Abstract

In this study, pyrolysis of Lantana camara stem biomass was carried out at different carbonization temperature i.e., 300, 400, 500, 600, 700 and 800 °C. The effect carbonization temperature on yield and energy value of charcoal was investigated. The fuel properties parameters (calorific value, ash, volatile content, fixed carbon content etc.) of charcoal were studied. The highest calorific value (31.74 MJ/kg) was recorded in charcoal obtained at 600 °C. The combustion characteristic of charcoal was studied under oxidizing atmosphere using thermogravimetric analyzer. Variation in the fuel properties and combustion characteristics of charcoal prepared at different temperatures was mainly due to difference in proximate and elemental composition of chars.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Historically, wood is oldest form of energy feedstock used by mankind. Wood is either burned directly as firewood or indirectly as charcoal (Matti 2004). In many developing countries, charcoal is used as a domestic fuel for cooking and heating. The other application of charcoal includes water purification, food industry, pharmaceutical industry, chemical industry, metallurgical industry etc. (Muylaert et al. 1999). Wood charcoal is porous and can adsorb liquids and gases on its porous surface. Therefore, it is used in water filters, gas masks and antigastric tablets for people suffering from indigestion. Charcoal is also used as a decolorizing agent for decolorizing sugar solutions, organic preparations, alcohol and petroleum products. Charcoal can be made from almost any lignocellulosic raw material, however, not all the species produces good quality charcoal (Kumar et al. 1992). The charcoal making process is affected by heating rate, residence time, particle size, chemical composition, moisture content of lignocellulosic material and final pyrolytic temperature (Kumar et al. 1992; Degroot and Shafizadeh 1984). The demand of charcoal has increased greatly in recent past due to multiple uses of charcoal. However, due to strict environmental regulations and forest protection policies there is hardly any supply of wood as feedstock from the forest, and therefore, the utilization of alternative available biomass resources (such as weeds) as feedstock for charcoal production is necessitated. In this study, we have focused on utilization of lantana stem biomass for production of charcoal. Lantana camara is an invasive weed species, which grows wild throughout the India. It is regarded as one of the worst weeds in almost 50 countries because of its invasiveness, potential for spread, and economic and environmental impacts. Lantana forms dense, impenetrable thickets that take over native vegetations. It is a dominating weed species which is reported as threat to biodiversity and ecology (Cronk and Fuller 1995; Rawat and Bhainsora 1999). However, they produce huge woody biomass which can be utilized for energy purposes. Some efforts in the past have been made to make use of these available biomass sources as feed stock for energy (Senelwa and Sims 1999; Prasad et al. 2001). In this work, we have studied the effect of carbonization temperature on yield and chemical composition of wood char prepared from L. camara. The calorific value, ash, volatile, fixed carbon content (FCC) etc. of charcoal prepared at different carbonization temperature was evaluated. The combustion characteristic of charcoal prepared at 300, 500 and 800 °C were investigated using thermogravimetric analyser (TGA). The burning profiles of the samples were derived by applying the derivative thermogravimetric technique. The combustion properties was studied to characterise the thermal decomposition of lantana, pre-charred at temperature, below and above the temperature of primary decomposition of biomass material i.e., <400 °C and >400 °C, respectively.

Materials and methods

The test samples of L. camara were procured from Shimoga Forest Division of Karnataka, India. The samples obtained for the experiments were from similar soil and climatic conditions. Samples for carbonization experiments (5 cm length) were prepared from discs cut from stems at different positions. The freshly cut water saturated samples were used for determination of basic density (g/cm3). The basic densities (d) of the samples were determined by using Eq. 1.

where WOD is the oven dry mass of wood and Vg is the green volume of wood. Volumes of freshly cut water-saturated samples were determined by mercury displacement method (Walker 1993; Kumar et al. 2010). The holocellulose and lignin content of lantana was determined by using standard methods. The extractive free powder sample was used for determination of lignin by digesting it with 72 % sulfuric acid for 2 h (Dence 1992). Holocellulose in the wood samples was also determined using standard method (TAPPI 1992). A small laboratory scale kiln with internally sealed chamber having dimensions of 8 cm length × 8 cm height × 12 cm depth was used for preparation of charcoal. The oxygen free environment was maintained inside the kiln by maintaining continuous flow of nitrogen gas. The temperature was controlled using a PID controller with an accuracy of ±1 °C. The oven dried wood samples were kept in the carbonization chamber at 300, 400, 500, 600, 700 and 800 °C, carbonization temperature. The ramp rate 5°C/min and 1 h soaking time was kept constant for all the experiments. After attaining the desired carbonization temperature and 1 h soaking, the kiln was switched off and allowed to cool down. When the kiln temperature reduced below 200 °C, the samples were removed from the furnace and then sprinkled with water to arrest the carbonisation process. The carbonized specimens were then oven-dried at 102 ± 2 °C. The yield of charcoal was estimated using Eq. 2.

