying rate is not significantly different at two different temperatures (p < 0.05) which may be due to low relative humidity at the low temperature. Lidhoo (2008) also recommended this model for drying of brinjal slices.

Effective moisture diffusivity

The effective moisture diffusivity was calculated by using the method of slopes. According to the experimental data obtained at different drying temperature conditions, the logarithm of moisture ratio values, ln(MR), were plotted against drying time (t). The linearity of the relationship between ln(MR) and drying time is illustrated in Fig. 5 (with R 2 > 0.95 for both the conditions). The moisture diffusivities were found to be 1.3E-09 m2/min at 35 °C, 27% R.H. and 2.1E-09 m2/min at 45 °C, 60% R.H. respectively. No documentary was found on the effective moisture diffusivity for Pandanus leaves undergoing any drying treatment. The ranges of effective moisture diffusivity of Pandanus leaves undergoing drying were higher than the values obtained by Akpinar (2006).

Effect of temperature on aromatic compound and sensory evaluation

The 2 ACPy content and mean sensory scores for different quality attributes of dried leaves are presented in Table 3. The retention of 2ACPy content in samples dried by heat pump at lower temperature of 35 °C was significantly higher than that dried in hot air dryer at 45 °C. The sensory attributes were almost same for aromatic rice and non aromatic rice with fresh leaves. The aroma and colour of low temperature dried samples were better as compared to hot air and shade dried samples. So this sample had better overall acceptability in comparison to shade dried samples. Though the average ambient temperature for shade drying was less than 35 °C (range 24–38 °C), the temperature values fluctuated round the clock throughout the drying period. At times it was more than 35 °C while during night time it was very less. This thermal stress was probably the reason for which 2 ACPy content got reduced. From the sensory evaluation of dried samples, it was also observed that the samples at lower temperature were preferred products. High temperature drying resulted in decrease in colour, aroma and overall acceptability scores. Samples dried at low temperature appeared slightly lighter in greenness as compared to fresh samples, but the product still looked attractive for use. It is observed that there is significant difference in all these quality parameters achieved at these two different conditions. Since the acceptance of any food product is highly dependent on its quality characteristics, Pandanus leaves without aroma may not fetch any consumer demand. Hence even though the total drying time requirement is more, drying at low temperature may be preferred, for its higher retention of aroma. Alternatively, further reduction in RH along with low temperature may be tried to reduce the total drying time.

Conclusion

The Page equation was fitted well to the experimental drying data to describe the thin-layer drying of Pandanus leaves. The effect of low RH is prominent during the initial period of drying when the product is moist. The effect of temperature was observed to be prominent in the later part of drying, which acted as a driving force for moisture diffusion and hence the total drying time was reduced. However, the retention of aromatic compound 2ACPy content was more in low temperature dried samples with higher sensory scores. So keeping in view the quality attributes of dehydrated leaves, it is recommended to dry aromatic Pandanus leaves at low temperature and low RH to obtain an acceptable product. Further reduction in RH may also be suggested to reduce the total drying time.

References

Abe T, Afzal TM (1997) Thin-layer infrared radiation drying of rough rice. J Agric Eng Res 67:289–297

Adapa PK, Sokhansanj S, Schoenau GJ (2002) Performance study of a re-circulating cabinet dryer using a household dehumidifier. Drying Technol 20:1673–1689

Ahmed J, Shivhare US (2001) Effect of pre-treatment on drying characteristics and colour of dehydrated green chillies. J Food Sci Technol 38:504–506

Akpinar EK (2006) Mathematical modelling of thin layer drying process under open sun of some aromatic plants. J Food Eng 77:864–870

Alves-Filho O (2002) Combined innovative heat pump drying technologies and new cold extrusion techniques for production of instant foods. Drying Technol 20:1541–1557

Crank J (1975) The mathematics of diffusion, 2nd edn. Clarendon, Oxford

Cronin K, Kearney S (1998) Monte Carlo modelling of a vegetable tray dryer. J Food Eng 35:233–250

Dadali G, Apar DK, Ozbek B (2007) Estimation of effective moisture diffusivity of okra for microwave drying. Drying Technol 25:1445–1450

Davinder D, Shashi P (2005) Optimization of drying conditions of garlic slices. J Food Sci Technol 42:348–352

Dincer I, Dost S (1995) An analytical model for moisture diffusion in solid objects during drying. Drying Technol 13:425–435

Günhan T, Demir V, Hancioglu E, Hepbasli A (2005) Mathematical modelling of drying of bay leaves. Energy Convers Manage 46:1667–1679

Gupta P, Ahmet J, Shivhare US, Raghavan GSV (2002) Drying characteristics of red chilli. Drying Technol 20:1975–1987

Hernandez JA, Pavon G, Garcia MA (2000) Analytical solution of mass transfer equation considering shrinkage for modelling food drying kinetics. J Food Eng 45:1–10

Kabganian R, Carrier DJ, Sokhansanj S (2002) Physical characteristics and drying rate of Echinacea root. Drying Technol 20:637–649

Laksanalamai V, Ilangantileke S (1993) Comparison of aroma compound (2-acetyl-1-pyrroline) in leaves from pandan (Pandanus amaryllifolius) and Thai fragrant rice (Khao Dawk Mali-105). Cereal Chem 70:381–384

Lidhoo CK (2008) Thin layer drying characteristics of brinjal slices. J Food Sci Technol 45:423–425

Midilli A, Kucuk H (2003) Mathematical modelling of thin layer drying of pistachio by using solar energy. Energy Convers Manage 44:1111–1122

Midilli A, Kucuk H, Yapar Z (2002) A new model for single layer drying. Drying Technol 20:1503–1513

Pal US, Khan MK (2008) Calculation steps for the design of different components of heat pump dryers under constant drying rate condition. Drying Technol 26:864–872

Pal US, Khan MK, Mohanty SN (2008) Heat pump drying of green sweet pepper. Drying Technol 26:1584–1590

Prasertsan S, Saen-Saby P, Nyamsritrakul P, Prateepchaikul G (1996) Low temperature drying. Part 1: simulation of the models. Int J Energy Res 20:1067–1079

Sosle V, Raghavan GSV, Kittler R (2003) Low-temperature drying using a versatile heat pump dehumidifier. Drying Technol 21:539–554

Togrul IT, Pehlivan D (2002) Mathematical modelling of solar drying of apricots in thin layers. Food Eng 55:209–216

Wang Z, Sun J, Chen F, Liao X, Hu X (2007) Mathematical modelling on thin layer microwave drying of apple pomace with and without hot-air pre drying. J Food Eng 80:536–544

Yaldiz O, Ertekin C (2001) Thin layer solar drying of some vegetables. Drying Technol 19:583–596

Acknowledgement

Authors are thankful to Orissa University of Agriculture and Technology for providing the infrastructure for the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rayaguru, K., Routray, W. Effect of drying conditions on drying kinetics and quality of aromatic Pandanus amaryllifolius leaves. J Food Sci Technol 47, 668–673 (2010). https://doi.org/10.1007/s13197-010-0114-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-010-0114-1