Abstract

In this review, CNT-based adsorbents have been extensively used in the adsorption of inorganic and organic pollutants from water and wastewater. The use of nanoadsorbents is an attractive and promising option in the water treatment process due to its high specific surface area and unique physical and chemical properties. They demonstrate excellent adsorption properties due to their high specific surface area, exceptional porosities, hollow and layered structures, numerous internal and external adsorption sites, π-conjugative structure, and ease of chemical activation and functionalization. A wide range of mechanical, physical, and chemical approaches have been used for the modification or functionalization of CNTs to enhance their adsorptive properties in general or to make them selective toward certain classes of pollutants. Depending on the adsorption conditions and the functionalization involved, CNT-based adsorbents can interact with inorganic contaminants through different mechanisms such as surface complexation, electrostatic interaction, ion exchange, physical adsorption, and precipitation. In the case of organic pollutants, besides physical adsorption, π-π and electrostatic interactions play a major role in adsorption. In some cases, chemical bonding between organics and carbon nanotubes has also been reported as a mechanism of interaction. Properties, functionalization, and mechanisms are involved in CNT-based adsorption of pollutants from aqueous media. An insightful overview of the critical parameters that should be considered while using CNT-based adsorbents for water purification is also provided. In the end, some challenges associated with CNT-based adsorbents are presented, along with the potential solutions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Increasing industrial activities and increasing population growth have led to the creation of large amounts of industrial and agricultural effluents and pollutants, the improper disposal of which imposes irreparable damage to human health and the environment [1,2,3,4]. Therefore, water supply required by human societies and improving water quality are two important issues in the field of water and wastewater treatment [4,5,6,7]. Because access to safe drinking water is key to maintaining public health, safe water is recognized as a basic need in communities. About one-sixth or 1.2 billion people in developing countries still do not have access to safe water. Also, about 2.6 billion people are deprived of basic health facilities. So far, various processes for water and wastewater treatment have been introduced [7,8,9,10,11]. Among these methods, adsorption using nanoadsorbent is one of the most effective and efficient methods to remove more contaminants in water. Water treatment with nanosorbents is a flexible method in terms of design and implementation; in most cases, it completely eliminates contaminants and the treated water in terms of color and odor is suitable for reuse [1, 10,11,12,13]. The use of nanotechnology in the treatment of pollutants from the environment, especially water, has gradually changed the climate, and its impact on the lives of humans and other living organisms can be clearly seen. It is predicted that the use of nanoadsorbent will lead to the development of new technologies and provide more effective tools to prevent, identify, and solve problems related to water pollution such as wastewater [2,3,4,5,6]. Although a research program on nanoadsorbent is underway in relation to contaminants in water, more research is still needed to further develop nanomaterials for water treatment [7, 14, 15]. In order to synthesize suitable nanoadsorbent to remove harmful compounds from leachate, chemical analyses must be performed on the functional groups of nanoadsorbent to obtain an optimal state of their molecular structure during synthesis. Leachate is a liquid that passes through waste and leaks out of solid waste [16,17,18,19,20]. Under these conditions, nanoadsorbent can react optimally in water and wastewater treatment reactors and do their job well. Harmful and stubborn compounds commonly found in leachates include alkaline compounds, phenols, chlorine-containing aromatic compounds, heavy metals, and so on. The functional groups that bind to these compounds usually include esters, aldehydes, ketones, alcohols, and carboxyl. In order to develop optimal nanoadsorbent for water and wastewater treatment operations, sufficient and in-depth information on the properties of nanoadsorbent as well as the properties of water or wastewater under treatment should be available [21,22,23,24]. The characteristics of industrial effluents depend on the type of industry and the processes carried out in it. For example, effluents from the petrochemical industry contain organic pollutants that can be removed by biological treatment and chemical oxidation or nanoadsorbent [25,26,27]. The uncontrolled entry of heavy metals and organic dyes into the environment has become a major global problem. These pollutants enter natural waters through industrial activities, domestic sewage, and effluents. Humans are the main cause of pollutants entering water. Of course, natural factors such as soil and rock erosion due to air and rainwater are also effective in the entry of heavy metals into the water [28,29,30,31,32]. Therefore, the presence of these factors causes toxic species to enter the water and then the body of living organisms. Using the adsorption process is one of the best ways to remove these contaminants from the water [33,34,35].

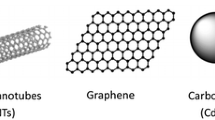

The adsorption has promising advantages of effectiveness, simplicity of operation, low cost, selective capturing, and reusability of the adsorbents [36,37,38,39]. The performance of the adsorption process is highly dependent on the nature of the adsorbent and target pollutants. Adsorbent surface area, pore diameter, interior and exterior morphology, and functional groups play an important role in the adsorption process. Besides that, initial pH of the sample solution, pollutant concentration, adsorbent dosage, contact time, temperature, ionic strength, and presence of interfering ions/pollutants are some critical parameters that may impact the performance of the adsorption process to various extent. Nanomaterials such as carbon nanotubes (CNTs), graphene, layered double hydroxides, and (MOFs) have been widely used as adsorbents because of their high surface area, enhanced reactivity, and ease of synthesis and functionalization [40,41,42,43,44]. Among these, carbon nanotubes have shown remarkable potential as an adsorbent material for capturing inorganic and organic pollutants from the aqueous media due to their hollow structures, numerous internal and external active sites, and high affinity toward target pollutants. carbon nanotube-based membranes have also been in water purification [45,46,47,48].

The advantages of this method are the lack of need for large amounts of energy, the lack of need for additional chemicals, the breadth and variety of the method, and the ability to remove various contaminants. In the following, various aspects of common nanoadsorbent in the water treatment industry are discussed.

2 Absorption Isotherm Models on Nanoadsorbent

In order to achieve new and efficient attractions, it is necessary to create a suitable relationship to attract equilibrium. This can lead to the production of an ideal adsorption system, which is necessary to reliably predict the adsorption parameters and to provide a statistical and quantitative comparison of different adsorption systems [49,50,51,52]. In simpler terms, the adsorption isotherm is a mathematical relation that shows the equilibrium value of a physically or chemically adsorbed substance on the surface of a solid by changes in pressure at a constant temperature [53,54,55]. The provision of adsorption isotherms is essential for optimizing the pathways of the adsorption mechanism [56,57,58,59]. In fact, adsorption isotherms, due to the description of how pollutants interact with adsorbents, express the surface properties and capacity of adsorbents and contribute to the design of adsorption systems [60,61,62,63]. The adsorption isotherm curve represents the phenomenon by which adsorbents at a constant temperature and pH move, or remain constant, through a porous aqueous medium or aqueous medium to a solid phase. These curves or graphs are very valuable and play an important role in understanding and analyzing the proposed models. The equilibrium isotherm curve of methylene blue adsorption on carrageenan/silica hybrid nanoadsorbent surfaces is shown in Fig. 1.

Equilibrium isotherm curve of aqueous methylene adsorption on carrageenan/silica hybrid nanoadsorbent surfaces [1]

An equilibrium is created when the concentration of the solution remains unchanged due to (1) lack of adsorption by the solution or (2) lack of desorption from the adsorbent. Therefore, the relationship between the equilibrium concentration of the adsorbed substance in the liquid and solid phases at constant temperature is expressed by the equilibrium adsorption isotherm. Isotherm states are linear, irreversible, desirable, undesirable, and highly desirable. Understanding the mechanism, surface properties, and degree of tendency of nanoadsorbent depends on physical, chemical, and thermodynamic parameters [64,65,66]. The three basic approaches in equilibrium isotherm models are kinetic considerations, thermodynamic considerations, and potential theory. The amount of pollutant adsorption in equilibrium (in milligrams per gram) is calculated using the mass balance equation as follows:

where Qe, C0, Ce, V, and m, respectively, indicate the amount of pollutants absorbed at equilibrium, the initial concentration of pollutants, the equilibrium concentration of pollutants, the adsorbent volume, and the adsorbent mass.

3 Kinetic Models of Adsorption on Nanoadsorbent

Kinetic studies are of particular importance for predicting optimal conditions in adsorption processes. The kinetic model provides information about the adsorption mechanism and the steps that may play a role in controlling the rate of the adsorption process. These steps involve mass transfer processes or chemical reactions. So far, several kinetic models have been proposed, such as quasi-first-order, quasi-second-order kinetics, intra-particle diffusion, and Elovich, Boyd, and Bangham. The most common proposed kinetic models are quasi-first-order and quasi-second-order kinetic models [37,38,39,40,41].

4 Classification of Nanoadsorbent

The most important factor determining the properties of nanoparticles is their size. Other factors include surface chemistry including functional groups and surface charge, agglomeration or agglomeration, shape and dimensions of crystals, chemical composition and crystal structure, and solubility [67,68,69,70,71]. The nanoadsorbent used in water treatment are classified according to their role in the adsorption process and also depending on the intrinsic properties of the surface and the addition of surface chemical agents. The first category includes metal nanoparticles such as gold nanoparticles, metal oxide nanoparticles such as titanium dioxide, nanostructures containing a combination of oxides such as iron–titanium oxides, and magnetic nanoparticles such as dioxide and iron trioxide [72,73,74,75]. The second category is carbon nanomaterials and includes carbon nanotubes, carbon nanoparticles, and carbon nanosheets. Other categories include silicon nanomaterials such as silicon nanotubes, silicon nanoparticles, and silicon nanosheets. Other nanomaterials used for the adsorption process include nanofibers, nanofibers, polymer-based nanomaterials, and aerogels (Fig. 2) [11].