where W1 is oven-dry weight of wood sample and W2 is oven-dry weight of charcoal. All the experiments were repeated four times to eliminate the effect of variation in furnace conditions on carbonisation process. The calorific value (MJ/kg) of wood and charcoal samples was determined by burning pelleted sample (1g) in oxygen bomb calorimeter (LECO AC-350). Proximate parameters ash content (AC) and volatile matter content (VMC) of wood and charcoal were carried out using a proximate analyzer (LECO- TGA-701). The ultimate parameters (carbon, hydrogen and sulfur content) were determined using a CHN analyzer (LECO- CHN-2000). FCC was estimated using Eq. 3 (Kumar et al. 2010).

The combustion characteristic of biomass sample and charcoal prepared at 300, 500 and 800 °C carbonisation temperature were studied under air atmosphere using TGA (TGA Q500 V20.2). A known quantity of powdered sample (~10 mg) was placed in a platinum crucible and heated from ambient to 800 °C at a heating rate of 10 °C/min. The air flow rate was kept uniform during the experiment i.e., 60 ml/min . General guidelines of ASTM D 3850 were followed. The burning profiles of the samples were derived by applying the derivative thermogravimetry technique.

Results and discussion

The results of yield and fuel properties analysis (calorific value, proximate and ultimate analysis) of char prepared at different carbonization temperatures are presented in Table 1. The combustion characteristic of charcoal was investigated under air atmosphere and burning profile results are summarized in Table 2.

Effect of carbonization temperatures on fuel properties

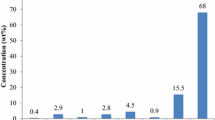

The result suggests that the wood char yield is strongly influenced by carbonization temperature. The charcoal yield was found to be decreasing with the increase in the carbonization temperatures (Table 1). The charcoal yield of L. camara at different carbonization temperatures is compared in Fig 1. It was observed that the yield of charcoal decreased from 38.8 to 25.3 % when the carbonization temperature was increased from 300 to 800 °C. The decrease in yield of char can be attributed to the removal of the volatile matter from the char at higher temperatures (Table 1). A higher charcoal yield at lower temperatures may be due to limited thermal decomposition of major chemical constituent’s of wood. The cellulose and hemicellulose, which constitutes about 55 % of tropical hardwood, is thermally degraded at temperatures between 270 and 325 °C (Demirbas 2001). The lignin, which makes up 25–30 % of the chemical composition of the wood, is thermally stable below 270 °C, while 90 % of lignin is thermally degraded at 400 °C (Yang et al. 2007).

The effect of carbonization temperature on calorific value of lantana char is shown in Fig. 2. A marginal increase in calorific values was observed with increase in carbonization temperature up to 600 °C (Table 1). This can be attributed gradual increase in FCC and reduction in VMC of charcoal with temperatures. The heat of combustion of carbon is higher than that of volatile matter and therefore, the samples having high proportion of fixed carbon have higher calorific value. The calorific values of charcoal prepared at higher temperatures (700 and 800 °C) were found to be marginally lower as compared to the one prepared at 600 °C (Table 1). This may be due to higher amount of ash in char made at higher temperatures i.e., 700 and 800 °C, which has a negative effect on the calorific values (Fuwape 1993). The calorific value of lantana stem (19.15 MJ/kg) was compared with char of the same species in Fig. 2.

The proximate and ultimate analysis data of char prepared at different carbonization temperatures are given in Table 1. When the carbonization temperature was raised from 300 to 800 °C, the FCC increased from 57 to 84 %. The AC also increased from 2.7 to 4.6 %. However, the VMC decreased from 40 to 11 %, when the temperatures were increased from 300 to 800 °C. The higher value of FCC and AC in charcoal prepared at higher temperature may be due to the removal of VMC from the wood during the pyrolytic process (Stubington and Sumaryono 1984). The AC, VMC and FCC of lantana stem were found to be 0.83, 80.39 and 17.38 %, respectively (Table 1).