Classification of nanoadsorbent [11]

5 Properties and Mechanisms Governing Nanoadsorbent

The application of nanoadsorbent strongly depends on changing their surface properties by reducing their dimensions to the nanometer scale and also adding external factors to improve the sensitivity and selectivity of their surface. Therefore, a clear definition of these two factors must be provided [12, 13].

5.1 Intrinsic Properties of the Surface

Determining the nature and distribution of active sites on the surface of nanostructures is a major challenge. Intrinsic factors affecting the performance of nanoparticles as nanoadsorbent in solution or substrate include high fraction of surface atoms, larger surface area, high chemical activity, high adsorption capacity, lack of internal resistance to penetration, and high surface adhesion energy [76,77,78,79,80]. Each of these factors affects the atoms or molecules present on the surface and the common season, increasing the surface energy, accessibility, and affinity for contact with the surface and its enrichment. Of course, in some cases, even with advanced surface study tools, the true nature of the nanoparticle surface cannot be identified. Therefore, a thorough study and in-depth understanding of the surface properties of nanoparticles is a major challenge in using nanoparticles as adsorbents in various applications, especially water treatment [81,82,83,84].

5.2 Foreign Causes

It is possible to make many changes in the surface properties of nanomaterials using different functional groups. In other words, the use of various methods of external actuation of different nanomaterials results in excellent adsorption properties. with continuing the process of functionalizing the surface of nanoparticles, their accumulation and agglomeration are prevented and the selectivity of nanoadsorbent increases [76, 85,86,87,88]. Factor groups improve various properties of nanoadsorbent such as high adsorption and fast desorption. In general, factor groups are used to improve parameters such as selectivity, surface contact tendency, and adsorption capacity. The reason for this is the entry of organic atoms into the surface of nanomaterials and thus the improvement of hydrophilic and polar interactions with the desired analyses. Analytic is a substance or chemical compound that is considered in analytical methods [89,90,91,92]. Experiments always seek to measure analyses, but analyses cannot measure themselves. Oxygen and amine groups have the ability to coordinate transition metals using electrostatic interactions. For example, research has been done on the functionalization of multi-walled carbon nanotubes with ethylene diamine by forming an amide bond with carboxyl groups on the surface of oxidized carbon nanotubes. The results show that this process removes dual-capacity cadmium from water. Also, coating nanoparticles with suitable coatings has a significant effect on their various properties [93,94,95,96,97]. A diagram of how carbon nanotubes are treated with ethylene diamine is shown in Fig. 3. Factorization of nanoparticles has a positive effect on the efficiency of nanoadsorbent and causes the isolation of isoelectric point (IEP) of nanoparticles according to the pH of the solution [12, 20,21,22,23]. The point at which the zeta potential equals zero is called the isoelectric point. The zeta potential is used to measure the surface charge of colloids and nanoparticles dispersed in a liquid. For example, when the pH of the solution is higher than the isoelectric point of the nanoadsorbent, the negative charge of the nanoadsorbent surface creates an electrostatic attraction and improves the absorption of cations. Oxidation is another way to activate the surface of nanoadsorbent. Common processes used for oxidation include nitric acid reflux and the use of oxidizing agents such as hydrogen peroxide or permanganate [98,99,100,101,102]. These processes increase the surface area by removing defects. Also, during these processes, defects that are able to enter the oxygen-containing functional groups are introduced. For example, the oxidation of carbon nanotube adsorbents causes hydroxyl, carboxyl, and carbonyl groups to enter these nanotubes. These groups have the ability to hold different metals at PHS above the isoelectric point [103,104,105,106].

Schematic of how carbon nanotubes are treated with ethylene diamine [12]

6 Challenges in the Use of Nanoadsorbent

In general, there are three main challenges in the use of nanoadsorbent in the water treatment process, which include the following [5]:

-

Supporting materials

-

Separation of nanomaterials

-

Regeneration of nanoadsorbents

6.1 Supporting Materials

Many nanomaterials are synthesized from aqueous suspensions in the form of very fine powders. Therefore, the use of these fine powders in adsorbent columns is not desirable due to their poor hydraulic conductivity. Also, due to the small particle size of the nanoadsorbent, they are not usually used in fixed bed columns, except in cases where the nanoadsorbent are either granular, or mounted (carried by them) on larger porous materials such as polymers, sand, activated carbon, etc. Of course, choosing the right carrier is very important [113,114,115, 110,111,112]. For example, spherical substrates cannot be used for metal oxide nanoparticles. Researchers typically use materials such as fiberglass and glass substrates to reduce the rapid flow of nanoparticles in adsorbent columns. Of course, the use of these materials is only effective at some point in time and they are not able to reduce the rapid flow of nanoparticles permanently. Another suitable carrier is composite gels. These materials have good mechanical stability [116,117,118,119,120,121]. Also, composite gels have a unique structure consisting of large cavities and their resistance to flow is low. Nanoadsorbent transported by composite gels are used to remove highly concentrated trivalent arsenic. A list of suitable carriers for different nanoadsorbent is given in Table 1 [1, 13].

6.2 Separation of Nanomaterials

The separation of nanoparticles from aqueous solution depends on their nature. In general, several methods for separating nanoparticles after reaching equilibrium during the adsorption process have been proposed, including magnetic separation, filtration, and centrifugation methods. Magnetic separation method is used to separate magnetic nanoparticles using a column magnetic separator that has a stainless-steel column [122,123,124,125]. Magnetic nanoparticles contain particles such as iron, nickel, and cobalt. This method is mostly used to separate iron nanoparticles, because iron has a very good magnetic property [126,127,128,129,130]. On the other hand, the filtration process according to the size and type of membranes is used to separate carbon nanotubes, magnetite nanoparticles, iron oxide nanoparticles, aragonite-surfactant hybrid nanostructures. An effective method for separating nonmagnetic particles is centrifugal separation [131,132,133]. The advantages of this method include high efficiency, usability to separate large amounts of nanoparticles and prevent the accumulation of nanoparticles. It is possible to separate nanoparticles from water using a centrifuge process at a speed of 50,000–200,000 rpm. External magnetic field separation and filtration methods are used to separate nanoparticles from aqueous solutions [134,135,136,137,138].

6.3 Regeneration of Nanoadsorbents

To reduce costs when using nanoadsorbents in water treatment, recovery of adsorbents is of particular importance. Nanoadsorbents become contaminated after absorbing contaminants. In order to reuse nanosorbents and dispose of adsorbed contaminants such as arsenic, the recovery and regeneration process is essential. The first goal of nanoadsorbents recovery is to maintain the ability to adsorbents contaminated nanoadsorbents. The pH factor plays a very important role in the recovery of nanoadsorbents [139,140,141,142,143]. From the pH point of view, the reduction of cations in acidic environment as well as the reduction of anions in alkaline environment is very small. Therefore, the desorption process can be easily performed by adjusting the pH. After the reduction process, nanoadsorbents can be reused. For example, hydrochloric acid is used to reduce quartz coated with iron nano-oxide. Studies on the reduction of nanoadsorbents used to remove arsenic from water show that after the reduction of iron-copper double oxide nanoadsorbents, only about 6% of its adsorption capacity is reduced [144,145,146,147,148].

7 Carbon-Based Nanoadsorbents

In general, carbon-based nanoadsorbents used in water treatment processes include reduced carbon nanotubes, graphene, graphene oxide, and graphene oxide [15].

7.1 Carbon Nanotubes

Carbon nanotubes have been noted for their unique physical and chemical properties. Large carbon nanotubes are cylindrical molecules with a hexagonal crystal structure of carbon atoms (similar to graphite atomic plates). Carbon nanotubes are divided into single-walled and multi-walled. Extremely high tensile strength, high Young modulus, good chemical and thermal stability, and good thermal and electrical conductivity are the salient features of carbon nanotubes. In the field of environmental engineering, carbon nanotubes are able to strongly interact with organic and inorganic pollutants due to their highly porous hollow structure, high specific surface area, low density, surfactant groups, and hydrophobic surfaces [149,150,151,152,153]. They are known to be toxic. In general, there are four locations for absorbing various contaminants on carbon nanotube coils [16,17,18, 154,155,156,157,158,159]:

A. Internal areas: These areas are within the hollow structure of individual pipes. Access to these locations is only possible by removing the cap (vertices) of the nanotubes and the open end of the tubes.

B. Channels created between the gaps: These places are located inside the tubes between individual nanotubes and easily come into contact with contaminants.

C. External grooves: The grooves are usually located around the coil of carbon nanotubes and the outer surface of the outer nanotubes, where the parallel tubes meet.

D. Outer surface: Contaminants can adhere to the curved surfaces of individual tubes outside the nanotube packages.

The different regions of adsorption on a homogeneous coil of single-walled carbon nanotubes with semi-closed ends are shown in Fig. 4.