The values of ultimate carbon and hydrogen were also found to be changing with carbonization temperature. As shown in Table 1, the ultimate carbon of the char increased with the increase in the carbonization temperature, whereas, the ultimate hydrogen in the resulting lantana chars decreases with the increase in the carbonization temperature. This increase in the carbon % with increase in the temperature may be due to the release of volatile matter (H2O, CO, CO2, non- cyclic hydrocarbon, etc.) from the wood and enrichment of remaining wood char matrix with aromatic compounds (Biagini et al. 2008). The loss in the hydrogen percentage also supports the aromatisation of the wood char matrix (Leckner and Karlsson 1993). The H/C ratios recorded for char produced at 300, 400, 500, 600, 700 and 800 °C temperatures are 0.06, 0.05, 0.04, 0.03, 0.02 and 0.02, respectively. The carbon, hydrogen and nitrogen of lantana stem were found to be 48.10, 6.22 and 1.04 %, respectively.

The charcoal produced from L. camara is as good as any other wood species. Kumar et al. (1992), have studied the carbonization of Acacia nilotica and Eucalyptus globulus wood samples at almost similar experimental condition i.e., 4 °C/min heating rates and 1 h soaking time. They reported a charcoal yield of 32.0, 27.47 and 26.74 % at 400, 600, and 800 °C, respectively, in case of E. globulus. Similarly, the yield of charcoal from A. nilotica at 400, 600, and 800 °C was found to be 31.70, 26.10 and 22.76 %, respectively. The yield of charcoal from L. camara at 400, 600, and 800 °C is found to be 32.30, 27.17 and 25.30 %, respectively which is almost similar to that of wood species. The other chemical properties of L. camara charcoal (ash, volatile and fixed carbon content) presented in this study are found similar to wood species (Kumar et al. 1992).

Combustion characteristics of L. camara stem biomass and charcoal

Thermogravimetric analysis (TGA) is one of the most commonly used thermo-analytical techniques (TGA and DTG) to study the thermal behavior and reactivity of carbonaceous materials (Nassar 1985; Munir et al. 2009). A plot of the rate of weight loss against temperature while burning a sample under oxidizing atmosphere is referred as “burning profile” (Haykiri-Acma 2003). The burning profile is useful for understanding the thermal behavior of a fuel during combustion process. The characteristic parameters of TGA analysis under air atmosphere are summarized in Table 2. The burning profiles of lantana charcoal prepared at 300, 500 and 800 °C are shown in Fig. 3. The DTG curve shows an initial weight loss between temperatures 40–90 °C which is mainly due to the removal of moisture and lighter volatiles from the charcoal samples (Munir et al. 2009). The ignition temperature and peak temperature are two important characteristic temperatures of a burning profile (Haykiri-Acma 2003; Munir et al. 2009). The ignition temperature corresponds to the point at which the burning profile underwent a rapid rise (Garcia-Ibanez et al. 2006). However, the temperature where the rate of weight loss due to combustion is highest is called as peak temperature (Haykiri-Acma 2003). The ignition temperature of charcoal obtained at 300, 500 and 800 °C was found to be 273, 339 and 373 °C, respectively. The variation in the ignition temperature may be due to difference in carbon containing volatile matter of the charcoal obtained at different temperatures. The charcoal obtained at lower temperatures has higher VMC as compared to the one carbonized at higher temperatures. The temperature corresponding to peak height is inversely proportional to reactivity while the peak height is directly proportional to the reactivity. The maximum combustion rate of 0.9233, 0.7134 and 0.6595 mg/min were found at peak temperatures of 419, 455 and 496 °C, for lantana charcoal prepared at 300, 500 and 800 °C, respectively (Table 2). The rate of combustion of charcoal (mg/min) was found to be lower (0.6595 mg/min) in charcoal prepared at higher temperatures (800 °C), whereas, it was found to be higher (0.9233 mg/min) in charcoal prepared at lower temperatures (Table 2). This shift in combustion rate and peak temperature of the samples can be attributed to different amount of carbon available in the samples. The charcoals prepared at higher temperatures have higher percentage of carbon and low amount of volatile matter as compared to the one obtained at lower temperatures (Table 1).Thermal decomposition of charcoal results in one major peak in the high temperature range of 250–545 °C (Fig. 3). However, three major steps of decomposition/weight loss are observed biomass samples i.e., moisture drying, main devolatilisation and continuous slight devolatilisation (Munir et al. 2009). In our earlier published paper we presented burning profile of lantana stem biomass (Kumar et al. 2009). The study suggested three major steps of decomposition/weight loss for biomass samples. The initial weight loss of 3–4 % was mainly due to the removal of moisture and lighter volatiles from samples. The second weight loss was observed between 190 and 310 °C temperatures during oxidative decomposition of lantana stem biomass. The third major weight loss observed in the temperature range of 390–460 °C, was due to combustion process of char. During the combustion of lantana stem biomass the maximum combustion rate i.e., 0.2977 mg/min was recorded at 319 °C, peak temperature. The maximum combustion rate and peak temperature of lantana stem, under char combustion zone were found to be 0.2083 mg/min and 440 °C, respectively (Kumar et al. 2009). The low ignition and peak temperature of lantana biomass sample signifies there higher reactivity (fast degradation) as compared to charcoal.