Different adsorption regions on a homogeneous coil of a single-walled carbon nanotubes with b semi-closed ends, c including internal areas, d channels created between cracks, external grooves, and external surfaces of nanotubes [13]

Adsorption on closed-ended carbon nanotubes first occurs in the grooves between the adjacent coil tubes. Then, adsorption is done on the outer convex walls. Also, in an open carbon nanotube coil, adsorption occurs primarily by the walls inside the open nanotubes. Under these conditions, one-dimensional chains are formed in the grooves on the outer surface of the coils. The second step involves occupying the remaining axial areas inside the nanotubes and completing the quasi-hexagonal components on the outer surfaces of the coils. The adsorption process in external places such as grooves and external surfaces is much faster than in internal places such as channels created in pipes and inside pipes and reaches a state of equilibrium [160,161,162,163]. The efficiency of carbon nanotubes in the adsorption process depends on several different factors such as the number of open and closed nanotubes. The open carbon nanotube coil has a higher adsorption capacity than the closed carbon nanotube coil. In open carbon nanotube coils, the adsorption kinetics are accelerated and the saturation is increased. Also, carbon nanotubes are usually mixed with impurities such as catalyst particles with carbon coating, soot, and other forms of carbon. The presence of these impurities significantly reduces their adsorption efficiency. Various methods such as acid treatment, heat treatment, etc. are used to remove these impurities. It is possible to increase the adsorption properties of carbon nanotubes by acting on their surface. The functional groups present on the surface of nanotubes include the hydroxyl (OH-), carbonyl (CO-) and carboxyl (COOH-) functional groups, which are formed during the synthesis and purification process or by spontaneous oxidation of various acids, ozone, or plasma [124, 155, 164,165,166]. These functional groups modify the wettability of carbon nanotube surfaces and change their hydrophobic levels to hydrophilic surfaces. Under these conditions, carbon nanotubes will be able to absorb polar compounds and relatively low molecular weight materials [16]. Also, by forming functional groups on the surface of carbon nanotubes, their resistance to penetration increases and their active surface area decreases. These factors reduce the tendency of the surface of carbon nanotubes to interact and absorb some organic chemicals. In addition, the presence of functional groups leads to loss of access to the interior of the carbon nanotubes. In order to eliminate chemical functional groups, heat treatment in a vacuum environment is used to involve the interior of the nanotubes in the adsorption process. Overall, the use of carbon nanotubes for water treatment has yielded promising results [125, 167, 168]. These nanoadsorbents have the ability to remove about 99–80% of mineral contaminants in water, with metal concentrations in the range of − 0.60 mg/L. After using these nanoadsorbents, it is possible to recover and reuse them without reducing the efficiency by performing sodium hydroxide (NaOH) reduction operations. with using recovery operations, the costs of water and wastewater treatment operations by adsorbing carbon nanotubes are drastically reduced [133, 134, 142, 169]. Despite the many benefits of using carbon nanotubes as nanoadsorbents, the use of these nanotubes in the water treatment process worldwide is still limited. The main limitation is the very high cost of producing carbon nanotubes. Despite the lower cost of producing multi-walled carbon nanotubes than single-walled carbon nanotubes, the production of multi-walled carbon nanotubes is an expensive process. The cost of producing carbon nanotubes is about 1000 times higher than that of granular activated carbon. Therefore, the use of carbon nanotubes on an industrial scale is not economically viable. However, the ability of carbon nanotubes to remove contaminants in water, such as microsystems, is much greater than that of granular activated carbon, and the recovery of nanotubes reduces the cost of using them in the water treatment process. It should be noted that many efforts have been made to produce and develop inexpensive multi-walled carbon nanotubes [141, 144, 146, 152, 170]. For example, for the production of cost-effective carbon nanotubes, the synthesis of graphite carbon nanostructures using pyrolysis of polypropylene nanotubes has been used, which in addition to being economical, its synthesis is also environmentally safe. As mentioned, carbon nanotubes are a promising option for removing heavy metals and toxic elements from water [171,172,173,174,175]. Thermodynamic, kinetic, and performance conditions of a number of studies on the removal of various dyes from water using a variety of carbon nanotubes are given in Table 2.

7.2 Application of Graphene in Color Removal

Graphene was used to remove methylene blue from aqueous solution [76, 82,83,84,85]. With increasing temperature from 293 to 330 K, the efficiency of pollutant absorption increases [86,87,88,89,90,91,92,93,94,95]. Also, under ideal operating conditions, it is possible to remove about 99.68% of the methylene blue in water using graphene nanoadsorbents [95,96,97,98,99,100,101]. It has been observed that the amount of methylene blue absorbed strongly depends on its initial concentration and the amount of equilibrium achievable after one hour of the process [102,103,104,105,106, 107,108,109,110]. Thermodynamic, kinetic, and performance conditions of a number of studies on the removal of various colors from water using graphene oxide are shown in Table 3.

8 Critical Factors in Adsorption Process

In some cases, the adsorption capacity of some metal ions increased with an increase in pH of the solution from acidic to nearly neutral conditions (pH = 2 to 6) (Table 4). The lower adsorption at lower pH was mainly attributed to competitive adsorption of hydrogen ion and metal ions. Hydrogen ions occupied sites hinder the adsorption of metal ions and electrostatic repulsion also comes into play in such cases. However, when the pH is increased, the concentration of hydrogen ions decreases and metal ions can easily bind active sites on the adsorbent. A similar situation has been described for the adsorption of copper(II) and zinc(II) ions onto AS-multi-walled carbon nanotube and OX-multi-walled carbon nanotube [77, 178, 179]. Table 5 summarizes selected applications of carbon nanotube-based adsorbents for the removal of organic molecules from aqueous media.

9 Application of Nanoadsorbents in Water and Wastewater Systems

Water plays an important role in the development of urban communities, but currently, access to quality water resources is facing challenges. On the other hand, with the amount of water demand for urban, agricultural and industrial uses, it is increasing, so it is important to pay attention to the new technologies of water and wastewater treatment, and one of these methods is the use of nanomaterials [180,181,182,183,184,185,186,187]. Nanotechnology has provided a clear vision for the development of new generation water supply systems that have high performance, proper water purification and reduction of waste water pollutants [188,189,190,191,192,193]. In recent years, the applications of nanotechnology in industry as a catalyst, medicine and pharmaceuticals, gas measurement, biology, environment and water and wastewater treatment have made significant progress. The use of nanoparticles, due to their high specific surface area and high adsorption and selectivity, has many advantages in water and industrial wastewater treatment systems, and these nanomaterials can effectively remove organic pollutants, mineral anions, bacteria, and heavy metals from aqueous solutions. The efficiency of water purification with nanoparticles directly depends on the efficiency of the nanoparticle; therefore, by using the appropriate nanoparticle, an efficient system can be designed. Pollutants are absorbed on the active surfaces of nanoadsorbents, which is a surface phenomenon and is carried out by physical forces, sometimes weak chemical bonds in the absorption process, which depends on several factors such as temperature, pressure, characteristics of the adsorbent, and absorption. It depends on the solvent, the simultaneous presence of other pollutants, and operational conditions such as pH, concentration of pollutants, contact time, and particle size. The nanomaterials used in the water and wastewater treatment system include carbon-based nanoadsorbents such as carbon nanotubes, metal-based nanoparticles, polymeric nanoparticles, and zeolites which have a high absorption potential due to their high active surface and the amount of adsorbent compared to conventional attractors are reduced, so it becomes possible to use smaller equipment in wastewater treatment systems. Table 6 presents the advantages, disadvantages and applications of these nanoparticles. In order to improve water and wastewater treatment, suitable solutions for the use of nanoadsorbents should be considered. Both carbon and metal nanotube absorbers are used to absorb heavy metals such as arsenic, cadmium, and mercury. In this context, metal nanoparticles and zeolites have been developed economically and compatible with water purification systems. In the use of nanoabsorbents, there are limitations such as operational limitations, high production costs, and the possibility of environmental and human risk. In order to remove these obstacles, it is necessary to industrialize the use of these nanoabsorbents with the support of the government and research institutions. Different methods are used in the industry to separate toxic compounds and heavy metals, and the surface absorption process is considered for wastewater treatment due to its ease and low cost. Nanoadsorbents are of interest due to their high specific surface, high efficiency, and ease of separation, and in recent years, with the development of nanotechnology, the use of nanoadsorbents in water and wastewater treatment has expanded. These applications are in the field of water and wastewater treatment for the separation of toxic compounds and pollutants, desalination, and separation of heavy metals. The results of the review of sources and references in this field show that the use of nanotechnology increases the efficiency of the water and wastewater treatment system. Surface adsorption is considered as an effective and economic method for removing heavy metals from industrial wastewater. In the surface absorption method, the adsorbent is able to absorb pollutants into its pores and separate them from water due to its surface area and high porosity volume. Nanoadsorbents have high capacity, high selectivity, and low density, which has led to the expansion of their use in water and wastewater treatment. In recent years, carbon nanotubes have been proposed to absorb toxic compounds such as lead and cadmium, which have the possibility of absorbing these harmful compounds from water. The physical characteristics of carbon nanotubes, such as their morphology and active surface, are effective on their absorption. The development of nanotechnology in the field of removing heavy metals from water has led to the improvement of water and wastewater treatment systems. In recent years, the use of nanoparticles for the surface adsorption of compounds has been expanded due to the high specific surface area, selectivity of the reaction, and high adsorption efficiency. Nitrate removal using nanoadsorbents is one of these industrial applications, which is proposed as an alternative to conventional adsorbents. In research, the possibility of using multi-walled carbon nanotubes modified with chitosan biopolymer to remove heavy metals has been investigated, the results of which showed that carbon nanotubes in optimal conditions have high efficiency for absorbing lead, zinc, and cadmium. It should be noted that nanotechnology and the use of nanoabsorbents in water and wastewater treatment are among the solutions that are expanding. Therefore, the selection of the absorbent according to the process conditions should be done with technical and economic issues in mind.

10 Future Challenges and Perspectives

In recent decade, various researches have been performed on the application of nanoparticles in the water and wastewater industries. In generally, these nanoparticles are divided to carbon nanotubes. Carbon nanotubes have a high active specific surface, while easy reuse. Water purification systems should be designed according to population and environmental conditions; therefore, attractants with selectivity and high absorption ability can improve water quality while improving the operational system of purification. Advances in nanotechnology have made it possible to use these materials in water and wastewater treatment processes. In recent years, nanoadsorbents have been developed to absorb heavy metals, toxic compounds, radionuclides, organic and mineral salts, bacteria and viruses in water and wastewater treatment systems. Progress in the field of synthesis of nanoadsorbents and their use in water and wastewater treatment systems improves the treatment performance and enables improvement in process operations. Increasing the efficiency of the system, reducing the space required for purification, as well as stable operations in different conditions are the advantages of using nano-absorbents in water and wastewater treatment. Therefore, with nanoabsorbents, the possibility of optimal use of water resources for expansion and sustainable development is provided. The combination of advanced nanotechnology with conventional purification processes has provided a suitable perspective for the development of water and wastewater units. This has caused nanoabsorbents to have a high potential for organic and inorganic pollutant removal processes and disinfection in water and wastewater treatment systems. In addition to saving the amount of absorbent materials, it enables the reduction of the dimensions of water and waste water treatment process equipment. Due to the specific surface of nanoabsorbents, they have unique properties based on their size (fast dissolution, high reactivity, strong absorption). These special properties of nanomaterials provide the possibility of developing new materials with high technology for water and wastewater treatment processes.

Nanoadsorbents, including carbon nanotubes and nanocomposites, have been developed in water and wastewater treatment, which are used to remove heavy metals and organic and biological pollutants from water. These nanoadsorbents have high efficiency in reducing pollutants and the required amount of nanoadsorbent to absorb the compounds of pollutants is very low. Therefore, with the development of nanotechnology, the use of these nanoadsorbents as new purification methods is proposed. Comparing the efficiency of nanoadsorbents and evaluating their mechanism of action in removing pollutants, it is possible to choose the appropriate adsorbent. It should be noted that the various applications of nanoadsorbents based on the high specific active surface and selectivity for absorbing the compounds of pollutants and toxins have led to their increasing use in water and wastewater treatment systems in the world. It is important to pay attention to the researches of nanoparticles in the world and to study the practical and industrial needs of the country in the direction of the production of nanoabsorbents and localization of purification methods. Although significant progress has been made in the field of using nanoparticles in water and wastewater treatment systems, there are limitations for nanoparticles in terms of water applications in the form of laws and regulations, as well as potential health risks. Therefore, researches on the development of nanoparticles compatible with living organisms have been proposed, and with targeted researches in the field of industrial applications of these nanoparticles, it is possible to preserve the environment and recover water resources while promoting and improving the operations of the purification system. Therefore, there is a need to investigate the methods of commercializing the use of nanoadsorbents in industrial treatment plants, and while reducing the production costs of nanoadsorbents and increasing the ease of operation of the treatment plant, environmental studies should be carried out so that the practical use of nanoadsorbents in water and sewage systems is possible.

11 Conclusion

1. In recent years, nanoparticles have been used as adsorbents due to their unique properties such as chemical activity, smaller grain size and good adsorption capacity. In this paper, nanoadsorbents are introduced and studied, isotherm equations and kinetics of nanoadsorbents, types of nanoadsorbents, properties and adsorption mechanisms in nanoadsorbents as well as the challenges in using nanoadsorbents. It has been said that adsorption using nanoadsorbents is one of the most effective and efficient ways to remove many contaminants in water. Providing adsorption isotherms is essential for optimizing adsorption pathways. In fact, adsorption isotherms, due to the description of how pollutants interact with adsorbents, express the surface properties and capacity of adsorbents and contribute significantly to the design of adsorption systems. Understanding the mechanism, surface properties and degree of tendency of nanoadsorbents depends on physical, chemical, and thermodynamic parameters. There are three basic approaches to equilibrium isotherm models: kinetic considerations, thermodynamic considerations, and potential theory. Kinetic models contain information about the adsorption mechanism and the steps affecting the control of the adsorption process. These steps involve mass transfer processes or chemical reactions. Quasi-first-order and quasi-second-order kinetic models are the most commonly proposed kinetic models. Nanomaterials are classified into different groups according to their role in the adsorption process and also depending on the intrinsic surface properties and external factors. The use of various methods to actuate the surface of different nanomaterials improves the adsorption process in them. By continuing the process of surfacing, the accumulation and agglomeration of nanoparticles is prevented and the selectivity of nanoadsorbents increases. Finally, the main challenges of using nanoadsorbents in the water treatment process include the use of carriers, separation of nanomaterials, and reduction of nanoadsorbents.

2. Nanoadsorbents are an attractive and promising option for use in the water treatment process due to their high specific surface area and unique physical and chemical properties. In this paper, carbon-based nanoadsorbents such as carbon nanotubes, graphene, graphene oxide, and reduced graphene oxide are introduced as common nanoadsorbents in the water treatment process. Carbon nanotubes are known as a new class of adsorbents for the treatment of toxic pollutants due to their highly porous hollow structure, high specific surface area, low density, surfactant groups, and hydrophobic surfaces, and are capable of strong interactions with organic pollutants. The adsorption regions on a carbon nanotube coil include the inner regions, the channels created between the cracks, the outer grooves, and the outer surface. The adsorption process in external places such as grooves and external surfaces is done much faster than internal places such as created channels and inside pipes and reaches a state of equilibrium. Open coils of carbon nanotubes have more adsorption capacity than closed nanotubes. Despite the advantages of using carbon nanotubes as nanoadsorbents, their use in the water treatment process still faces limitations, the most important of which is the very high cost of production. By recycling carbon nanotubes, the cost of water and wastewater treatment using these nanoadsorbents is greatly reduced. Carbon nanotubes are used to absorb and remove organic dyes such as safranin, red acid, methyl orange, methylene blue, rosin ink, Morin, etc. from water. Graphene, due to its unique properties such as perfect carbon nanostructure with sp2 hybridization, large specific surface area, and strong interactions with other atoms and molecules, is an attractive and promising option for absorbing and removing harmful contaminants from aqueous systems such as dyes, pollutants, and toxic elements.

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Mohmood, Iram, Lopes, Cláudia Batista., Lopes, Isabel, Ahmad, Iqbal, & Armando, C. (2013). Duarte, Eduarda Pereira “Nanoscale materials and their use in water contaminants removal—a review.” Environmental SciencePollution Research, 20(3), 1239–1260.

Khajeh, M., Laurent, S., & Dastafkan, K. (2013). Nanoadsorbents: Classification, preparation, applications (with emphasis on aqueous media). Chemical reviews, 113(10), 7728–7768.

Chowdhury, S., & Balasubramanian, R. (2014). Recent advances in the use of graphene-family nanoadsorbents for removal of toxic pollutants wastewater. Advances in colloidinterface science, 204, 35–56.

Lata, Sneh, & Samadder, S. R. (2016). Removal of arsenic water using nano adsorbents challenges: a review. Journal of environmental management, 166, 387–406.

Ray, Phoebe Zito, & Shipley, Heather J. (2015). Inorganic nano-adsorbents for the removal of heavy metals and arsenic: a review. RSC Advances, 5(38), 29885–29907.

Bao, S., Li, K., Ning, P., Jinhui Peng, Xu., & Jin, L. T. (2017). Highly effective removal of mercury and lead ions wastewater by mercaptoamine-functionalised silica-coated magnetic nano-adsorbents: Behaviours and mechanisms. Applied Surface Science, 393, 457–466.

Zare, E. N., Motahari, A., & Sillanpää, M. (2018). Nanoadsorbents based on conducting polymer nanocomposites with main focus on polyaniline and its derivatives for removal of heavy metal ions/dyes: A review. Environmental research, 162, 173–195.

Gatabi, M. P., Moghaddam, H. M., & Ghorbani, M. (2016). Efficient removal of cadmium using magnetic multiwalled carbon nanotube nanoadsorbents: Equilibrium, kinetic, and thermodynamic study. Journal of Nanoparticle Research, 18(7), 189.

Nassar, N. N. (2010). Rapid removal recovery of Pb (II) wastewater by magnetic nanoadsorbents. Journal of hazardous materials, 184(1–3), 538–546.

Kyzas, G. Z., & Matis, K. A. (2015). Nanoadsorbents for pollutants removal: A review. Journal of Molecular Liquids, 203, 159–168.

Omprakash Sahu, Nagender Singh (2019) 13 - Significance of bioadsorption process on textile industry wastewater, Editor(s): Shahid-ul-Islam, B.S. Butola,In The Textile Institute Book Series,The Impact and Prospects of Green Chemistry for Textile Technology, Woodhead Publishing 367–416ISBN 9780081024911 https://doi.org/10.1016/B978-0-08-102491-1.00013-7.