Conclusions

Following conclusion can be drawn from the results discussed above.

-

The yield of char decreases with the rise of carbonization temperature. It was found that volatile content decreases with the temperature but the fixed carbon and AC increases with rise in carbonization temperature.

-

A definite trend of increase in the calorific value of char with carbonization temperature up to 600 °C has been noticed. However, further increase in temperature resulted in reduction in calorific value due to higher proportion of ash in char.

-

The burning profiles of pre-charred (300, 500 and 800 °C) lantana stem biomass was studied. The ignition temperature of the pre-charred sample was found to be increasing with increases in reaction temperature. The reactivity (rate of combustion) of charcoal prepared at lower temperature (300 °C) was found to be more compared to charcoal obtained at higher temperatures.

References

Biagini E, Fantei A, Tognotti L (2008) Effect of the heating rate on the devolatilization of biomass residues. Thermochim Acta 1–2:55–63

Cronk QCB, Fuller JL (1995) Plant invaders: the threat to natural systems. Chapman and Hall, London, p 241

Degroot WF, Shafizadeh (1984) Kinetics of gasification of douglas fir and cottonwood chars by CO2. Fuel 63:210–216

Demirbas A (2001) Relationships between lignin contents and heating values of biomass. Energy Convers Manag 42:183–188

Dence CW (1992) The determination of lignin. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer series in wood science, Springer, Berlin, pp 33–61

Fuwape JA (1993) Charcoal and fuel value of agroforestry tree crops. Agrofor Syst 22:55–59

Garcia-Ibanez P, Sanchez M, Cabanillas A (2006) Thermogravimetric analysis of olive-oil residue in air atmosphere. Fuel Process Technol 87:103–107

Haykiri-Acma H (2003) Combustion characteristics of different biomass materials. Energy Convers Manag 44:155–162

Kumar M, Gupta RC, Sharma T (1992) Effect of carbonisation conditions on the yield and chemical composition of Acacia and Eucalyptus wood chars. Biomass Bioenergy 3:411–417

Kumar R, Chandrashekar N, Pandey KK (2009) Study on fuel properties and combustion characteristic of Lantana camara and Eupatorium spp. Curr Sci 97(6):930–934

Kumar R, Pandey KK, Chandrashekar N, Mohan S (2010) Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J For Res 21(4):514–516

Leckner B, Karlsson M (1993) Gaseous emissions from circulating fluidized bed combustion of wood. Biomass Bioenergy 4(5):379–389

Matti P (2004) Global biomass fuel resources. Biomass Bioenergy 27:613–620

Munir S, Daood SS, Nimmo W, Cunliffe AM, Gibbs BM (2009) Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour Technol 100:1413–1418

Muylaert MS, Sala J, Vasconcelos de Freitas MA (1999) The charcoal production in Brazil—process efficiency and environmental effect. Renew Energy 16:1037–1040

Nassar M (1985) Kinetic studies on thermal degradation of non woody plants. Wood Fiber Sci 17(2):266–273

Prasad R, Maithel S, Mirza A (2001) Renewable energy technologies for fuelwood conservation in the Indian Himalayan region. Sustain Dev 9(2):103–108

Rawat GS, Bhainsora NS (1999) Woody vegetation of shivaliks and outer Himalaya in north western India. Tropical-Ecology 40(1):119–128

Senelwa K, Sims REH (1999) Opportunities for small scale biomass–electricity systems in Kenya. Biomass Bioenergy 17(3):239–255

Stubington JP, Sumaryono (1984) Release of volatiles from large coal particles in hot fluidzed bed. Fuel 63:1013–1019

Technical Association for Paper and Pulp Industries (1992) TAPPI test methods. Technical Association for Paper and Pulp Industries (TAPPI) Publication, Atlanta (USA)

Walker JCF (1993) Primary wood processing—principles and practices. Chapman and Hall Publication, London

Yang H, Yan R, Chen H, Ho Lee D, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Acknowledgments

We express our sincere thanks to Sri S. C. Joshi (IFS), Director, Institute of Wood Science and Technology, Bangalore for encouragement and support during the course of this work.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kumar, R., Chandrashekar, N. Study on chemical, elemental and combustion characteristics of Lantana camara wood charcoal. J Indian Acad Wood Sci 10, 134–139 (2013). https://doi.org/10.1007/s13196-013-0103-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-013-0103-x