Muhammad, A., Yusof, N., Hajian, R., & Abdullah, J. (2016). Decoration of carbon nanotubes with gold nanoparticles by electroless deposition process using ethylenediamine as a cross linker. Journal of Materials Research, 31(18), 2897–2905. https://doi.org/10.1557/jmr.2016.304

Britz, D. A., & Khlobystov, A. N. (2006). Noncovalent interactions of molecules with single walled carbon nanotubes. Chemical Society Reviews, 35, 637. https://doi.org/10.1039/B507451G

Mohammadi, A., Kazemipour, M., Ranjbar, H., Walker, R. B., & Ansari, M. (2014). Amoxicillin removal from aqueous media using multi-walled carbon nanotubes. Fullerenes, Nanotubes, and Carbon Nanostructures, 23, 165–169. https://doi.org/10.1080/1536383X.2013.866944

Huang, S. Z., Wee, A. T. S., & Ariando, A. (2020). Room-temperature colossal magnetoresistance in terraced single-layer graphene. Advance Material, 32, 2002201. https://doi.org/10.1002/adma.202002201

Viti, L., Cadore, A. R., Yang, X., Vorobiev, A., Muench, J. E., Watanabe, K., Taniguchi, T., Stake, J., Ferrari, A. C., & Vitiello, M. S. (2021). Thermoelectric graphene photodetectors with sub-nanosecond response times at terahertz frequencies. Nanophotonics, 10(1), 89–98. https://doi.org/10.1515/nanoph-2020-0255

Azak, H. (2020). Electrochemical hydrogen peroxide nanosensor using a reduced graphene oxide-poly(6-(4H-dithieno[3,2-b:2′,3′-d]pyrrol-4-yl)hexan-1-amine) hybrid-modified electrode. Journal of Applied Polymer Science, 137, 48538. https://doi.org/10.1002/app.48538

Han, G., Chen, Z., Cai, L., Zhang, Y., Tian, J., Ma, H., & Fang, S. (2020). Poly(vinyl alcohol)/carboxyl graphene membranes for ethanol dehydration by pervaporation. Chemical Engineering and Technology, 43, 574–581. https://doi.org/10.1002/ceat.201900149

Salimi, M., Pirouzfar, V., & Kianfar, E. (2017). Enhanced gas transport properties in silica nanoparticle filler-polystyrene nanocomposite membranes. Colloid and Polymer Science, 295, 215–226. https://doi.org/10.1007/s00396-016-3998-0

Kianfar, E. (2018). Synthesis and characterization of AlPO4/ZSM-5 catalyst for methanol conversion to dimethyl ether. Russian Journal of Applied Chemistry, 91, 1711–1720. https://doi.org/10.1134/S1070427218100208

Kianfar, E. (2019). Ethylene to propylene conversion over Ni-W/ZSM-5 catalyst. Russian Journal of Applied Chemistry, 92, 1094–1101. https://doi.org/10.1134/S1070427219080068

Kianfar, E., Salimi, M., Kianfar, F., et al. (2019). CO2/N2 separation using polyvinyl chloride iso-phthalic acid/aluminium nitrate nanocomposite membrane. Macromolecular Research, 27, 83–89. https://doi.org/10.1007/s13233-019-7009-4

Kianfar, E. (2019). Ethylene to propylene over zeolite ZSM-5: Improved catalyst performance by treatment with CuO. Russian Journal of Applied Chemistry, 92, 933–939. https://doi.org/10.1134/S1070427219070085

Kianfar, E., Shirshahi, M., Kianfar, F., et al. (2018). Simultaneous prediction of the density, viscosity and electrical conductivity of pyridinium-based hydrophobic ionic liquids using artificial neural network. SILICON, 10, 2617–2625. https://doi.org/10.1007/s12633-018-9798-z

Salimi, M., Pirouzfar, V., & Kianfar, E. (2017). Novel nanocomposite membranes prepared with PVC/ABS and silica nanoparticles for C2H6/CH4 separation. Polymer Science, Series A, 59, 566–574. https://doi.org/10.1134/S0965545X17040071

Kianfar, F., & Kianfar, E. (2019). Synthesis of isophthalic acid/aluminum nitrate thin film nanocomposite membrane for hard water softening. Journal of Inorganic and Organometallic Polymers, 29, 2176–2185. https://doi.org/10.1007/s10904-019-01177-1

Kianfar, E., Azimikia, R., & Faghih, S. M. (2020). Simple and strong dative attachment of α-diimine nickel (II) catalysts on supports for ethylene polymerization with controlled morphology. Catalysis Letters, 150, 2322–2330. https://doi.org/10.1007/s10562-020-03116-z

Kianfar, E. (2019). Nanozeolites: Synthesized, properties, applications. Journal of Sol-Gel Science and Technology, 91, 415–429. https://doi.org/10.1007/s10971-019-05012-4

Liu, H., & Kianfar, E. (2020). Investigation the synthesis of nano-SAPO-34 Catalyst prepared by different templates for MTO process. Catalysis Letters. https://doi.org/10.1007/s10562-020-03333-6

Kianfar, E., Salimi, M., Hajimirzaee, S., Koohestani, B. (2018). Methanol to gasoline conversion over CuO/ZSM-5 catalyst synthesized using sonochemistry method. International Journal of Chemical Reactor Engineering. 17.

Kianfar, E., Salimi, M., Pirouzfar, V., & Koohestani, B. (2018). Synthesis of modified catalyst and stabilization of CuO/NH4-ZSM-5 for conversion of methanol to gasoline. International Journal of Applied Ceramic Technology, 15, 734–741. https://doi.org/10.1111/ijac.12830

Kianfar, E., Salimi, M., Pirouzfar, V., & Koohestani, B. (2018). Synthesis and modification of zeolite ZSM-5 catalyst with solutions of calcium carbonate (CaCO3) and sodium carbonate (Na2CO3) for methanol to gasoline conversion. International Journal of Chemical Reactor Engineering, 16(7), 20170229. https://doi.org/10.1515/ijcre-2017-0229

kianfar, E. (2019). Comparison and assessment of zeolite catalysts performance dimethyl ether and light olefins production through methanol: a review. Reviews in Inorganic Chemistry., 39, 157–177.

Ehsan Kianfar, & Mahmoud Salimi. (2020). A review on the production of light olefins from hydrocarbons cracking and methanol conversion: In book: Advances in chemistry research, volume 59: Edition: James C. Taylor Chapter: 1: Publisher: Nova Science Publishers, Inc., NY, USA

Wei, H., Deng, S., Huang, Q., Nie, Y., Wang, B., Huang, J., & Yu, G. (2013). Regenerable granular carbon nanotubes/alumina hybrid adsorbents for diclofenac sodium and carbamazepine removal from aqueous solution. Water Research, 47, 4139–4147. https://doi.org/10.1016/J.WATRES.2012.11.062

Ehsan Kianfar (2020) Zeolites: properties, applications, modification and selectivity: In book: Zeolites: advances in research and applications, Edition: Annett Mahler Chapter: 1: Publisher: Nova Science Publishers, Inc., NY, USA.

Kianfar E, Hajimirzaee S, Musavian SS, Mehr AS. (2020) Zeolite-based Catalysts for Methanol to Gasoline process: A review. Microchemical Journal. 104822

Kianfar, E., Baghernejad, M., & Rahimdashti, Y. (2015). Study synthesis of vanadium oxide nanotubes with two template hexadecylamin and hexylamine. Biological Forum., 7, 1671–1685.

Ehsan kianfar. (2020). Synthesizing of vanadium oxide nanotubes using hydrothermal and ultrasonic method. Publisher: Lambert Academic Publishing. 1–80. ISBN: 978–613–9–81541–8.

Kianfar, E., Pirouzfar, V., & Sakhaeinia, H. (2017). An experimental study on absorption/stripping CO2 using Mono-ethanol amine hollow fiber membrane contactor. Journal of the Taiwan Institute of Chemical Engineers, 80, 954–962.

Kianfar, E., & Viet, C. (2021). Polymeric membranes on base of polymethyl methacrylate for air separation: A review. Journal of Materials Research and Technology., 10, 1437–1461.

nmousavian, S. S., Faravar, P., Zarei, Z., zimikia, R., Monjezi, M. G., & kianfar, E. (2020). Modeling and simulation absorption of CO2 using hollow fiber membranes (HFM) with mono-ethanol amine with computational fluid dynamics. Journal of Environment Chemical Engineering, 8(4), 103946.

Yang, Zhidong, Zhang, Liehui, Zhou, Yuhui, Wang, Hui, Wen, Lichen, & Kianfar, Ehsan. (2020). Investigation of effective parameters on SAPO-34 Nano catalyst the methanol-to-olefin conversion process: a review. Reviews in Inorganic Chemistry, 40(3), 91–105. https://doi.org/10.1515/revic-2020-0003

Gao, C., Liao, J., Jingqiong, Lu., Ma, J., & Kianfar, E. (2020). The effect of nanoparticles on gas permeability with polyimide membranes and network hybrid membranes: A review. Reviews in Inorganic Chemistry. https://doi.org/10.1515/revic-2020-0007

Ehsan Kianfar, Mahmoud Salimi, Behnam Koohestani. (2020). Zeolite catalyst: a review on the production of light olefins. Publisher: Lambert Academic Publishing. 1–116 ISBN:978–620–3–04259–7.

Ehsan Kianfar. (2020). Investigation on catalysts of “methanol to light olefins”. Publisher: Lambert Academic Publishing. 1–168 ISBN: 978–620–3–19402–9.

Kianfar, E. (2020). Application of nanotechnology in enhanced recovery oil and gas. Importance & Applications of Nanotechnology, MedDocs Publishers, 5(3), 16–21.

Kianfar, E. (2020). Catalytic properties of nanomaterials and factors affecting it. Importance & Applications of Nanotechnology, MedDocs Publishers, 5(4), 22–25.

Kianfar, E. (2020). Introducing the application of nanotechnology in lithium-ion battery. Importance & Applications of Nanotechnology, MedDocs Publishers, 4(4), 1–7.

Kianfar, E., & Mazaheri, H. (2020). Synthesis of nanocomposite (CAU-10-H) thin-film nanocomposite (TFN) membrane for removal of color from the water. Fine Chemical Engineering, 1, 83–91.

Kianfar, E. (2020). Simultaneous prediction of the density and viscosity of the ternary system water-ethanol-ethylene glycol using support vector machine. Fine Chemical Engineering, 1, 69–74.

Kianfar, E., Salimi, M., & Koohestani, B. (2020). Methanol to gasoline conversion over CuO / ZSM-5 catalyst synthesized and influence of water on conversion. Fine Chemical Engineering, 1, 75–82.

Kianfar, E. (2020). An experimental study PVDF and PSF hollow fiber membranes for chemical absorption carbon dioxide. Fine Chemical Engineering, 1, 92–103.

Kianfar, E. (2020). S Mafi 2020 Ionic liquids: properties, application, and synthesis. Fine Chemical Engineering, 2, 22–31.

Faghih, S. M., & Kianfar, E. (2018). Modeling of fluid bed reactor of ethylene dichloride production in Abadan Petrochemical based on three-phase hydrodynamic model. International Journal of Chemical Reactor Engineering, 16, 1–14.

Ehsan Kianfar, H. Mazaheri. (2020). Methanol to gasoline: a sustainable transport fuel, In book: Advances in chemistry research. Volume 66, Edition: james C.taylor, Chapter: 4. Publisher: Nova Science Publishers, Inc., NY, USA

Kianfar. (2020). “A Comparison and assessment on performance of zeolite catalyst based selective for the process methanol to gasoline: a review, “in Advances in Chemistry Research, Vol. 63, Chapter 2 (NewYork: Nova Science Publishers, Inc.)

Ehsan Kianfar, Saeed Hajimirzaee, Seyed Mohammad Faghih, et al. (2020). Polyvinyl chloride + nanoparticles titanium oxide Membrane for Separation of O2 / N2. Advances in Nanotechnology. NY, USA: Nova Science Publishers, Inc

Ehsan Kianfar. (2020). Synthesis of characterization Nanoparticles isophthalic acid / aluminum nitrate (CAU-10-H) using method hydrothermal. Advances in Chemistry Research. NY, USA: Nova Science Publishers, Inc.

Ehsan Kianfar. (2020). CO2 capture with ionic liquids: a review. Advances in Chemistry Research. Volume 67Publisher: Nova Science Publishers, Inc., NY, USA.

Ehsan Kianfar. (2020). Enhanced light olefins production via methanol dehydration over promoted SAPO-34. Advances in Chemistry Research. Volume 63, Chapter: 4, Nova Science Publishers, Inc., NY, USA.

Ehsan Kianfar. (2020). Gas hydrate: applications, structure, formation, separation processes, Thermodynamics. Advances in Chemistry Research. Volume 62, Edition: James C. Taylor .Chapter: 8.Publisher: Nova Science Publishers, Inc., NY, USA.

Kianfar, E. (2016). The effect of nano-composites on the mechanic and morphological characteristics of NBR/PA6 blends. American Journal of Oil and Chemical Technologies, 4(1), 27–42.

Kianfar, F. (2015). Seyed Reza Mahdavi Moghadam1 and Ehsan Kianfar, Energy optimization of Ilam Gas Refinery Unit 100 by using HYSYS Refinery Software (2015). Indian Journal of Science and Technology, 8(S9), 431–436.

Kianfar, E. (2015). Production and identification of vanadium oxide nanotubes. Indian Journal of Science and Technology, 8(S9), 455–464.

Kianfar, F. (2015). Seyed Reza Mahdavi Moghadam1 and Ehsan Kianfar, Synthesis of spiro pyran by using silica-bonded N-propyldiethylenetriamine as recyclable basic catalyst, Indian. Journal of Science and Technology, 8(11), 68669.

Kianfar, E. (2019). Recent advances in synthesis, properties, and applications of vanadium oxide nanotube. Microchemical Journal., 145, 966–978.

Saeed Hajimirzaee, Amin Soleimani Mehr, & Ehsan Kianfar. (2020) Modified ZSM-5 zeolite for conversion of LPG to aromatics, polycyclic aromatic compounds https://doi.org/10.1080/10406638.2020.1833048.

Kianfar, E. (2021). Investigation of the effect of crystallization temperature and time in synthesis of SAPO-34 catalyst for the production of light olefins. Petroleum Chemistry, 61, 527–537. https://doi.org/10.1134/S0965544121050030

Huang, X., Zhu, Y., & Kianfar, E. (2021). Nano biosensors: properties, applications and electrochemical techniques. Journal of Materials Research and Technology, 12, 1649–1672. https://doi.org/10.1016/j.jmrt.2021.03.048

Kianfar, E. (2021). Protein nanoparticles in drug delivery: Animal protein, plant proteins and protein cages, albumin nanoparticles. Journal of Nanbiotechnology, 19, 159. https://doi.org/10.1186/s12951-021-00896-3

Kianfar, E. (2021). Magnetic nanoparticles in targeted drug delivery: A review. Journal of Superconductivity and Novel Magnetism. https://doi.org/10.1007/s10948-021-05932-9

Fattah, I. M. R., Farhan, Z. A., Kontoleon, K. J., Kianfar, E., & Hadrawi, S. K. (2023). Hollow fiber membrane contactor based carbon dioxide absorption− stripping: a review. Macromolecular Research, 1–27.

Kadhim, M. M., Rheima, A. M., Abbas, Z. S., Jlood, H. H., Hachim, S. K., & Kadhum, W. R. (2023). Evaluation of a biosensor-based graphene oxide-DNA nanohybrid for lung cancer. RSC Advances, 13(4), 2487–2500.

Kianfar, E. (2022). A review of recent advances in carbon dioxide absorption–stripping by employing a gas–liquid hollow fiber polymeric membrane contactor. Polymer Bulletin, 1–37.

Smaisim, G. F., Mohammed, D. B., Abdulhadi, A. M., Uktamov, K. F., Alsultany, F. H., Izzat, S. E., ... & Kianfar, E. (2022). Nanofluids: properties and applications. Journal of Sol-Gel Science and Technology, 104(1), 1–35.

Kianfar, E., & Sayadi, H. (2022). Recent advances in properties and applications of nanoporous materials and porous carbons. Carbon Letters, 1–25.

Hachem, K., Ansari, M. J., Saleh, R. O., Kzar, H. H., Al-Gazally, M. E., Altimari, U. S., ... & Kianfar, E. (2022). Methods of chemical synthesis in the synthesis of nanomaterial and nanoparticles by the chemical deposition method: a review. BioNanoScience, 12(3), 1032–1057.

Isola, L. A., Chen, T. C., Elveny, M., Alkaim, A. F., Thangavelu, L., & Kianfar, E. (2022). Application of micro and porous materials as nano-reactors. Reviews in Inorganic Chemistry, 42(2), 121–136.

Jasima, S. A., Kzarb, H. H., Sivaramanc, R., & Jweegd, M. J. (2022). Engineered nanomaterials, plants, plant toxicity and biotransformation: A review. Egyptian Journal of Chemistry, 65(12), 151–164.

Abed Hussein, B., Mahdi, A. B., Emad Izzat, S., Acwin Dwijendra, N. K., Romero Parra, R. M., Barboza Arenas, L. A., ... & Kianfar, E. (2022). Production, structural properties nano biochar and effects nano biochar in soil: a review. Egyptian Journal of Chemistry, 65(12), 607–618.

Smaisim, G. F., Mohammed, K. J., Hadrawi, S. K., Koten, H., & Kianfar, E. (2023). Properties and application of nanostructure in liquid crystals. BioNanoScience, 1–21.

Mohammed, K. J., Hadrawi, S. K., & Kianfar, E. (2023). Synthesis and modification of nanoparticles with ionic liquids: a review. BioNanoScience, 1–24.

Smaisim, G. F., Abed, A. M., Al-Madhhachi, H., Hadrawi, S. K., Al-Khateeb, H. M. M., & Kianfar, E. (2023). Graphene-based important carbon structures and nanomaterials for energy storage applications as chemical capacitors and supercapacitor electrodes: A review. BioNanoScience, 13(1), 219–248.

Abderrahmane, A., Mourad, A., Mohammed, S., Smaisim, G. F., Toghraie, D., Koulali, A., ... & Younis, O. (2023). Second law analysis of a 3D magnetic buoyancy-driven flow of hybrid nanofluid inside a wavy cubical cavity partially filled with porous layer and non-Newtonian layer. Annals of Nuclear Energy, 181, 109511.

Wang, Y., Zheng, J., Smaisim, G. F., & Toghraie, D. (2022). Molecular dynamics simulation of phase transition procedure of water-based nanofluid flow containing CuO nanoparticles. Alexandria Engineering Journal, 61(12), 12453–12461.

Xiao, M., & Smaisim, G. F. (2022). Joint chance-constrained multi-objective optimal function of multi-energy microgrid containing energy storages and carbon recycling system. Journal of Energy Storage, 55, 105842.

Mourad, A., Aissa, A., Abed, A. M., Smaisim, G. F., Toghraie, D., Fazilati, M. A., ... & Alizadeh, A. A. (2022). The numerical analysis of the melting process in a modified shell-and-tube phase change material heat storage system. Journal of Energy Storage, 55, 105827.

Smaisim, G. F., Abed, A. M., & Alavi, H. (2022). Analysis of pollutant emission reduction in a coal power plant using renewable energy. International Journal of Low-Carbon Technologies.

Abderrahmane, A., Jamshed, W., Abed, A. M., Smaisim, G. F., Guedri, K., Akbari, O. A., ... & Baghaei, S. (2022). Heat and mass transfer analysis of non-Newtonian power-law nanofluid confined within annulus enclosure using Darcy-Brinkman-Forchheimer model. Case Studies in Thermal Engineering, 102569.

Tan, X., Obaid, R. F., Smaisim, G. F., Esfahani, M. M., Alsaikhan, F., Baghaei, S., ... & Yadav, A. (2022). Investigation of addition of calcium phosphate ceramic to multilayer scaffold for bone applications with improved mechanical properties: Fuzzy logic analysis. Ceramics International.

Mir, S., Abed, A. M., Akbari, O. A., Mohammadian, A., Toghraie, D., Marzban, A., ... & Smaisim, G. F. (2022). Effects of curvature existence, adding of nanoparticles and changing the circular minichannel shape on behavior of two-phase laminar mixed convection of Ag/water nanofluid. Alexandria Engineering Journal.

Ruhani, B., Andani, M. T., Abed, A. M., Sina, N., Smaisim, G. F., Hadrawi, S. K., & Toghraie, D. (2022). Statistical modeling and investigation of thermal characteristics of a new nanofluid containing cerium oxide powder. Heliyon, 8(11), e11373.

Cai, W., Sabetvand, R., Abed, A. M., Toghraie, D., Hekmatifar, M., Rahbari, A., ... & Smaisim, G. F. (2022). Thermal analysis of hydration process in the vicinity of the Copper matrix using molecular dynamics simulation for application in thermal engineering. Energy Reports, 8, 7468–7475.

Moarrefzadeh, A., Morovvati, M. R., Angili, S. N., Smaisim, G. F., Khandan, A., & Toghraie, D. (2022). Fabrication and finite element simulation of 3D printed poly L-lactic acid scaffolds coated with alginate/carbon nanotubes for bone engineering applications. International Journal of Biological Macromolecules.

Hai, T., Abidi, A., Wang, L., Abed, A. M., Mahmoud, M. Z., El Din, E. M. T., & Smaisim, G. F. (2022). Simulation of solar thermal panel systems with nanofluid flow and PCM for energy consumption management of buildings. Journal of Building Engineering, 58, 104981.

Fadhil Smaisim, G., Abed, A. M., Hadrawi, S. K., & Shamel, A. (2022). Parametric investigation of thermal behaviour of salt-gradient solar pool for climatic conditions. Clean Energy, 6(5), 693–704.

Smaisim, G. F., Gholami, M., Toghraie, D., Hashemian, M., & Abed, A. M. (2022). Numerical investigation of the flow and heat transfer of Al2O3/water nanofluid in a tube equipped with stationary and self-rotating twisted tapes. Progress in Nuclear Energy, 151, 104335.

Jiang, Y., Smaisim, G. F., Mahmoud, M. Z., Li, Z., Aybar, H. Ş, & Abed, A. M. (2022). Simultaneous numerical investigation of the passive use of phase-change materials and the active use of a nanofluid inside a rectangular duct in the thermal management of lithium-ion batteries. Journal of Power Sources, 541, 231610.

Tian, M. W., Abed, A. M., Yan, S. R., Sajadi, S. M., Mahmoud, M. Z., Aybar, H. Ş, & Smaisim, G. F. (2022). Economic cost and numerical evaluation of cooling of a cylindrical lithium-ion battery pack using air and phase change materials. Journal of Energy Storage, 52, 104925.

Alharbi, K. A. M., Smaisim, G. F., Sajadi, S. M., Fagiy, M. A., Aybar, H. Ş, & Elkhatib, S. E. (2022). Numerical study of lozenge, triangular and rectangular arrangements of lithium-ion batteries in their thermal management in a cooled-air cooling system. Journal of Energy Storage, 52, 104786.

Wu, W., Smaisim, G. F., Sajadi, S. M., Fagiry, M. A., Li, Z., Shamseldin, M. A., & Aybar, H. Ş. (2022). Impact of phase change material-based heatsinks on lithium-ion battery thermal management: A comprehensive review. Journal of Energy Storage, 52, 104874.

Tian, M. W., Smaisim, G. F., Yan, S. R., Sajadi, S. M., Mahmoud, M. Z., Aybar, H. Ş, & Abed, A. M. (2022). Economic cost and efficiency analysis of a lithium-ion battery pack with the circular and elliptical cavities filled with phase change materials. Journal of Energy Storage, 52, 104794.

Brontowiyono, W., AbdulHussein, W. A., Smaisim, G. F., Mahmoud, M. Z., Singh, S., Lafta, H. A., ... & Aravindhan, S. (2022). Annealing temperature effect on structural, magnetic properties and methyl green degradation of Fe2O3 nanostructures. Arabian Journal for Science and Engineering, 1–8.

Tian, Y., Patra, I., Majdi, H. S., Ahmad, N., Sivaraman, R., Smaisim, G. F., ... & Hekmatifar, M. (2022). Investigation of atomic behavior and pool boiling heat transfer of water/Fe nanofluid under different external heat fluxes and forces: a molecular dynamics approach. Case Studies in Thermal Engineering, 38, 102308.

Smaisim, G. F., Al-Madhhachi, H., & Abed, A. M. (2022). Study the thermal management of Li-ion batteries using looped heat pipes with different nanofluids. Case Studies in Thermal Engineering, 37, 102227.

Mozafarifard, M., Azimi, A., Sobhani, H., Smaisim, G. F., Toghraie, D., & Rahmani, M. (2022). Numerical study of anomalous heat conduction in absorber plate of a solar collector using time-fractional single-phase-lag model. Case Studies in Thermal Engineering, 34, 102071.

Sharba, Z. M., Smaisim, G. F., & Arani, A. A. A. (2022). Thermal performance of inline and staggered bank of tubes with laminar cross flow. In 2022 5th International Conference on Engineering Technology and its Applications (IICETA) (77–84).

Smaisim, G. F., Prabu, N. M., Senthilkumar, A. P., & Abed, A. M. (2022). Synthesis of biodiesel from fish processing waste by nano magnetic catalyst and its thermodynamic analysis. Case Studies in Thermal Engineering, 102115.

AbdulHussein, W. A., Abed, A. M., Mohammed, D. B., Smaisim, G. F., & Baghaei, S. (2022). Investigation of boiling process of different fluids in microchannels and nanochannels in the presence of external electric field and external magnetic field using molecular dynamics simulation. Case Studies in Thermal Engineering, 102105.

Ahamad, S., Mohseni, M., Shekher, V., Smaisim, G. F., Tripathi, A., & Alanya-Beltran, J. (2022). A detailed analysis of the critical role of artificial intelligence in enabling high-performance cloud computing systems. In 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE) (156–159). IEEE.

Doss, A. N., Shah, D., Smaisim, G. F., Olha, M., & Jaiswal, S. (2022). A comprehensive analysis of Internet of things (IOT) in enhancing data security for better system integrity-a critical analysis on the security attacks and relevant countermeasures. In 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE) (165–167). IEEE.

Smaisim, G. F., Abed, A. M., & Shamel, A. (2022). Modeling the thermal performance for different types of solar chimney power plants. Complexity, 2022.

Smaisim, G. F., Bidgoli, M. O., Goh, K. L., & Bakhtiari, H. (2022). Review of thermoelastic, thermal properties and creep analysis of functionally graded cylindrical shell. Australian Journal of Mechanical Engineering, 1–12.

Smaisim, G. F., Abed, A. M., Hadrawi, S. K., & Shamel, A. (2022). Modeling and thermodynamic analysis of solar collector cogeneration for residential building energy supply. Journal of Engineering, 2022.

Lefteh, A., Houshmand, M., Khorrampanah, M., & Smaisim, G. F. (2022). Optimization of modified adaptive neuro-fuzzy inference system (MANFIS) with artificial bee colony (ABC) algorithm for classification of bone cancer. In 2022 Second International Conference on Distributed Computing and High Performance Computing (DCHPC) (78–81). IEEE.

Sallal, A. S., Smaisim, G. F., & Thahab, S. M. (2021). The heat transfer from fined perforated pipe improved due to nano-fluid. In Journal of Physics: Conference Series (1973, 1 012075). IOP Publishing.

Al-Madhhachi, H., & Smaisim, G. F. (2021). Experimental and numerical investigations with environmental impacts of affordable square pyramid solar still. Solar Energy, 216, 303–314.

Smaisim, G. F. (2018). Investigation on heat transfer augmentation using continuous and broken ribs on a plate of heat exchanger. International Journal of Energy & Environment, 9(3).

Smaisim, G. F. (2017). Augmentation of heat transfer in corrugated tube using four-start spiral wall. Al-Qadisiya Journal for Engineering Sciences, 10(4), 451–467.

Smaisim, G. F. (2017). Enhancement heat transfer of Cu-water nanofluids with thermophysical properties modeling by artificial neural network. Journal of University of Babylon, 25(5), 1721–1735.

Smaisim, G., Fatta, O., Valera-Medina, A., Rageb, A., & Syred, N. (2016). Investigation of heat transfer and fluid mechanics across a heated rotating circular cylinder in crossflow. In 54th AIAA Aerospace Sciences Meeting (0494).

Smaisim, G., Fatla, O., Valera Medina, A., Rageb, A. M., & Syred, N. (2016). Experimental and theoretical investigation of the effect of rotating circular cylinder speed on the lift and drag forces. International Journal of Energy and Environment, 7(1), 23–36.

Nasajpour-Esfahani, N., Garmestani, H., Rozati, M., & Smaisim, G. F. (2023). The role of phase change materials in lithium-ion batteries: A brief review on current materials, thermal management systems, numerical methods, and experimental models. Journal of Energy Storage, 63, 107061.

Niknejadi, M., Alizadeh, A. A., Zekri, H., Ruhani, B., Nasajpour-Esfahani, N., & Smaisim, G. F. (2023). Numerical simulation of the thermal-hydraulic performance of solar collector equipped with vector generators filled with two-phase hybrid nanofluid Cu-TiO2/H2O. Engineering Analysis with Boundary Elements, 151, 670–685.

Dai, X., Andani, H. T., Alizadeh, A. A., Abed, A. M., Smaisim, G. F., Hadrawi, S. K., ... & Toghraie, D. (2023). Using Gaussian process regression (GPR) models with the Matérn covariance function to predict the dynamic viscosity and torque of SiO2/Ethylene glycol nanofluid: a machine learning approach. Engineering Applications of Artificial Intelligence, 122, 106107.

Zhang, Y. X., Alizadeh, A. A., Abed, A. M., Nasajpour-Esfahani, N., Smaisim, G. F., Hadrawi, S. K., ... & Wang, M. X. (2023). Investigating the effect of size and number of layers of iron nanochannel on the thermal behavior and phase change process of calcium chloride/sodium sulfate hexa-hydrate with molecular dynamics simulation. Journal of Energy Storage, 62, 106762.

Tang, J., Ahmadi, A., Alizadeh, A. A., Abedinzadeh, R., Abed, A. M., Smaisim, G. F., ... & Toghraie, D. (2023). Investigation of the mechanical properties of different amorphous composites using the molecular dynamics simulation. Journal of Materials Research and Technology, 24, 1390–1400.

Alizadeh, A. A., Abed, A. M., Zekri, H., Smaisim, G. F., Jalili, B., Pasha, P., & Ganji, D. D. (2023). Numerical investigation of the effect of the turbulator geometry (disturber) on heat transfer in a channel with a square section. Alexandria Engineering Journal, 69, 383–402.

Abed, A. M., Yakoob, A. K., Smaisim, G. F., & Gatea, H. T. (2023). Design and sizing of stand-alone photovoltaic (PV) system for powered mobile cleaning and disinfection chamber system. In AIP Conference Proceedings (2776, 1 050001). AIP Publishing LLC.

Wang, H., Alizadeh, A. A., Abed, A. M., Piranfar, A., Smaisim, G. F., Hadrawi, S. K., ... & Hekmatifar, M. (2023). Investigation of the effects of porosity and volume fraction on the atomic behavior of cancer cells and microvascular cells of 3DN5 and 5OTF macromolecular structures during hematogenous metastasis using the molecular dynamics method. Computers in Biology and Medicine, 106832.

Sengupta, A., & Gupta, N. K. (2017). MWCNTs based sorbents for nuclear waste management: a review. Journal of Environmental Chemical Engineering, 5, 5099–5114. https://doi.org/10.1016/J.JECE.2017.09.054

Siswanto, W. A., Romero-Parra, R. M., Sivaraman, R., Turki Jalil, A., Gatea, M. A., Alhassan, M. S., & Mahmoud, Z. H. (2023). The characterization of plastic behavior and mechanical properties in the gradient nanostructured copper. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 14644207231161752.

Mahmoud, Z. H., Mahmood, J. M., Al-Obaidi, N. S., & Rahima, A. M. (2023). Gama-Fe2O3 silica-coated 2-(2-benzothiazolyl azo)-4-methoxyaniline for supercapacitive performance: Original scientific paper. Journal of Electrochemical Science and Engineering.

Jasim, S. A., Ali, S. A. J., Fadhil, O. Q., Rakhmatova, M. K., Kzar, H. H., Margiana, R., ... & Sultan, M. Q. (2023). Investigating the effects of hydro-alcoholic urtica dioica extract and retinoic acid on follicular development: an animal study. Medical Journal of the Islamic Republic of Iran, 37.

Mahmoud, Z. H., Mahdi, A. B., Alnassar, Y. S., & AL-Salman, H. N. K. (2023). Formulation and sustained-release of verapamil hydrochloride tablets. The Chemistry, 76.

Al-Obaidi, N. S., Sadeq, Z. E., Mahmoud, Z. H., Abd, A. N., Al-Mahdawi, A. S., & Ali, F. K. (2023). Synthesis of chitosan-TiO2 nanocomposite for efficient Cr (VI) removal from contaminated wastewater sorption kinetics, thermodynamics and mechanism. Journal of Oleo Science, 72(3), 337–346.

Jasim, S. A., Jabbar, A. H., Bokov, D. O., Al Mashhadani, Z. I., Surendar, A., Taban, T. Z., ... & Mustafa, Y. F. (2023). the effects of oxide layer on the joining performance of CuZr metallic glasses. Transactions of the Indian Institute of Metals, 76(1), 239–247.

Jasim, S. A., Ali, M. H., Mahmood, Z. H., Rudiansyah, M., Alsultany, F. H., Mustafa, Y. F., ... & Surendar, A. (2022). Role of alloying composition on mechanical properties of CuZr metallic glasses during the nanoindentation Process. Metals and Materials International, 28(9), 2075–2082.

Bokov, D. O., Mustafa, Y. F., Mahmoud, Z. H., Suksatan, W., Jawad, M. A., & Xu, T. (2022). Cr-SiNT, Mn-SiNT, Ti-C70 and Sc-CNT as effective catalysts for CO2 reduction to CH3OH. SILICON, 14(14), 8493–8503.

Jasim, S. A., Abdelbasset, W. K., Hachem, K., Kadhim, M. M., Yasin, G., Obaid, M. A., ... & Mahmoud, Z. H. (2022). Novel Gd2O3/SrFe12O19@ Schiff base chitosan (Gd/SrFe@ SBCs) nanocomposite as a novel magnetic sorbent for the removal of Pb (II) and Cd (II) ions from aqueous solution. Journal of the Chinese Chemical Society, 69(7), 1079–1087.

Mansoor Al Sarraf, A. A., Alsultany, H., Mahmoud, F. H., Shafik, Z. S., AIMashhadani, S. Z. I., & Sajjadi, A. (2022). Magnetic nanoparticles supported zinc (II) complex (Fe3O4@ SiO2-Imine/Thio-Zn (OAc) 2): a green and efficient magnetically reusable zinc nanocatalyst for synthesis of nitriles via cyanation of aryl iodides. Synthetic Communications, 52(9–10), 1245–1253.

Hameed Mahmood, Z., Riadi, Y., Hammoodi, H. A., Alkaim, A. F., & Fakri Mustafa, Y. (2022). Magnetic nanoparticles supported copper nanocomposite: a highly active nanocatalyst for synthesis of benzothiazoles and polyhydroquinolines. Polycyclic Aromatic Compounds, 1–19.

Mahmoud, Z. H., AL-Bayati, R. A., & Khadom, A. A. (2022). The efficacy of samarium loaded titanium dioxide (Sm: TiO2) for enhanced photocatalytic removal of rhodamine B dye in natural sunlight exposure. Journal of Molecular Structure, 1253, 132267.

Raya, I., Mansoor Al Sarraf, A. A., Widjaja, G., Ghazi Al-Shawi, S., F Ramadan, M., Mahmood, Z. H., ... & Ghaleb Maabreh, H. (2022). ZnMoO4 nanoparticles: novel and facile synthesis, characterization, and photocatalytic performance. Journal of Nanostructures, 12(2), 446-454

Mahmood, Z. H., Jarosova, M., Kzar, H. H., Machek, P., Zaidi, M., Dehno Khalaji, A., ... & Kadhim, M. M. (2022). Synthesis and characterization of Co3O4 nanoparticles: Application as performing anode in Li‐ion batteries. Journal of the Chinese Chemical Society, 69(4), 657–662.

Mahmoud, Z. H., AL-Bayati, R. A., & Khadom, A. A. (2022). Electron transport in dye-sanitized solar cell with tin-doped titanium dioxide as photoanode materials. Journal of Materials Science: Materials in Electronics, 33(8), 5009–5023.